Linde 1183-01 – L14-01, L14AP-01, L16-01, L16AP-01, L20-01, L20AP-01 Production site Xiamen Workshop Manuals

$40.00

- Type Of Manual: Workshop Manuals

- Format: PDF

- Size: 93.2MB

- Number of Pages: 779

Category: Linde Workshop Manual PDF

-

Model List:

- L14-01

- L14AP-01

- L16-01

- L16AP-01

- L20-01

- L20AP-01 Production site Xiamen

- 1. Regular testing

- 1.1. Table of content

- 1.2. Regular testing

- 1.2.1. Principles for testing industrial trucks

- 1.2.2. Test log

- 1.2.3. Testing instruments, measuring devices, tools and devices

- 1.3. Electric motor

- 1.3.1. Test steps for the electric traction motor

- 1.4. Internal combustion engine

- 1.4.1. Test steps for the exhaust system

- 1.4.2. Diesel internal combustion engine

- 1.4.3. LPG internal combustion engine

- 1.5. Drive axle

- 1.5.1. Drive axle test steps

- 1.6. Chassis

- 1.6.1. Test steps for chassis

- 1.7. Drivers compartment

- 1.7.1. Test steps for drivers compartment

- 1.8. Steering systems

- 1.8.1. Test steps for the steering

- 1.9. Wheels and tyres

- 1.9.1. Test steps for wheels

- 1.9.2. Tyre test steps

- 1.10. Brake system

- 1.10.1. Definition and description of the industrial truck groups

- 1.10.2. Permissible braking distances for unladen industrial trucks

- 1.10.3. Service brake

- 1.10.4. Parking brake

- 1.11. Operating devices

- 1.11.1. Test steps for operating devices

- 1.12. Electrics.electronics

- 1.12.1. Test steps for electrical equipment

- 1.12.2. Notes regarding insulation testing

- 1.12.3. Insulation testing

- 1.12.4. Test steps for the battery and battery connection assemblies

- 1.13. Hydraulics

- 1.13.1. Test steps for hydraulic system

- 1.13.2. Safety regulations for hydraulic hose lines

- 1.14. Lift mast

- 1.14.1. Test steps for lift mast

- 1.14.2. Test steps for load chains

- 1.15. Load support

- 1.15.1. Test steps for fork arms

- 1.15.2. Combined testing device for testing fork arms, lifting chains and lifting hydraulics

- 1.16. Attachments

- 1.16.1. Test steps for attachments and other lifting accessories

- 1.17. Special equipment.accessories

- 1.17.1. LPG tanks on trucks

- 1.17.2. Test steps for other accessories

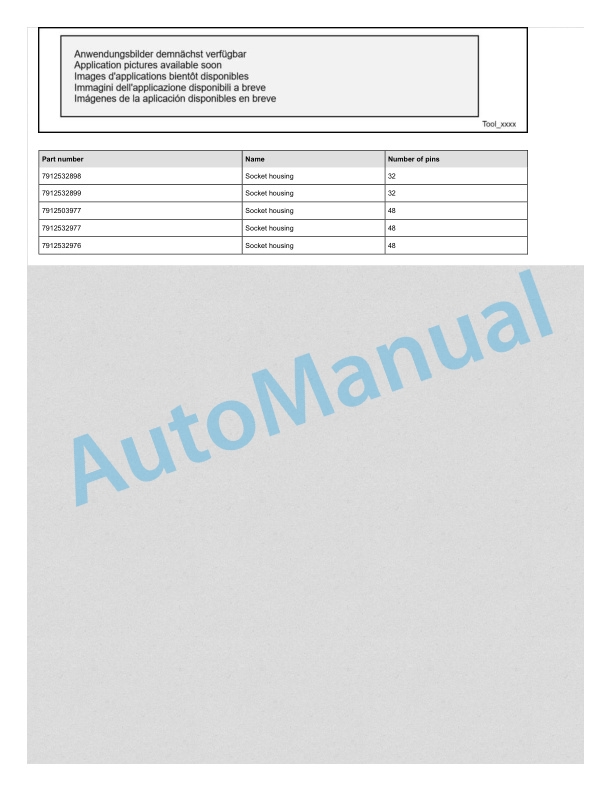

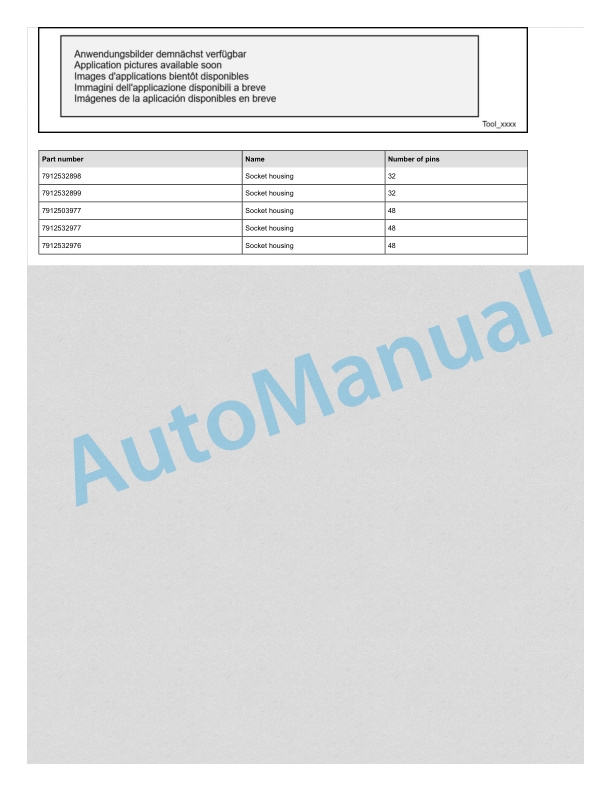

- 2. Service case Release tools for contacts

- 2.1. Table of content

- 2.2. Safety information

- 2.2.1. Safety information for repair and maintenance work

- 2.3. Information

- 2.3.1. Information

- 2.4. Overview

- 2.4.1. Overview of service cases

- 2.5. Plug systems

- 2.5.1. ATS 2.8 plug connector

- 2.5.2. CMC plug connector

- 2.5.3. DCS 9.5 plug connector

- 2.5.4. DIN 1.5mm circular connector

- 2.5.5. DIN 2.5mm circular connector

- 2.5.6. Deutsch DTM plug connector

- 2.5.7. ECU appliance plug

- 2.5.8. MCON appliance plug

- 2.5.9. Appliance plug with JPT and MQS contacts

- 2.5.10. Appliance plug with MT2 and JPT contacts

- 2.5.11. SICMA appliance plug

- 2.5.12. Econoseal JMark 2 plug connector

- 2.5.13. Elobau 11pin receptacle housing

- 2.5.14. E5931 plug connector

- 2.5.15. FASTINFASTON 6.3mm plug connector

- 2.5.16. GT150 plug connector

- 2.5.17. HDSCS plug connector

- 2.5.18. JPT plug connector

- 2.5.19. JPT SLD plug connector

- 2.5.20. JPT plug connector Saab

- 2.5.21. JPT plug connector VW

- 2.5.22. Kompakt 1.1 plug connector

- 2.5.23. Bosch Kompakt 4 plug connector

- 2.5.24. Leavyseal plug connector

- 2.5.25. MCON 1.2mm LL plug connector

- 2.5.26. MCON 1.2mm CB plug connector

- 2.5.27. MCP plug connector

- 2.5.28. MetriPack 150 plug connector

- 2.5.29. MiniFit plug connector

- 2.5.30. Mini Universal MATENLOK plug connector

- 2.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 2.5.32. MKR Plus plug connector

- 2.5.33. MQS plug connector

- 2.5.34. MR plug connector

- 2.5.35. MTA plug housing and fuse housing

- 2.5.36. MT2 plug connector

- 2.5.37. MT2 1.5mm plug connector VW

- 2.5.38. Multilock plug connector

- 2.5.39. MX150 plug connector

- 2.5.40. NG1 plug connector

- 2.5.41. Phönix Contact HC plug connector

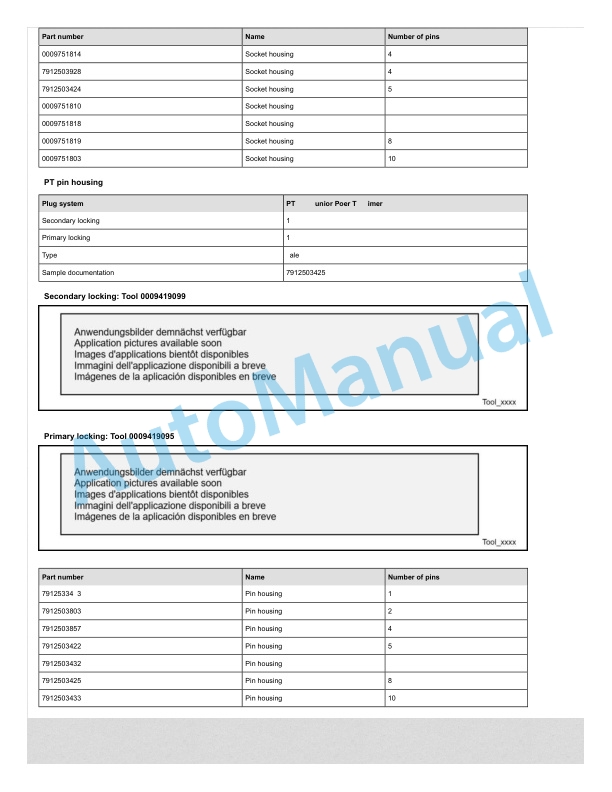

- 2.5.42. PT 3F plug connector

- 2.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 2.5.44. Relay socket with SPT and MPT contacts

- 2.5.45. Fuse holder with SPT contacts

- 2.5.46. Sicma plug connector

- 2.5.47. SLK 2.8 plug connector

- 2.5.48. Souriau UTL7 plug connector

- 2.5.49. Superseal 1.5mm plug connector

- 2.5.50. Trident Neptune plug connector

- 2.5.51. Universal MATENLOK plug connector

- 2.5.52. VW 9.5mm plug connector

- 3. Automatic Pallet StackerLMaticAGV

- 3.1. Table of content

- 3.2. Product information

- 3.2.1. Characteristics

- 3.2.2. Safety guidelines

- 3.2.3. Tightening torque

- 3.2.4. Special tools

- 3.3. Service

- 3.3.1. Maintenance

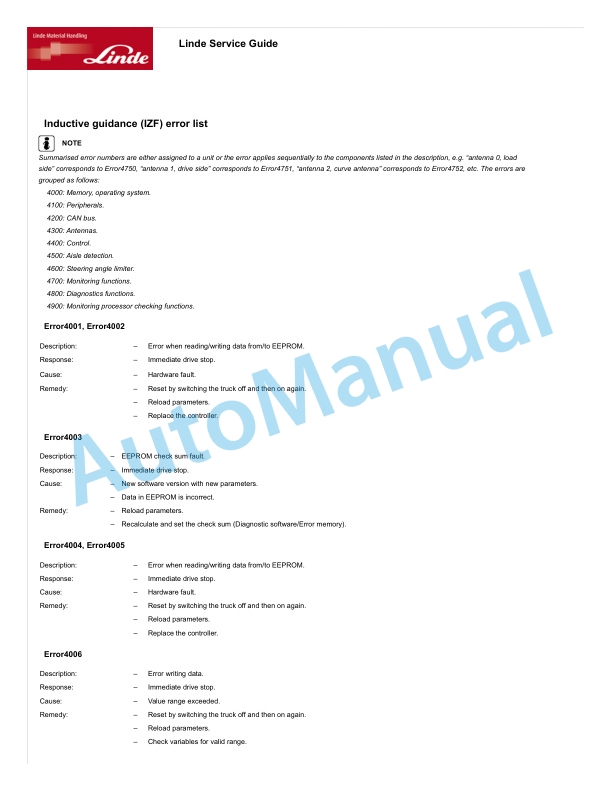

- 3.4. Diagnostics and configuration

- 3.4.1. Basic vehicle diagnostics

- 3.4.2. Basic vehicle error codes

- 3.4.3. AGV postsales tools

- 3.4.4. AGV error codes

- 3.5. Traction motor

- 3.5.1. Description

- 3.5.2. Inspection

- 3.5.3. Plugs

- 3.5.4. Sensors

- 3.6. Transmission system

- 3.6.1. Gearbox

- 3.7. Bodywork and attachments

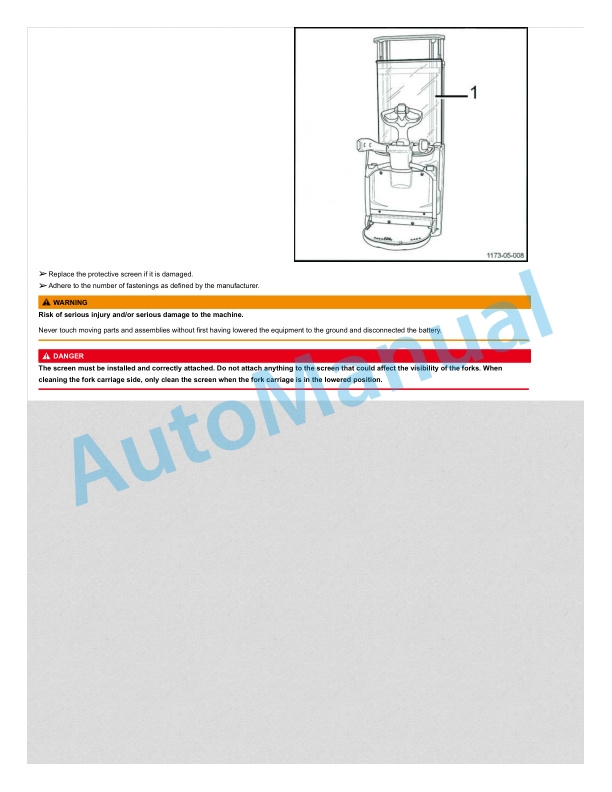

- 3.7.1. Fixed chassis

- 3.7.2. Chassis equipment

- 3.7.3. Fork legs

- 3.7.4. Truck linkage

- 3.7.5. Battery lock

- 3.8. Running system

- 3.8.1. ES3024 steering unit

- 3.8.2. Tiller

- 3.8.3. Steering centre unit

- 3.8.4. Electromagnetic brake

- 3.8.5. Drive wheel

- 3.8.6. Load wheels

- 3.9. Operation parts

- 3.9.1. Acceleration potentiometer function

- 3.9.2. Lift potentiometer function

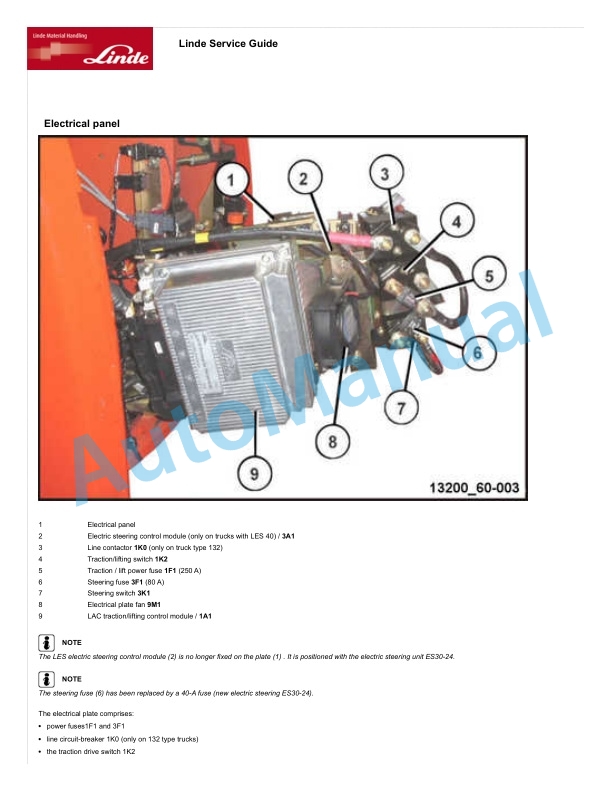

- 3.10. Electronic.electrical components

- 3.10.1. Safety

- 3.10.2. General

- 3.10.3. Drive and hydraulic controller (LAC)

- 3.10.4. LAB control unit

- 3.10.5. ES3024 steering unit description

- 3.10.6. Hydraulic control mechanism

- 3.10.7. Display unit

- 3.10.8. Key switch

- 3.10.9. Battery lock lever

- 3.11. AGV electronic.electrical components

- 3.11.1. Laser navigation

- 3.11.2. Safety laser scanner

- 3.11.3. AGV system control box

- 3.12. Hydraulic system

- 3.12.1. Hydraulic system

- 3.12.2. Pump unit

- 3.12.3. Pressure sensor

- 3.13. Load lifting system

- 3.13.1. Mast type

- 3.13.2. Mast clearance

- 3.13.3. Height sensors (0.3 m and 1.5 m)

- 3.13.4. Height sensor (load management, optional)

- 4. Lithiumion batteryWNE, WEB series

- 4.1. Table of content

- 4.2. Product information

- 4.2.1. Series no

- 4.3. Error diagnosis

- 4.3.1. Error diagnosis

- 4.4. Schematic diagrams

- 4.4.1. Electrical diagrams

- 5. Maintenance of charger ADY 6117

- 6. Pallet StackerL1401, L14AP01, L1601,L16AP01, L2001, L20AP01

- 6.1. Table of content

- 6.2. Product information

- 6.2.1. Characteristics

- 6.2.2. Safety guidelines

- 6.2.3. Tightening torque

- 6.2.4. Special tools

- 6.3. Service

- 6.3.1. Maintenance

- 6.4. Diagnostics

- 6.4.1. Truck diagnostics

- 6.4.2. Error codes

- 6.5. Traction motor

- 6.5.1. Description

- 6.5.2. Checking

- 6.5.3. Plugs

- 6.5.4. Sensors

- 6.6. Transmission system

- 6.6.1. Gearbox

- 6.7. Bodywork and attachments

- 6.7.1. Fixed chassis

- 6.7.2. Folding platform

- 6.7.3. Chassis equipment

- 6.7.4. Fork legs

- 6.7.5. Truck linkage

- 6.7.6. Battery lock

- 6.8. Walking system

- 6.8.1. ES3024 steering unit

- 6.8.2. Tiller

- 6.8.3. Steering centre unit

- 6.8.4. Electromagnetic brake

- 6.8.5. Drive wheel

- 6.8.6. Load wheels

- 6.9. Operation parts

- 6.9.1. Acceleration potentiometer function

- 6.9.2. Lift potentiometer function

- 6.10. Electrics.electronics

- 6.10.1. Safety

- 6.10.2. General

- 6.10.3. Drive and hydraulic controller (LAC)

- 6.10.4. ES3024 steering unit description

- 6.10.5. Hydraulic control mechanism

- 6.10.6. Display unit

- 6.10.7. Key switch

- 6.10.8. Battery lock lever

- 6.11. Hydraulics

- 6.11.1. Hydraulics

- 6.11.2. Pump unit

- 6.11.3. Pressure sensor

- 6.12. Load lifting system

- 6.12.1. Mast type

- 6.12.2. Mast clearance

- 6.12.3. Height sensors (0.3 m and 1.5 m)

- 6.12.4. Height sensor (load management, optional)

Rate this product

You may also like

Linde Workshop Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Workshop Manuals SN W41110V00529 and up

$40.00

Linde Workshop Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Workshop Manuals

$40.00

Linde Workshop Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Workshop Manuals SN A11102V00001 and up

$40.00

Linde Workshop Manual PDF

Linde 1110-01 – V08-01, V08-02 Workshop Manuals SN 11.09 and up SN up to W41110V00528

$40.00