Linde 1204-01 – H35D to H50T Production site Aschaffenburg Operating Instructions SN H21204L00001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN H21204L00001 and up

- Format: PDF

- Size: 92.8MB

- Number of Pages: 805

- Serial Number:

SN H21204L00001 and up

Category: Linde Operator Manual PDF

-

Model List:

- H35D

- H35T

- H40D

- H40T

- H45T

- H50D

- H50T

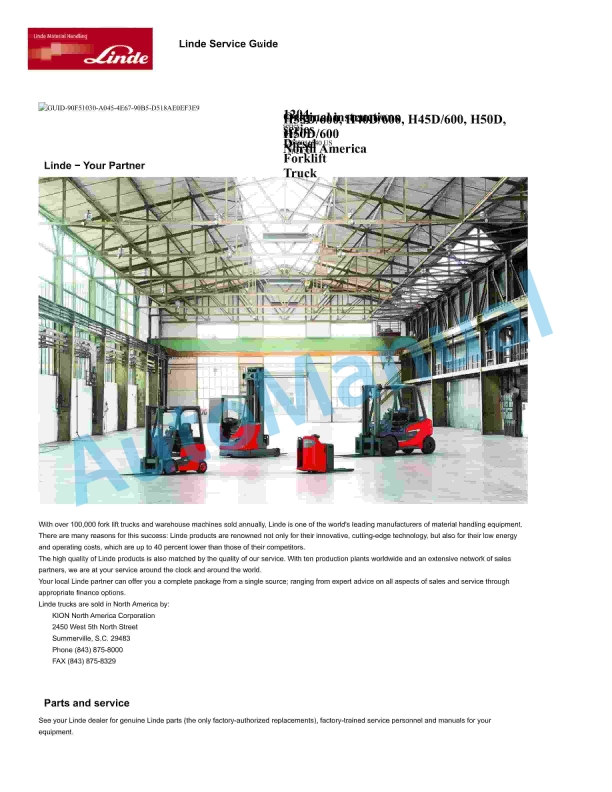

- 1. series Diesel Forklift TruckH35D.600, H40D.600, H45D.600, H50D, H50D.600North America

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Scope

- 1.2.2. Obligations of the Equipment Owner

- 1.2.3. Operator Responsibilities

- 1.2.4. Proper use

- 1.2.5. Hazard messages

- 1.3. Safety

- 1.3.1. Before Operation

- 1.3.2. Operator Daily Checklist

- 1.3.3. Operating position

- 1.3.4. Pedestrians

- 1.3.5. Travel

- 1.3.6. Lifting and Lowering

- 1.3.7. Inclines, Ramps, Docks, Elevators

- 1.3.8. Avoiding Falls and Tipovers

- 1.3.9. Suspended Loads

- 1.3.10. Parking

- 1.3.11. Safety During Maintenance

- 1.3.12. Operator Warning Decals

- 1.4. Overview

- 1.4.1. Technical Description

- 1.4.2. Truck Components

- 1.4.3. Overhead Switches

- 1.4.4. Display Unit Symbols

- 1.4.5. Data Plate

- 1.4.6. Truck Configuration Label

- 1.4.7. Definition of directions

- 1.5. Operation

- 1.5.1. Initial Commissioning

- 1.5.2. Fuel

- 1.5.3. Operator Compartment

- 1.5.4. Display Unit

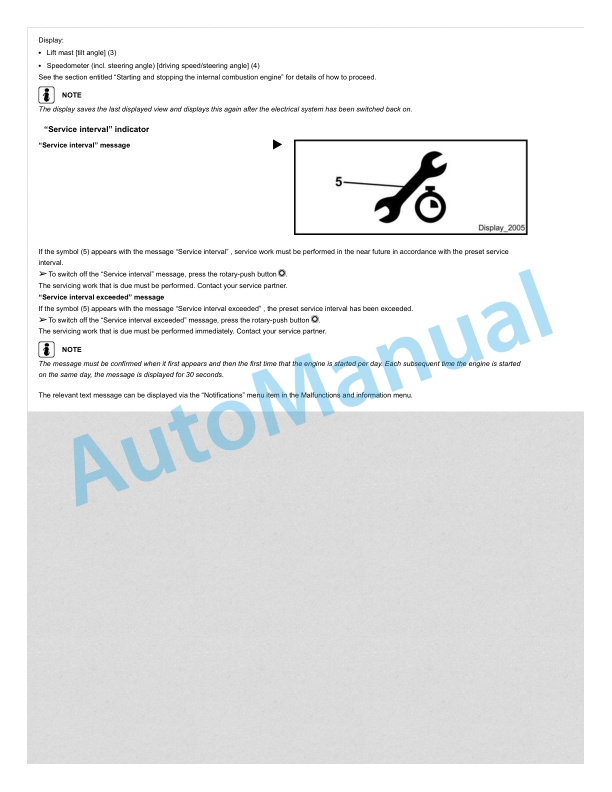

- 1.5.5. Premium Display Unit (optional equipment)

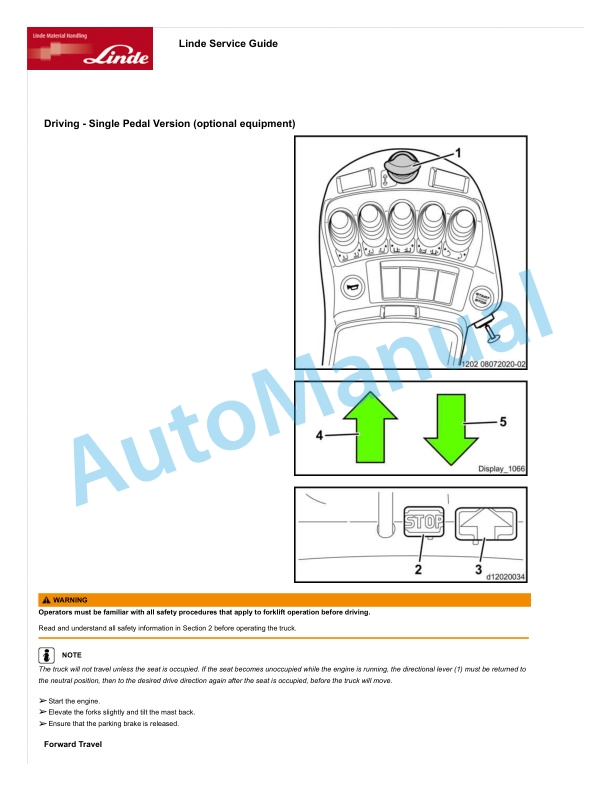

- 1.5.6. Operation

- 1.5.7. Additional Procedures

- 1.5.8. Loading.transportation

- 1.6. Maintenance

- 1.6.1. Personnel Qualifications

- 1.6.2. Cleaning

- 1.6.3. Operator Inspection and Maintenance

- 1.6.4. Routine Lubrication and Inspection

- 1.6.5. Scheduled Maintenance

- 1.6.6. Fluids and Lubricants

- 1.6.7. Troubleshooting

- 1.7. Specifications

- 1.7.1. Specifications

- 1.7.2. Mast Heights

- 2. series LP Gas Forklift TruckH35T.600, H40T.600, H45T.600, H50T, H50T.600North America

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Scope

- 2.2.2. Obligations of the Equipment Owner

- 2.2.3. Operator Responsibilities

- 2.2.4. Proper use

- 2.2.5. Hazard messages

- 2.3. Safety

- 2.3.1. Before Operation

- 2.3.2. Operator Daily Checklist

- 2.3.3. Operating position

- 2.3.4. Pedestrians

- 2.3.5. Travel

- 2.3.6. Lifting and Lowering

- 2.3.7. Inclines, Ramps, Docks, Elevators

- 2.3.8. Avoiding Falls and Tipovers

- 2.3.9. Suspended Loads

- 2.3.10. Parking

- 2.3.11. Using LP Gas

- 2.3.12. Safety During Maintenance

- 2.3.13. Operator Warning Decals

- 2.4. Overview

- 2.4.1. Technical Description

- 2.4.2. Truck Components

- 2.4.3. Overhead Switches

- 2.4.4. Display Unit Symbols

- 2.4.5. Decal and Data Plate Location Exterior

- 2.4.6. Data Plate

- 2.4.7. Truck Configuration Label

- 2.4.8. Definition of directions

- 2.5. Operation

- 2.5.1. Initial Commissioning

- 2.5.2. Fuel

- 2.5.3. Operator Compartment

- 2.5.4. Display Unit

- 2.5.5. Premium Display Unit (optional equipment)

- 2.5.6. Operation

- 2.5.7. Additional Procedures

- 2.5.8. Loading.transportation

- 2.6. Maintenance

- 2.6.1. Personnel Qualifications

- 2.6.2. Cleaning

- 2.6.3. Operator Inspection and Maintenance

- 2.6.4. Routine Lubrication and Inspection

- 2.6.5. Scheduled Maintenance

- 2.6.6. Fluids and Lubricants

- 2.6.7. Troubleshooting

- 2.7. Specifications

- 2.7.1. Specifications

- 2.7.2. Mast Heights

- 3. LPG truck, CNG truckH35T, H35CNG,H40T, H40CNG,H45T, H45CNG,H50T, H50CNG

- 3.1. Table of content

- 3.2. Introduction

- 3.2.1. The truck

- 3.2.2. General information

- 3.2.3. Conformity marking

- 3.2.4. Declaration that reflects the content of the declaration of conformity

- 3.2.5. Declarations of conformity in accordance with directive RED 2014.53.EU

- 3.2.6. Labelling

- 3.2.7. Description of use and climatic conditions

- 3.2.8. Hazard assessment

- 3.2.9. Impermissible use

- 3.2.10. Symbols used

- 3.2.11. Reception of truck

- 3.2.12. Documentation

- 3.2.13. Disposing of components and batteries

- 3.3. Safety

- 3.3.1. Data security

- 3.3.2. Handling consumables

- 3.3.3. Characteristic values for body vibrations

- 3.3.4. Residual risks

- 3.3.5. Stability

- 3.3.6. Operating company

- 3.3.7. Drivers

- 3.3.8. Competent person

- 3.3.9. Safety information about the gas system

- 3.3.10. Safety guidelines for LPG

- 3.3.11. Type approval for gas engine

- 3.3.12. Safety measures when working on ignition systems

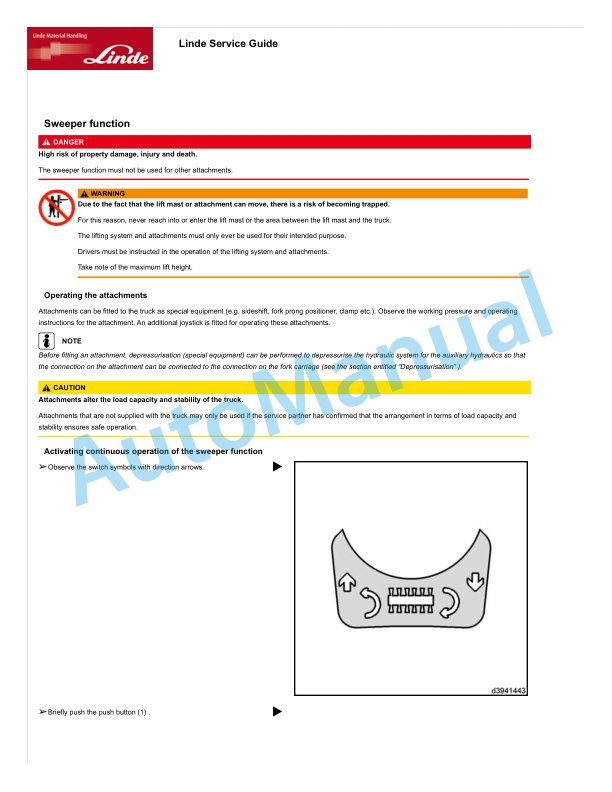

- 3.3.13. Fitting attachments

- 3.3.14. Wheelslide protection chains in winter operation

- 3.4. Overview

- 3.4.1. Standard display unit

- 3.4.2. Comfort display unit

- 3.4.3. Comfort display unit menu structure on the display

- 3.4.4. Push buttons and switches in the overhead console

- 3.4.5. Push buttons in the armrest console standard

- 3.4.6. Push buttons in the armrest console comfort

- 3.5. Operating

- 3.5.1. Checks before initial commissioning

- 3.5.2. Drivers compartment

- 3.5.3. Standard display unit

- 3.5.4. Comfort display unit

- 3.5.5. Operation

- 3.5.6. Working with a load

- 3.5.7. Fuel

- 3.5.8. Emergency operation

- 3.5.9. Loading.transporting

- 3.6. Service and maintenance

- 3.6.1. Cleaning the truck

- 3.6.2. Internal combustion engine

- 3.6.3. Running gear and drive train

- 3.6.4. Chassis and bodywork

- 3.6.5. Drivers compartment

- 3.6.6. Electrics.electronics

- 3.6.7. Hydraulics

- 3.6.8. Lifting system

- 3.6.9. Selfhelp

- 3.6.10. Decommissioning

- 4. Linde Safety Guard

- 4.1. Inhaltsverzeichnis

- 4.2. Einführung

- 4.2.1. Assistenzsystem Linde Safety Guard

- 4.2.2. Bestimmungsgemäße Verwendung

- 4.2.3. Konformitätserklärung Funkanlagen

- 4.2.4. Beschränkungen für die Inbetriebnahme oder für die Nutzungsgenehmigung

- 4.2.5. Verwendete Symbole

- 4.3. Sicherheit

- 4.3.1. Sicherheitshinweise

- 4.3.2. Service Personal

- 4.4. Bedien und Anzeigeelemente

- 4.4.1. Übersicht

- 4.4.2. Anzeigegerät Safety Guard Truck Unit

- 4.4.3. Anzeigegerät Safety Guard Truck Unit für Schubmaststapler

- 4.4.4. Kommunikationseinheit Safety Guard Truck Unit Small

- 4.4.5. Interaktive Warnweste

- 4.4.6. Mobile Warneinrichtung für interaktive Warnweste Vest Unit

- 4.4.7. Powerbank

- 4.4.8. Ladestation für Powerbank

- 4.4.9. Mobile Warneinrichtung Safety Guard Portable Unit

- 4.4.10. Ladestation Safety Guard

- 4.4.11. Ladestation Safety Guard ab 10.2019

- 4.4.12. Safety GuardSensor

- 4.4.13. Statische Warneinrichtung Safety Guard Static Unit

- 4.4.14. Funkmodul Safety GuardZone Zone Marker

- 4.5. Bedienung

- 4.5.1. Installation

- 4.5.2. Prüfungen vor Arbeitsbeginn

- 4.5.3. Betrieb

- 4.6. Pflege und Entsorgung

- 4.6.1. Pflege

- 4.6.2. Entsorgung

- 4.7. Technische Daten

- 4.7.1. Anzeigegerät Safety Guard

- 4.7.2. Aktive Warnweste Safety Guard

- 4.7.3. Mobile Warneinrichtung Safety Guard

- 4.7.4. Safety Guard Sensor

- 4.7.5. Kommunikationseinheit Safety Guard

- 4.7.6. Statische Warneinrichtung Safety Guard

- 4.7.7. Funkmodul Safety GuardZone

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00