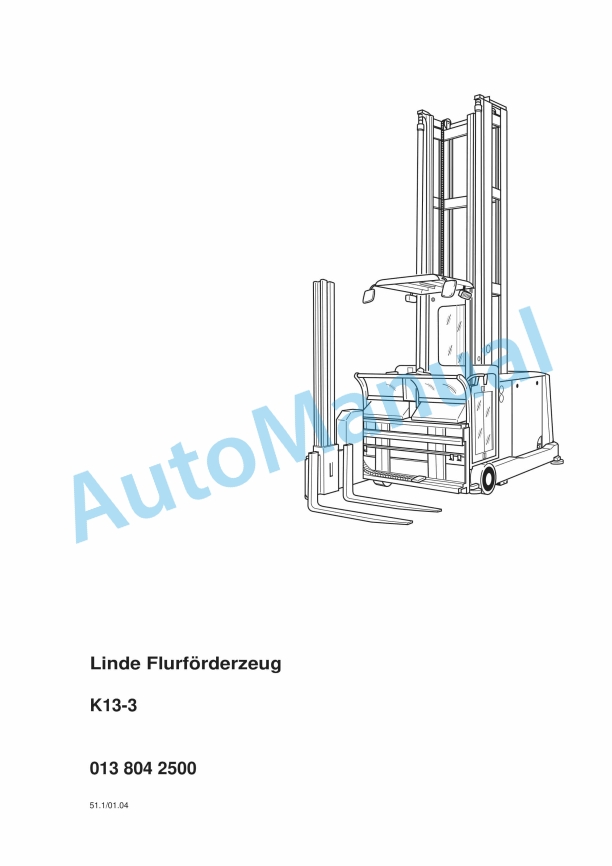

Linde 1216-01 – HT16Ds to HT20Ts Production site Xiamen Operating Instructions SN C11216F00001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN C11216F00001 and up

- Format: PDF

- Size: 77.4MB

- Number of Pages: 384

- Serial Number:

SN C11216F00001 and up

Category: Linde Operator Manual PDF

-

Model List:

- HT16Ds

- HT16Ts

- HT18Ds

- HT18Ts

- HT20Ds

- HT20Ts

- 1. Diesel truckHT16Ds, HT18Ds, HT20Ds

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. Intended use

- 1.2.3. Improper use

- 1.2.4. Impermissible use

- 1.2.5. Additional information

- 1.2.6. Description of use and climatic conditions

- 1.2.7. Symbols used

- 1.2.8. Technical description

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the event of tipover

- 1.3.5. Noise level

- 1.3.6. Frequency characteristic for vibrations imparted to the human body

- 1.3.7. Handling consumables

- 1.3.8. EMC Electromagnetic compatibility

- 1.3.9. Competent person

- 1.3.10. Regulations

- 1.3.11. Fitting attachments

- 1.3.12. Manually lowering the load forks

- 1.4. Overview

- 1.4.1. Identification plates

- 1.4.2. General view

- 1.4.3. Controller and panel

- 1.4.4. Instrument cluster

- 1.5. Operation

- 1.5.1. Checks before starting a new vehicle

- 1.5.2. Instructions for runningin

- 1.5.3. Preshift checks

- 1.5.4. Climbing on.off the forklift

- 1.5.5. Seat belt status and performance checks

- 1.5.6. Adjusting the steering column

- 1.5.7. Starting the engine

- 1.5.8. Driving

- 1.5.9. Steering

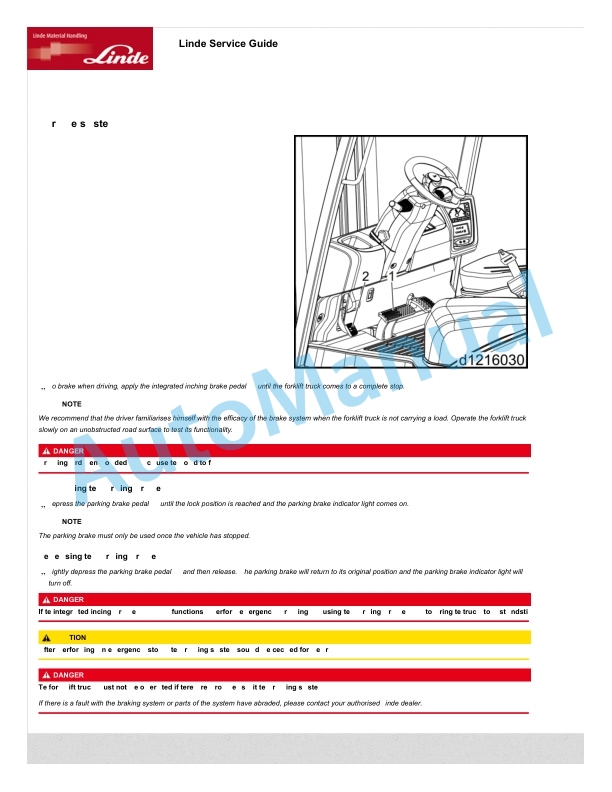

- 1.5.10. Brake system

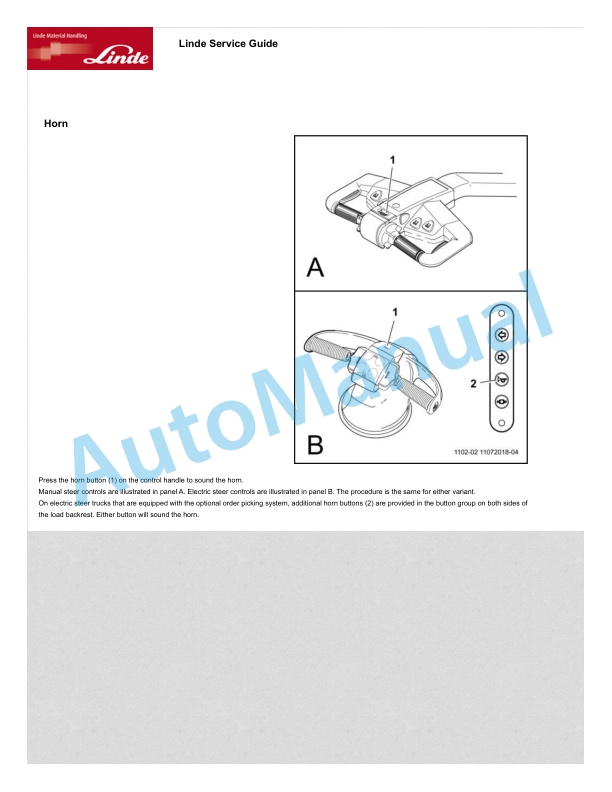

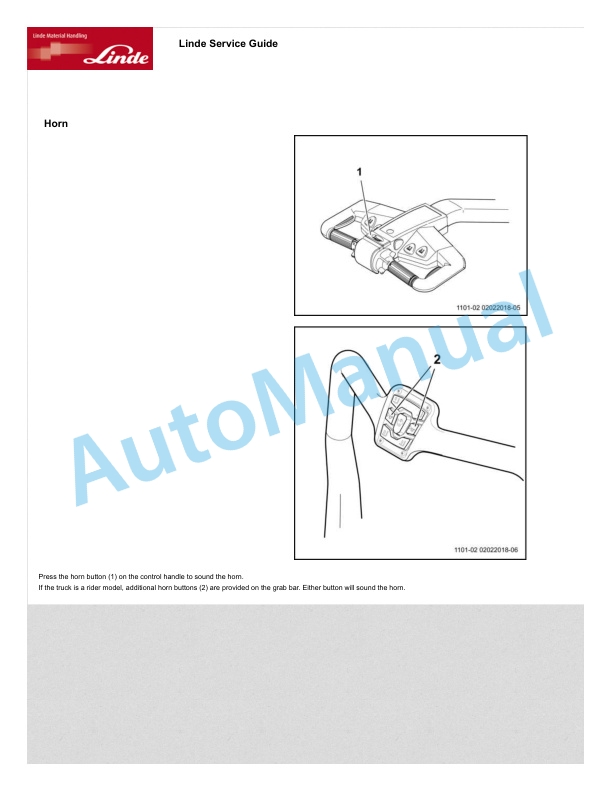

- 1.5.11. Horn operation

- 1.5.12. Lifting devices and attachments

- 1.5.13. Installing additional equipment

- 1.5.14. Transporting loads

- 1.5.15. Before exiting the truck

- 1.5.16. Truck transport

- 1.5.17. Truck storage

- 1.6. Maintenance

- 1.6.1. Summary

- 1.6.2. General information

- 1.6.3. Preservice preparatory work

- 1.6.4. Recommended fuels and oils

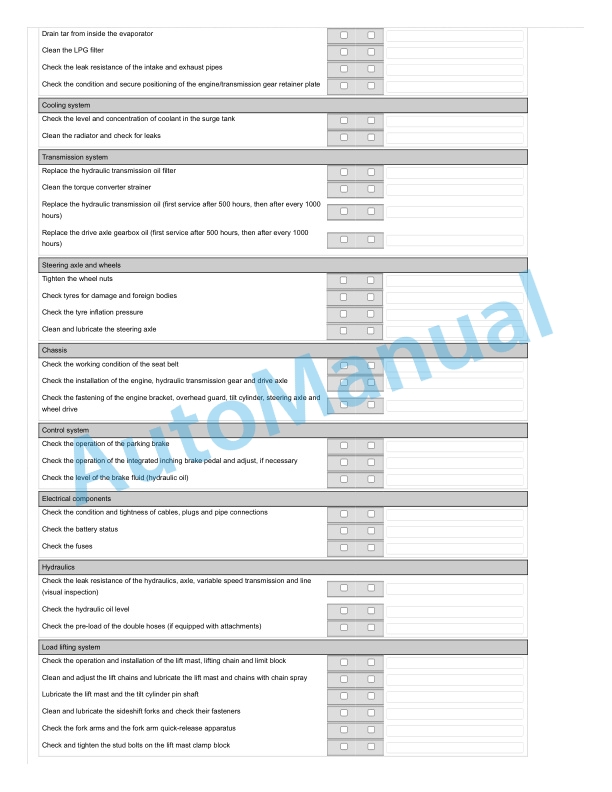

- 1.6.5. Periodic checks and maintenance

- 1.6.6. hr service plan

- 1.6.7. hr service plan

- 1.6.8. hr service plan

- 1.6.9. Preparations

- 1.6.10. Engine

- 1.6.11. Cooling system

- 1.6.12. Transmission system

- 1.6.13. Steering axle and wheels

- 1.6.14. Chassis

- 1.6.15. Control system

- 1.6.16. Electrical components

- 1.6.17. Hydraulics

- 1.6.18. Load lifting system

- 1.7. Technical datasheet

- 1.7.1. Technical datasheet

- 1.7.2. Technical datasheet HT16Ds

- 1.7.3. Technical datasheet HT18Ds

- 1.7.4. Technical datasheet HT20Ds

- 2. LPG Forklift TruckHT16Ts, HT18Ts, HT20Ts

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Introduction

- 2.2.2. Intended use

- 2.2.3. Improper use

- 2.2.4. Impermissible use

- 2.2.5. Additional information

- 2.2.6. Description of use and climatic conditions

- 2.2.7. Symbols used

- 2.2.8. Technical description

- 2.3. Safety

- 2.3.1. Safety guidelines

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. In the event of tipover

- 2.3.5. Noise level

- 2.3.6. Frequency characteristic for vibrations imparted to the human body

- 2.3.7. Handling consumables

- 2.3.8. EMC Electromagnetic compatibility

- 2.3.9. Competent person

- 2.3.10. Regulations

- 2.3.11. Fitting attachments

- 2.3.12. Manually lowering the load forks

- 2.3.13. LPG system safety regulations

- 2.3.14. Safety information on the LPG system

- 2.3.15. Safety guidelines for LPG (extract)

- 2.4. Overview

- 2.4.1. Identification plates

- 2.4.2. General view

- 2.4.3. Controller and panel

- 2.4.4. Instrument cluster

- 2.5. Operation

- 2.5.1. Checks before starting a new vehicle

- 2.5.2. Instructions for runningin

- 2.5.3. Preshift checks

- 2.5.4. Climbing on.off the forklift

- 2.5.5. Seat belt status and performance checks

- 2.5.6. Adjusting the steering column

- 2.5.7. Changing the LPG cylinder

- 2.5.8. Filling the LPG tank

- 2.5.9. Starting the engine

- 2.5.10. Driving

- 2.5.11. Steering

- 2.5.12. Brake system

- 2.5.13. Horn operation

- 2.5.14. Lifting devices and attachments

- 2.5.15. Installing additional equipment

- 2.5.16. Transporting loads

- 2.5.17. Before exiting the truck

- 2.5.18. Truck transport

- 2.5.19. Truck storage

- 2.6. Maintenance

- 2.6.1. Summary

- 2.6.2. General information

- 2.6.3. General LPG system maintenance information

- 2.6.4. Preservice preparatory work

- 2.6.5. Recommended fuels and oils

- 2.6.6. Periodic checks and maintenance

- 2.6.7. hr service plan

- 2.6.8. hr service plan

- 2.6.9. hr service plan

- 2.6.10. Preparations

- 2.6.11. Engine

- 2.6.12. Cooling system

- 2.6.13. Transmission system

- 2.6.14. Steering axle and wheels

- 2.6.15. Chassis

- 2.6.16. Control system

- 2.6.17. Electrical components

- 2.6.18. Hydraulics

- 2.6.19. Load lifting system

- 2.7. Technical datasheet

- 2.7.1. Technical datasheet

- 2.7.2. Technical datasheet HT16Ts (GCT engine with IMPOCO electronic control system)

- 2.7.3. Technical datasheet HT16Ts (GCT engine with NIKKI mechanical control system)

- 2.7.4. Technical datasheet HT18Ts (GCT engine with IMPOCO electronic control system)

- 2.7.5. Technical datasheet HT18Ts (GCT engine with NIKKI mechanical control system)

- 2.7.6. Technical datasheet HT20Ts (GCT engine with IMPOCO electronic control system)

- 2.7.7. Technical datasheet HT20Ts (GCT engine with NIKKI mechanical control system)

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

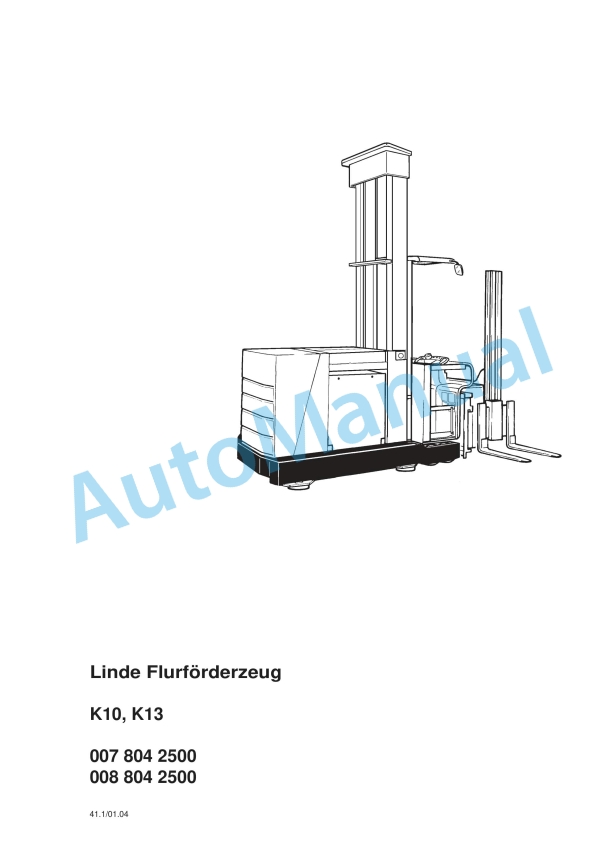

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00