Linde 1219-01 – HT25Ds, HT25T, HT27T, HT30Ds, HT30T, HT32T, HT35Ds, HT35Ts Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 100.6MB

- Number of Pages: 519

Category: Linde Operator Manual PDF

-

Model List:

- HT25Ds

- HT25T

- HT27T

- HT30Ds

- HT30T

- HT32T

- HT35Ds

- HT35Ts

- 1. series LP Gas Forklift TruckModels HT25T, HT27T, HT30T, HT32T

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Scope

- 1.2.2. Obligations of the Equipment Owner

- 1.2.3. Operator Responsibilities

- 1.2.4. Proper use

- 1.2.5. Hazard messages

- 1.3. Safety

- 1.3.1. Before Operation

- 1.3.2. Operator Daily Checklist

- 1.3.3. Operating position

- 1.3.4. Pedestrians

- 1.3.5. Travel

- 1.3.6. Lifting and Lowering

- 1.3.7. Inclines, Ramps, Docks, Elevators

- 1.3.8. Avoiding Falls and Tipovers

- 1.3.9. Suspended Loads

- 1.3.10. Parking

- 1.3.11. Using LP Gas

- 1.3.12. Safety During Maintenance

- 1.3.13. Operator Warning Decals

- 1.4. Overview

- 1.4.1. Technical Description

- 1.4.2. Truck Components

- 1.4.3. Controls

- 1.4.4. Display Unit

- 1.4.5. Definition of directions

- 1.4.6. Vehicle Marking

- 1.4.7. Variants and Options

- 1.5. Operation

- 1.5.1. Unloading and Preparing a New Truck for Operation

- 1.5.2. Setting Up the LP Tank Bracket

- 1.5.3. Adjusting the Operators Seat

- 1.5.4. Steering Column Tilt Angle Adjustment

- 1.5.5. Seat Belt

- 1.5.6. Operating the Display Unit

- 1.5.7. Engine Starting and Shutdown

- 1.5.8. Driving

- 1.5.9. Inching Control

- 1.5.10. Brake System

- 1.5.11. Steering System

- 1.5.12. Horn

- 1.5.13. Fork Position Adjustment

- 1.5.14. Hydraulic Controls

- 1.5.15. Lights and BackUp Alarm

- 1.5.16. Fan (optional equipment)

- 1.5.17. Changing the LP Gas Tank

- 1.5.18. Opening the Hood

- 1.5.19. Towing Loads

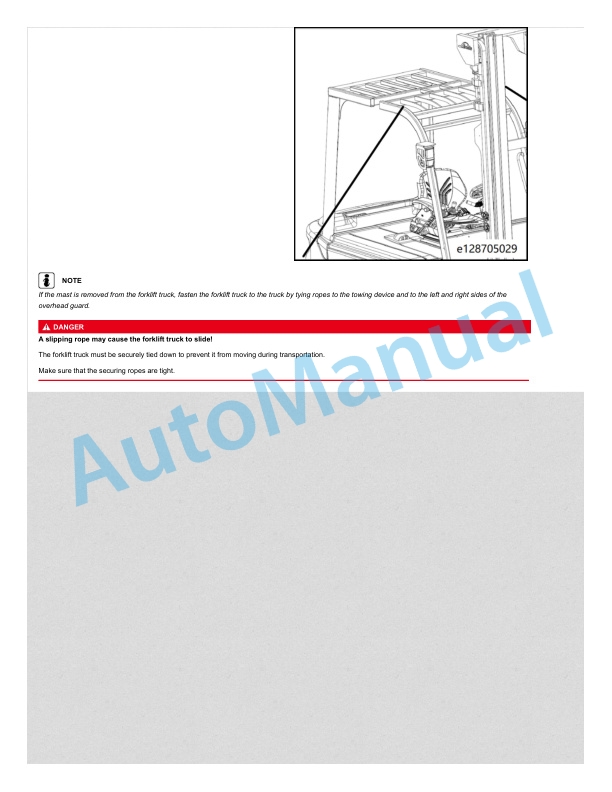

- 1.5.20. Securing the Truck for Transport

- 1.5.21. Hoisting the Truck

- 1.5.22. Towing the Truck

- 1.5.23. Manual Lowering of Fork Carriage

- 1.5.24. LongTerm Storage

- 1.6. Maintenance

- 1.6.1. Personnel Qualifications

- 1.6.2. Cleaning

- 1.6.3. Operator Inspection and Maintenance

- 1.6.4. Scheduled Maintenance

- 1.6.5. Fluids and Lubricants

- 1.6.6. Troubleshooting

- 1.7. Specifications

- 1.7.1. Specifications

- 1.7.2. Mast Heights

- 2. Diesel forklift trucks (Kubota engine)HT25Ds01.HT30Ds01.HT35Ds01

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Introduction

- 2.2.2. Intended use

- 2.2.3. Impermissible use

- 2.2.4. Description of use and climatic conditions

- 2.2.5. Symbols used

- 2.2.6. Technical description

- 2.3. Safety

- 2.3.1. Safety guidelines

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. In the event of tipover

- 2.3.5. Noise level

- 2.3.6. Frequency characteristic for vibrations imparted to the human body

- 2.3.7. Handling consumables

- 2.3.8. EMC Electromagnetic compatibility

- 2.3.9. Competent person

- 2.3.10. Regulations

- 2.3.11. Fitting attachments

- 2.3.12. Manually lowering the load forks

- 2.4. Overview

- 2.4.1. Identification plates

- 2.4.2. General view

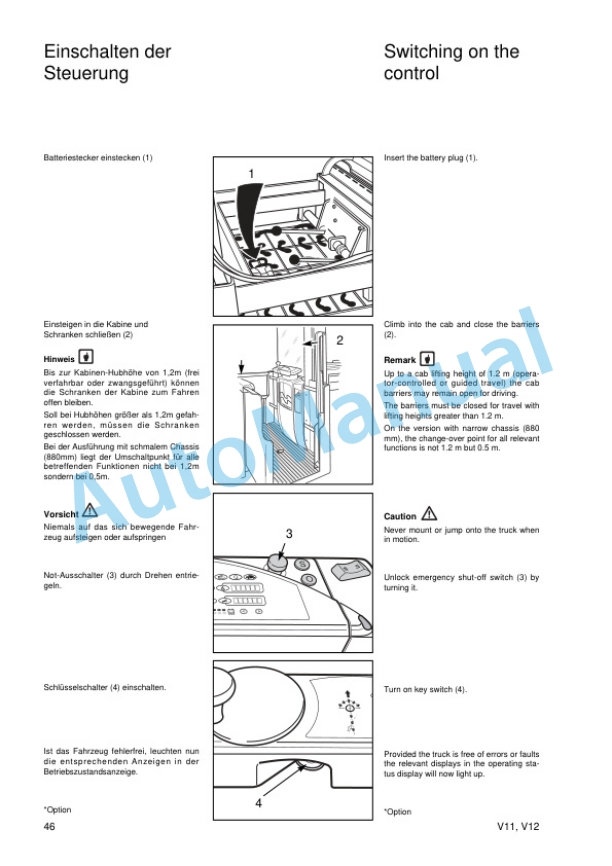

- 2.4.3. Controller and panel

- 2.4.4. Instrument cluster

- 2.5. Operation

- 2.5.1. Checks before starting a new vehicle

- 2.5.2. Instructions for runningin

- 2.5.3. Preshift checks

- 2.5.4. Climbing on.off the forklift

- 2.5.5. Seat belt status and performance checks

- 2.5.6. Adjusting the steering column

- 2.5.7. Starting the engine

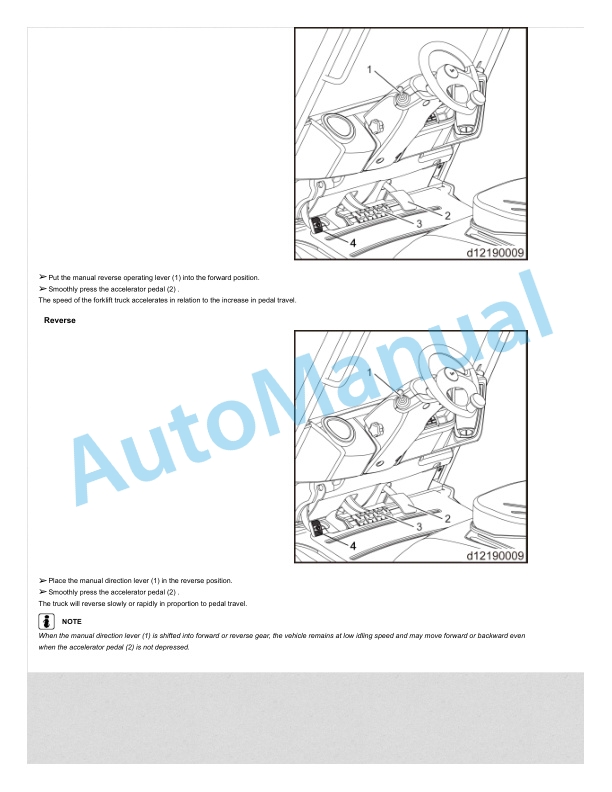

- 2.5.8. Driving

- 2.5.9. Steering

- 2.5.10. Brake system

- 2.5.11. Horn operation

- 2.5.12. Lifting devices and attachments

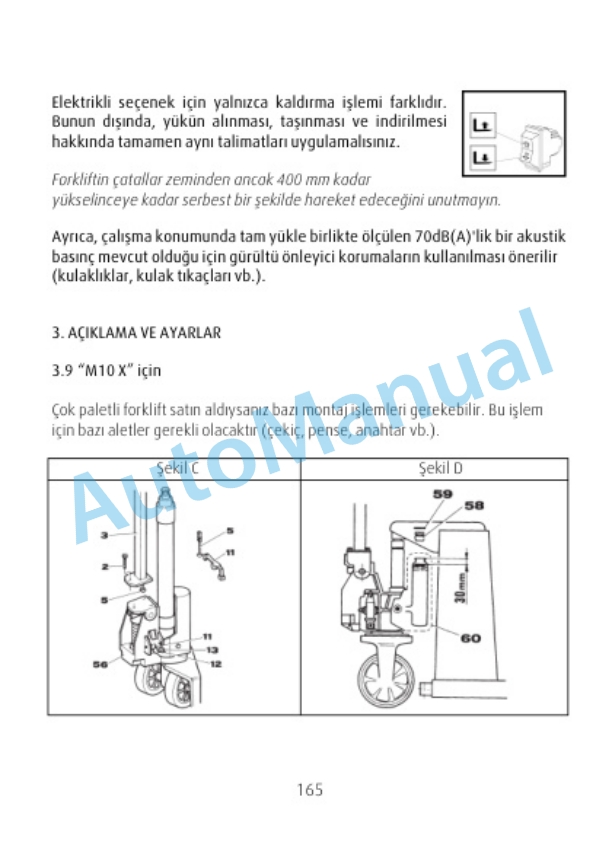

- 2.5.13. Installing additional equipment

- 2.5.14. Transporting loads

- 2.5.15. Before exiting the truck

- 2.5.16. Truck transport

- 2.5.17. Truck storage

- 2.5.18. Disposal of old trucks

- 2.6. Maintenance

- 2.6.1. Summary

- 2.6.2. General information

- 2.6.3. Preservice preparatory work

- 2.6.4. Recommended fuels and oils

- 2.6.5. Periodic checks and maintenance

- 2.6.6. hr service plan

- 2.6.7. hr service plan

- 2.6.8. hr service plan

- 2.6.9. hr service plan

- 2.6.10. Preparations

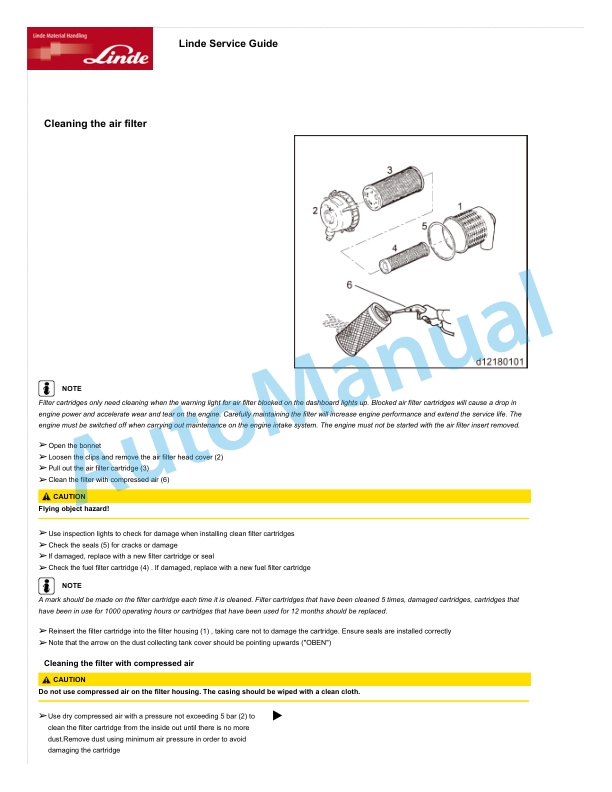

- 2.6.11. Engine

- 2.6.12. Cooling system

- 2.6.13. Transmission system

- 2.6.14. Steering axle and wheels

- 2.6.15. Chassis

- 2.6.16. Control system

- 2.6.17. Electrical components

- 2.6.18. Hydraulics

- 2.6.19. Load lifting system

- 2.7. Technical datasheet

- 2.7.1. Technical datasheet

- 2.7.2. Technical datasheet

- 2.7.3. Technical datasheet

- 2.7.4. Technical datasheet

- 3. LPG Forklift TruckHT25Ts01.HT30Ts01.HT35Ts01

- 3.1. Table of content

- 3.2. Introduction

- 3.2.1. Introduction

- 3.2.2. Intended use

- 3.2.3. Impermissible use

- 3.2.4. Description of use and climatic conditions

- 3.2.5. Symbols used

- 3.2.6. Technical description

- 3.3. Safety

- 3.3.1. Safety guidelines

- 3.3.2. Residual risks

- 3.3.3. Stability

- 3.3.4. In the event of tipover

- 3.3.5. Noise level

- 3.3.6. Frequency characteristic for vibrations imparted to the human body

- 3.3.7. Handling consumables

- 3.3.8. EMC Electromagnetic compatibility

- 3.3.9. Competent person

- 3.3.10. Regulations

- 3.3.11. Fitting attachments

- 3.3.12. Manually lowering the load forks

- 3.3.13. LPG system safety regulations

- 3.3.14. Safety information on the LPG system

- 3.3.15. Safety guidelines for LPG (extract)

- 3.4. Overview

- 3.4.1. Identification plates

- 3.4.2. General view

- 3.4.3. Controller and panel

- 3.4.4. Instrument cluster

- 3.5. Operation

- 3.5.1. Checks before starting a new vehicle

- 3.5.2. Instructions for runningin

- 3.5.3. Preshift checks

- 3.5.4. Climbing on.off the forklift

- 3.5.5. Seat belt status and performance checks

- 3.5.6. Adjusting the steering column

- 3.5.7. Changing the LPG cylinder

- 3.5.8. Filling the LPG tank

- 3.5.9. Starting the engine

- 3.5.10. Driving

- 3.5.11. Steering

- 3.5.12. Brake system

- 3.5.13. Horn operation

- 3.5.14. Lifting devices and attachments

- 3.5.15. Installing additional equipment

- 3.5.16. Transporting loads

- 3.5.17. Before exiting the truck

- 3.5.18. Truck transport

- 3.5.19. Truck storage

- 3.5.20. Resuming use of the forklift truck

- 3.5.21. Disposal of old trucks

- 3.6. Maintenance

- 3.6.1. Summary

- 3.6.2. General information

- 3.6.3. General LPG system maintenance information

- 3.6.4. Preservice preparatory work

- 3.6.5. Recommended fuels and oils

- 3.6.6. Periodic checks and maintenance

- 3.6.7. hr service plan

- 3.6.8. hr service plan

- 3.6.9. hr service plan

- 3.6.10. hr service plan

- 3.6.11. Preparations

- 3.6.12. Engine

- 3.6.13. Cooling system

- 3.6.14. Transmission system

- 3.6.15. Steering axle and wheels

- 3.6.16. Chassis

- 3.6.17. Control system

- 3.6.18. Electrical components

- 3.6.19. Hydraulics

- 3.6.20. Load lifting system

- 3.7. Technical datasheet

- 3.7.1. Technical datasheet

- 3.7.2. Technical datasheet

- 3.7.3. Technical datasheet

- 3.7.4. Technical datasheet

Rate this product

You may also like

Linde Operator Manual PDF

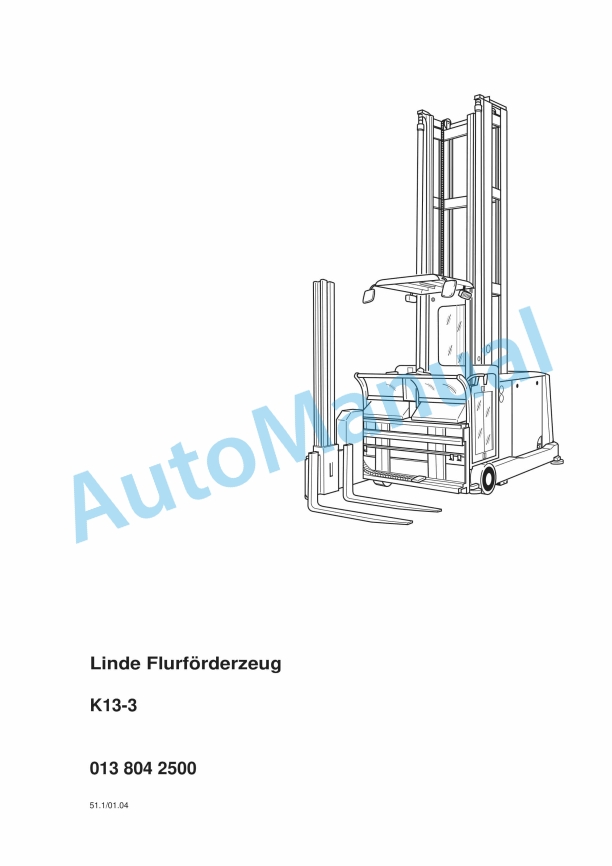

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

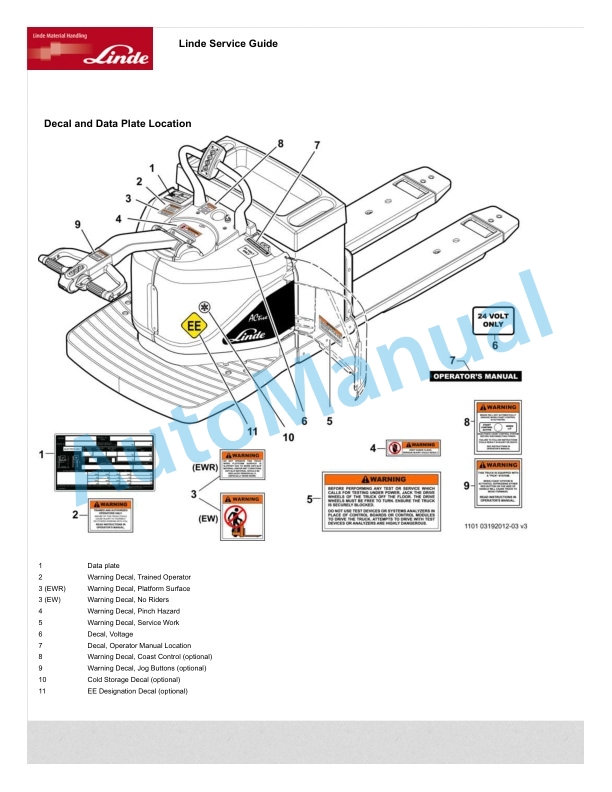

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00