Linde 1220-01 – H25D, H25T, H30D, H30T, H35D, H35T Production site Xiamen Operating Instructions SN C11220G00001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN C11220G00001 and up

- Format: PDF

- Size: 70.0MB

- Number of Pages: 384

- Serial Number:

SN C11220G00001 and up

Category: Linde Operator Manual PDF

-

Model List:

- H25D

- H25T

- H30D

- H30T

- H35D

- H35T

- 1. Diesel Forklift TruckH25D, H30D, H35D

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. Intended use

- 1.2.3. Improper use

- 1.2.4. Additional information

- 1.2.5. Description of use and climatic conditions

- 1.2.6. Symbols used

- 1.2.7. Legal requirements for marketing

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the event of tipover

- 1.3.5. Handling consumables

- 1.3.6. EMC Electromagnetic Compatibility

- 1.3.7. Competent person

- 1.3.8. Regulations

- 1.3.9. Fitting attachments

- 1.3.10. Emergency exit for models with rear window

- 1.3.11. Manually lowering the load forks

- 1.4. Overview

- 1.4.1. General view

- 1.4.2. Identification plates

- 1.4.3. Display unit

- 1.4.4. Controller and panel

- 1.5. Operation

- 1.5.1. Checks before starting a new vehicle

- 1.5.2. Instructions for runningin

- 1.5.3. Fully enclosed cab (optional)

- 1.5.4. Climbing on.off the forklift

- 1.5.5. Seat belt status and performance checks

- 1.5.6. Engine cover

- 1.5.7. Adjusting the steering column

- 1.5.8. Engine

- 1.5.9. Driving

- 1.5.10. Steering

- 1.5.11. Brake system

- 1.5.12. Horn operation

- 1.5.13. Lifting devices and attachments

- 1.5.14. Installing additional equipment

- 1.5.15. Transporting loads

- 1.5.16. Before exiting the truck

- 1.5.17. Truck transport

- 1.5.18. Truck storage

- 1.5.19. Disposal of old trucks

- 1.6. Maintenance

- 1.6.1. Summary

- 1.6.2. General information

- 1.6.3. Preservice preparatory work

- 1.6.4. Preparations

- 1.6.5. Engine

- 1.6.6. Cooling system

- 1.6.7. Transmission system

- 1.6.8. Steering axle and wheels

- 1.6.9. Chassis

- 1.6.10. Control system

- 1.6.11. Electrical components

- 1.6.12. Hydraulics

- 1.6.13. Load lifting system

- 1.7. Technical datasheet

- 1.7.1. Technical datasheet

- 1.7.2. Technical datasheet H25D

- 1.7.3. Technical datasheet H30D

- 1.7.4. Technical datasheet H35D

- 2. LPG Forklift TruckH25T, H30T, H35T

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Introduction

- 2.2.2. Intended use

- 2.2.3. Improper use

- 2.2.4. Additional information

- 2.2.5. Description of use and climatic conditions

- 2.2.6. Symbols used

- 2.2.7. Technical description

- 2.2.8. Legal requirements for marketing

- 2.3. Safety

- 2.3.1. Safety guidelines

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. In the event of tipover

- 2.3.5. Noise level

- 2.3.6. Handling consumables

- 2.3.7. EMC Electromagnetic Compatibility

- 2.3.8. Competent person

- 2.3.9. Regulations

- 2.3.10. Fitting attachments

- 2.3.11. Emergency exit for models with rear window

- 2.3.12. Manually lowering the load forks

- 2.3.13. LPG system safety regulations

- 2.3.14. Safety information on the LPG system

- 2.3.15. Safety guidelines for LPG (extract)

- 2.4. Overview

- 2.4.1. General view

- 2.4.2. Identification plates

- 2.4.3. Display unit

- 2.4.4. Controller and panel

- 2.5. Operation

- 2.5.1. Checks before starting a new vehicle

- 2.5.2. Instructions for runningin

- 2.5.3. Preshift checks

- 2.5.4. Fully enclosed cab (optional)

- 2.5.5. Climbing on.off the forklift

- 2.5.6. Seat belt status and performance checks

- 2.5.7. Engine cover

- 2.5.8. Adjusting the steering column

- 2.5.9. Changing the LPG cylinder

- 2.5.10. Filling the LPG tank

- 2.5.11. Engine

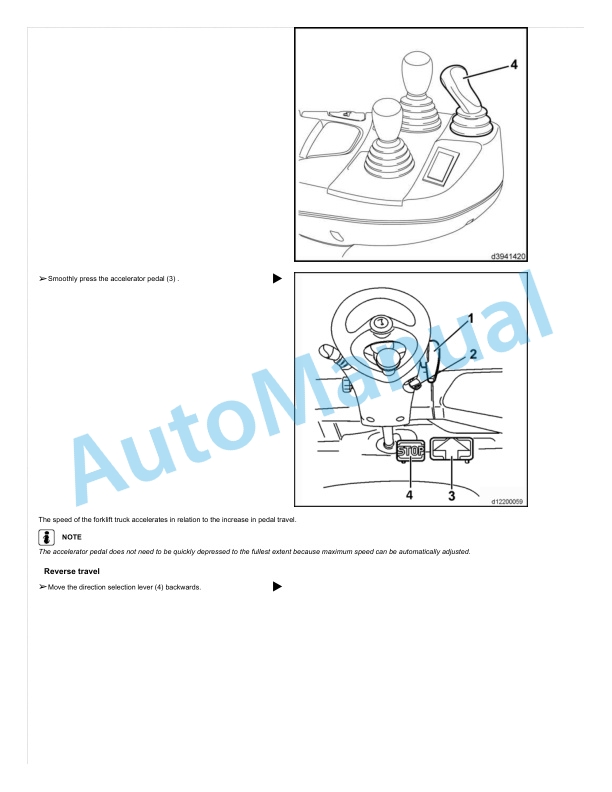

- 2.5.12. Driving

- 2.5.13. Steering

- 2.5.14. Brake system

- 2.5.15. Horn operation

- 2.5.16. Lifting devices and attachments

- 2.5.17. Installing additional equipment

- 2.5.18. Transporting loads

- 2.5.19. Before exiting the truck

- 2.5.20. Truck transport

- 2.5.21. Truck storage

- 2.5.22. Disposal of old trucks

- 2.6. Maintenance

- 2.6.1. Summary

- 2.6.2. General information

- 2.6.3. General LPG system maintenance information

- 2.6.4. Preservice preparatory work

- 2.6.5. Recommended fuels and oils

- 2.6.6. Periodic checks and maintenance

- 2.6.7. hr service plan

- 2.6.8. hr service plan

- 2.6.9. hr service plan

- 2.6.10. hr service plan

- 2.6.11. Preparations

- 2.6.12. Engine

- 2.6.13. Cooling system

- 2.6.14. Transmission system

- 2.6.15. Steering axle and wheels

- 2.6.16. Chassis

- 2.6.17. Control system

- 2.6.18. Electrical components

- 2.6.19. Hydraulics

- 2.6.20. Load lifting system

- 2.7. Technical datasheet

- 2.7.1. Technical datasheet

- 2.7.2. Technical datasheet H25T

- 2.7.3. Technical datasheet H30T

- 2.7.4. Technical datasheet H35T

Rate this product

You may also like

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

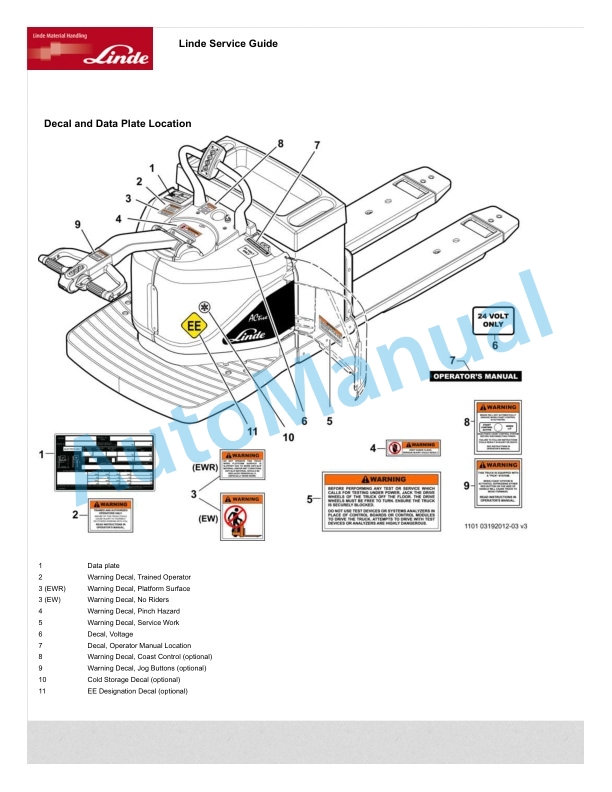

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00