Linde 1286-01 – E30SL, E35SL Production site Xiamen Operating Instructions SN C11286H00001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN C11286H00001 and up

- Format: PDF

- Size: 37.9MB

- Number of Pages: 277

- Serial Number:

SN C11286H00001 and up

Category: Linde Operator Manual PDF

-

Model List:

- E30SL

- E35SL

- 1. Electric Forklift TruckE30SL, E35SL

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. Intended use

- 1.2.3. Improper use

- 1.2.4. Additional information

- 1.2.5. Description of use and climatic conditions

- 1.2.6. Symbols used

- 1.2.7. Technical description

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the event of tipover

- 1.3.5. Handling consumables

- 1.3.6. Regulations

- 1.3.7. Competent person

- 1.3.8. Installing attachments

- 1.3.9. Emergency exit from cab with rear window

- 1.3.10. Manually lowering the forks

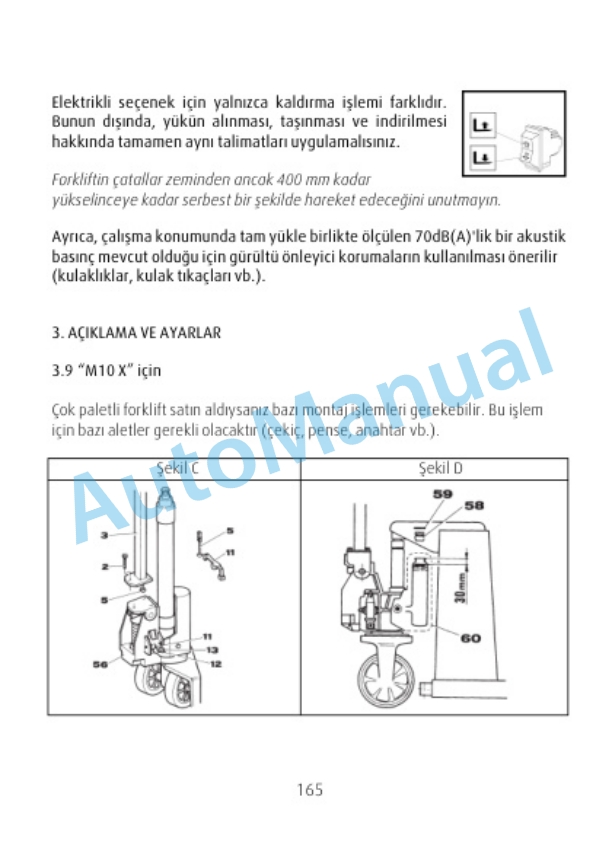

- 1.4. Overview

- 1.4.1. Identification plates

- 1.4.2. Identification plates

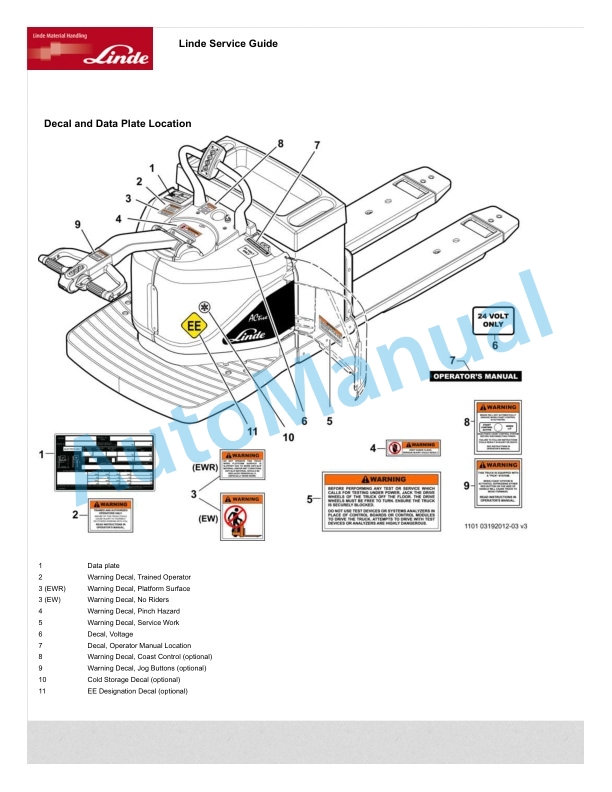

- 1.4.3. Warning labels

- 1.4.4. General view

- 1.4.5. Controller and display unit

- 1.4.6. Display unit

- 1.4.7. Switch panel

- 1.5. Operation

- 1.5.1. Service plan before first start

- 1.5.2. Instructions for runningin

- 1.5.3. Preshift checks

- 1.5.4. Daily inspection items

- 1.5.5. Mounting.dismounting

- 1.5.6. Seat belt status and performance checks

- 1.5.6.1. Checking condition and performance

- 1.5.6.2. Adjusting the seat and seat belt

- 1.5.6.3. Adjusting the seat and seat belt (comfort)

- 1.5.7. Horn operation

- 1.5.8. Adjusting the steering column

- 1.5.9. Emergency off switch

- 1.5.10. Setting the display unit

- 1.5.11. Switching the truck on and off

- 1.5.12. Driving (dual pedal operation)

- 1.5.12.1. Driving (dual pedal)

- 1.5.12.2. Forward and reverse movement (dual pedal)

- 1.5.12.3. Changing the drive direction

- 1.5.13. Driving (single pedal operation)

- 1.5.13.1. Driving (single pedal)

- 1.5.13.2. Forward and reverse movement (single pedal)

- 1.5.13.3. Changing the drive direction

- 1.5.14. Steering system

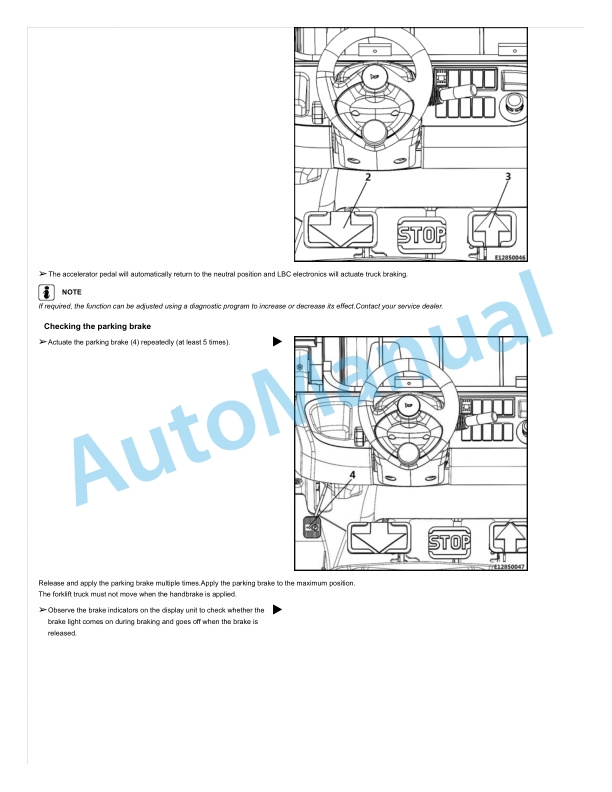

- 1.5.15. Brake system

- 1.5.15.1. Brake system information

- 1.5.15.2. Foot brake.emergency brake

- 1.5.15.3. Electronic regenerative braking

- 1.5.15.4. Parking brake

- 1.5.16. Lifting devices and attachments

- 1.5.16.1. Operating the lifting device

- 1.5.16.2. Operating attachments

- 1.5.17. Transporting loads

- 1.5.17.1. Load centre distance and load capacity

- 1.5.17.2. Load rating plate

- 1.5.17.3. Before loading

- 1.5.17.4. Adjusting the fork spacing

- 1.5.17.5. Picking up a load

- 1.5.17.6. Loading

- 1.5.17.7. Driving with a load

- 1.5.17.8. Unloading

- 1.5.17.9. Tow coupling

- 1.5.17.10. Before exiting the truck

- 1.5.18. Truck transport

- 1.5.18.1. Removing the mast, towing regulations and procedure

- 1.5.18.2. Driving without a lift mast

- 1.5.18.3. Use a truck or flatbed trailer to carry the forklift truck

- 1.5.18.4. Lifting the truck with a crane

- 1.5.19. Truck storage

- 1.5.19.1. Taking the forklift truck out of operation

- 1.5.19.2. Disposal of old trucks

- 1.6. Maintenance

- 1.6.1. Safety information for inspection and maintenance work

- 1.6.2. Inspection and maintenance data

- 1.6.3. Recommended fuels and oils

- 1.6.4. Regular maintenance

- 1.6.5. First service

- 1.6.6. hour service plan

- 1.6.7. hour service plan

- 1.6.8. hour service plan

- 1.6.9. Cleaning the truck

- 1.6.10. Transmission system

- 1.6.10.1. Checking the retarder case and drive axle for leaks

- 1.6.10.2. Checking for leaks and checking the mounting between the retarder case and the drive motor

- 1.6.10.3. Checking for leakage and tightness between the retarder and drive axle

- 1.6.10.4. Checking the retarder case and drive axle gearbox oil level

- 1.6.10.5. Changing the retarder and drive axle gearbox oil

- 1.6.10.6. Checking the fastening between the drive axle and chassis

- 1.6.11. Steering axle and wheels

- 1.6.11.1. Checking the tyres

- 1.6.11.2. Checking the condition of the antistatic belt

- 1.6.11.3. Tighten the wheel nuts

- 1.6.11.4. Checking the tyre inflation pressure

- 1.6.11.5. Changing wheels

- 1.6.11.6. Cleaning and lubricating the steering axle

- 1.6.12. Chassis

- 1.6.12.1. Checking seat belt condition and correct operation

- 1.6.12.2. Battery cover

- 1.6.12.3. Rechargeablebattery side door

- 1.6.12.4. Joystick base

- 1.6.12.5. Checking the battery cover and joystick base locking devices

- 1.6.12.6. Checking and tightening the bolts connecting the lift mast to the drive axle

- 1.6.12.7. Checking other bearings and connections and lubricating

- 1.6.13. Control system

- 1.6.13.1. Checking the brake system

- 1.6.13.2. Checking the brake fluid level

- 1.6.13.3. Checking the horn is working normally

- 1.6.13.4. Checking the joystick bellows

- 1.6.13.5. Adjust joysticks

- 1.6.13.6. Calibrating the accelerator pedal potentiometer

- 1.6.13.7. Checking the pedal group for ease of movement and lubricating as required

- 1.6.14. Electrical system

- 1.6.14.1. Checking the main contactor

- 1.6.14.2. Checking the operation of the fan and cleaning, if necessary

- 1.6.14.3. Checking electric cables

- 1.6.14.4. Checking fuses

- 1.6.14.5. Fuse box

- 1.6.14.6. Battery discharged

- 1.6.14.7. Checking battery charging status

- 1.6.14.8. Connecting the rechargeable battery to an external charger

- 1.6.14.9. Preparing to change the battery

- 1.6.14.10. Replacing the battery using a suspension arrangement (hoist)

- 1.6.15. Hydraulic system

- 1.6.15.1. Checking the hydraulic oil level

- 1.6.15.2. Checking the hydraulic system for leaks

- 1.6.15.3. Checking the breather filter is working normally

- 1.6.15.4. Checking the control valve unit is working normally

- 1.6.16. Load lifting system

- 1.6.16.1. Checking the fork arms and the fork arm quick release apparatus

- 1.6.16.2. Checking the operation and installation of the lift mast, lifting chain and limit block

- 1.6.16.3. Checking the fastening of the tilt cylinder eyebolt

- 1.6.16.4. Lubricate the lift mast and chains with chain spray

- 1.6.16.5. Adjusting the length of the lift chains, and lubricating using chain spray

- 1.6.17. Special equipment

- 1.6.17.1. Checking the preload of the double hoses (if equipped with attachments)

- 1.6.17.2. Cleaning and lubricating the sideshift forks and checking connections

- 1.7. Technical datasheet

- 1.7.1. Technical datasheet

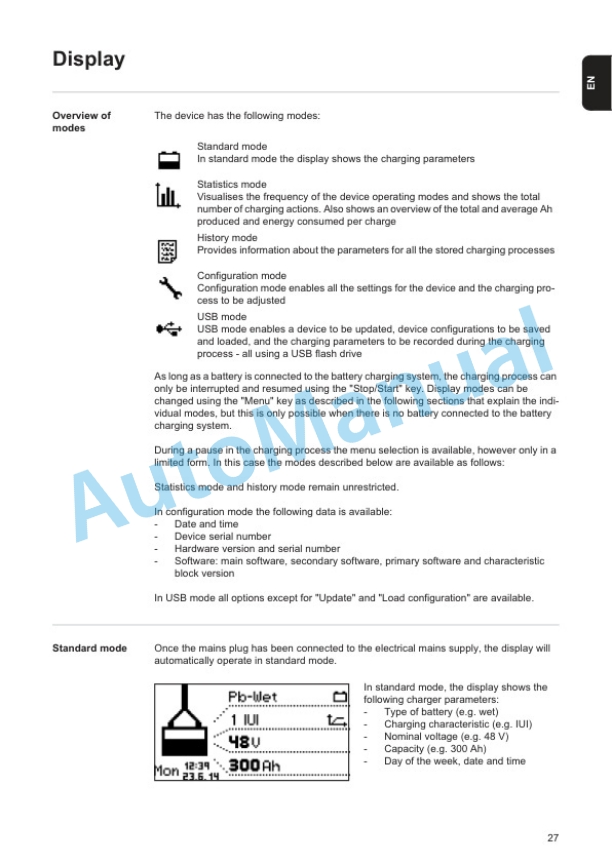

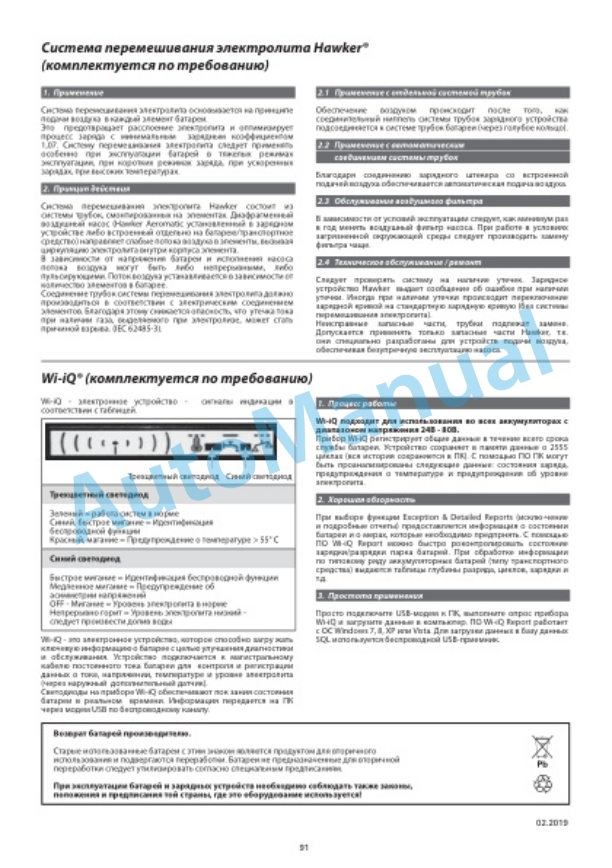

- 2. Leadacid battery charger 24V . 48V . 80V

- 3. Lithiumion batteryWNE, WEB Lithium BatteryWNE lithiumion battery

- 3.1. Table of content

- 3.2. Overview

- 3.2.1. Purpose of use

- 3.2.2. Lithium battery product series

- 3.2.3. Scope of use

- 3.2.4. Target personnel

- 3.2.5. Environmental protection

- 3.3. Safety

- 3.3.1. Safety philosophy

- 3.3.2. Customer obligations

- 3.3.3. Personnel qualification requirements

- 3.3.4. General safety requirements

- 3.3.5. Responding to emergencies

- 3.3.6. Explanation of technical terms

- 3.4. General view

- 3.4.1. Product appearance

- 3.5. Operating instructions

- 3.5.1. Operating instructions

- 3.5.2. Safety matters and precautions

- 3.5.3. Battery temperature properties

- 3.5.4. Battery system transportation requirements

- 3.5.5. Predriving inspection

- 3.5.6. Requirements for vehicles in normal operation

- 3.5.7. Requirements for vehicles in longterm storage

- 3.5.8. Procedure for the user to connect and disconnect electricity for discharge

- 3.5.9. User charging procedure and precautions

- 3.5.10. Lithium battery replacement

- 3.5.11. Description of display unit screens

- 3.5.12. Differences between integrated and nonintegrated product malfunction displays

- 3.6. Maintenance

- 3.6.1. Battery maintenance operations

- 3.6.2. Regular inspection requirements

- 3.7. Warranty description

- 3.7.1. Quality assurance and warranty period

- 3.7.2. Scope of quality assurance and warranty responsibility exemptions

Rate this product

You may also like

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

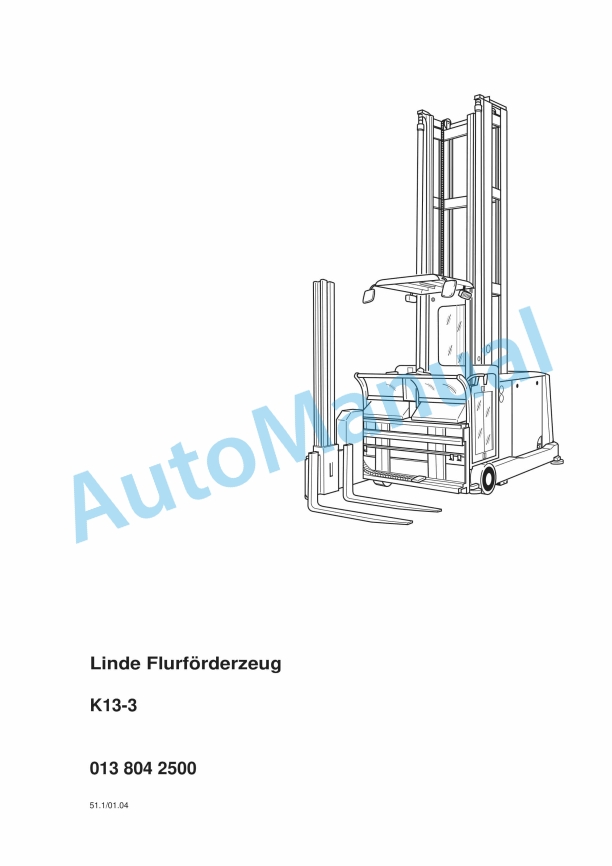

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00