Linde 1287-01 – E40 to E50B Production site China, LX Operating Instructions SN C11287X00009 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN C11287X00009 and up

- Format: PDF

- Size: 33.7MB

- Number of Pages: 208

- Serial Number:

SN C11287X00009 and up

Category: Linde Operator Manual PDF

-

Model List:

- E40

- E40-20

- E40B

- E45

- E45-20

- E45B

- E50

- E50-20

- E50B

- 1. Electric Forklift TruckE40, E45, E50E4020, E4520, E5020

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. General information

- 1.2.3. Conformity marking

- 1.2.4. Declaration that reflects the content of the declaration of conformity

- 1.2.5. Intended use

- 1.2.6. Hazard assessment

- 1.2.7. Improper use

- 1.2.8. Symbols used

- 1.2.9. Disposing of components and batteries

- 1.2.10. Description of use and climatic conditions

- 1.2.11. Technical description

- 1.3. Safety

- 1.3.1. Residual risks

- 1.3.2. Noise level

- 1.3.3. Frequency characteristics for vibrations imparted to the human body

- 1.3.4. Stability

- 1.3.5. In the case of tipover

- 1.3.6. Operating company

- 1.3.7. Drivers

- 1.3.8. Competent person

- 1.3.9. Regulations

- 1.3.10. Handling consumables

- 1.3.11. Fitting attachments

- 1.3.12. Emergency exit from drivers cab with windows

- 1.3.13. Manually lowering the forks

- 1.4. Overview

- 1.4.1. General view

- 1.4.2. Controller and display unit

- 1.4.3. Summary diagram of labels

- 1.4.4. Display unit

- 1.4.5. Switch panel

- 1.5. Operation

- 1.5.1. Service plan before initial commissioning

- 1.5.2. Instructions for runningin

- 1.5.3. Preshift checks

- 1.5.4. Daily inspection items

- 1.5.5. Mounting.dismounting

- 1.5.6. Seat belt status and performance checks

- 1.5.6.1. Checking condition and performance

- 1.5.6.2. Adjusting the drivers armrest

- 1.5.6.3. Adjusting the seat and seat belt (comfort)

- 1.5.6.4. Seat belt monitoring and alarm function

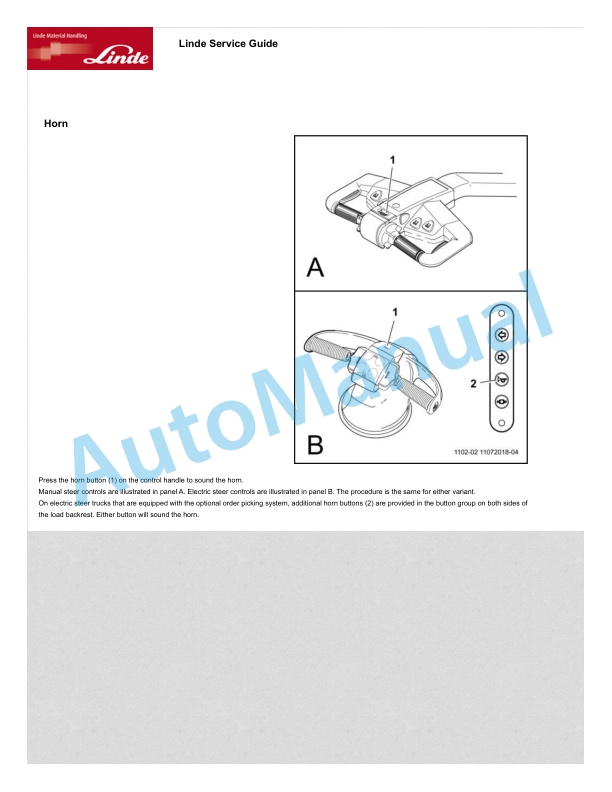

- 1.5.7. Operating the horn

- 1.5.8. Adjusting the steering column

- 1.5.9. Setting the display unit

- 1.5.10. Emergency off switch

- 1.5.11. Switching the truck on and off

- 1.5.12. Using the RFID Keypad (China only)

- 1.5.12.1. RFID Keypad installation position

- 1.5.12.2. RFID Keypad

- 1.5.13. Driving (dual pedal operation)

- 1.5.13.1. Driving

- 1.5.13.2. Forward travel

- 1.5.13.3. Reverse travel

- 1.5.13.4. Changing the drive direction

- 1.5.13.5. Starting on a slope

- 1.5.14. Driving (single pedal operation)

- 1.5.14.1. Driving

- 1.5.14.2. Forward travel

- 1.5.14.3. Reverse travel

- 1.5.14.4. Changing the drive direction

- 1.5.14.5. Forward travel E4020.E4520.E5020

- 1.5.14.6. Reverse travel E4020.E4520.E5020

- 1.5.14.7. Changing the drive direction E4020.E4520.E5020

- 1.5.14.8. Starting on a slope

- 1.5.15. Steering system

- 1.5.16. Brake system

- 1.5.16.1. Brake system information

- 1.5.16.2. Foot brake.emergency brake

- 1.5.16.3. Electronic regenerative braking

- 1.5.16.4. Electronic parking brake

- 1.5.16.5. Manually releasing the electronic parking brake

- 1.5.17. Battery cover Open Closed

- 1.5.18. Checking battery charging status

- 1.5.19. Connecting the rechargeable battery to an external charger

- 1.5.20. Lifting devices and attachments

- 1.5.20.1. Operating the centralised joystick for the lift mast

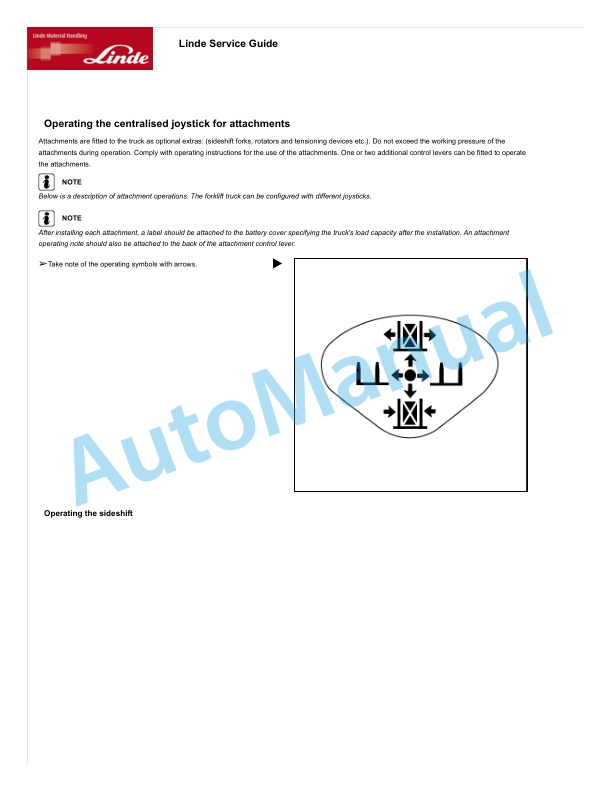

- 1.5.20.2. Operating the centralised joystick for attachments

- 1.5.20.3. Lift mast singlelever operation

- 1.5.20.4. Singlelever operation of attachments

- 1.5.20.5. Operating the joystick for the lift mast_E4020.E4520.E5020

- 1.5.20.6. Operating the joystick for attachments_E4020.E4520.E5020

- 1.5.21. Transporting loads

- 1.5.21.1. Load centre distance and load capacity

- 1.5.21.2. Adjusting the fork spacing

- 1.5.21.3. Picking up a load

- 1.5.21.4. Loading

- 1.5.21.5. Driving with a load

- 1.5.21.6. Unloading

- 1.5.21.7. Tow coupling

- 1.5.21.8. Leaving the truck temporarily

- 1.5.21.9. Before exiting the truck

- 1.5.22. Truck transport

- 1.5.22.1. Dismantling.installing the lift mast

- 1.5.22.2. Regulations for removing the mast and towing

- 1.5.22.3. Driving without a lift mast

- 1.5.22.4. Use a truck or flatbed trailer to carry the forklift truck

- 1.5.22.5. Lifting the truck with a crane

- 1.5.22.6. Description of lifting points

- 1.5.23. Truck storage

- 1.5.23.1. Taking the truck out of operation

- 1.5.24. Disposal of old trucks

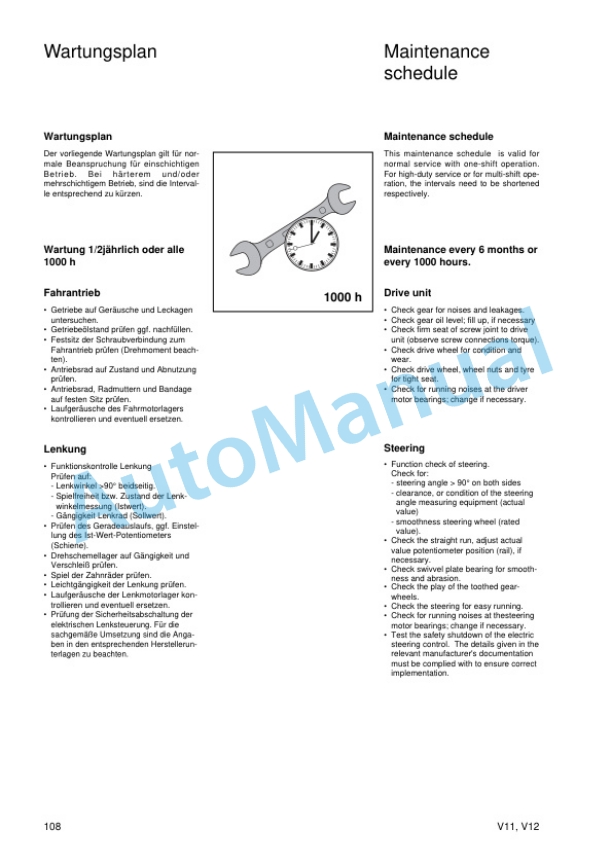

- 1.6. Maintenance

- 1.6.1. Safety information for inspection and maintenance work

- 1.6.2. Inspection and maintenance data

- 1.6.3. Recommended fuels and oils

- 1.6.4. Regular maintenance

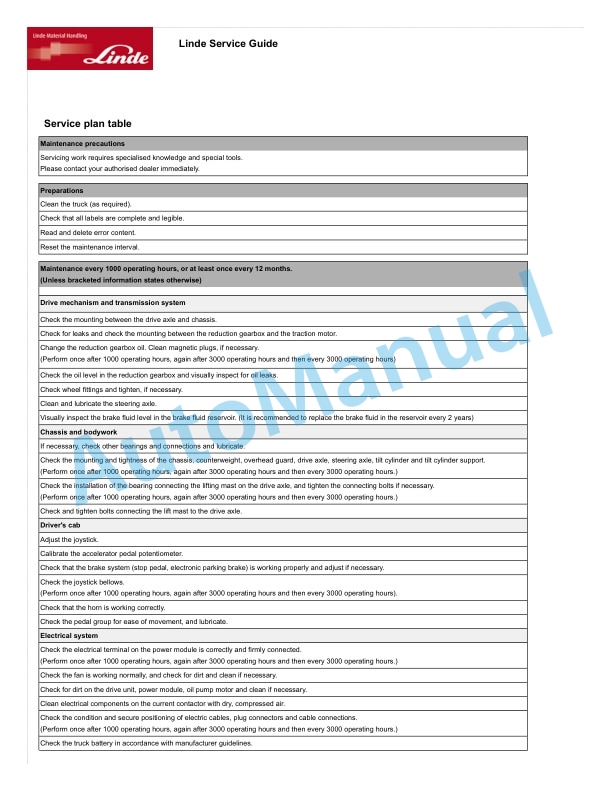

- 1.6.5. Service plan table

- 1.6.6. Cleaning the truck

- 1.6.7. Drive mechanism and transmission system

- 1.6.7.1. Checking the oil level of the reduction gearbox

- 1.6.7.2. Changing the reduction gearbox oil

- 1.6.7.3. Checking the reduction gearbox for leaks

- 1.6.7.4. Checking for leaks and checking the mounting between the reduction gearbox and the drive motor

- 1.6.7.5. Checking the fastening between the drive axle and chassis

- 1.6.7.6. Checking the brake fluid level in the brake fluid reservoir

- 1.6.7.7. Replacing the brake fluid in the brake fluid reservoir

- 1.6.7.8. Checking the wheels

- 1.6.7.9. Checking the condition of the antistatic belt

- 1.6.7.10. Tighten the wheel nuts

- 1.6.7.11. Changing wheels

- 1.6.7.12. Lubricating the steering axle

- 1.6.8. Chassis and bodywork

- 1.6.8.1. Checking other bearings and connections and lubricating

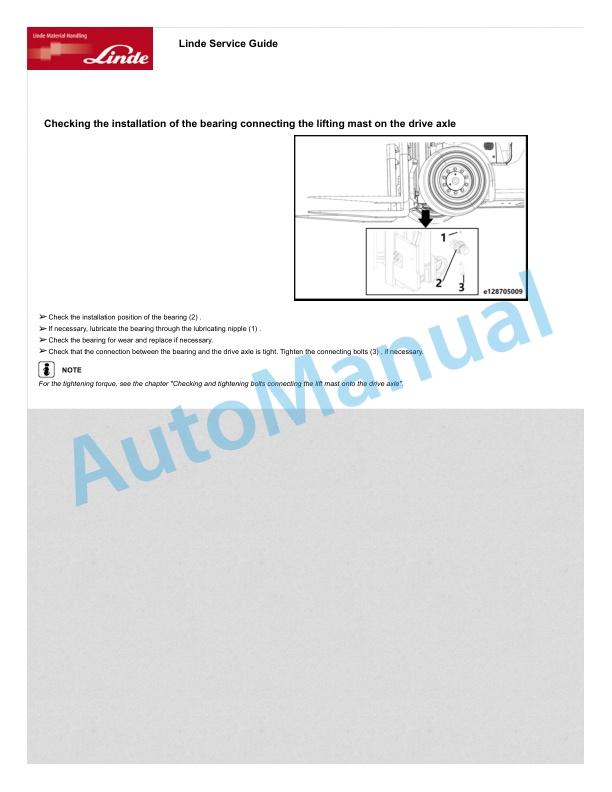

- 1.6.8.2. Checking the installation of the bearing connecting the lifting mast on the drive axle

- 1.6.8.3. Checking and tightening bolts connecting the lift mast onto the drive axle

- 1.6.9. Drivers cab

- 1.6.9.1. Checking seat belt condition and correct operation

- 1.6.9.2. Checking the brake system

- 1.6.9.3. Checking the horn is working normally

- 1.6.9.4. Checking the joystick bellows

- 1.6.9.5. Adjust joysticks

- 1.6.9.6. Calibrating the accelerator pedal potentiometer

- 1.6.9.7. Checking the pedal group for ease of movement and lubricating as required

- 1.6.9.8. Checking the battery cover locking devices

- 1.6.10. Electrics.electronics

- 1.6.10.1. Checking the power module for dirt and cleaning if necessary

- 1.6.10.2. Checking the main contactor

- 1.6.10.3. Checking the operation of the fan and cleaning, if necessary

- 1.6.10.4. Checking electric cables

- 1.6.10.5. Fuses

- 1.6.10.6. Fuse box

- 1.6.10.7. Leadacid battery discharge

- 1.6.10.8. Changing the battery

- 1.6.10.9. Replacing the battery using a suspension arrangement

- 1.6.10.10. Inspecting and maintaining the lithiumion battery

- 1.6.11. Hydraulic system

- 1.6.11.1. Checking the hydraulic system for leaks

- 1.6.11.2. Checking the hydraulic oil level

- 1.6.11.3. Changing the hydraulic oil

- 1.6.11.4. Checking the breather filter is working normally

- 1.6.11.5. Replacing the breather filter, high pressure filter and suction filter

- 1.6.12. Lifting system

- 1.6.12.1. Checking the fork arms and the fork arm quick release apparatus

- 1.6.12.2. Checking the working condition and installation of the lift mast, lifting chains and lift cylinder

- 1.6.12.3. Lubricating the lift mast and chains with chain spray

- 1.6.12.4. Adjusting the length of the lifting chains and lubricating using chain spray

- 1.6.13. Special equipment

- 1.6.13.1. Checking the preload of the double hoses (if equipped with attachments)

- 1.6.13.2. Cleaning and lubricating the sideshift forks and checking connections

- 1.7. Technical datasheet

- 1.7.1. Dimensions overview

- 1.7.2. Technical datasheet

- 1.7.3. Technical datasheet load centre of gravity distance 600

- 1.7.4. Ecodesign requirements for electric motors and variable speed drives

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00