Linde 1293-01 – E20B-01, E20BHP-01, E25B-01, E25BHP-01 Production site Jinan Operating Instructions SN C31293Y00001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN C31293Y00001 and up

- Format: PDF

- Size: 27.3MB

- Number of Pages: 210

- Serial Number:

SN C31293Y00001 and up

Category: Linde Operator Manual PDF

-

Model List:

- E20B-01

- E20BHP-01

- E25B-01

- E25BHP-01

- 1. series Electric Forklift TruckE20BHP, E25BHPNorth America

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Scope

- 1.2.2. Obligations of the Equipment Owner

- 1.2.3. Operator Responsibilities

- 1.2.4. Proper use

- 1.2.5. Hazard messages

- 1.3. Safety

- 1.3.1. Before Operation

- 1.3.2. Operator Daily Checklist

- 1.3.3. Operating position

- 1.3.4. Pedestrians

- 1.3.5. Travel

- 1.3.6. Lifting and Lowering

- 1.3.7. Inclines, Ramps, Docks, Elevators

- 1.3.8. Avoiding Falls and Tipovers

- 1.3.9. Suspended Loads

- 1.3.10. Parking

- 1.3.11. Leadacid Battery Safety

- 1.3.12. Lithiumion Battery Safety

- 1.3.13. Safety During Maintenance

- 1.3.13.1. Personnel Qualifications

- 1.3.13.2. Hazardous Substances

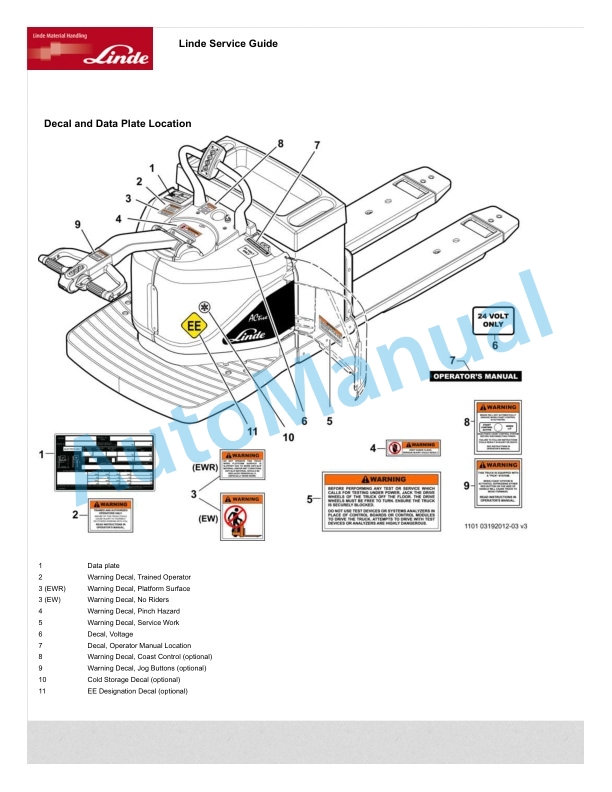

- 1.3.14. Operator warning decals

- 1.3.14.1. Data plate

- 1.3.14.2. Parking brake warning decal

- 1.3.14.3. Voltage decal

- 1.3.14.4. Operator warning decal

- 1.3.14.5. Trained operator warning decal

- 1.3.14.6. Test or service warning decal

- 1.3.14.7. Never stand or walk under forks warning decal

- 1.3.14.8. Do not lift personnel warning decal

- 1.3.14.9. Crushed fingers warning decal

- 1.3.14.10. No step warning decal

- 1.3.14.11. Tipover warning decal

- 1.3.14.12. Back up alarm warning decal

- 1.3.14.13. Hood latch warning decal

- 1.3.14.14. Lithiumion safety rules warning decal

- 1.4. Overview

- 1.4.1. Technical Description

- 1.4.2. Truck Components

- 1.4.3. Controls

- 1.4.4. Display Unit

- 1.4.5. Definition of directions

- 1.4.6. Decal and Data Plate Location

- 1.4.7. Data Plate

- 1.5. Operation

- 1.5.1. Unloading and Preparing a New Truck for Operation

- 1.5.2. Adjusting the Operators Seat

- 1.5.3. Steering Column Adjustment

- 1.5.4. Seat Belt

- 1.5.5. Operating the Display Unit

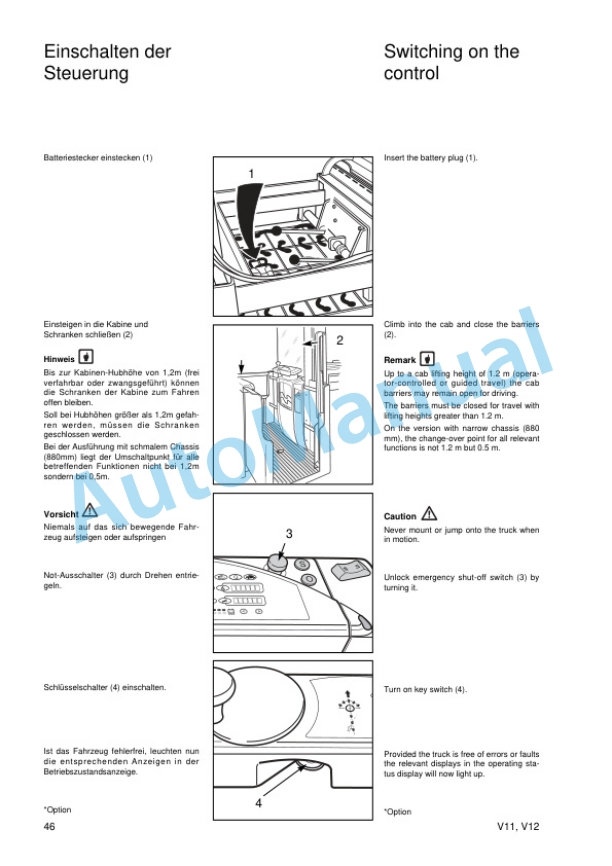

- 1.5.6. Turning the Truck On and Off

- 1.5.7. Access Control Systems (optional equipment)

- 1.5.8. Driving

- 1.5.9. Braking

- 1.5.10. Steering System

- 1.5.11. Emergency Stop Switch

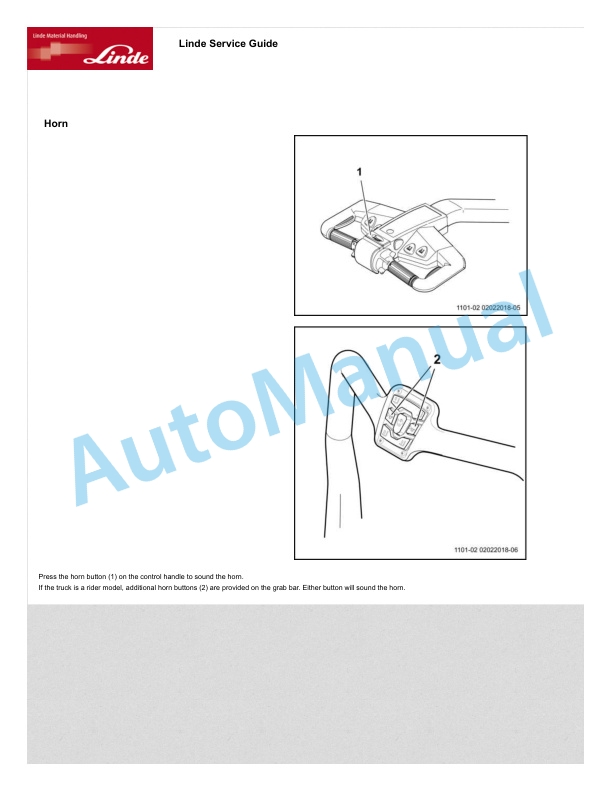

- 1.5.12. Horn

- 1.5.13. Fork Position Adjustment

- 1.5.14. Hydraulic Controls

- 1.5.15. Lighting

- 1.5.16. Fan (optional equipment)

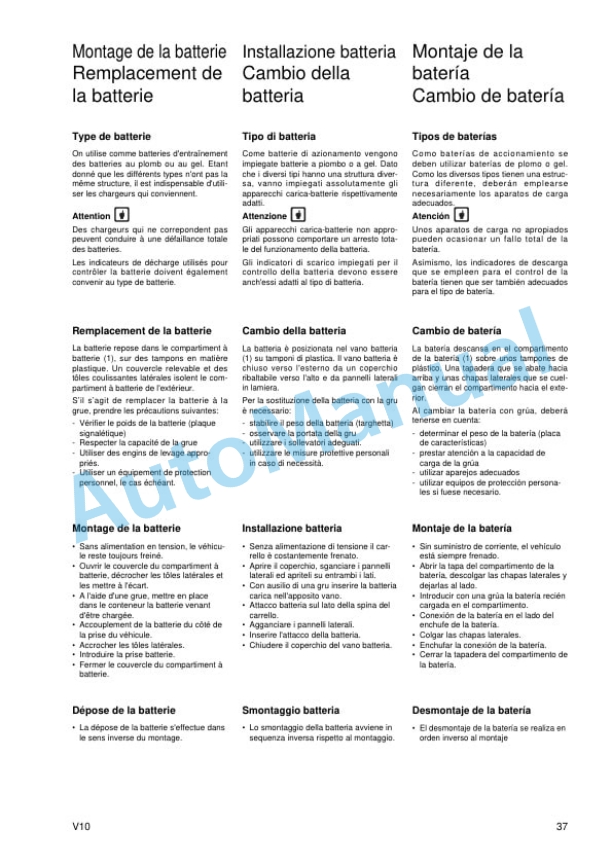

- 1.5.17. Battery Operations

- 1.5.17.1. Reading Battery Charge Level

- 1.5.17.2. Opening and Closing the Battery Cover

- 1.5.17.3. Battery Power Switch

- 1.5.17.4. Connecting the Battery to an External Charger

- 1.5.17.5. On Board Battery Charger (optional equipment)

- 1.5.17.6. Charging the Battery with the OnBoard Charger (optional equipment)

- 1.5.17.7. Removing the Battery

- 1.5.18. Towing Loads

- 1.5.19. Manual Lowering of Fork Carriage

- 1.5.20. Towing the Truck

- 1.5.21. Securing the Truck for Transport

- 1.5.22. Hoisting the Truck

- 1.6. Maintenance

- 1.6.1. Personnel Qualifications

- 1.6.2. Cleaning

- 1.6.2.1. Cleaning the Truck

- 1.6.2.2. Cleaning the Lift Chains

- 1.6.3. Operator Inspection and Maintenance

- 1.6.3.1. Daily Inspection Overview

- 1.6.3.2. Daily Inspection Checklist

- 1.6.3.3. Check for fluid leakage

- 1.6.3.4. Check overhead guard

- 1.6.3.5. Check hydraulic cylinders

- 1.6.3.6. Check lift chains

- 1.6.3.7. Check fork carriage

- 1.6.3.8. Check battery cover latch

- 1.6.3.9. Check battery connector

- 1.6.3.10. Check hydraulic oil level

- 1.6.3.11. Check wheels and tires

- 1.6.3.12. Check the steering axle

- 1.6.3.13. Check decal condition

- 1.6.3.14. Check control lever bellows

- 1.6.3.15. Check the seat and seat belt

- 1.6.3.16. Antistatic strap (optional equipment)

- 1.6.3.17. Operational checks

- 1.6.4. Routine Lubrication and Inspection

- 1.6.4.1. Routine Lubrication and Inspection Intervals

- 1.6.4.2. Check the Brake Fluid Level

- 1.6.4.3. Checking Gear Oil Level

- 1.6.4.4. Steering Axle Lubrication

- 1.6.4.5. Hydraulic Tank Pressure Valve Test

- 1.6.4.6. Inspect and Lubricate Pedal Assemblies

- 1.6.4.7. Lubricating the Sideshifter (optional equipment)

- 1.6.4.8. Check and Lubricate Lift Chains

- 1.6.4.9. Checking Reeving Hose Preload (optional equipment)

- 1.6.5. Scheduled Maintenance

- 1.6.5.1. General Maintenance Information

- 1.6.5.2. Sideshifter Maintenance Intervals

- 1.6.5.3. Scheduled Maintenance Chart

- 1.6.5.4. Sideshifter Maintenance (optional equipment)

- 1.6.6. Fluids and Lubricants

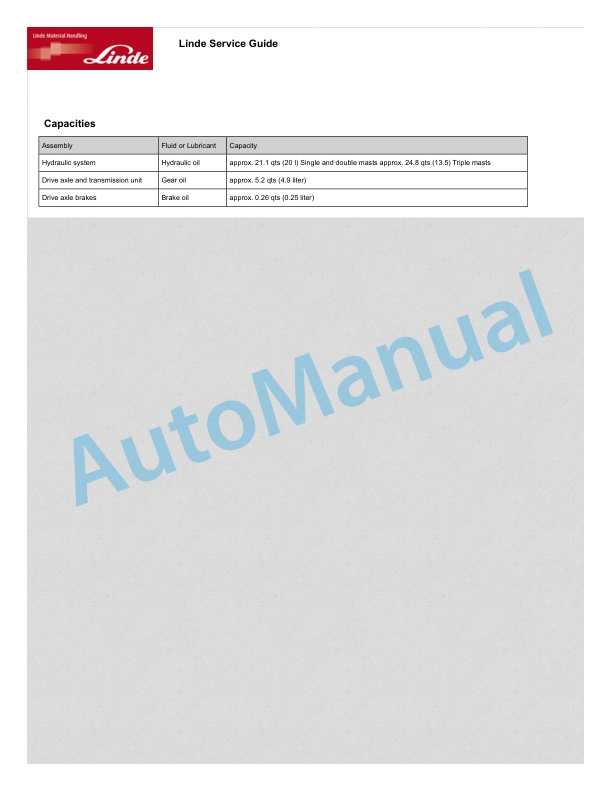

- 1.6.6.1. Capacities

- 1.6.6.2. Fluid and Lubricant Specifications

- 1.6.7. Troubleshooting

- 1.6.7.1. Fuses and Relays

- 1.7. Specifications

- 1.7.1. Dimensions

- 1.7.2. Specifications E20BHP and E25BHP

- 1.7.3. Mast Heights

- 2. Lithiumion batteryLG11, GF11, GF12, GF13, KG11, KG12, KG13, KG14, KG15, KG16, KG17

- 2.1. Table of content

- 2.2. Overview

- 2.2.1. Purpose of use

- 2.2.2. Lithiumion battery product series

- 2.2.3. Scope of use

- 2.2.4. Target personnel

- 2.2.5. Environmental protection

- 2.3. Safety

- 2.3.1. Safety philosophy

- 2.3.2. Customer obligations

- 2.3.3. Personnel qualification requirements

- 2.3.4. General safety requirements

- 2.3.5. Responding to emergencies

- 2.3.6. Explanation of technical terms

- 2.4. General view

- 2.4.1. Product appearance

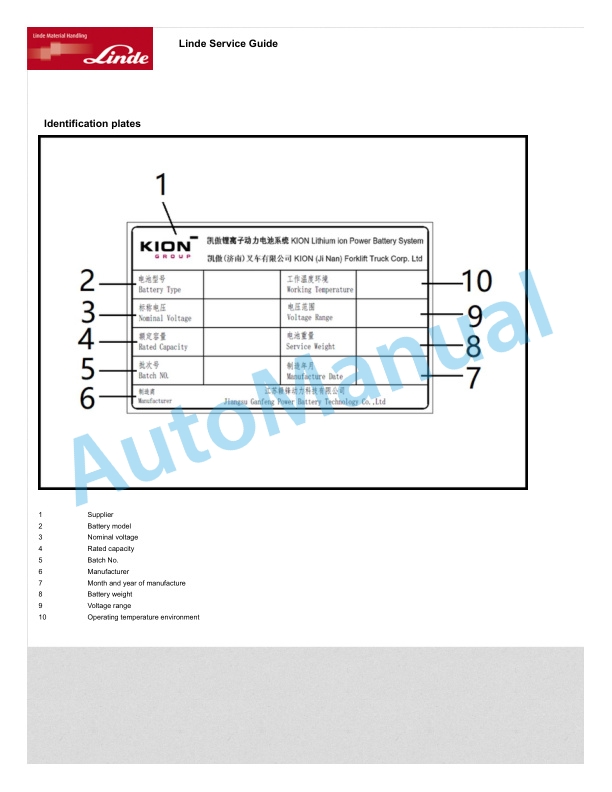

- 2.4.2. Identification plates

- 2.4.3. Dataplate (for export)

- 2.4.4. Product identification

- 2.5. Operating instructions

- 2.5.1. Operating instructions

- 2.5.2. Safety matters and precautions

- 2.5.3. Battery temperature properties

- 2.5.4. Battery system transportation requirements

- 2.5.5. Predriving inspection

- 2.5.6. Requirements for vehicles in normal operation

- 2.5.7. Requirements for vehicles in longterm storage

- 2.5.8. Procedure for the user to connect and disconnect electricity for discharge

- 2.5.9. User charging procedure and precautions

- 2.5.10. Emergency battery life function

- 2.5.11. Lithium battery replacement

- 2.5.12. Description of display unit screens

- 2.5.13. Error code definitions for lithiumion battery products

- 2.5.14. Product error codes display

- 2.6. Maintenance

- 2.6.1. Battery maintenance operations

- 2.6.2. Regular inspection requirements

- 2.7. Warranty description

- 2.7.1. Quality assurance and warranty period

- 2.7.2. Scope of quality assurance and warranty responsibility exemptions

- 2.8. Technical parameters

- 2.8.1. Technical parameters (GF11, GF12, GF13)

- 2.8.2. Technical parameters (KG11)

- 2.8.3. Technical parameters (KG13)

- 2.8.4. Technical parameters (KG14)

- 2.8.5. Technical parameters (KG15)

- 2.8.6. Technical parameters (KG16)

- 2.8.7. Technical parameters (KG17)

Rate this product

You may also like

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

$20.00