Linde 1294-01 – E30, E35 Production site Jinan Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 24.4MB

- Number of Pages: 169

Category: Linde Operator Manual PDF

-

Model List:

- E30

- E35 Production site Jinan

- 1. Electric Forklift TruckE30B01, E35B01, E30BHP01, E35BHP01, E30B30, E35B30, E30BHP30, E35BHP30

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Introduction

- 1.2.2. General information

- 1.2.3. Conformity marking

- 1.2.4. Declaration that reflects the content of the declaration of conformity

- 1.2.5. Declarations of conformity in accordance with directive RED 2014.53.EU

- 1.2.6. Nameplate (LX)

- 1.2.7. Factory dataplate (for exports)

- 1.2.8. Intended use

- 1.2.9. Hazard assessment

- 1.2.10. Improper use

- 1.2.11. Illustrations

- 1.2.12. Symbols used

- 1.2.13. Disposing of components and batteries

- 1.2.14. Description of use and climatic conditions

- 1.2.15. Technical description

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Data security

- 1.3.3. Residual risks

- 1.3.4. Stability

- 1.3.5. Operating company

- 1.3.6. Drivers

- 1.3.7. Competent person

- 1.3.8. Regulations

- 1.3.9. Fitting attachments

- 1.3.10. Handling consumables

- 1.3.11. Emergency exit from drivers cab with windows

- 1.3.12. Manually lowering the fork arms with ISO

- 1.4. Overview

- 1.4.1. General view (V5)

- 1.4.2. General view (V3)

- 1.4.3. Controller and display unit (V5)

- 1.4.4. Controller and display unit (V5) dual pedal

- 1.4.5. Controller and display unit (V3)

- 1.4.6. Summary diagram of labels

- 1.4.7. Display unit (V5)

- 1.4.7.1. Display unit

- 1.4.8. Display unit (V3)

- 1.4.8.1. Display unit

- 1.4.9. Switch panel

- 1.5. Operation

- 1.5.1. Service plan before first start

- 1.5.2. Instructions for runningin

- 1.5.3. Preshift checks

- 1.5.4. Daily inspection items

- 1.5.5. Periodic inspection items

- 1.5.6. Mounting.dismounting

- 1.5.7. Seat belt status and performance checks

- 1.5.7.1. Checking condition and performance

- 1.5.7.2. Adjusting the seat and seat belt

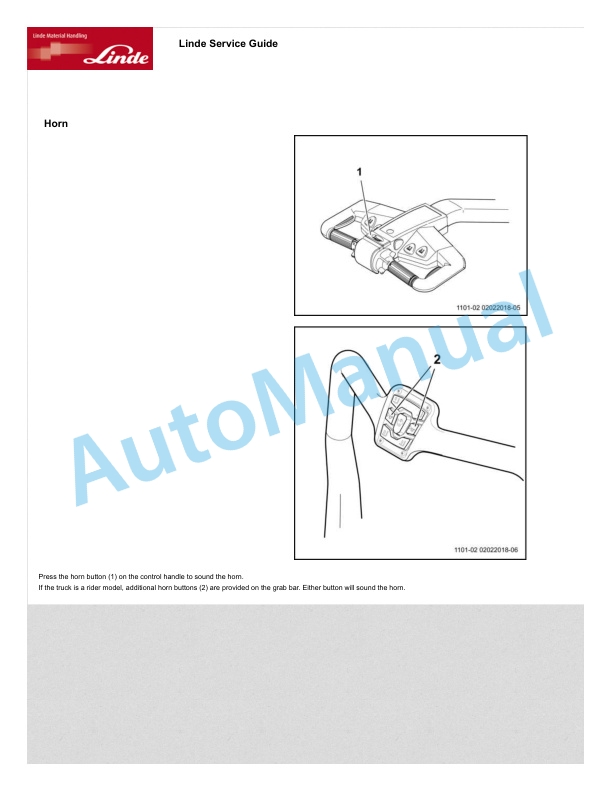

- 1.5.8. Operating the horn

- 1.5.9. Steering operation

- 1.5.10. Adjusting the steering column

- 1.5.11. Keypad installation and use (option)

- 1.5.11.1. RFID Keypad

- 1.5.11.2. RFID Keypad usage and settings.

- 1.5.12. Operation differences between V5 and V3 models

- 1.5.13. Emergency off switch

- 1.5.14. Switching the truck on and off

- 1.5.15. Driving (singlepedal operation)

- 1.5.15.1. Driving

- 1.5.15.2. Forward travel

- 1.5.15.3. Reverse travel

- 1.5.15.4. Changing the drive direction

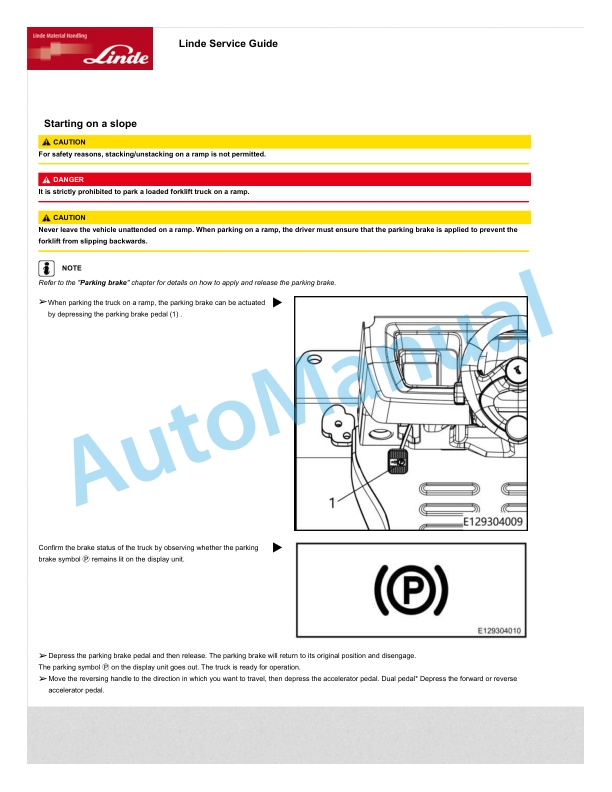

- 1.5.15.5. Starting on a slope

- 1.5.16. Driving (dualpedal operation)

- 1.5.16.1. Driving

- 1.5.16.2. Forward travel

- 1.5.16.3. Reverse travel

- 1.5.16.4. Changing the drive direction

- 1.5.16.5. Starting on a slope

- 1.5.17. Brake system

- 1.5.17.1. Brake system information

- 1.5.17.2. Foot brake.emergency brake

- 1.5.17.3. Electronic regenerative braking

- 1.5.17.4. Parking brake

- 1.5.18. Setting the display unit (V5)

- 1.5.18.1. Setting the display unit

- 1.5.19. Battery cover Open Closed

- 1.5.20. Battery hood gas spring

- 1.5.21. Checking battery level

- 1.5.22. Connecting the rechargeable battery to an external charger

- 1.5.23. Lifting devices and attachments

- 1.5.23.1. Operating the lifting device

- 1.5.23.2. Operating attachments

- 1.5.24. Transporting loads

- 1.5.24.1. Load centre distance and load capacity

- 1.5.24.2. Adjusting the fork spacing

- 1.5.24.3. Picking up a load

- 1.5.24.4. Loading

- 1.5.24.5. Driving with a load

- 1.5.24.6. Transporting suspended loads

- 1.5.24.7. Unloading

- 1.5.24.8. Tow coupling

- 1.5.24.9. Leaving the truck temporarily

- 1.5.24.10. Before exiting the truck

- 1.5.25. Transporting the truck

- 1.5.25.1. Dismantling.installing the lift mast

- 1.5.25.2. Regulations for removing the mast and towing

- 1.5.25.3. Use a truck or flatbed trailer to carry the forklift truck

- 1.5.25.4. Lifting the truck with a crane

- 1.5.26. Storing the truck

- 1.5.26.1. Taking the truck out of operation

- 1.5.27. Disposal of old trucks

- 1.6. Maintenance

- 1.6.1. Safety information for inspection and maintenance work

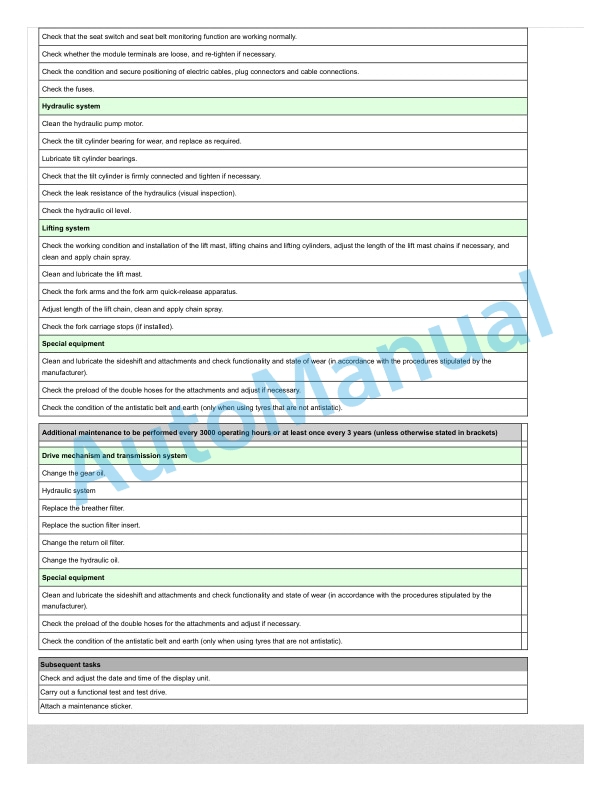

- 1.6.2. Regular maintenance

- 1.6.3. Table of first service checks

- 1.6.4. Service plan table

- 1.6.5. Cleaning the truck

- 1.6.6. Drive mechanism and transmission system

- 1.6.6.1. Checking the transmission gear and drive axle for leaks

- 1.6.6.2. Checking the brake fluid level in the brake fluid reservoir

- 1.6.6.3. Checking the joystick bellows

- 1.6.6.4. Adjust joysticks

- 1.6.6.5. Checking the wheels

- 1.6.6.6. Check the tyre inflation pressure

- 1.6.6.7. Tightening the wheel nuts

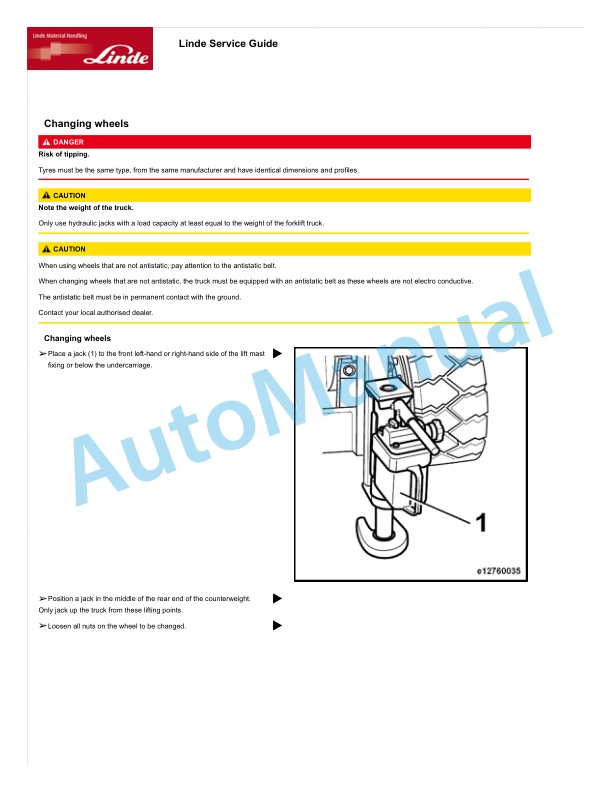

- 1.6.6.8. Changing wheels

- 1.6.6.9. Checking the condition of the antistatic belt

- 1.6.6.10. Clean and lubricate the steering axle

- 1.6.7. Chassis and bodywork

- 1.6.7.1. Checking the connecting bolts of the drive axle and lift mast

- 1.6.7.2. Check the overhead guard

- 1.6.7.3. Checking the battery cover locking devices

- 1.6.8. Drivers cab

- 1.6.8.1. Checking the pedal group for ease of movement and lubricating as required

- 1.6.8.2. Checking other bearings and connections and lubricating

- 1.6.8.3. Checking that the brake system is functioning properly

- 1.6.9. Electrics.electronics

- 1.6.9.1. Checking the condition of the batteries

- 1.6.9.2. Replacing the battery using a suspension arrangement

- 1.6.9.3. Inspecting and maintaining the lithiumion battery

- 1.6.10. Hydraulic system

- 1.6.10.1. Checking the hydraulic system for leaks

- 1.6.10.2. Checking the hydraulic oil level

- 1.6.10.3. Checking the breather filter is working normally

- 1.6.10.4. Checking installation of the tilt cylinder

- 1.6.10.5. Lubricating tilt cylinder bearings

- 1.6.11. Lifting system

- 1.6.11.1. Checking the fork arms and the fork arm quick release apparatus

- 1.6.11.2. Checking the working condition and installation of the lift mast, lifting chains and lift cylinder

- 1.6.11.3. Adjusting the length of the lifting chains and lubricating using chain spray

- 1.6.11.4. Lubricating the lift mast and chains with chain spray

- 1.6.12. Special equipment

- 1.6.12.1. Checking the preload of the double hoses (if equipped with attachments)

- 1.6.12.2. Cleaning and lubricating the sideshift forks and checking connections

- 1.7. Technical datasheet

- 1.7.1. Technical datasheet (V5)

- 1.7.2. Technical datasheet (V3)

- 1.7.3. Ecodesign requirements for electric motors and variable speed drives

Rate this product

You may also like

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

$20.00