Linde 133-01 – D12, D12HP, D14 Operating Instructions SN 03.07 and up SN up to W4X133V02096

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 03.07 and up SN up to W4X133V02096

- Format: PDF

- Size: 89.4MB

- Number of Pages: 1253

- Serial Number:

SN 03.07 and up SN up to W4X133V02096

Category: Linde Operator Manual PDF

-

Model List:

- D12

- D12HP

- D14

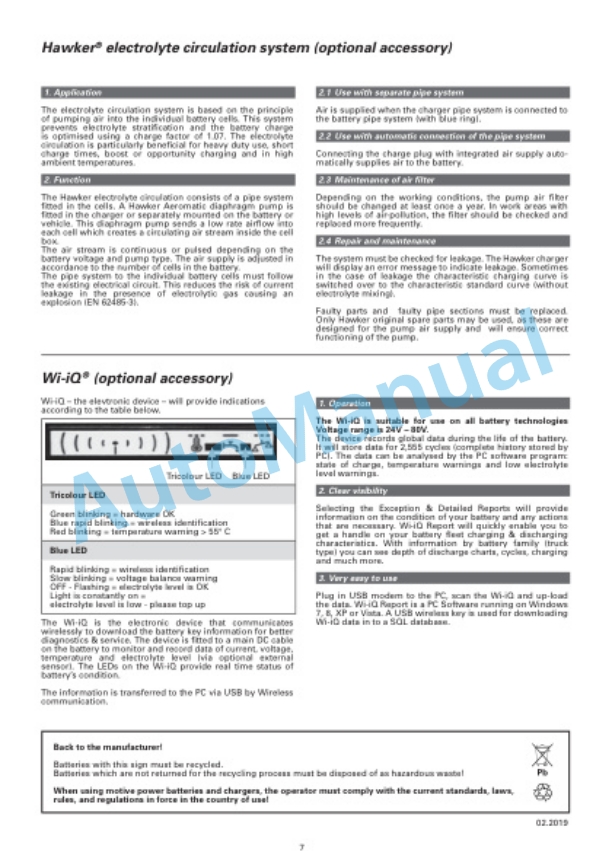

- 1. EnerSys.Hawker Batteries

- 2. KF Charger

- 3. LMatic SDK3

- 4. Leadacid battery charger 24V

- 5. Leadacid battery charger 24V . 48V

- 6. Leadacid battery charger 24V . 48V . 80V

- 7. LiIonCharger 18 kW

- 8. LiIonCharger 24V . 120A

- 9. Lithiumion batteriesD12 . 14, L12 . 14, N24HP, N20HP . L . Li, P30 . 50C, T20 . 25 AP . SP, T30

- 9.1. Table of content

- 9.2. Introduction

- 9.2.1. Introduction

- 9.2.2. Information on the conformity of lithiumion batteries

- 9.3. Safety

- 9.3.1. Special lithiumion safety rules

- 9.3.2. What to do in the event of incorrect use

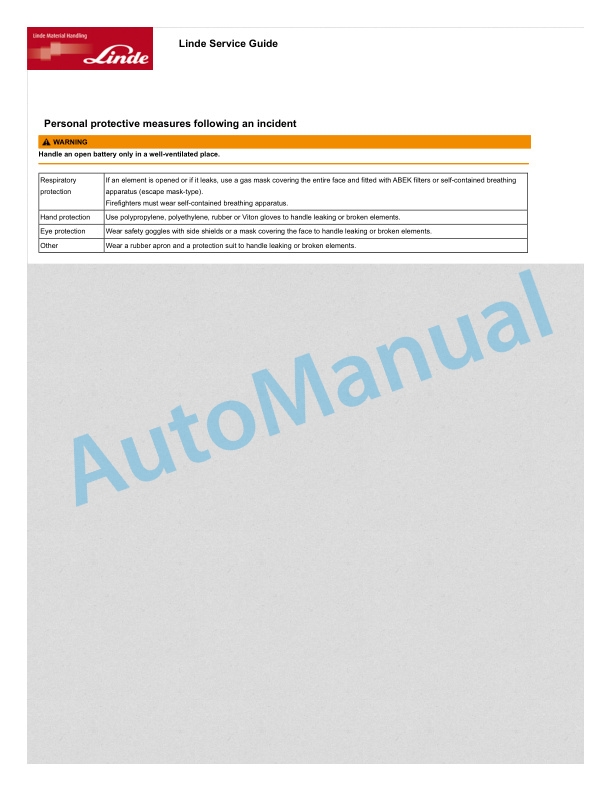

- 9.3.3. Personal protective measures following an incident

- 9.3.4. What to do in the event of an accidental spillage

- 9.3.5. Transporting a lithiumion battery

- 9.3.6. Scrapping lithiumion batteries

- 9.4. General views

- 9.4.1. Lithiumion battery types

- 9.4.2. Labels on the top of lithiumion batteries

- 9.4.3. Labels on the sides of lithiumion batteries

- 9.5.1. Checking the charge status

- 9.5.2. Connecting.disconnecting the battery connector

- 9.5.3. Commissioning a truck equipped with a side access lithiumion battery

- 9.5.4. Automatic battery shutoff

- 9.5.5. Battery fitted with a compartment

- 9.5.6. Display on a truck equipped with a lithiumion battery

- 9.5.7. Display functions

- 9.5.8. Installing the external charger

- 9.5.9. Charging lithiumion batteries using an external charger

- 9.5.10. Using the side socket to charge the battery

- 9.5.11. Battery charging times

- 9.5.12. Side access lithiumion battery Changing the battery

- 9.5.13. Battery error codes

- 9.5.14. Lithiumion batteries Longterm storage

- 9.6. Maintenance

- 9.6.1. Maintenance plan for lithiumion batteries

- 9.6.2. Chassis, bodywork and fittings

- 9.6.3. Electrical equipment

- 9.7. Technical specifications

- 9.7.1. Lithiumion battery weight precision

- 10. MIDAC Batteries

- 11. Pallet stacker.double pallet stackerL12, L14, D12, D14, D12 HP

- 11.1. Table of content

- 11.2. Introduction

- 11.2.1. Your truck

- 11.2.2. Conformity marking

- 11.2.3. Declaration that reflects the content of the declaration of conformity

- 11.2.4. Identification label

- 11.2.5. Correct use

- 11.2.6. Description of use and climatic conditions

- 11.2.7. Impermissible use

- 11.2.8. Symbols used

- 11.2.9. Taking delivery of the industrial truck

- 11.2.10. Rules for the operating company of industrial trucks

- 11.2.11. Disposing of gel and lead batteries

- 11.3. Safety

- 11.3.1. Safety regulations

- 11.3.2. Handling consumables

- 11.3.3. Emissions

- 11.3.4. Residual risks

- 11.3.5. Stability

- 11.3.6. Competent person

- 11.3.7. Periodic general checks on the trucks

- 11.4. General views

- 11.4.1. General view for ACC . AP versions

- 11.4.2. General view of SP version

- 11.4.3. Technical compartment four support points

- 11.4.4. Technical compartment five support points (HP version)

- 11.4.5. Controls for ACC and AP versions

- 11.4.6. SP controls

- 11.4.7. Display function

- 11.4.8. ACC.AP labels

- 11.4.9. SP labels

- 11.5.1. Technical description

- 11.5.2. Checks before first commissioning

- 11.5.3. Preshift checks

- 11.5.4. Daily checks before starting work

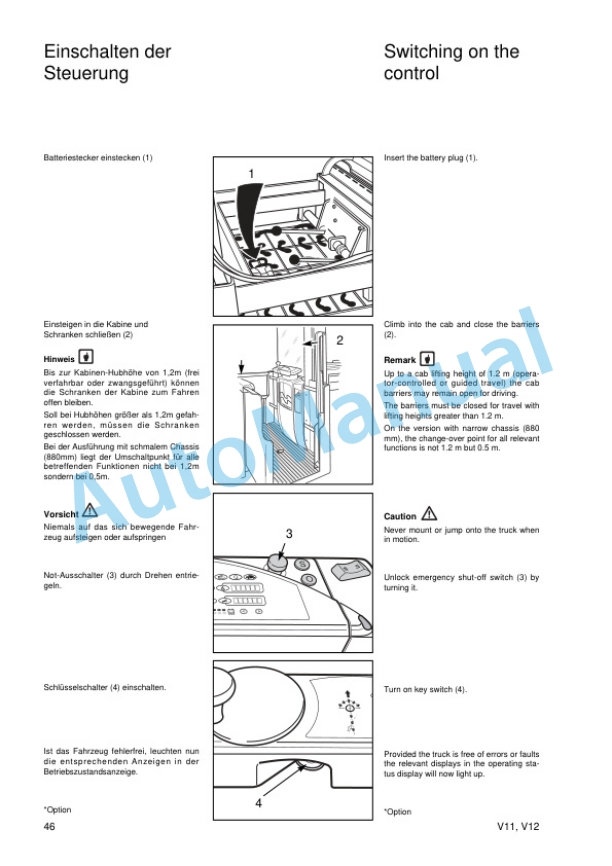

- 11.5.5. Truck operating instructions

- 11.5.6. Display

- 11.5.7. Driving regulations

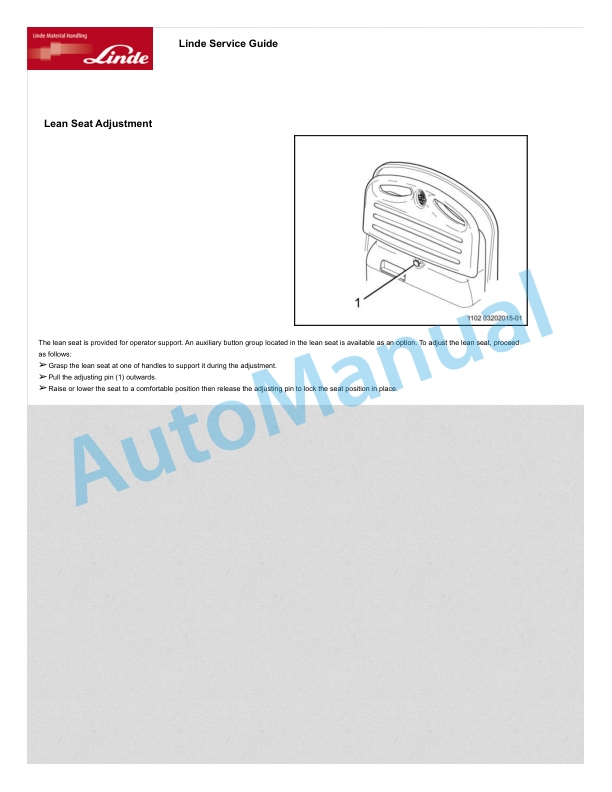

- 11.5.8. Driving L12L14, D12D14 and D12 HP (ACC) trucks

- 11.5.9. Driving L12L14, D12D14 and D12 HP (AP) trucks

- 11.5.10. Driving L12L14, D12D14 and D12 HP (SP) trucks

- 11.5.11. Horn

- 11.5.12. Braking

- 11.5.13. Using the truck on a slope

- 11.5.14. connect access system (LFM)

- 11.5.15. Transporting loads

- 11.5.16. Cold store usage (optional)

- 11.5.17. Suspended platform (option)

- 11.5.18. Symmetrical handlebar (option)

- 11.5.19. Batteries

- 11.5.20. Handling the truck in an emergency

- 11.5.21. Handling the truck in specific situations

- 11.6. Maintenance

- 11.6.1. General information

- 11.6.2. Technical data for inspection and maintenance

- 11.6.3. Recommended lubricants

- 11.6.4. Accessing the technical compartment

- 11.6.5. Regular maintenance

- 11.6.6. Maintenance schedule

- 11.6.7. Chassis, bodywork and fittings

- 11.6.8. Motor

- 11.6.9. Steering and wheels

- 11.6.10. Electrical equipment

- 11.6.11. Hydraulic systems

- 11.6.12. Lift mast

- 11.6.13. Storage and disposal

- 11.7. Datasheet

- 11.7.1. L12 AP . L14 AP datasheet

- 11.7.2. L12 SP . L14 SP datasheet

- 11.7.3. Mast type L12 AP L14 AP . L12 SP L14 SP

- 11.7.4. D12 ACC . D14 ACC D12 AP . D14 AP datasheet

- 11.7.5. D12 SP . D14 SP datasheet

- 11.7.6. Mast type D12 ACC D12 ACC . D12 AP D14 AP . D12 SP D14 SP

- 11.7.7. D12 HP . D12 HP AP . D12 HP SP datasheet

- 11.7.8. Mast type D12 HP AP . D12 HP SP

- 11.7.9. Ecodesign requirements for electric motors and variable speed drives

- 12. TAB Batteries

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00