Linde 1411-01 – HT100, HT120, HT140, HT150, HT160 Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 122.9MB

- Number of Pages: 778

-

Model List:

- HT100

- HT120

- HT140

- HT150

- HT160

- 1. series Forklift TruckModels HT100Ds HT180Ds

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Scope

- 1.2.2. Obligations of the Equipment Owner

- 1.2.3. Operator Responsibilities

- 1.2.4. Proper use

- 1.2.5. Hazard messages

- 1.3. Safety

- 1.3.1. Before Operation

- 1.3.2. Operator Daily Checklist

- 1.3.3. Operating position

- 1.3.4. Pedestrians

- 1.3.5. Travel

- 1.3.6. Lifting and Lowering

- 1.3.7. Inclines, Ramps, Docks, Elevators

- 1.3.8. Avoiding Falls and Tipovers

- 1.3.9. Suspended Loads

- 1.3.10. Parking

- 1.3.11. Safety During Maintenance

- 1.3.12. Operator Warning Decals

- 1.4. Overview

- 1.4.1. Technical Description

- 1.4.2. General view of Truck

- 1.4.3. Controls

- 1.4.4. Switch panel

- 1.4.5. Display Unit

- 1.4.6. Decal and Data Plate Location Interior

- 1.4.7. Decal and Data Plate Location Exterior

- 1.4.8. Data Plate

- 1.4.9. Definition of directions

- 1.5. Operation

- 1.5.1. Unloading and Preparing a New Truck for Operation

- 1.5.2. Initial Maintenance Interval

- 1.5.3. Filling Fuel and Diesel Exhaust Fluid

- 1.5.4. Standard equipment

- 1.5.5. Optional equipment

- 1.5.6. Loading.transportation

- 1.6. Maintenance

- 1.6.1. Personnel Qualifications

- 1.6.2. Cleaning

- 1.6.3. Operator Inspection and Maintenance

- 1.6.4. Routine Lubrication and Inspection

- 1.6.5. Scheduled Maintenance

- 1.6.6. Fluids and Lubricants

- 1.6.7. Troubleshooting

- 1.6.8. Taking the truck out of service

- 1.7. Technical data

- 1.7.1. Truck dimensions

- 1.7.2. Specifications (24inch load center models)

- 1.7.3. Specifications (48inch load center models)

- 1.7.4. Mast Heights

- 1.7.5. Frequency characteristic for human body vibrations

- 1.7.6. Noise emission data

- 2. Forklift Truck Perkins Tier 3HT100Ds HT180DsPerkins_E70TA

- 2.1. Table of content

- 2.2. Introduction

- 2.2.1. Your Linde truck

- 2.2.2. Intended use

- 2.2.3. Improper use

- 2.2.4. Additional information

- 2.2.5. Description of use and climatic conditions

- 2.2.6. Symbols used

- 2.2.7. Technical Description

- 2.2.8. Engine registration

- 2.2.9. Legal requirements for marketing

- 2.3. Safety

- 2.3.1. Safety guidelines

- 2.3.2. Residual risks

- 2.3.3. Stability

- 2.3.4. In the case of tipover

- 2.3.5. Handling consumables

- 2.3.6. Periodic safety inspection

- 2.3.7. Competent person

- 2.3.8. Do not operate with guards removed

- 2.3.9. Malfunctions

- 2.3.10. EMC Electromagnetic compatibility

- 2.4. Overview

- 2.4.1. General view of Truck

- 2.4.2. Name Plates

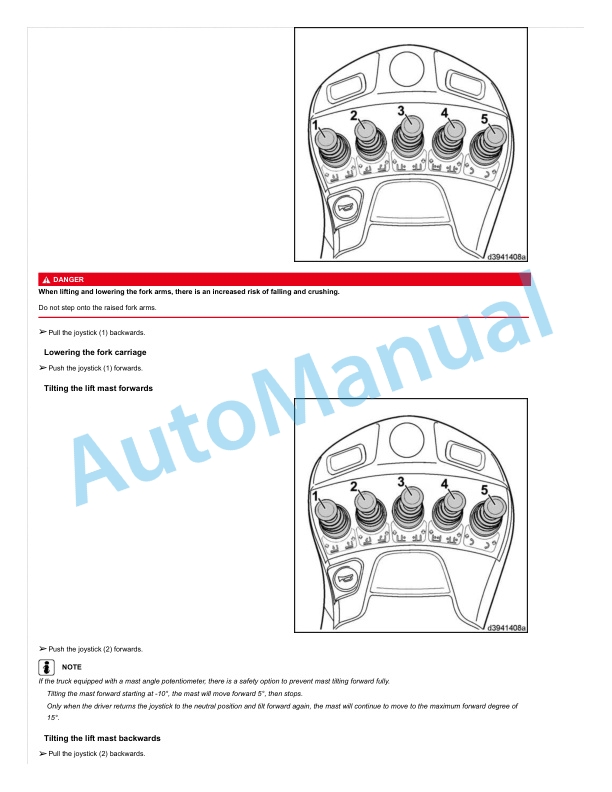

- 2.4.3. Controls

- 2.4.4. Switch panel

- 2.5. Operation

- 2.5.1. Wheel removal drive axle

- 2.5.2. Wheel refitting drive axle

- 2.5.3. Examples of restraining devices

- 2.5.4. Service plan before initial commissioning

- 2.5.5. Preshift checks

- 2.5.6. Regular maintenance

- 2.5.7. Standard equipment

- 2.5.8. Optional equipment

- 2.5.9. Working with a load

- 2.5.10. Loading.transportation

- 2.6. Maintenance

- 2.6.1. General remarks

- 2.6.2. Service plan

- 2.6.3. Engine

- 2.6.4. Transmission

- 2.6.5. Chassis bodywork and fittings

- 2.6.6. Chassis frame

- 2.6.7. Controls

- 2.6.8. Electrics

- 2.6.9. Hydraulics

- 2.6.10. Load lift system

- 2.6.11. Troubleshooting

- 2.6.12. Taking the truck out of service

- 2.7. Technical data

- 2.7.1. Truck dimensions

- 2.7.2. Overview of type sheets 600 mm load centre

- 2.7.3. Overview of type sheets 1200 mm load centre

- 3. Forklift truck Tier 4HT100Ds HT180Ds

- 3.1. Table of content

- 3.2. Introduction

- 3.2.1. Your Linde truck

- 3.2.2. Intended use

- 3.2.3. Improper use

- 3.2.4. Additional information

- 3.2.5. Description of use and climatic conditions

- 3.2.6. Symbols used

- 3.2.7. Technical Description

- 3.2.8. Engine registration

- 3.2.9. Legal requirements for marketing

- 3.3. Safety

- 3.3.1. Safety guidelines

- 3.3.2. Residual risks

- 3.3.3. Stability

- 3.3.4. In the case of tipover

- 3.3.5. Handling consumables

- 3.3.6. Periodic safety inspection

- 3.3.7. Competent person

- 3.3.8. Do not operate with guards removed

- 3.3.9. Malfunctions

- 3.3.10. EMC Electromagnetic compatibility

- 3.4. Overview

- 3.4.1. General view of Truck

- 3.4.2. Name Plates

- 3.4.3. Controls

- 3.4.4. Switch panel

- 3.4.5. Display unit

- 3.5. Operation

- 3.5.1. Service plan before initial commissioning

- 3.5.2. Preshift checks

- 3.5.3. Regular maintenance

- 3.5.4. Standard equipment

- 3.5.5. Optional equipment

- 3.5.6. Coil boom

- 3.5.7. Cold Climate Options

- 3.5.8. Lift height programmable function

- 3.5.9. Central lubrication system steer.mast.tilt

- 3.5.10. Working with a load

- 3.5.11. Loading.transporting

- 3.6. Maintenance

- 3.6.1. General maintenance

- 3.6.2. Maintenance schedule

- 3.6.3. Engine

- 3.6.4. Transmission

- 3.6.5. Chassis, bodywork and fittings

- 3.6.6. Chassis

- 3.6.7. Controls

- 3.6.8. Electrical system

- 3.6.9. Hydraulics

- 3.6.10. Load lifting system

- 3.6.11. Remedy

- 3.6.12. Decommissioning the truck

- 3.7. Technical data

- 3.7.1. Truck dimensions

- 3.7.2. Overview of type sheets 600 mm load centre

- 3.7.3. Overview of type sheets 1200 mm load centre

- 3.7.4. Frequency characteristic for human body vibrations

- 3.7.5. Noise emission data

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

Linde Operator Manual PDF

Linde 1123-01 – R14SP, R16SP, R18SP Operating Instructions SN 12.09 and up

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions