Linde 1468-01 – C4026CH – C4535CH, C4230TL – C4540TL Operating Instructions SN 09.11 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 09.11 and up

- Format: PDF

- Size: 34.2MB

- Number of Pages: 289

- Serial Number:

SN 09.11 and up

Category: Linde Operator Manual PDF

-

Model List:

- C4026CH – C4535CH

- C4230TL – C4540TL

- 1. ReachstackerC4230TL C4540TL, C4020CH C4535CH

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your Linde truck

- 1.2.2. Technical Description

- 1.2.3. Intended use

- 1.2.4. Improper use

- 1.2.5. Symbols used

- 1.2.6. Commissioning

- 1.2.7. Engine registration

- 1.2.8. Illustrations within this manual

- 1.2.9. EC declaration of conformity

- 1.3. Safety

- 1.3.1. Safety rules

- 1.3.1.1. Safety rules

- 1.3.1.2. Handling Fuel, Lubricants and Coolant

- 1.3.1.3. Residual risks

- 1.3.1.4. Stability

- 1.3.2. Frequency characteristic for human body vibrations

- 1.3.2.1. Frequency characteristic for human body vibrations

- 1.3.3. Noise emission data

- 1.3.3.1. Noise emission data

- 1.4. Overview

- 1.4.1. General view of the truck

- 1.4.2. General view of the handler

- 1.4.3. Controls and Indicators

- 1.4.4. Gauges, switches and warning lights

- 1.5. Operation

- 1.5.1. Wheel removal drive axle

- 1.5.2. Wheel removal steer axle

- 1.5.3. Wheel assembly inspection

- 1.5.4. Wheel refitting drive axle

- 1.5.5. Wheel refitting steer axle

- 1.5.6. Examples of restraining devices

- 1.5.7. Mirrors

- 1.5.8. Cab door opening and closing

- 1.5.9. Opening the engine and transmission cover

- 1.5.10. Opening the working hydraulic system oil tank cover

- 1.5.11. Opening the brake hydraulic system oil tank cover

- 1.5.12. Opening the battery and air filter compartment door

- 1.5.13. Opening the fuse box cover

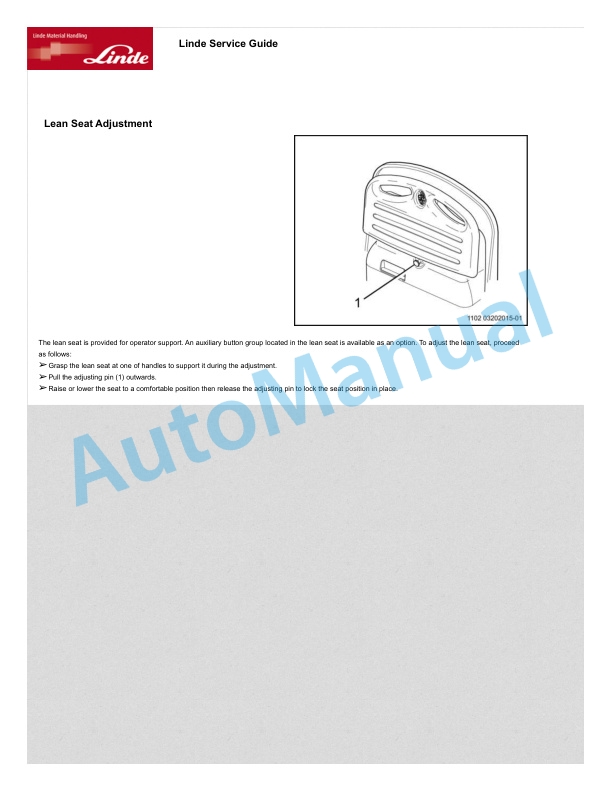

- 1.5.14. Adjusting the drivers seat

- 1.5.15. Isolating the battery

- 1.5.16. Check battery condition

- 1.5.17. Check working hydraulic system oil level

- 1.5.18. Check brake hydraulic system oil level

- 1.5.19. Check engine oil level

- 1.5.20. Automatic greasing tank level check

- 1.5.21. Checking the fuel level

- 1.5.22. Filling fuel

- 1.5.23. Filling reductant

- 1.5.24. Gearbox oil level check

- 1.5.25. Check coolant level in header tank

- 1.5.26. Check windscreen washer reservoir fluid level

- 1.5.27. Checking the twistlocks and warning lights for proper operation

- 1.5.28. Normal start

- 1.5.29. Jump start procedure

- 1.5.30. Truck status display

- 1.5.31. Malfunctions during operation

- 1.5.32. Overload safety switch

- 1.5.33. Startup indications

- 1.5.34. Air conditioning operation

- 1.5.35. Driving

- 1.5.36. Gear shift control

- 1.5.37. Steering

- 1.5.38. Stopping the truck

- 1.5.39. Operating transmission dump

- 1.5.40. Service brake

- 1.5.41. Parking brake

- 1.5.42. Truck lighting and turn indicators

- 1.5.43. Operating the horn

- 1.5.44. Turning on the front windscreen wiper

- 1.5.45. Opening the fuse box cover

- 1.5.46. Fuses

- 1.5.47. Boom and handler controls

- 1.5.48. Before lifting a load

- 1.5.49. Picking up a container

- 1.5.50. Travelling with loads

- 1.5.51. Depositing the load

- 1.5.52. Parking the truck

- 1.5.53. Trailer coupling

- 1.5.54. Towing

- 1.5.55. Hoisting the truck

- 1.5.56. Transporting the truck

- 1.5.57. Instructions on the safe use of lifting eyes on the spreader

- 1.5.58. Taking the truck out of operation

- 1.5.59. Taking the truck out of service SCR

- 1.6. Maintenance

- 1.6.1. General remarks

- 1.6.1.1. Wheel removal drive axle

- 1.6.1.2. Wheel removal steer axle

- 1.6.1.3. Wheel assembly inspection

- 1.6.1.4. Wheel refitting drive axle

- 1.6.1.5. Wheel refitting steer axle

- 1.6.1.6. Examples of restraining devices

- 1.6.1.7. General information

- 1.6.1.8. Work on the boom and the front part of the truck

- 1.6.1.9. Inspection and maintenance data

- 1.6.1.10. Fuel and oil recommendations

- 1.6.1.11. Check the condition of structured components

- 1.6.1.12. Truck welds inspection

- 1.6.2. Inspection and maintenance schedule

- 1.6.2.1. Inspection and maintenance schedule

- 1.6.2.2. Service plan

- 1.6.2.3. h Service plan

- 1.6.2.4. h Service plan

- 1.6.2.5. h Service plan

- 1.6.2.6. h Service plan

- 1.6.2.7. h Service plan

- 1.6.2.8. h Service plan

- 1.6.3. Engine

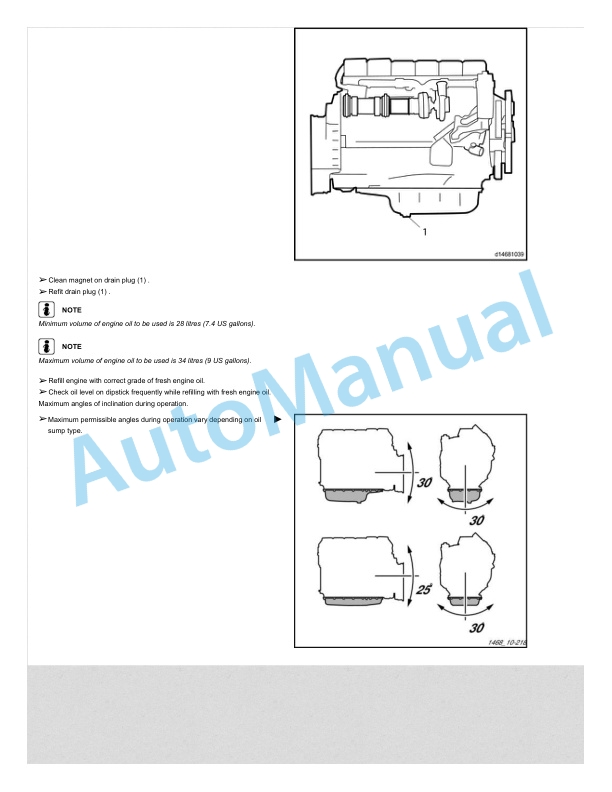

- 1.6.3.1. Check engine oil level

- 1.6.3.2. Engine oil replace

- 1.6.3.3. Engine oil filter change

- 1.6.3.4. Centrifugal oil cleaner cleaning

- 1.6.3.5. Drain the fuel filter

- 1.6.3.6. Fuel filter replace

- 1.6.3.7. Fuel system bleed

- 1.6.3.8. Replace reductant filter

- 1.6.3.9. Check the air filter

- 1.6.3.10. Air filter assembly check

- 1.6.3.11. Change the air filter safety element

- 1.6.3.12. Check the engine mountings

- 1.6.3.13. Clean the radiator and check for leaks

- 1.6.3.14. Check the injection nozzles

- 1.6.3.15. Valve clearances checking and adjusting

- 1.6.3.16. Check the intake and exhaust systems for leaks and tightness

- 1.6.3.17. Check the cooling system for leaks and tightness

- 1.6.3.18. Cooling system clean

- 1.6.3.19. Coolant change

- 1.6.3.20. Check the vibration damper

- 1.6.3.21. Drive belt Inspect

- 1.6.3.22. Fan hub, belt driven

- 1.6.3.23. Check the turbocharger

- 1.6.4. Gearbox

- 1.6.4.1. Gearbox oil change and oil filling capacity

- 1.6.4.2. Gearbox oil filter remove install

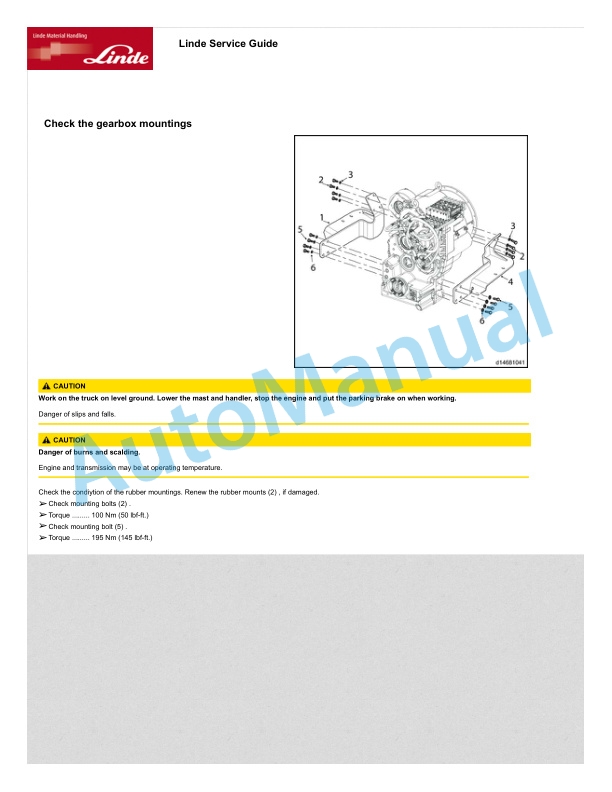

- 1.6.4.3. Check the gearbox mountings

- 1.6.5. Chassis, bodywork and fittings

- 1.6.5.1. Clean the truck

- 1.6.5.2. Check seat belt for condition and correct operation

- 1.6.5.3. Tighten wheel nuts

- 1.6.5.4. Check the tyres for damage and foreign objects

- 1.6.5.5. Check the cab mountings

- 1.6.5.6. Truck welds inspection

- 1.6.6. Chassis frame

- 1.6.6.1. Check steer axle hub oil level

- 1.6.6.2. Clean and lubricate steer axle, check the mounting

- 1.6.6.3. Check and lubricate the drive shaft

- 1.6.6.4. Check the drive axle mounting

- 1.6.6.5. Check the drive axle centre differential oil level

- 1.6.6.6. Check the drive axle hub differential oil level

- 1.6.6.7. Change the drive axle hub differential oil

- 1.6.6.8. Check and adjust hub bearings

- 1.6.7. Controls

- 1.6.7.1. Check the steering lock

- 1.6.7.2. Check the parking brake condition and mounting

- 1.6.7.3. Check the brake disc wear

- 1.6.7.4. Air conditioning diagnostics

- 1.6.8. Electrics

- 1.6.8.1. Check battery condition

- 1.6.8.2. Check electric cables, connectors and connections for conditionand tightness

- 1.6.9. Hydraulics

- 1.6.9.1. Check the hydraulic system, pumps, valves and lines

- 1.6.9.2. Change the pilot circuit filter

- 1.6.9.3. Change the working hydraulic system oil return filter

- 1.6.9.4. Change the brake hydraulic system oil pressure and suction filters

- 1.6.9.5. Change the brake hydraulic system oil pressure filter

- 1.6.9.6. Change the brake hydraulic system oil

- 1.6.9.7. Change the hydraulic oil working system

- 1.6.10. Load lift system

- 1.6.10.1. Check and lubricate boom cylinder, boom pivot and sliding bearings

- 1.6.10.2. Boom pivot bearings check

- 1.6.10.3. Lubricate slewing ring bearing and gear

- 1.6.10.4. Slew gearbox and brake oil level check

- 1.6.10.5. Check and lubricate the twistlocks

- 1.6.10.6. Spreader wear pads check

- 1.6.10.7. Check and lubricate feet at the bottom of each leg

- 1.6.10.8. Change the twistlocks

- 1.6.11. Special equipment, accessories

- 1.6.11.1. Check the central lubrication lubricating points

- 1.6.11.2. Fill central lubrication canister with grease

- 1.6.12. Troubleshooting

- 1.6.12.1. Troubleshooting guide Diesel engine

- 1.6.12.2. Troubleshooting guide hydraulic system

- 1.6.13. User manual feedback

- 1.6.13.1. User manual improvement record.

- 1.7. Technical Data

- 1.7.1. Datasheet

- 1.7.1.1. Technical Data

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

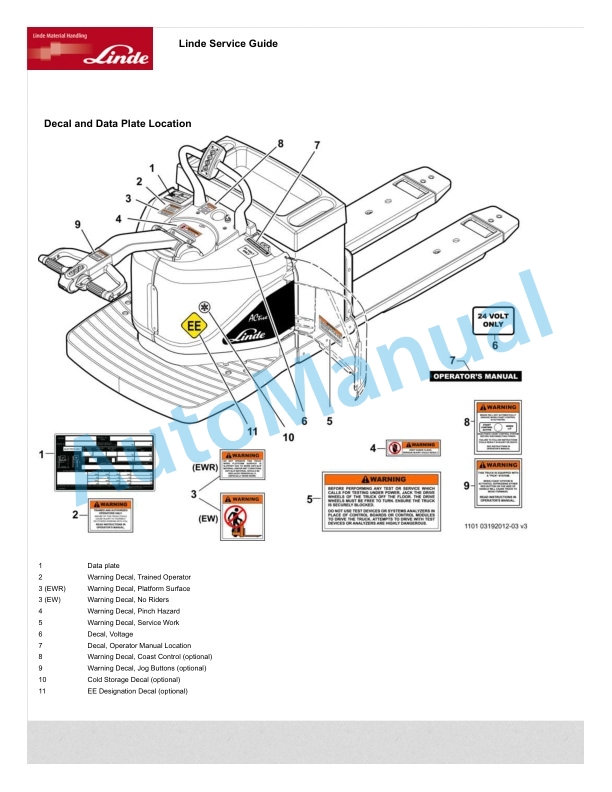

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

$20.00

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

$20.00