Linde 351-05 – H25D, H25T, H30D Production site Xiamen Workshop Manuals SN 07.08 and up

$40.00

- Type Of Manual: Workshop Manuals

- Manual ID: SN 07.08 and up

- Format: PDF

- Size: 55.1MB

- Number of Pages: 968

- Serial Number:

SN 07.08 and up

Category: Linde Workshop Manual PDF

-

Model List:

- H25D

- H25T

- H30D

- 1. Regular testing

- 1.1. Table of content

- 1.2. Regular testing

- 1.3. Electric motor

- 1.4. Internal combustion engine

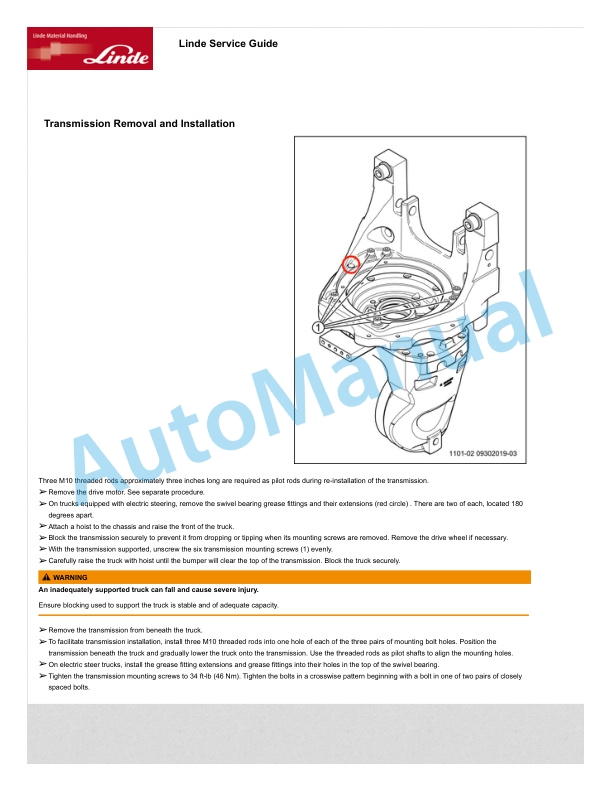

- 1.5. Drive axle

- 1.6. Chassis

- 1.7. Drivers compartment

- 1.8. Steering systems

- 1.9. Wheels and tyres

- 1.10. Brake system

- 1.11. Operating devices

- 1.12. Electrics.electronics

- 1.13. Hydraulics

- 1.14. Lift mast

- 1.15. Load support

- 1.16. Attachments

- 1.17. Special equipment.accessories

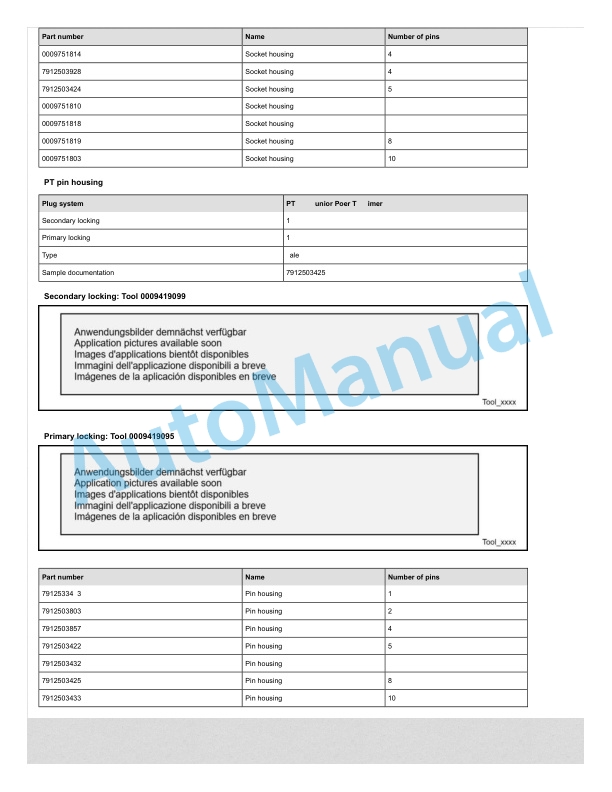

- 2. Service case Release tools for contacts

- 2.1. Table of content

- 2.2. Safety information

- 2.3. Information

- 2.4. Overview

- 2.5. Plug systems

- 3. Steering axle crimping tool

- 3.1. Table of content

- 3.2. Crimping tool

- 3.3. Replacement kits

- 3.4. Steering axle 301.302.303

- 3.5. Steering axle 1601

- 3.6. Steering axle 1602.1603

- 4. Deutz engine

- 4.1. Frontpage

- 4.2. Table of contents

- 4.3. Checking the compression pressure

- 4.4. Mounting engine on assembly block and demounting

- 4.5. Setting valve clearance

- 4.6. Removing and installing the rocker arm and rocker arm bracket

- 4.7. Disassembling, assembling and checking the rocker arm and rocker arm bracket

- 4.8. Removing and installing cylinder head

- 4.9. Checking piston overhang

- 4.10. Removing and installing the crankcase bleeding

- 4.11. Removing and installing the exhaust line

- 4.12. Removing and install the charge air line

- 4.13. Removing and installing the turbocharger

- 4.14. Removing and installing the intake manifold

- 4.15. Removing and installing the exhaust gas return valve

- 4.16. Removing and installing the exhaust gas return pipe

- 4.17. Removing and installing the exhaust gas collection pipe (Exhaust gas recirculation)

- 4.18. Removing and installing the lifting magnet (Start amount release)

- 4.19. Renewing the injection lines

- 4.20. Removing and installing the fuel injectors

- 4.21. Removing and installing the lifting magnet (charge air pressuredependent full load stop)

- 4.22. Installing and removing charge air pressuredependent full load stop

- 4.23. Removing and installing fuel pipes

- 4.24. Removing and installing the fuel filter console

- 4.25. Removing and installing the fuel supply pump

- 4.26. Removing and installing the lubricating oil cooler

- 4.27. Removing and installing the oil filter console

- 4.28. Removing and installing the oil pressure switch

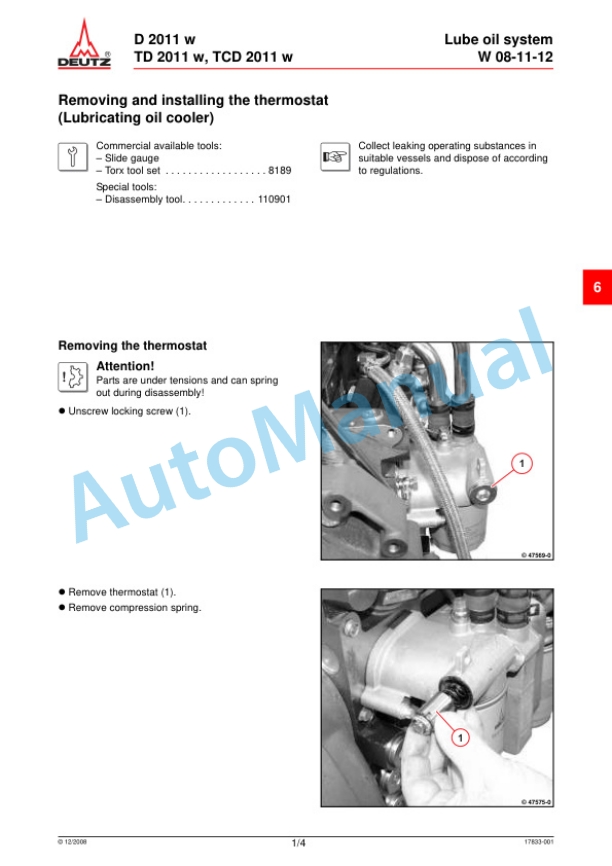

- 4.29. Removing and installing the thermostat (Lubricating oil cooler)

- 4.30. Removing and installing the control line

- 4.31. Removing and installing the coolant pump

- 4.32. Checking the thermostat (in the removed state)

- 4.33. Removing and installing the thermostat

- 4.34. Removing and installing the thermostat housing

- 4.35. Removing and installing temperature transmitter

- 4.36. Removing and installing the lifting magnet (Engine shutdown)

- 4.37. Removing and installing the Vbelt pulley

- 4.38. Renew Vbelts, check Vbelt tension

- 4.39. Removing and installing the flywheel

- 4.40. Removing and installing the hydraulic pump

- 4.41. Removing and installing the generator

- 4.42. Removing and installing the starter

- 4.43. Removing and installing the heating plugs

- 4.44. Removing and installing the glow plug

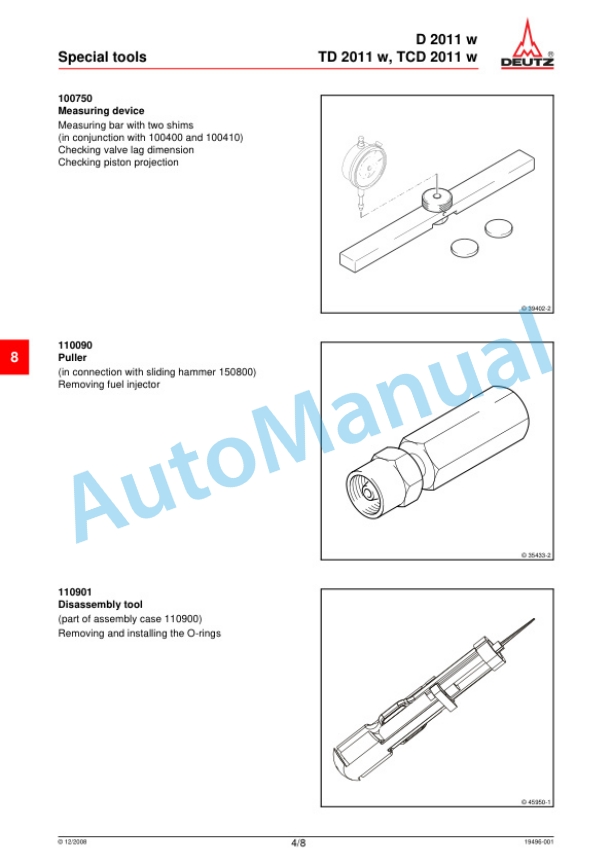

- 4.45. Standard tools

- 4.46. Special tools

- 5. IC Engined Truck H25.30 D05

- 5.1. Frontpage

- 5.2. Table of contents

- 5.3. Checking the compression pressure

- 5.4. Mounting engine on assembly block and demounting

- 5.5. Setting valve clearance

- 5.6. Removing and installing the rocker arm and rocker arm bracket

- 5.7. Disassembling, assembling and checking the rocker arm and rocker arm bracket

- 5.8. Removing and installing cylinder head

- 5.9. Checking piston overhang

- 5.10. Removing and installing the crankcase bleeding

- 5.11. Removing and installing the exhaust line

- 5.12. Removing and install the charge air line

- 5.13. Removing and installing the turbocharger

- 5.14. Removing and installing the intake manifold

- 5.15. Removing and installing the exhaust gas return valve

- 5.16. Removing and installing the exhaust gas return pipe

- 5.17. Removing and installing the exhaust gas collection pipe (Exhaust gas recirculation)

- 5.18. Removing and installing the lifting magnet (Start amount release)

- 5.19. Renewing the injection lines

- 5.20. Removing and installing the fuel injectors

- 5.21. Removing and installing the lifting magnet (charge air pressuredependent full load stop)

- 5.22. Installing and removing charge air pressuredependent full load stop

- 5.23. Removing and installing fuel pipes

- 5.24. Removing and installing the fuel filter console

- 5.25. Removing and installing the fuel supply pump

- 5.26. Removing and installing the lubricating oil cooler

- 5.27. Removing and installing the oil filter console

- 5.28. Removing and installing the oil pressure switch

- 5.29. Removing and installing the thermostat (Lubricating oil cooler)

- 5.30. Removing and installing the control line

- 5.31. Removing and installing the coolant pump

- 5.32. Checking the thermostat (in the removed state)

- 5.33. Removing and installing the thermostat

- 5.34. Removing and installing the thermostat housing

- 5.35. Removing and installing temperature transmitter

- 5.36. Removing and installing the lifting magnet (Engine shutdown)

- 5.37. Removing and installing the Vbelt pulley

- 5.38. Renew Vbelts, check Vbelt tension

- 5.39. Removing and installing the flywheel

- 5.40. Removing and installing the hydraulic pump

- 5.41. Removing and installing the generator

- 5.42. Removing and installing the starter

- 5.43. Removing and installing the heating plugs

- 5.44. Removing and installing the glow plug

- 5.45. Standard tools

- 5.46. Special tools

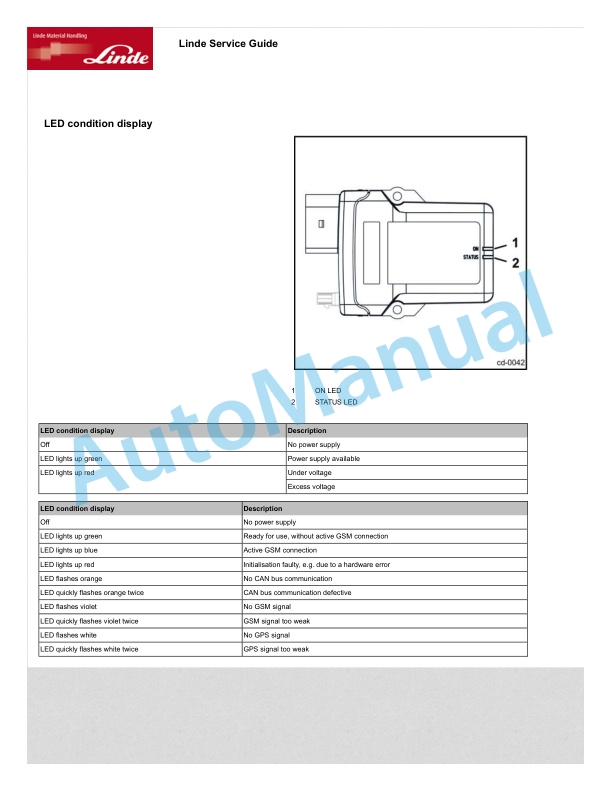

- 6. connectdesk

- 6.1. Table of content

- 6.2. Introduction

- 6.3. System overview

- 6.4. Hardware

- 6.5. Software

- 6.6. Status checking (PreOpCheck)

- 7. connectportal

- 7.1. Table of content

- 7.2. Introduction

- 7.3. Data transfer

- 7.4. Hardware

- 7.5. Software

- 8. connectdt operating hoursRetrofitting the connectdt operating hours

- 8.1. Table of content

- 8.2. connectdt operating hours

- 9. connectdt trouble codesRetrofitting connectdt trouble codes

- 9.1. Table of content

- 9.2. connectdt trouble codes

Rate this product

You may also like

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

$40.00

Linde Workshop Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Workshop Manuals

$40.00

Linde Workshop Manual PDF

Linde 1110-01 – V08-01, V08-02 Workshop Manuals SN 11.09 and up SN up to W41110V00528

$40.00