Linde 387-01 – E25 EX, E30 EX, E35 EX Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 29.4MB

- Number of Pages: 285

Category: Linde Operator Manual PDF

-

Model List:

- E25 EX

- E30 EX

- E35 EX

- 1. Electric forklift truckE25 . 30 . 35 Ex

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your industrial truck

- 1.2.2. Intended use

- 1.2.3. Impermissible use

- 1.2.4. Basic information on explosion protection

- 1.2.5. Description of use and climatic conditions

- 1.2.6. Symbols used

- 1.2.7. Technical description

- 1.2.8. Receiving the industrial truck

- 1.2.9. Legal requirements for marketing

- 1.2.10. Disposing of components and batteries

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the case of tipover

- 1.3.5. Handling consumables

- 1.3.6. Qualified person

- 1.3.7. Periodic safety inspection

- 1.3.8. Fitting attachments

- 1.3.9. Emergency exit with attached rear window

- 1.3.10. Emergency lowering

- 1.3.11. Towing

- 1.4. Overview

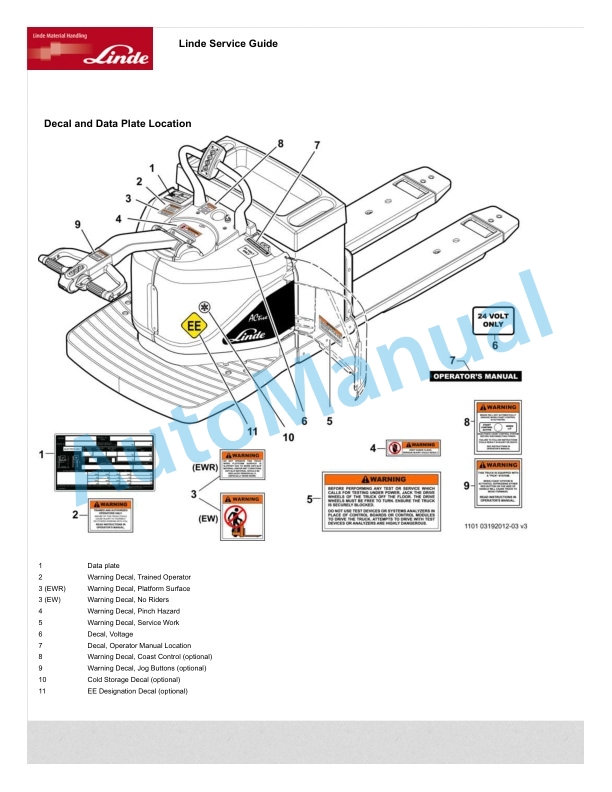

- 1.4.1. Labelling

- 1.4.1.1. Position of nameplate

- 1.4.1.2. Nameplate

- 1.4.1.3. Truck numbers and identification plates

- 1.4.1.4. Truck configuration

- 1.4.2. Truck overview

- 1.4.3. Truck view rear

- 1.4.4. Operating devices

- 1.4.5. Display unit

- 1.4.6. Switch panel

- 1.5. Operation

- 1.5.1. Service plan before initial commissioning

- 1.5.2. Instructions for runningin

- 1.5.3. Preshift checks

- 1.5.4. Checking the tyres

- 1.5.5. Regular maintenance

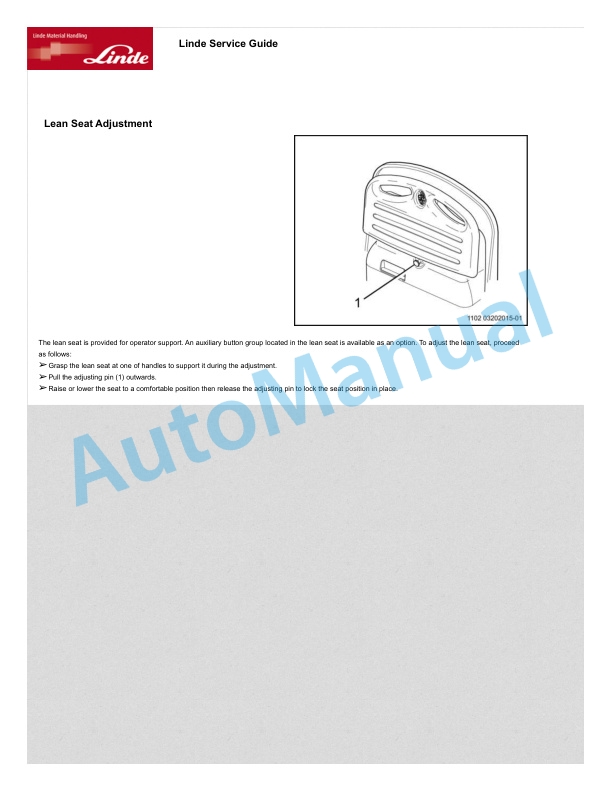

- 1.5.6. Drivers compartment

- 1.5.6.1. Entering and exiting the truck

- 1.5.6.2. Minimum distance between head and overhead guard

- 1.5.6.3. Adjusting the drivers seat

- 1.5.6.4. Adjusting the drivers seat armrest

- 1.5.6.5. Adjusting the steering column

- 1.5.6.6. Seat belt

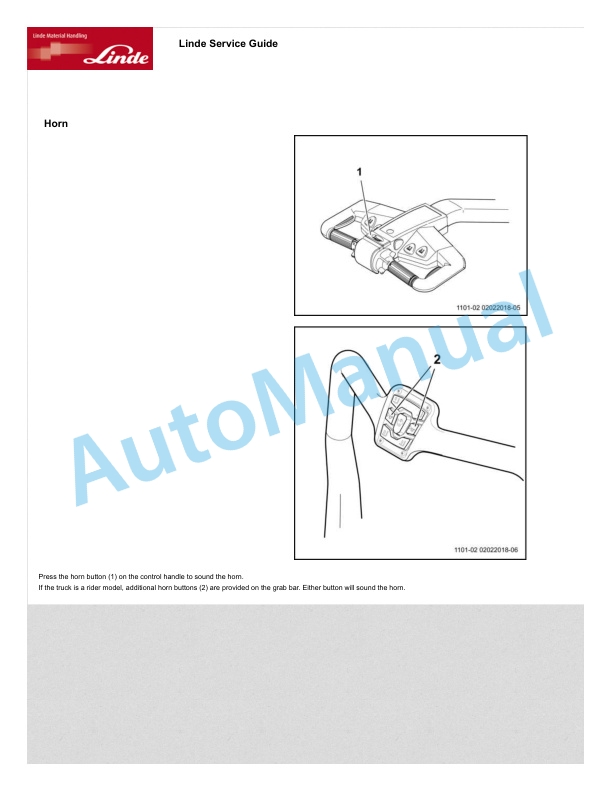

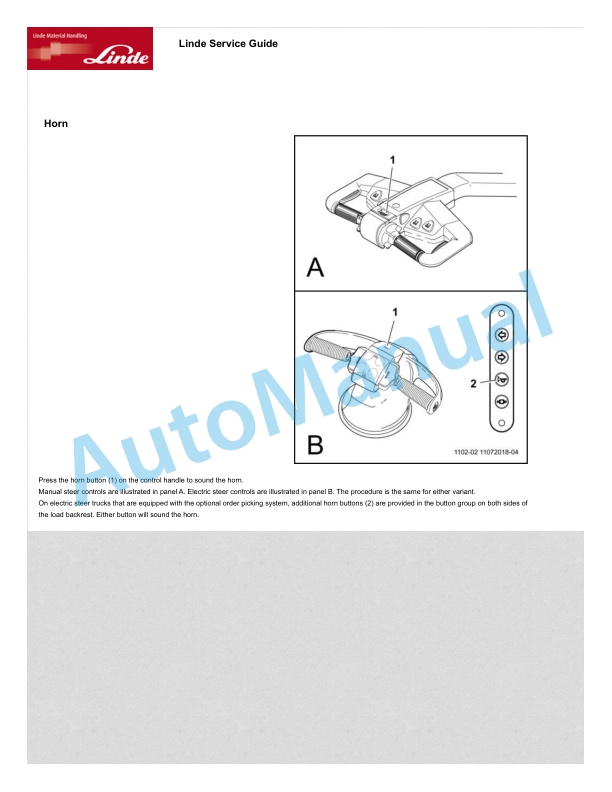

- 1.5.6.7. Horn

- 1.5.6.8. Lighting

- 1.5.6.9. Windscreen wipers

- 1.5.6.10. Heating system

- 1.5.6.11. Overhead guard with optimised visibility

- 1.5.7. Operation

- 1.5.7.1. Switching the truck on and off

- 1.5.7.2. Access system connect (LFM)

- 1.5.7.3. Emergency off switch

- 1.5.7.4. Driving (singlepedal operation)

- 1.5.7.5. Driving (dualpedal operation)

- 1.5.7.6. Briefly leaving the truck

- 1.5.7.7. Adjusting the time

- 1.5.7.8. Steering system

- 1.5.7.9. Brake system

- 1.5.7.10. Turn indicators

- 1.5.7.11. Joystick Central lever operation

- 1.5.7.12. Joystick Single lever operation

- 1.5.7.13. Depressurisation

- 1.5.7.14. Driving speed reduction via a switch

- 1.5.8. Working with a load

- 1.5.8.1. Load capacity diagram

- 1.5.8.2. Adjusting the fork arm distance

- 1.5.8.3. Picking up a load

- 1.5.8.4. Determining visibility conditions when driving with a load

- 1.5.8.5. Driving under load

- 1.5.8.6. Setting down loads

- 1.5.8.7. Mast positioning

- 1.5.8.8. Lift height limitation

- 1.5.8.9. Steering angle display

- 1.5.8.10. Towing device

- 1.5.9. Leaving the truck

- 1.5.10. Drive batteries

- 1.5.10.1. Checking the battery charge status

- 1.5.10.2. Battery hoodOpening Closing

- 1.5.10.3. Charging the battery

- 1.5.10.4. Battery chargers

- 1.5.10.5. Replacing the battery

- 1.5.11. Loading.transporting

- 1.5.11.1. Removing.attaching the lift mast

- 1.5.11.2. Driving without the lift mast

- 1.5.11.3. Transporting the truck using a lorry or flatbed trailer

- 1.5.11.4. Crane loading

- 1.6. Maintenance

- 1.6.1. Safety information regarding servicing work

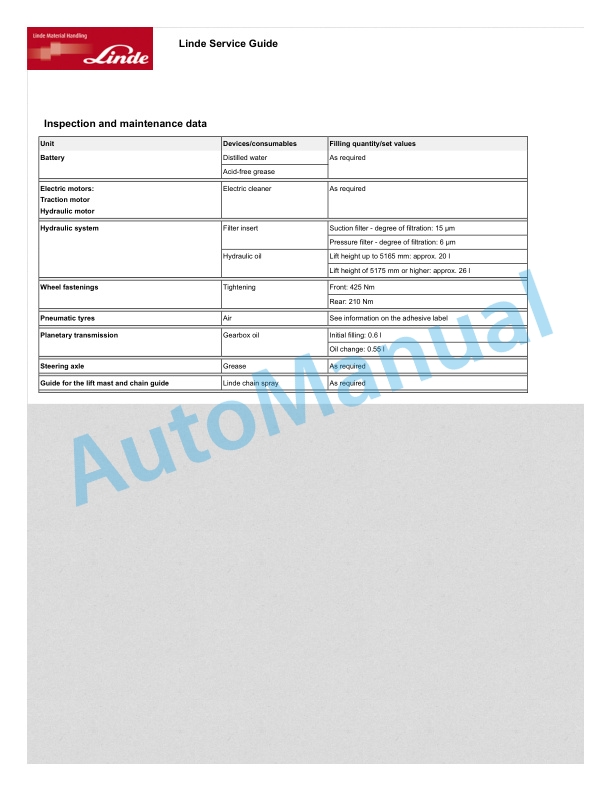

- 1.6.2. Inspection and maintenance data

- 1.6.3. Recommendations for consumables

- 1.6.4. Service plan

- 1.6.5. Additional service plan for explosion protection

- 1.6.6. Gearbox

- 1.6.6.1. Planetary transmissionChecking the oil level

- 1.6.6.2. Checking the planetary transmission for leak tightness

- 1.6.7. Chassis, bodywork and fittings

- 1.6.7.1. Cleaning the industrial truck

- 1.6.7.2. Checking and lubricating the bearing points and joints

- 1.6.7.3. Battery door and battery hoodLubricating the bolts, hinges and interlocks

- 1.6.7.4. Battery door and battery hoodChecking and adjusting the interlocks

- 1.6.7.5. Battery compartment Checking the battery side stop

- 1.6.7.6. Checking the condition and function of the seat belt

- 1.6.7.7. Filling up the washer system.water tank

- 1.6.8. Chassis frame

- 1.6.8.1. Information on antistatic tyres

- 1.6.8.2. Checking the leak resistance

- 1.6.8.3. Checking the wheels for damage, foreign objects and wear

- 1.6.8.4. Wheel change

- 1.6.8.5. Tightening the wheel fastenings

- 1.6.8.6. Checking the tyre pressure

- 1.6.8.7. Lubricating the steering axle

- 1.6.9. Operating devices

- 1.6.9.1. Checking the brake system for correct function

- 1.6.9.2. Checking and lubricating the pedal group and linkage

- 1.6.9.3. Checking the horn for correct function

- 1.6.10. Electrics.electronics

- 1.6.10.1. Checking the pressuretight housing

- 1.6.10.2. Checking the main contactor

- 1.6.10.3. Tightening the connections of the power electronics

- 1.6.10.4. Checking the condition of the drive battery

- 1.6.10.5. Checking the cables and the plugs on the drive battery

- 1.6.10.6. Checking the heat sinks on the power modules for contamination and cleaning the heat sinks

- 1.6.11. Hydraulics

- 1.6.11.1. Hydraulic systemChecking the oil level

- 1.6.11.2. Hydraulic systemChecking for leak tightness

- 1.6.11.3. Checking that the bleeder valve on the hydraulic tank is functioning correctly

- 1.6.11.4. Hose linesChecking the preload

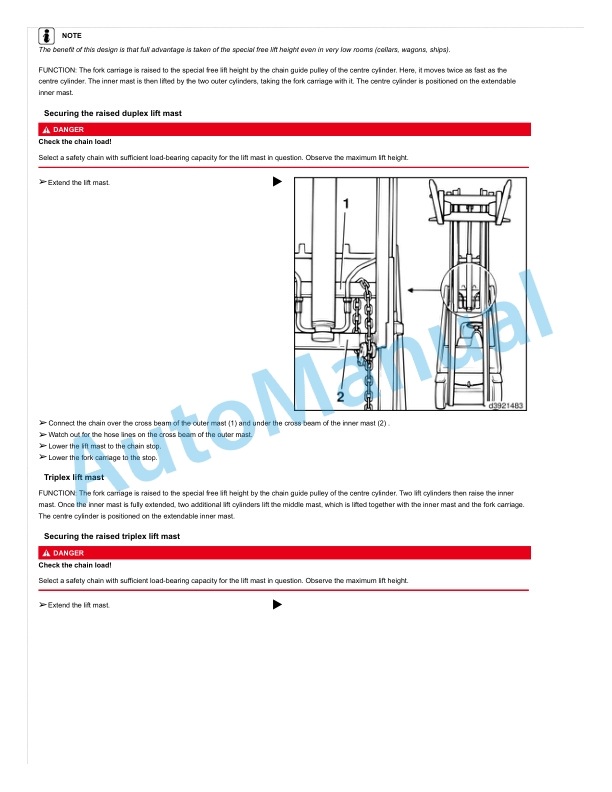

- 1.6.12. Load lift system

- 1.6.12.1. Working on the lift mast and at the front of the truck

- 1.6.12.2. Checking the condition of the lift mast

- 1.6.12.3. Cleaning and spraying the lift mast chain

- 1.6.12.4. Lift mast adjusting the chain

- 1.6.12.5. Checking the load fork

- 1.6.12.6. Checking and lubricating the fork prong positioner (special equipment)

- 1.6.13. Selfhelp

- 1.6.13.1. Fuses

- 1.6.13.2. Diagnostic connector

- 1.6.13.3. Malfunctions during operation

- 1.6.13.4. Malfunctions, causes and remedies Hydraulic system

- 1.6.14. Shutting down

- 1.6.14.1. Decommissioning the industrial truck

- 1.6.14.2. Disposal of old trucks

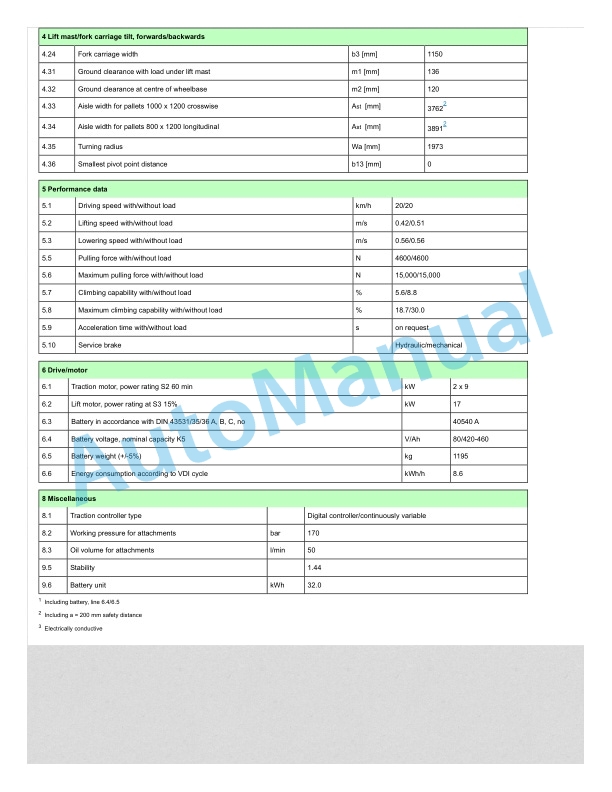

- 1.7. Technical data

- 1.7.1. Overview of dimensions

- 1.7.2. E 25.500 Ex type sheet, as at 08.2012

- 1.7.3. E 25.500 L Ex type sheet, as at 08.2012

- 1.7.4. E 30.500 Ex type sheet, as at 08.2012

- 1.7.5. E 30.500 L Ex type sheet, as at 08.2012

- 1.7.6. E 35.500 L Ex type sheet, as at 08.2012

- 1.7.7. Lift mast data

- 1.7.8. Tyre variants and rim sizes

- 1.7.9. Additional capacity rating plate for attachments

- 1.7.10. Noise emission values

- 1.7.11. Vibration characteristics for bodily vibrations

- 2. Leadacid battery charger 24V . 48V . 80V

Rate this product

You may also like

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00