Linde 396-01 – H50D EX, H60D EX Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 33.4MB

- Number of Pages: 269

Category: Linde Operator Manual PDF

-

Model List:

- H50D EX

- H60D EX

- 1. Diesel trucksH50D.Ex, H60D.Ex, H70D.Ex, H80D.Ex

- 1.1. Table of content

- 1.2. Introduction

- 1.2.1. Your truck

- 1.2.2. Intended use

- 1.2.3. Impermissible use

- 1.2.4. Basic information on explosion protection

- 1.2.5. Description of use and climatic conditions

- 1.2.6. Symbols used

- 1.2.7. Technical description

- 1.2.8. Taking delivery of the industrial truck

- 1.2.9. Legal requirements for placing on the market

- 1.3. Safety

- 1.3.1. Safety guidelines

- 1.3.2. Residual risks

- 1.3.3. Stability

- 1.3.4. In the case of tipover

- 1.3.5. Handling consumables

- 1.3.6. Qualified person

- 1.3.7. Regulations

- 1.3.8. Fit attachments

- 1.3.9. Fork carriage emergency lowering

- 1.3.10. Emergency exit with attached rear window

- 1.4. Overview

- 1.4.1. Identification plates

- 1.4.2. Nameplate

- 1.4.3. Truck overview

- 1.4.4. Controls

- 1.4.5. Display unit

- 1.5. Operation

- 1.5.1. Service plan before initial commissioning

- 1.5.2. Instructions for runningin

- 1.5.3. Preshift checks

- 1.5.4. Standard equipment

- 1.5.4.1. Entering and exiting the truck

- 1.5.4.2. Adjusting the drivers seat

- 1.5.4.3. Adjusting the steering column

- 1.5.4.4. Setting the clock

- 1.5.4.5. Seat belt

- 1.5.4.6. Starting and stopping the internal combustion engine (dualpedal operation)

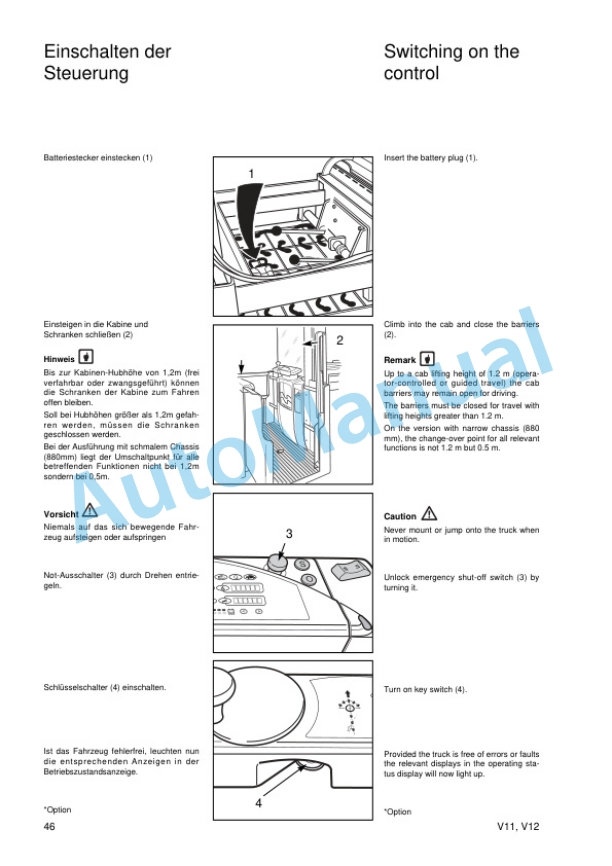

- 1.5.4.7. Driving (dualpedal operation)

- 1.5.4.8. Starting and stopping the internal combustion engine (singlepedal operation)

- 1.5.4.9. Driving (singlepedal operation)

- 1.5.4.10. Steering system

- 1.5.4.11. Brake system

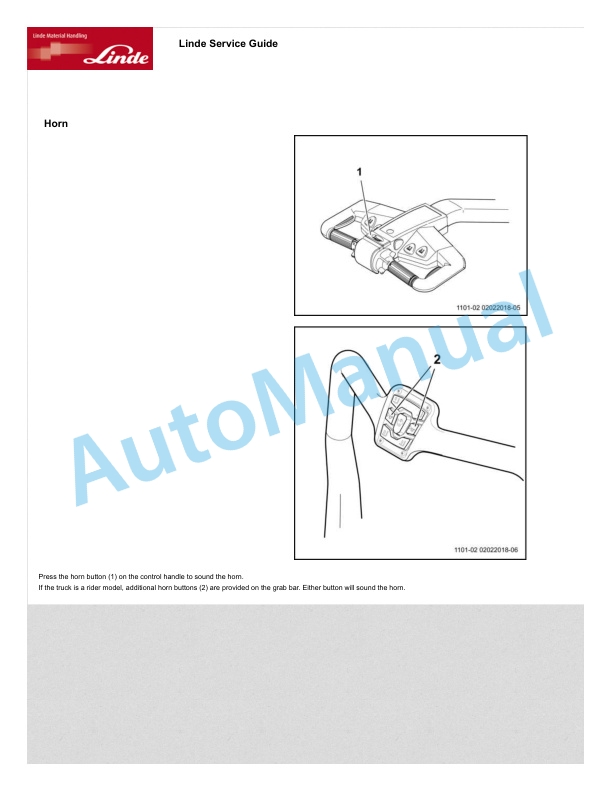

- 1.5.4.12. horn

- 1.5.4.13. Joystick with central lever operation

- 1.5.4.14. Joystick with single lever operation

- 1.5.5. Special equipment

- 1.5.5.1. Depressurisation

- 1.5.5.2. Drivers cab

- 1.5.5.3. Lighting

- 1.5.5.4. Windscreen wipers

- 1.5.5.5. Heating system, air conditioning

- 1.5.6. Working with a load

- 1.5.6.1. Before taking up load

- 1.5.6.2. Adjusting the fork arm distance

- 1.5.6.3. Loading

- 1.5.6.4. Taking up loads

- 1.5.6.5. Travelling with load

- 1.5.6.6. Setting down loads

- 1.5.6.7. Towing device

- 1.5.7. Before leaving the truck

- 1.5.8. Loading.transporting

- 1.5.8.1. Removing.attaching the lift mast

- 1.5.8.2. Securing the overhead guard against moving forwards or backwards

- 1.5.8.3. Loading

- 1.5.8.4. Transportation by lorry or lowbed semitrailer

- 1.6. Servicing

- 1.6.1. General information

- 1.6.2. Inspection and maintenance data

- 1.6.3. Recommendations for consumables

- 1.6.4. Inspection and maintenance overview

- 1.6.4.1. Service plan as required

- 1.6.4.2. hour service plan

- 1.6.4.3. hour service plan

- 1.6.4.4. hour service plan

- 1.6.4.5. hour service plan

- 1.6.4.6. hour service plan

- 1.6.4.7. hour service plan

- 1.6.4.8. hour service plan

- 1.6.5. Engine

- 1.6.5.1. Checking the engine oil level

- 1.6.5.2. Changing the engine oil

- 1.6.5.3. Changing the engine oil filter

- 1.6.5.4. Fuel

- 1.6.5.5. Draining the fuel system water strainer

- 1.6.5.6. Changing the fuel filter

- 1.6.5.7. Changing the fuel prefilter

- 1.6.5.8. Bleeding the fuel system

- 1.6.5.9. Cleaning the fuel tank ventilation hose

- 1.6.5.10. Checking the coolant level

- 1.6.5.11. Changing the coolant

- 1.6.5.12. Check the coolant concentration

- 1.6.5.13. Checking coolant level for exhaust gas and turbocharger

- 1.6.5.14. Clean the water cooler and hydraulic oil cooler and check for leaks

- 1.6.5.15. Checking the condition and secure positioning of the engine support and engine mounting

- 1.6.5.16. Checking the condition and tension of the Vribbed belt

- 1.6.5.17. Changing the Vribbed belt

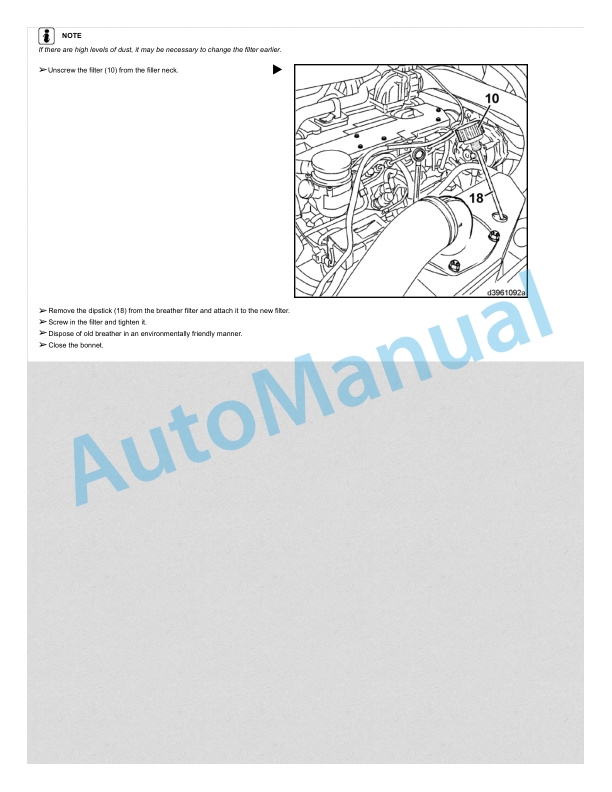

- 1.6.5.18. Changing the air filter cartridge, checking the vacuumoperated switch

- 1.6.5.19. Changing the air filter safety cartridge

- 1.6.5.20. Checking the dust discharge valve

- 1.6.5.21. Checking the intake and exhaust pipes for leaks

- 1.6.5.22. Clean the heat exchanger

- 1.6.5.23. Draining water from the intercooler

- 1.6.5.24. Checking the valve clearance

- 1.6.5.25. Regenerating the changing particle filter

- 1.6.5.26. Draining water from the water trap at the changing particle filter (special equipment)

- 1.6.5.27. Cleaning the water trap at the changing particle filter (special equipment)

- 1.6.5.28. Cleaning the pressure control device at the changing particle filter (special equipment)

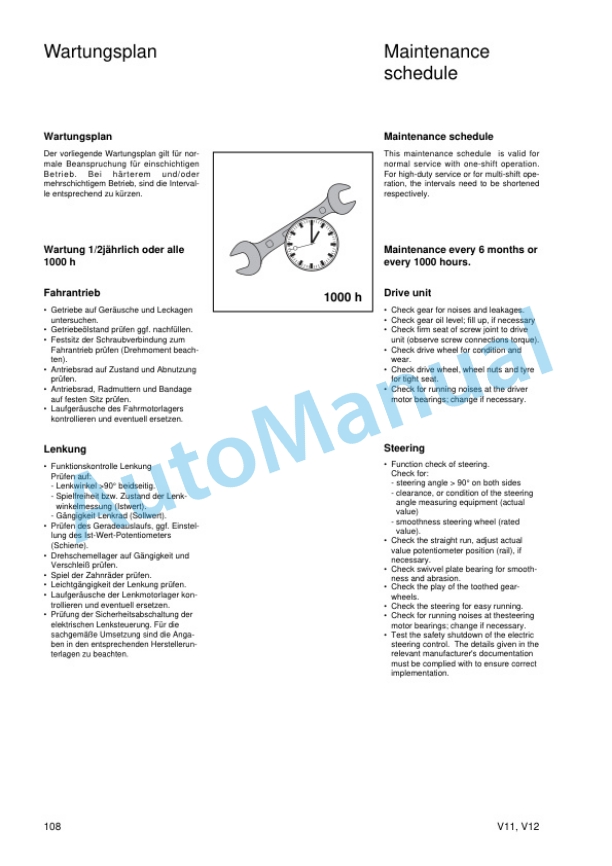

- 1.6.6. Gearbox

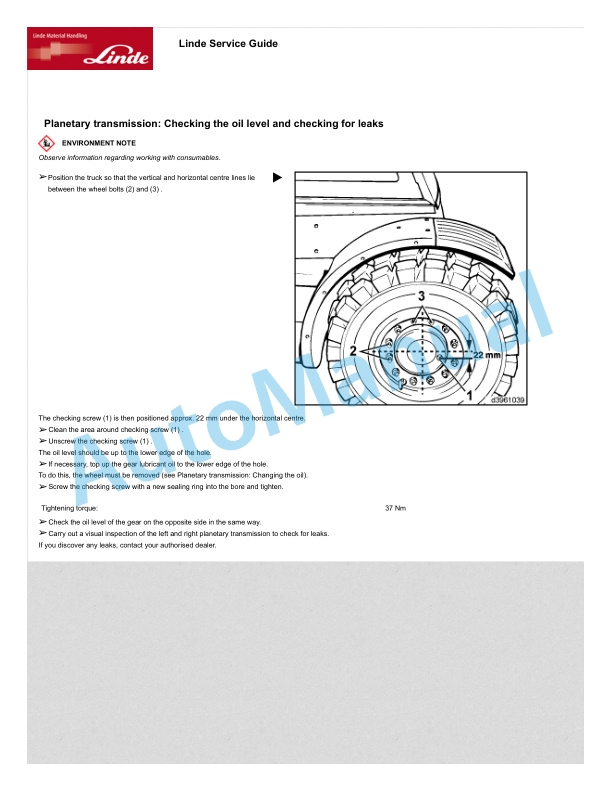

- 1.6.6.1. Planetary transmission Checking the oil level and checking for leaks

- 1.6.6.2. Planetary transmission Changing the oil and cleaning the magnetic plug

- 1.6.6.3. Checking the fastenings of the axle clamps

- 1.6.6.4. Checking the hydraulic pumps mounting on the engine

- 1.6.7. Chassis, bodywork and fittings

- 1.6.7.1. Cleaning the truck

- 1.6.7.2. Bonnet

- 1.6.7.3. Floorplate

- 1.6.7.4. Checking the condition and correct function of the seat belt

- 1.6.7.5. Checking the mounting of the chassis, tilt cylinders and steering axle

- 1.6.7.6. Lubricating the overhead guard bearings and tilt cylinder bearings

- 1.6.7.7. Checking and oiling other bearing points and joints

- 1.6.7.8. Topping up the water tank in the washer system

- 1.6.8. Chassis frame

- 1.6.8.1. Wheel change

- 1.6.8.2. Tightening the wheel fastenings

- 1.6.8.3. Checking tyres for damage and foreign objects

- 1.6.8.4. Check the tyre pressure

- 1.6.8.5. Cleaning and greasing the steering axle

- 1.6.8.6. Checking the mountings of the steering cylinder and steering pivot pin

- 1.6.9. Operating devices

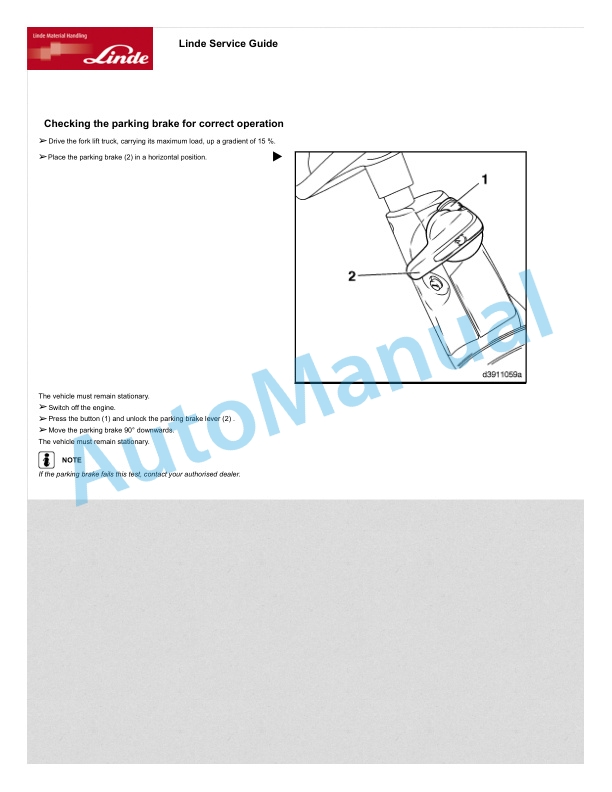

- 1.6.9.1. Checking the parking brake for correct operation

- 1.6.9.2. Checking the pedal group

- 1.6.9.3. Checking the bellows at the actuating lever

- 1.6.10. Electrics

- 1.6.10.1. Checking electric cables and connections for condition and tightness

- 1.6.10.2. Battery condition check, disposal

- 1.6.11. Hydraulics

- 1.6.11.1. Changing the hydraulic oil

- 1.6.11.2. Checking the oil level in the hydraulic system

- 1.6.11.3. Hydraulic system changing the filter

- 1.6.11.4. Check that the bleeder valve on the hydraulic tank is working correctly

- 1.6.11.5. Checking the hydraulic system for leaks

- 1.6.11.6. Checking the preload of the double hoses

- 1.6.12. Load lift system

- 1.6.12.1. Working on the lift mast and at the front of the truck

- 1.6.12.2. Cleaning and spraying the lift mast chain

- 1.6.12.3. Checking the mounting, condition and function of the lift mast, lift mast chains, lift cylinders and end stops

- 1.6.12.4. Adjusting the lift mast chain

- 1.6.12.5. Checking the fork arms and fork arm safety devices

- 1.6.12.6. Lubricating the mast fixation

- 1.6.13. Selfhelp

- 1.6.13.1. Opening the cover to the electrical system

- 1.6.13.2. Fuses for special electrical equipment

- 1.6.13.3. Opening the central electrical system cover

- 1.6.13.4. Fuses for basic electrical equipment

- 1.6.13.5. Diagnostic connector

- 1.6.13.6. Malfunctions during operation

- 1.6.13.7. Error statuses CEU05.00

- 1.6.13.8. Malfunctions, causes and remedies (diesel engine)

- 1.6.13.9. Malfunctions, causes and remedies hydraulic system

- 1.6.13.10. Jump start

- 1.6.13.11. Towing

- 1.6.14. Shutting down

- 1.6.14.1. Shutting down the truck

- 1.6.14.2. Disposal of old trucks

- 1.7. Technical data

- 1.7.1. Overview of dimensions

- 1.7.2. H50DEx type sheet

- 1.7.3. H60DEx type sheet

- 1.7.4. Type sheet H70DEx

- 1.7.5. Type sheet H80DEx

- 1.7.6. Truck configuration

- 1.7.7. Tyre variants and rim sizes

- 1.7.8. Load capacity diagrams and lift mast data as at 11.2011

- 1.7.9. Additional capacity rating plate for attachments

- 1.7.10. Noise emission values

- 1.7.11. Vibration characteristic values for bodily vibrations

Rate this product

You may also like

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

$20.00

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00

Linde Operator Manual PDF

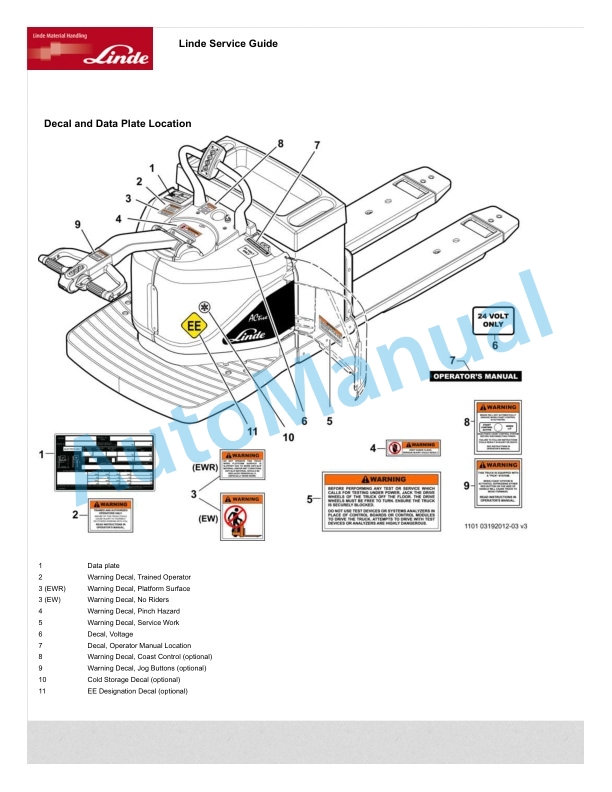

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00