Linde 396-02 – H50D, H50T, H60D, H60T, H70D, H70T, H80D, H80T Operating Instructions SN 07.12 and up SN up to 03.16

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 07.12 and up SN up to 03.16

- Format: PDF

- Size: 75.0MB

- Number of Pages: 647

- Serial Number:

SN 07.12 and up SN up to 03.16

Category: Linde Operator Manual PDF

-

Model List:

- H50D

- H50T

- H60D

- H60T

- H70D

- H70T

- H80D

- H80T

- 1. Customised optionsH50D02, H60D02, H70D02, H80D02

- 1.1. Table of content

- 1.2. Driving speed reduction

- 1.2.1. Driving speed reduction

- 1.3. Reverse proximity alarm

- 1.3.1. Reverse proximity alarm

- 1.4. Lift height restriction

- 1.4.1. Lift height restriction

- 1.5. Battery main switch

- 1.5.1. Battery main switch

- 1.6. Customised key switch

- 1.6.1. Customised key switch

- 1.7. Quickrelease couplings

- 1.7.1. Quickrelease couplings for auxiliary hydraulics

- 1.8. Heated outside mirrors

- 1.8.1. Heated outside mirrors

- 1.9. Switchoff delay for electrical equipment

- 1.9.1. Switchoff delay for electrical equipment

- 1.10. V, 7pin socket for trailer lighting

- 1.10.1. V, 7pin socket for trailer lighting

- 1.11. Auxiliary heater

- 1.11.1. Auxiliary heater

- 1.12. Buckle monitoring

- 1.12.1. Buckle monitoring on seat belt

- 1.13. Door monitoring

- 1.13.1. Door monitoring

- 1.14. Trailer coupling

- 1.14.1. Trailer coupling

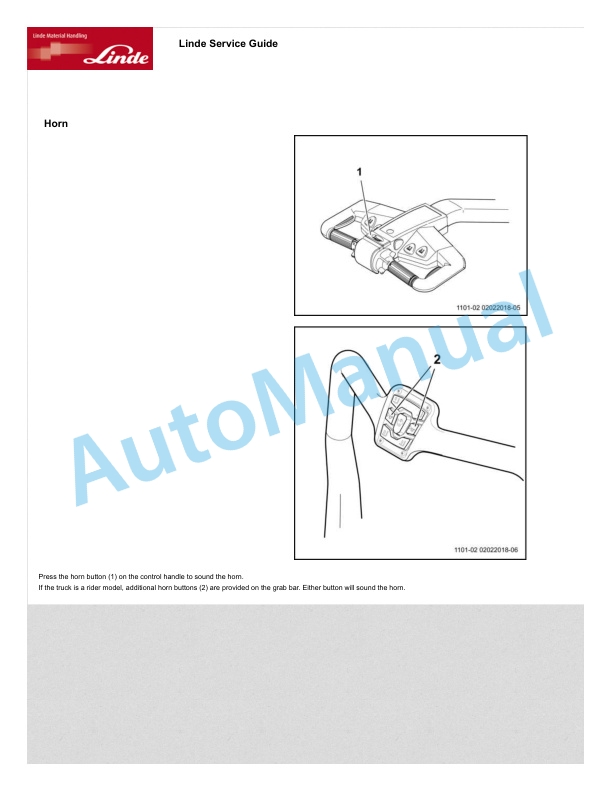

- 1.15. Horn in foot well

- 1.15.1. Horn in foot well

- 2. Customised optionsH50T02, H60T02, H70T02, H80T02

- 2.1. Table of content

- 2.2. Driving speed reduction

- 2.2.1. Driving speed reduction

- 2.3. Reverse proximity alarm

- 2.3.1. Reverse proximity alarm

- 2.4. Lift height restriction

- 2.4.1. Lift height restriction

- 2.5. Battery main switch

- 2.5.1. Battery main switch

- 2.6. Customised key switch

- 2.6.1. Customised key switch

- 2.7. Quickrelease couplings

- 2.7.1. Quickrelease couplings for auxiliary hydraulics

- 2.8. Heated outside mirrors

- 2.8.1. Heated outside mirrors

- 2.9. Switchoff delay for electrical equipment

- 2.9.1. Switchoff delay for electrical equipment

- 2.10. V, 7pin socket for trailer lighting

- 2.10.1. V, 7pin socket for trailer lighting

- 2.11. Auxiliary heater

- 2.11.1. Auxiliary heater

- 2.12. Buckle monitoring

- 2.12.1. Buckle monitoring on seat belt

- 2.13. Door monitoring

- 2.13.1. Door monitoring

- 2.14. Trailer coupling

- 2.14.1. Trailer coupling

- 2.15. Horn in foot well

- 2.15.1. Horn in foot well

- 3. Diesel truckH50D02, H60D02, H70D02, H80D02

- 3.1. Table of content

- 3.2. Introduction

- 3.2.1. Your forklift truck

- 3.2.2. Intended use

- 3.2.3. Impermissible use

- 3.2.4. Description of use and climatic conditions

- 3.2.5. Symbols used

- 3.2.6. Technical description

- 3.2.7. Taking delivery of the industrial truck

- 3.2.8. Customised options

- 3.2.9. Legal requirements for placing on the market

- 3.2.10. Disposing of components and batteries

- 3.3. Safety

- 3.3.1. Safety guidelines

- 3.3.2. Residual risks

- 3.3.3. Stability

- 3.3.4. In the case of tipover

- 3.3.5. Handling consumables

- 3.3.6. Competent person

- 3.3.7. Periodic safety inspection

- 3.3.8. Fit attachments

- 3.3.9. Emergency exit with attached rear window

- 3.3.10. Emergency lowering

- 3.3.11. Towing

- 3.4. Overview

- 3.4.1. Identification plates

- 3.4.2. Truck overview

- 3.4.3. Controls

- 3.4.4. Display unit

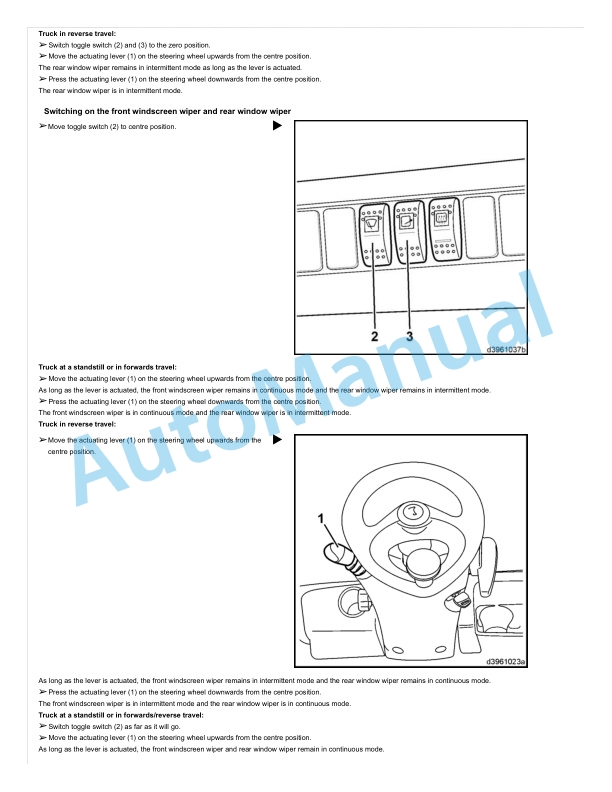

- 3.4.5. Switch panel

- 3.5. Operation

- 3.5.1. Service plan before initial commissioning

- 3.5.2. Instructions for runningin

- 3.5.3. Preshift checks

- 3.5.4. Regular maintenance

- 3.5.5. Standard equipment

- 3.5.6. Special equipment

- 3.5.7. Working with a load

- 3.5.8. Before leaving the truck

- 3.5.9. Loading.transporting

- 3.6. Maintenance

- 3.6.1. Safety information regarding servicing work

- 3.6.2. Overview of the filling quantities and set values

- 3.6.3. Recommendations for consumables

- 3.6.4. Service plan

- 3.6.5. Engine

- 3.6.6. Gearbox

- 3.6.7. Chassis, bodywork and fittings

- 3.6.8. Chassis frame

- 3.6.9. Operating devices

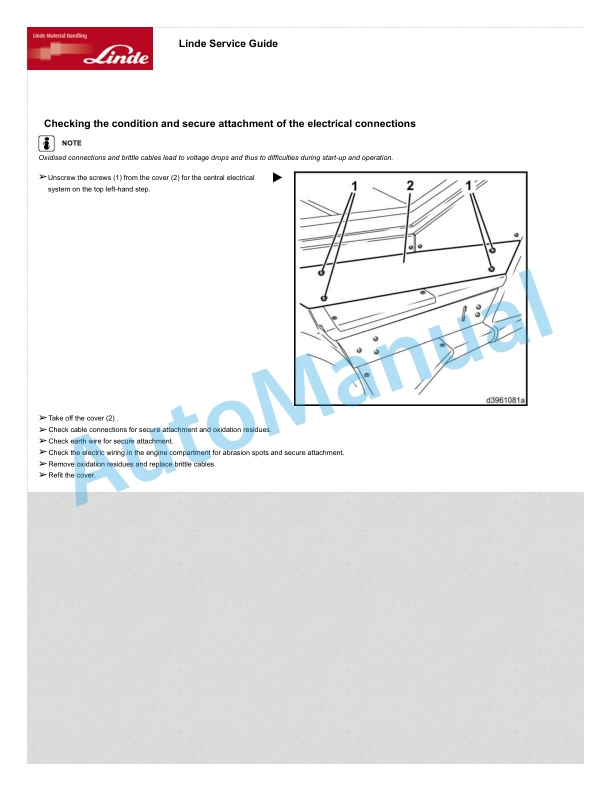

- 3.6.10. Electrics

- 3.6.11. Hydraulics

- 3.6.12. Load lift system

- 3.6.13. Selfhelp

- 3.6.14. Shutting down

- 3.7. Technical data

- 3.7.1. Overview of dimensions

- 3.7.2. Overview of type sheets

- 3.7.3. Lift mast data type 195

- 3.7.4. Truck configuration

- 3.7.5. Tyre variants and rim sizes

- 3.7.6. Additional capacity rating plate for attachments

- 3.7.7. Noise emission values

- 3.7.8. Vibration characteristic values for bodily vibrations

- 4. LPG truckH50T02, H60T02, H70T02, H80T02

- 4.1. Table of content

- 4.2. Introduction

- 4.2.1. Your forklift truck

- 4.2.2. Intended use

- 4.2.3. Impermissible use

- 4.2.4. Description of use and climatic conditions

- 4.2.5. Symbols used

- 4.2.6. Technical description

- 4.2.7. Taking delivery of the industrial truck

- 4.2.8. Customised options

- 4.2.9. Legal requirements for placing on the market

- 4.2.10. Disposing of components and batteries

- 4.3. Safety

- 4.3.1. Safety guidelines

- 4.3.2. Residual risks

- 4.3.3. Stability

- 4.3.4. In the case of tipover

- 4.3.5. Handling consumables

- 4.3.6. Competent person

- 4.3.7. Periodic safety inspection

- 4.3.8. Safety information on the LPG system

- 4.3.9. Safety guidelines for LPG (extract)

- 4.3.10. Safety measures when working on ignition systems

- 4.3.11. Fit attachments

- 4.3.12. Emergency exit with attached rear window

- 4.3.13. Emergency lowering

- 4.3.14. Towing

- 4.4. Overview

- 4.4.1. Type plates

- 4.4.2. Truck overview

- 4.4.3. Controls

- 4.4.4. Display unit

- 4.4.5. Switch panel

- 4.5. Operation

- 4.5.1. Service plan before initial commissioning

- 4.5.2. Instructions for runningin

- 4.5.3. Preshift checks

- 4.5.4. Regular maintenance

- 4.5.5. Standard equipment

- 4.5.6. Special equipment

- 4.5.7. Working with a load

- 4.5.8. Before leaving the truck

- 4.5.9. Loading.transporting

- 4.6. Maintenance

- 4.6.1. Safety information regarding servicing work

- 4.6.2. Overview of the filling quantities and set values

- 4.6.3. Recommendations for consumables

- 4.6.4. Service plan

- 4.6.5. Engine

- 4.6.6. Gearbox

- 4.6.7. Chassis, bodywork and fittings

- 4.6.8. Chassis frame

- 4.6.9. Operating devices

- 4.6.10. Electrics

- 4.6.11. Hydraulics

- 4.6.12. Load lift system

- 4.6.13. Selfhelp

- 4.6.14. Shutting down

- 4.7. Technical data

- 4.7.1. Overview of dimensions

- 4.7.2. Overview of type sheets

- 4.7.3. Lift mast data type 195

- 4.7.4. Truck configuration

- 4.7.5. Tyre variants and rim sizes

- 4.7.6. Additional capacity rating plate for attachments

- 4.7.7. Noise emission values

- 4.7.8. Vibration characteristic values for bodily vibrations

- 5. Linde Safety Guard

- 5.1. Table of content

- 5.2. Introduction

- 5.2.1. Linde Safety Guard assistance system

- 5.2.2. Intended use

- 5.2.3. Declaration of conformity for radio equipment

- 5.2.4. Limitations for commissioning or for the permission to operate

- 5.2.5. Symbols used

- 5.3. Safety

- 5.3.1. Safety information

- 5.3.2. Service personnel

- 5.4. Operating devices and display elements

- 5.4.1. Overview

- 5.4.2. Safety Guard display unit Truck Unit

- 5.4.3. Safety Guard Truck Unit display unit for reach trucks

- 5.4.4. Safety Guard communication unit Truck Unit Small

- 5.4.5. Interactive warning vest

- 5.4.6. Mobile warning unit for the interactive warning vest Vest Unit

- 5.4.7. Power bank

- 5.4.8. Charging station for the power bank

- 5.4.9. Safety Guard portable warning unit Portable Unit

- 5.4.10. Safety Guard charging station

- 5.4.11. Safety Guard charging station from 10.2019

- 5.4.12. Safety Guard sensor

- 5.4.13. Safety Guard static warning unit Static Unit

- 5.4.14. Safety Guard Zone radio module Zone Marker

- 5.5. Operating

- 5.5.1. Installation

- 5.5.2. Preshift checks

- 5.5.3. Operation

- 5.6. Maintenance and disposal

- 5.6.1. Maintenance

- 5.6.2. Disposal

- 5.7. Technical data

- 5.7.1. Safety Guard display unit

- 5.7.2. Safety Guard active warning vest

- 5.7.3. Safety Guard mobile warning unit

- 5.7.4. Safety Guard sensor

- 5.7.5. Safety Guard communication unit

- 5.7.6. Safety Guard static warning unit

- 5.7.7. Safety Guard Zone radio module

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1120-01 – R-matic, R10, R12, R14, R16, R20, R25 Operating Instructions SN 10.12 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528

$20.00

Linde Operator Manual PDF

Linde 1102-01 – ECR27, ECR36 Production site LMH-NA Operating Instructions

$20.00