Linde 5214-01 – V Production site KWS Reutlingen Operating Instructions

$20.00

- Type Of Manual: Operating Instructions

- Format: PDF

- Size: 30.3MB

- Number of Pages: 256

Category: Linde Operator Manual PDF

-

Model List:

- V Production site KWS Reutlingen

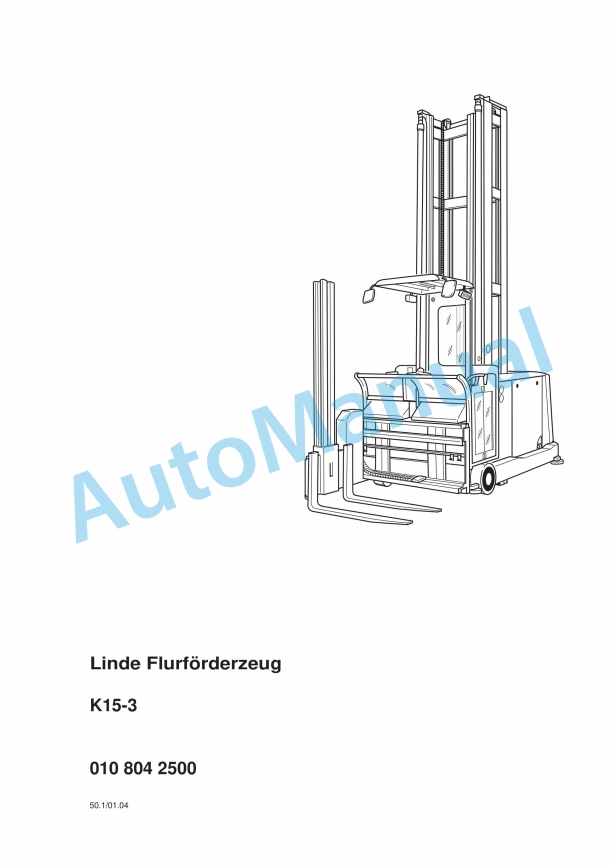

- 1. Highlevel order pickerV1002V

- 1.1. Table of content

- 1.2. Foreword

- 1.2.1. Linde Material Handling Your Partner

- 1.2.2. Rules for the operating company of industrial trucks

- 1.2.3. Conformity marking

- 1.2.4. Declaration that reflects the content of the declaration of conformity

- 1.2.5. General

- 1.2.6. Safety instructions

- 1.2.7. Nameplate

- 1.2.8. Operator,Form of address

- 1.2.9. Dimensions of the operators compartment

- 1.2.10. Product documentation

- 1.2.11. Accessories accompanying the product

- 1.2.12. Standard design and options Special version Special equipment

- 1.2.13. Copyright and proprietary rights

- 1.2.14. Storage and transfer

- 1.3. Safety

- 1.3.1. Working safely

- 1.3.2. Climbing into or out of the truck

- 1.3.3. Vibrations

- 1.3.4. Medical equipment, implants

- 1.3.5. Special safety information about load pick up

- 1.3.6. Safe handling of consumables

- 1.3.7. Safe handling of the battery cable

- 1.3.8. Risk assessment

- 1.3.9. Residual risks

- 1.3.10. Residual risks with the drivers cab raised

- 1.3.11. Residual risks when using order pickers

- 1.3.12. Intended use

- 1.3.13. Regular testing

- 1.3.14. Area of application

- 1.3.15. Floor structure, cleaning

- 1.3.16. Narrowaisle trucks

- 1.3.17. Original parts

- 1.3.18. Directives and guidelines

- 1.3.19. Drivers licence

- 1.3.20. Alterations to industrial trucks

- 1.3.21. Personal protective equipment

- 1.3.22. Conversion, retrofitting, rebuilding

- 1.4. Overview

- 1.4.1. Components of the industrial truck

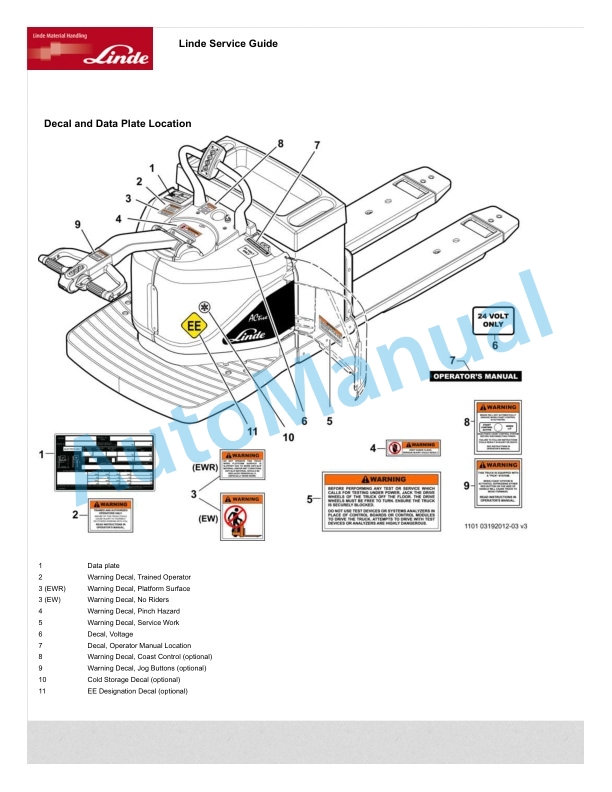

- 1.4.2. Standard design of labelling

- 1.4.3. Labelling for special equipment

- 1.4.4. Truck description

- 1.4.5. Safety equipment

- 1.4.6. Operating panel, variants

- 1.4.7. Operators console

- 1.4.8. Standard display unit

- 1.4.9. Displays

- 1.4.10. Displays

- 1.4.11. LCD display unit with a keypad

- 1.4.12. Displays, information

- 1.4.13. Operating panel LCD display with keypad

- 1.4.14. Operating the display

- 1.4.15. LCD display with keypad

- 1.4.16. Operating the display

- 1.4.17. Operating instructions

- 1.4.18. View into the control compartment

- 1.5. Operation

- 1.5.1. General commissioning

- 1.5.1.1. Initial commissioning

- 1.5.1.2. Transporting and loading

- 1.5.1.3. Weights of the units

- 1.5.1.4. Support screws

- 1.5.1.5. Safe handling of the traction battery

- 1.5.1.6. Traction battery

- 1.5.1.7. Charging socketLithiumion battery

- 1.5.1.8. Battery replacement

- 1.5.2. Daily commissioning

- 1.5.2.1. Checklist before starting work

- 1.5.3. Drivers compartment

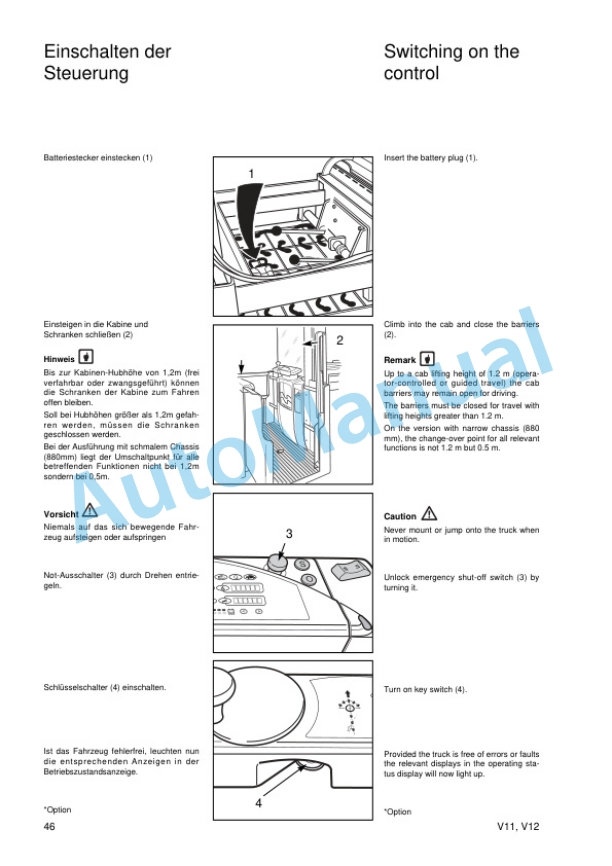

- 1.5.3.1. Climbing into or out of the truck

- 1.5.3.2. Barriers

- 1.5.4. Operating devices

- 1.5.4.1. Brake system

- 1.5.5. Driving

- 1.5.5.1. Types of guidance

- 1.5.5.2. Driving with guidance

- 1.5.6. Load pick up

- 1.5.6.1. Picking up and setting down loads

- 1.5.6.2. Load capacity diagram

- 1.5.6.3. Support screws

- 1.5.6.4. Picking up a load

- 1.5.6.5. Packages out of reach

- 1.5.6.6. Lifting accessories

- 1.5.6.7. Load pick up without guidance

- 1.5.6.8. Load pick up with guidance

- 1.5.7. Emergency operation

- 1.5.7.1. Emergency operation

- 1.5.7.2. Emergency abseil system

- 1.5.8. Parking, decommissioning

- 1.5.8.1. Parking and leaving the industrial truck

- 1.5.8.2. Decommissioning

- 1.6. Regular care and maintenance

- 1.6.1. Securing the load carrier

- 1.6.2. Removing the hood

- 1.6.3. General information about fuses

- 1.6.4. Fuses

- 1.6.5. Regular care and maintenance

- 1.6.6. Special versions, special equipment

- 1.6.7. Maintenance schedule, 1000 hours

- 1.6.8. hour maintenance schedule

- 1.6.9. Lubricants

- 1.7. Technical data

- 1.7.1. Technical data

- 1.7.2. Ecodesign requirements for electric motors and variable speed drives

- 1.8. Options

- 1.8.1. Options, enabling Options, retrofitting

- 1.8.2. Linde System Control LSC

- 1.8.3. Inductive guidance (IZF)

- 1.8.4. Inductive guidance IZF LCD display with keypad

- 1.8.5. Inductive guidance IZFOperating panel variants

- 1.8.6. Intermediate lift cutout

- 1.8.7. Traction cutout

- 1.8.8. Aisle entry assistant

- 1.8.9. Electronic access control

- 1.8.10. LFM, electronic access control

- 1.8.11. Automatic braking systems

- 1.8.12. Personal protection systemLINDE PSA

- 1.8.13. Personal protection system (MPSE)

- 1.8.14. Safety laser scanner

- 1.8.15. Preparation for the personal protection system

- 1.8.16. Safety laser scanner

- 1.8.17. Personal protection system, preparation

- 1.8.18. Other battery male connectors

- 1.8.19. Battery on a roller channel

- 1.8.20. Tilt barrier

- 1.8.21. Leaning cushion

- 1.8.22. Radio installation

- 1.8.23. Overhead guard switch

- 1.8.24. Drivers compartment options

- 1.8.25. Mounting system for auxiliary components

- 1.8.26. Protective roof cover

- 1.8.27. Mirror and lighting module

- 1.8.28. Operating panel, load side

- 1.8.29. Video system for monitoring the travel path

- 1.8.30. MMS interface

- 1.8.31. USB charging station

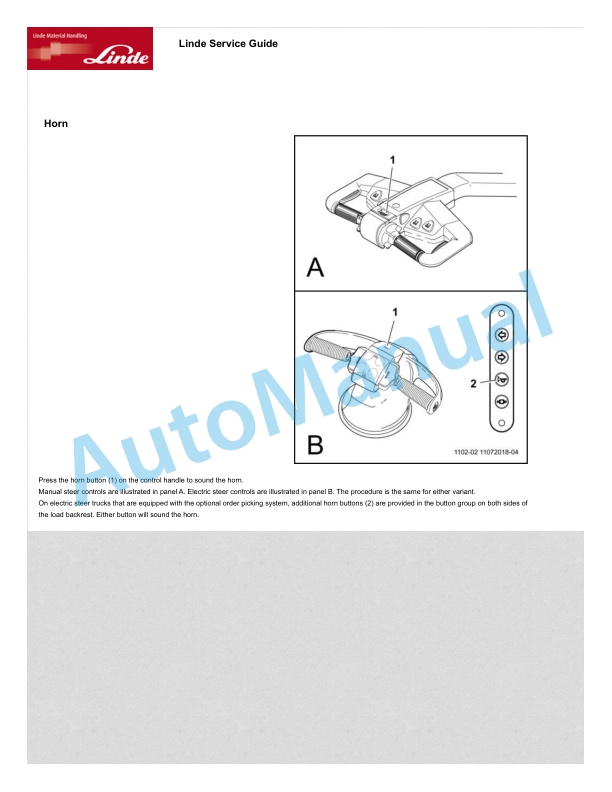

- 1.8.32. Acoustic warning signal

- 1.8.33. Acoustic alarm

- 1.8.34. Rescue Alarm

- 1.8.35. Special equipment for cold store application

- 1.8.36. Lifting accessories

- 1.8.37. Modified load pick up

- 1.8.38. Twoperson cab

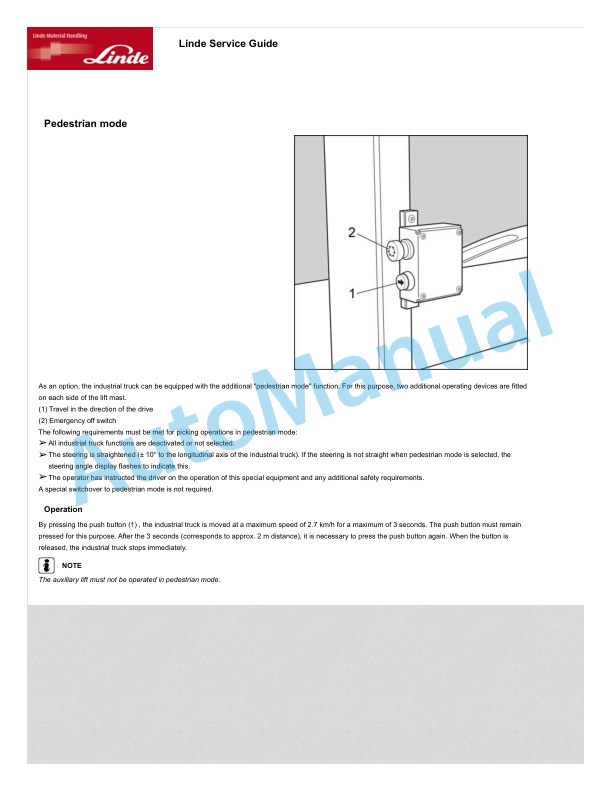

- 1.8.39. Pedestrian mode

- 1.8.40. Fall protection device

- 1.8.41. Working platforms

- 1.8.42. Blue Spot safety headlight

- 2. LINDE mobile personal protection system5213_V, 5214_V, 5224_A, 5231_K

- 2.1. Table of content

- 2.2. Foreword

- 2.2.1. Legal basis

- 2.2.2. Directive and standards

- 2.2.3. Mode of operation, safety category

- 2.3. Safety

- 2.3.1. Safety instructions

- 2.3.2. Target group of this document

- 2.4. Overview

- 2.4.1. Description

- 2.4.2. Area of application of the MPSE

- 2.4.3. General

- 2.5. Operation

- 2.5.1. Displays

- 2.5.2. Operating status display

- 2.5.3. Error messages

- 2.5.4. Scanner status display

- 2.5.5. Safety laser scanner

- 2.5.6. Emergency operation

- 2.6. Regular care and maintenance

- 2.6.1. Daily visual inspection and function checking

- 2.6.2. Regular care and maintenanceRegular testing

- 2.6.3. Regular care

- 2.6.4. Maintenance schedule, 1000 hours

- 2.6.5. Periodic testing

- 3. VNA Navigationfor vertical order pickerV

- 3.1. Table of content

- 3.2. Foreword

- 3.2.1. Linde Material Handling Your Partner

- 3.3. VNA Navigation

- 3.3.1. Important terms

- 3.3.2. Warehouse limit data

- 3.3.3. Display variants

- 3.3.4. Activating Navigation

- 3.3.5. Approaching a targetLCD display with keypad

- 3.3.6. Approaching a targetLCD display

Rate this product

You may also like

Linde Operator Manual PDF

Linde 1102-02 – ECR30, ECR40 Production site LMH-NA Operating Instructions SN A11102V00001 and up

$20.00

Linde Operator Manual PDF

Linde 1111-01 – N20C, N20VI, N20VLI Operating Instructions SN W41110V00529 and up

$20.00

Linde Operator Manual PDF

$20.00

Linde Operator Manual PDF

Linde 1101-01 – EW27, EW36, EWR27, EWR36 Production site LMH-NA Operating Instructions

$20.00

Linde Operator Manual PDF

Linde 1115-01 – N16Li to N25SA Operating Instructions SN W41115V00001 and up

$20.00

Linde Operator Manual PDF

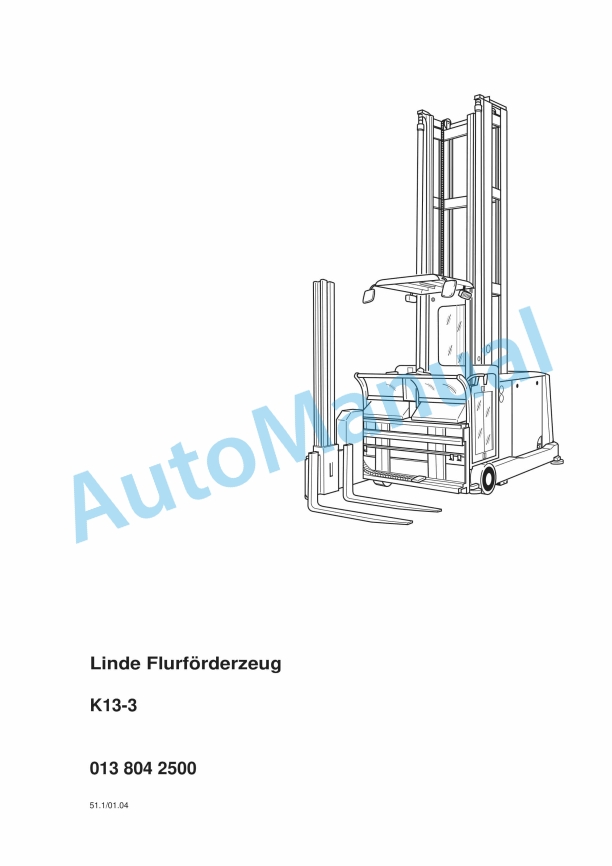

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

$20.00