Linde 5214-01 – V Production site KWS Reutlingen Workshop Manuals

$40.00

- Type Of Manual: Workshop Manuals

- Format: PDF

- Size: 174.8MB

- Number of Pages: 1530

Category: Linde Workshop Manual PDF

-

Model List:

- V Production site KWS Reutlingen

- 1. Operating Instructions

- 1.1. Highlevel order pickerV1002V

- 1.1.1. Table of content

- 1.1.2. Foreword

- 1.1.3. Safety

- 1.1.4. Overview

- 1.1.5. Operation

- 1.1.6. Regular care and maintenance

- 1.1.7. Technical data

- 1.1.8. Options

- 1.2. LINDE mobile personal protection system5213_V, 5214_V, 5224_A, 5231_K

- 1.2.1. Table of content

- 1.2.2. Foreword

- 1.2.3. Safety

- 1.2.4. Overview

- 1.2.5. Operation

- 1.2.6. Regular care and maintenance

- 1.3. VNA Navigationfor vertical order pickerV

- 1.3.1. Table of content

- 1.3.2. Foreword

- 1.3.3. VNA Navigation

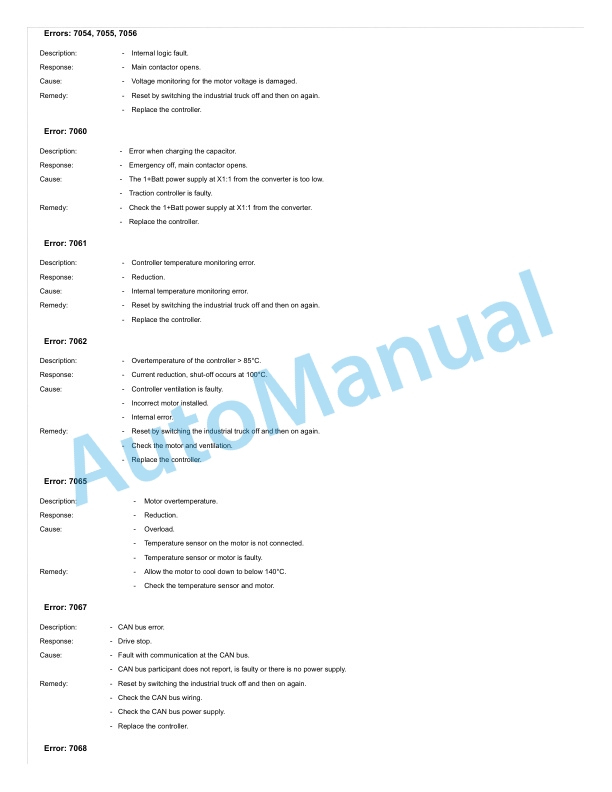

- 2. Fault descriptionsInformation on the displayV

- 2.1. Table of content

- 2.2. Foreword

- 2.2.1. General

- 2.3. Information on the display

- 2.3.1. Truck control unit (FZS)

- 2.4. Fault descriptions

- 2.4.1. Truck control unit (FZS) 8U60

- 2.4.2. FleetManager (FLM)

- 2.4.3. Display (DIS) 8A12

- 2.4.4. Electric steering (ELK) 3M1

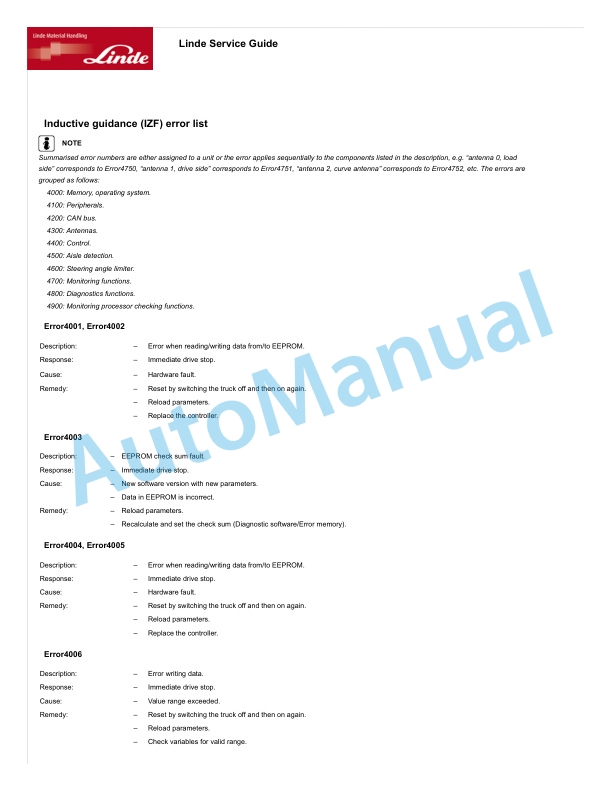

- 2.4.5. Inductive guidance (IZF) 3A21

- 2.4.6. Operating panel controller on the drive side (BPS) 8U62

- 2.4.7. Operating panel controller on the load side (BPS) 8U62

- 2.4.8. Traction controller (FS) 1U6

- 2.4.9. Pump controller (PS) 2U3

- 3. Linde mobile personal protection systemK 5231 seriesA 5224 seriesV 5213.5214 series

- 3.1. Table of content

- 3.2. Foreword

- 3.2.1. Mobile personal protection system

- 3.2.2. System requirements

- 3.3. Safety

- 3.3.1. Safety instructions

- 3.3.2. Legal basis

- 3.3.3. Intended use

- 3.4. Functionality of the personal protection system

- 3.4.1. General

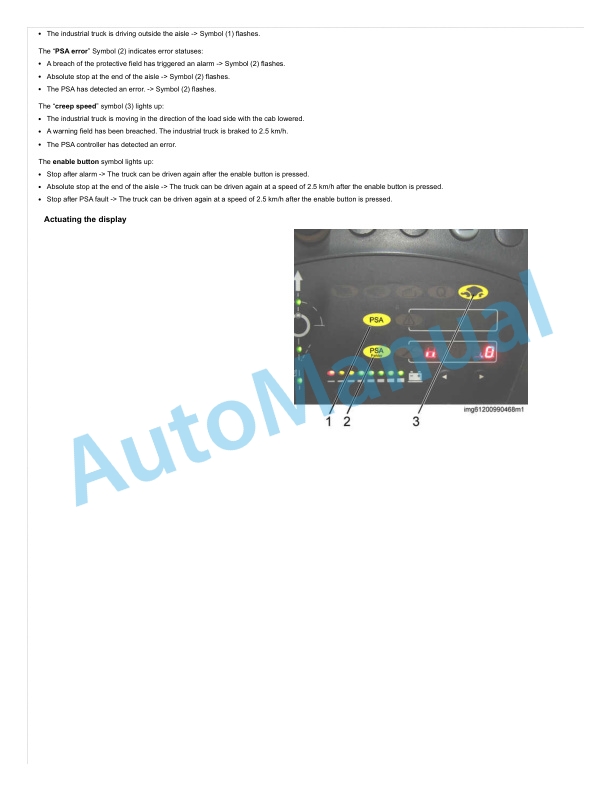

- 3.4.2. Alarms and errors

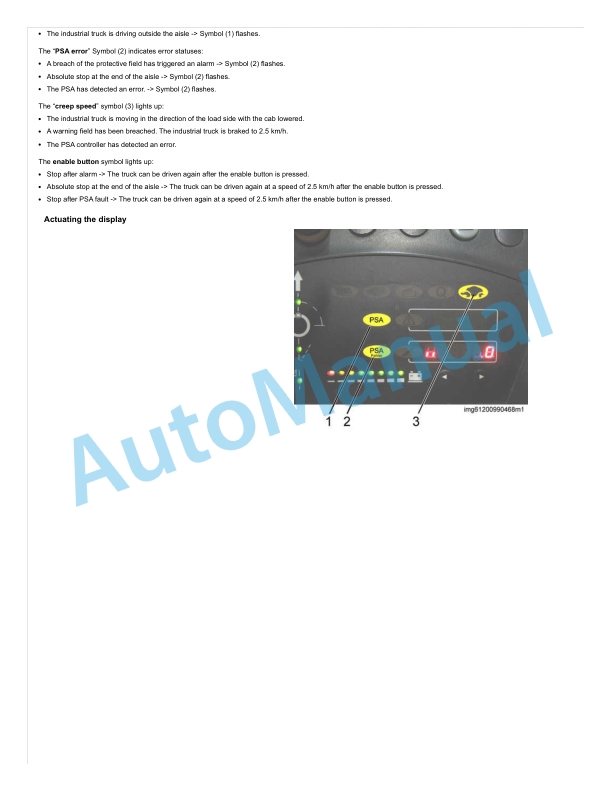

- 3.4.3. Operating status display

- 3.4.4. Position detection

- 3.5. Software

- 3.5.1. Diagnostic software

- 3.6. Commissioning

- 3.6.1. Commissioning

- 3.6.2. Setting the protective field

- 3.6.3. Required braking capabilities for group C industrial trucks

- 3.7. Maintenance

- 3.7.1. Maintenance

- 3.8. Periodic testing

- 3.8.1. Periodic testing

- 3.8.2. Test procedure

- 3.8.3. Test piece

- 3.9. Retrofitting

- 3.9.1. General

- 3.10. Appendix

- 3.10.1. Commissioning log

- 3.10.2. Maintenance schedule

- 3.10.3. Test log

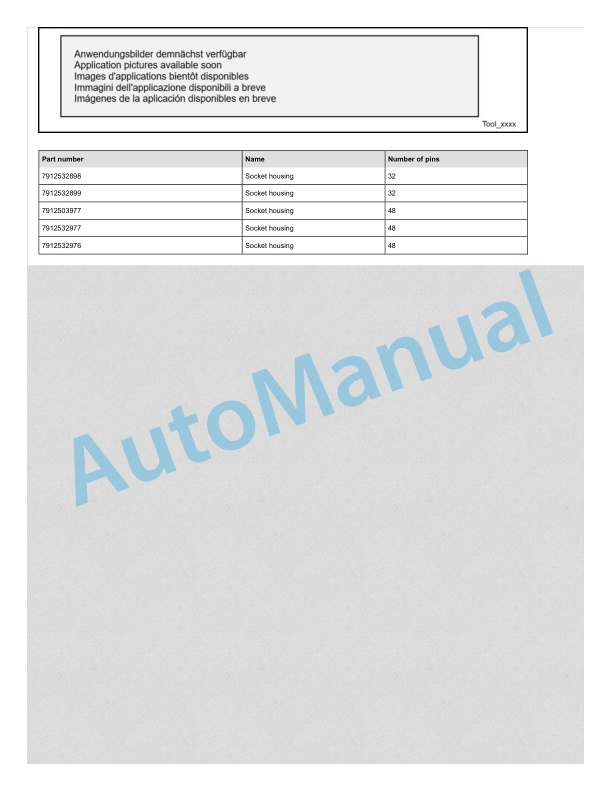

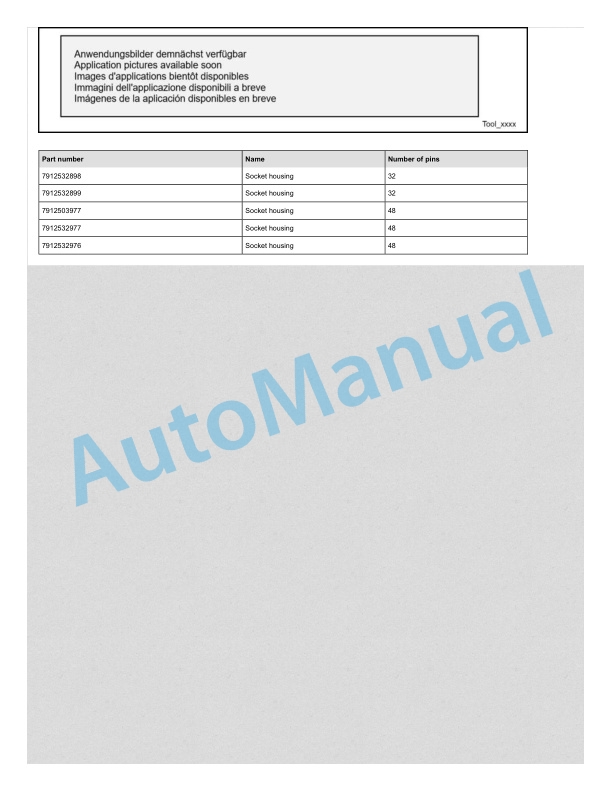

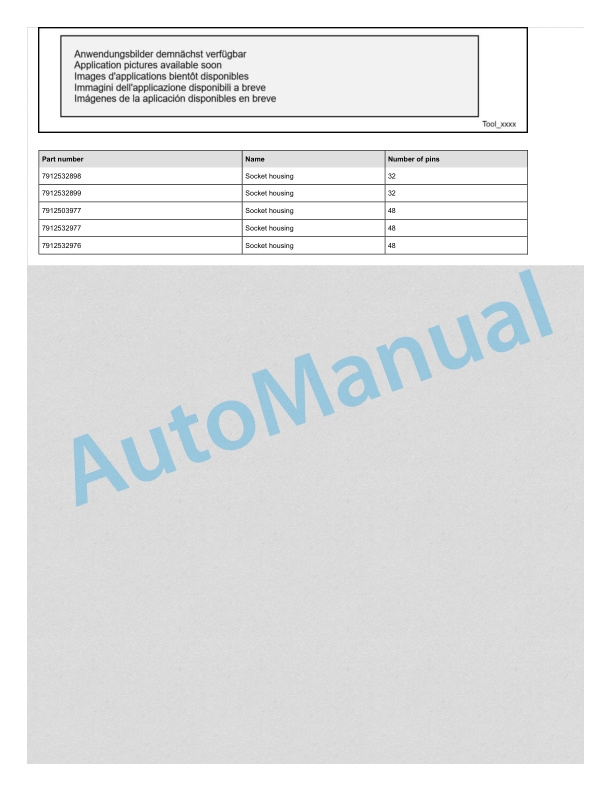

- 4. Service case Release tools for contacts

- 4.1. Table of content

- 4.2. Safety information

- 4.2.1. Safety information for repair and maintenance work

- 4.3. Information

- 4.3.1. Information

- 4.4. Overview

- 4.4.1. Overview of service cases

- 4.5. Plug systems

- 4.5.1. ATS 2.8 plug connector

- 4.5.2. CMC plug connector

- 4.5.3. DCS 9.5 plug connector

- 4.5.4. DIN 1.5mm circular connector

- 4.5.5. DIN 2.5mm circular connector

- 4.5.6. Deutsch DTM plug connector

- 4.5.7. ECU appliance plug

- 4.5.8. MCON appliance plug

- 4.5.9. Appliance plug with JPT and MQS contacts

- 4.5.10. Appliance plug with MT2 and JPT contacts

- 4.5.11. SICMA appliance plug

- 4.5.12. Econoseal JMark 2 plug connector

- 4.5.13. Elobau 11pin receptacle housing

- 4.5.14. E5931 plug connector

- 4.5.15. FASTINFASTON 6.3mm plug connector

- 4.5.16. GT150 plug connector

- 4.5.17. HDSCS plug connector

- 4.5.18. JPT plug connector

- 4.5.19. JPT SLD plug connector

- 4.5.20. JPT plug connector Saab

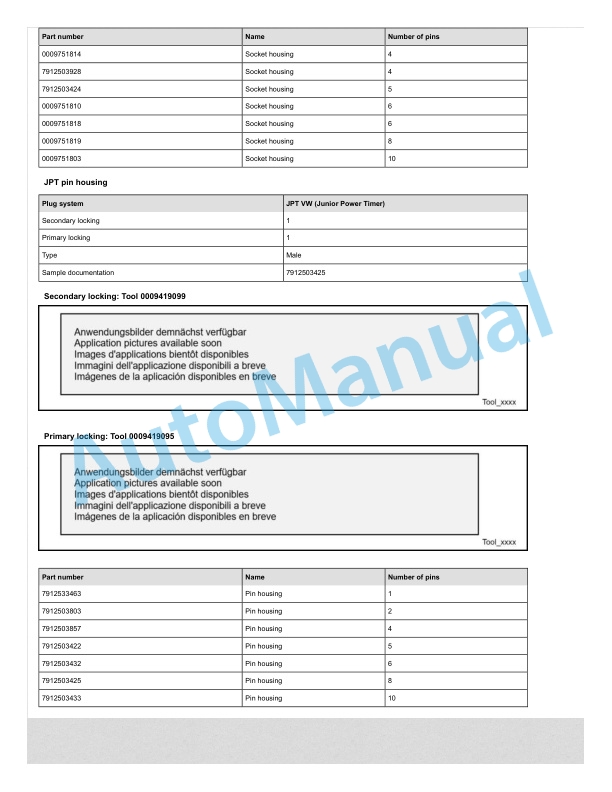

- 4.5.21. JPT plug connector VW

- 4.5.22. Kompakt 1.1 plug connector

- 4.5.23. Bosch Kompakt 4 plug connector

- 4.5.24. Leavyseal plug connector

- 4.5.25. MCON 1.2mm LL plug connector

- 4.5.26. MCON 1.2mm CB plug connector

- 4.5.27. MCP plug connector

- 4.5.28. MetriPack 150 plug connector

- 4.5.29. MiniFit plug connector

- 4.5.30. Mini Universal MATENLOK plug connector

- 4.5.31. Mini relay socket for DFK 1.3 and MDK 1.3

- 4.5.32. MKR Plus plug connector

- 4.5.33. MQS plug connector

- 4.5.34. MR plug connector

- 4.5.35. MTA plug housing and fuse housing

- 4.5.36. MT2 plug connector

- 4.5.37. MT2 1.5mm plug connector VW

- 4.5.38. Multilock plug connector

- 4.5.39. MX150 plug connector

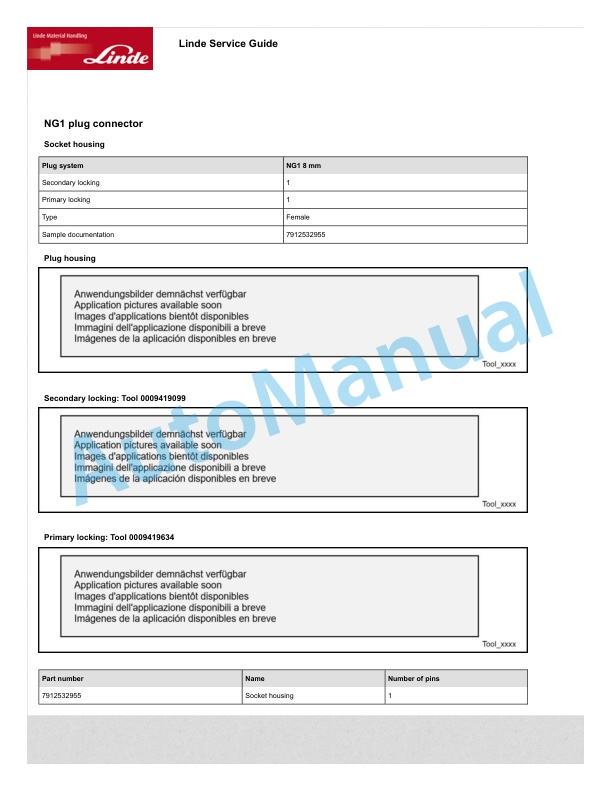

- 4.5.40. NG1 plug connector

- 4.5.41. Phönix Contact HC plug connector

- 4.5.42. PT 3F plug connector

- 4.5.43. Relay socket with SPT contacts for DFK 1.3.4 and MDK 1.3.4

- 4.5.44. Relay socket with SPT and MPT contacts

- 4.5.45. Fuse holder with SPT contacts

- 4.5.46. Sicma plug connector

- 4.5.47. SLK 2.8 plug connector

- 4.5.48. Souriau UTL7 plug connector

- 4.5.49. Superseal 1.5mm plug connector

- 4.5.50. Trident Neptune plug connector

- 4.5.51. Universal MATENLOK plug connector

- 4.5.52. VW 9.5mm plug connector

- 5. Highlevel order pickerV

- 5.1. Table of content

- 5.2. Service

- 5.2.1. Operating materials

- 5.2.2. Service software

- 5.2.3. Documentation

- 5.2.4. Teachin

- 5.3. Drive components

- 5.3.1. Traction motor

- 5.3.2. Wheel gear

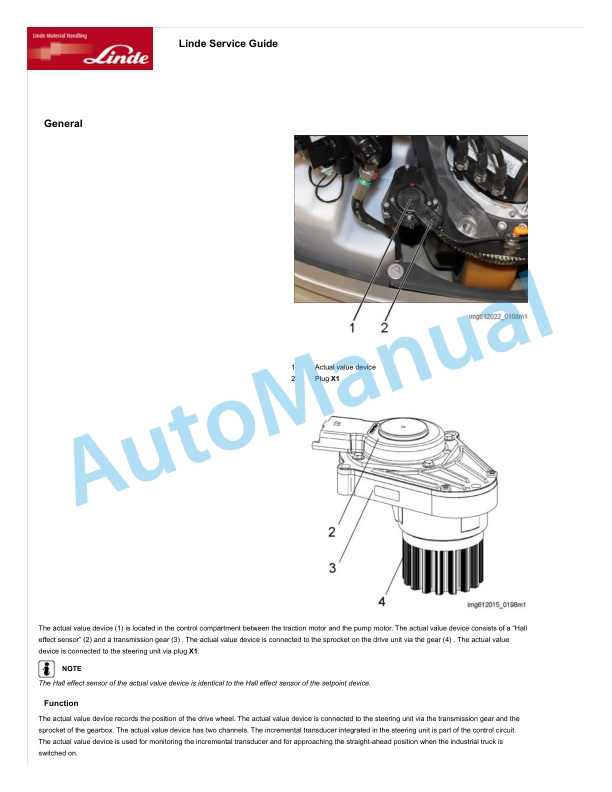

- 5.4. Steering system

- 5.4.1. Electric steering 3M1

- 5.5. Wheels and tyres

- 5.5.1. Wheels

- 5.6. Brake system

- 5.6.1. Service brake

- 5.6.2. Checking the brake system

- 5.6.3. Load wheel brake

- 5.6.4. Parking brake

- 5.6.5. End of aisle automatic braking (ZAG)

- 5.7. Mechanical guidance

- 5.7.1. Guide elements

- 5.7.2. Aisle detection

- 5.8. Inductive guidance

- 5.8.1. Inductive guidance in general

- 5.8.2. Central unit

- 5.8.3. Peripherals

- 5.8.4. Aisle detection

- 5.9. Drivers compartment

- 5.9.1. Tilting order picking barrier

- 5.10. Operating units

- 5.10.1. Operating panel

- 5.11. Display elements

- 5.11.1. Displayoperating unit

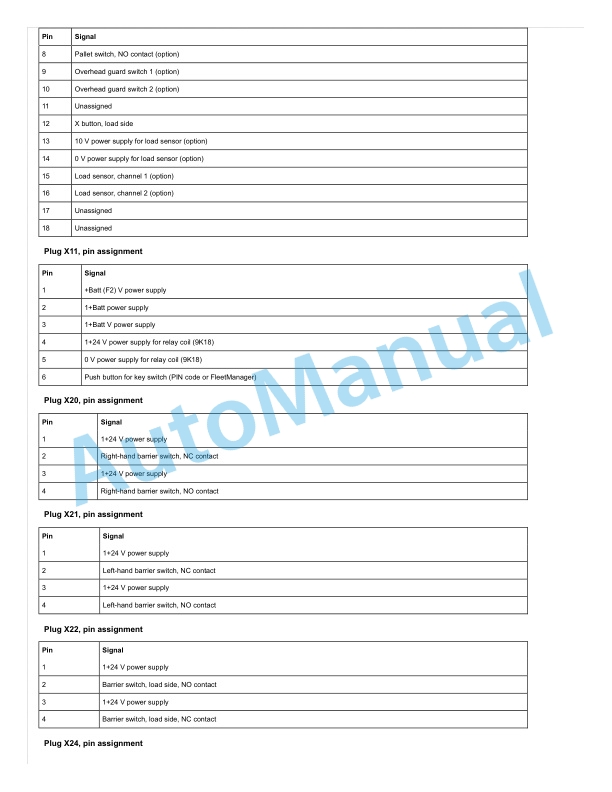

- 5.12. Wiring

- 5.12.1. Mast cable

- 5.12.2. Chassis plug retaining plate

- 5.12.3. Cab plug retaining plate

- 5.12.4. CAN bus

- 5.13. Electrics.electronics components

- 5.13.1. Transmitters and sensors

- 5.14. Control units

- 5.14.1. Truck control unit (FZS) 8U60

- 5.14.2. Converter

- 5.14.3. Auxiliary control units

- 5.15. Energy supply

- 5.15.1. Voltage transformer

- 5.15.2. Lithiumion technology

- 5.16. Assistance systems

- 5.16.1. PIN code access control

- 5.16.2. Other assistance systems

- 5.17. Basic and working hydraulics

- 5.17.1. Pumpmotor unit

- 5.17.2. Hydraulic pump

- 5.17.3. Oil tank

- 5.17.4. Hydraulic oil filter

- 5.17.5. Valve block

- 5.18. Cylinders

- 5.18.1. Lift cylinder

- 5.19. Lifting system

- 5.19.1. Installing and removing the lift mast

- 5.19.2. Telescopic mast

- 5.19.3. Triple mast

- 5.20. Assembly parts

- 5.20.1. Mast bracing

- 5.21. Suspension element

- 5.21.1. Chains

- 5.21.2. Chain monitoring switches

- 6. Workshop Manuals

- 6.1. Fault descriptionsInformation on the displayV

- 6.1.1. Table of content

- 6.1.2. Foreword

- 6.1.3. Information on the display

- 6.1.4. Fault descriptions

- 6.2. Linde mobile personal protection systemK 5231 seriesA 5224 seriesV 5213.5214 series

- 6.2.1. Table of content

- 6.2.2. Foreword

- 6.2.3. Safety

- 6.2.4. Functionality of the personal protection system

- 6.2.5. Software

- 6.2.6. Commissioning

- 6.2.7. Maintenance

- 6.2.8. Periodic testing

- 6.2.9. Retrofitting

- 6.2.10. Appendix

- 6.3. Service case Release tools for contacts

- 6.3.1. Table of content

- 6.3.2. Safety information

- 6.3.3. Information

- 6.3.4. Overview

- 6.3.5. Plug systems

- 6.4. Highlevel order pickerV

- 6.4.1. Table of content

- 6.4.2. Service

- 6.4.3. Drive components

- 6.4.4. Steering system

- 6.4.5. Wheels and tyres

- 6.4.6. Brake system

- 6.4.7. Mechanical guidance

- 6.4.8. Inductive guidance

- 6.4.9. Drivers compartment

- 6.4.10. Operating units

- 6.4.11. Display elements

- 6.4.12. Wiring

- 6.4.13. Electrics.electronics components

- 6.4.14. Control units

- 6.4.15. Energy supply

- 6.4.16. Assistance systems

- 6.4.17. Basic and working hydraulics

- 6.4.18. Cylinders

- 6.4.19. Lifting system

- 6.4.20. Assembly parts

- 6.4.21. Suspension element

- 7. Maintenance schedule, 1000 hours2131_EKX, 2133_EKX

Rate this product

You may also like

Linde Workshop Manual PDF

$40.00