Linde 5224-01 – A Operating Instructions SN 615224Y00001 and up

$20.00

- Type Of Manual: Operating Instructions

- Manual ID: SN 615224Y00001 and up

- Format: PDF

- Size: 21.8MB

- Number of Pages: 188

- Serial Number:

SN 615224Y00001 and up

-

Model List:

- A

- 1. LINDE mobile personal protection system5213_V, 5214_V, 5224_A, 5231_K

- 1.1. Table of content

- 1.2. Foreword

- 1.2.1. Legal basis

- 1.2.2. Directive and standards

- 1.2.3. Mode of operation, safety category

- 1.3. Safety

- 1.3.1. Safety instructions

- 1.3.2. Target group of this document

- 1.4. Overview

- 1.4.1. Description

- 1.4.2. Area of application of the MPSE

- 1.4.3. General

- 1.5. Operation

- 1.5.1. Displays

- 1.5.2. Operating status display

- 1.5.3. Error messages

- 1.5.4. Scanner status display

- 1.5.5. Safety laser scanner

- 1.5.6. Emergency operation

- 1.6. Regular care and maintenance

- 1.6.1. Daily visual inspection and function checking

- 1.6.2. Regular care and maintenanceRegular testing

- 1.6.3. Regular care

- 1.6.4. Maintenance schedule, 1000 hours

- 1.6.5. Periodic testing

- 2. Turret truckA

- 2.1. Table of content

- 2.2. Foreword

- 2.2.1. Linde Material Handling Your Partner

- 2.2.2. Rules for the operating company of industrial trucks

- 2.2.3. Conformity marking

- 2.2.4. Declaration that reflects the content of the declaration of conformity

- 2.2.5. General

- 2.2.6. Safety instructions

- 2.2.7. Nameplate

- 2.2.8. Operator,Form of address

- 2.2.9. Dimensions of the operators compartment

- 2.2.10. Product documentation

- 2.2.11. Accessories accompanying the product

- 2.2.12. Standard design and options Special version Special equipment

- 2.2.13. Copyright and proprietary rights

- 2.2.14. Storage and transfer

- 2.3. Safety

- 2.3.1. Working safely

- 2.3.2. Climbing into or out of the truck

- 2.3.3. Vibrations

- 2.3.4. Medical equipment, implants

- 2.3.5. Special safety advices for engaging loads

- 2.3.6. Safe handling of consumables

- 2.3.7. Safe handling of the battery cable

- 2.3.8. Risk assessment

- 2.3.9. Residual risks

- 2.3.10. Intended use

- 2.3.11. Regular testing

- 2.3.12. Area of application

- 2.3.13. Floor structure, cleaning

- 2.3.14. Narrowaisle trucks

- 2.3.15. Original parts

- 2.3.16. Directives and guidelines

- 2.3.17. Drivers licence

- 2.3.18. Overhead guard

- 2.3.19. Alterations to industrial trucks

- 2.3.20. Personal protective equipment

- 2.3.21. Conversion, retrofitting, rebuilding

- 2.4. Overview

- 2.4.1. View of the truck

- 2.4.2. Functions

- 2.4.3. Joystick functions

- 2.4.4. Standard labelling

- 2.4.5. Labelling for options

- 2.4.6. Turret head attachment

- 2.5. Operation

- 2.5.1. General commissioning

- 2.5.1.1. Initial commissioning

- 2.5.1.2. Transporting and loading

- 2.5.1.3. Wheel screws

- 2.5.1.4. Support screws

- 2.5.1.5. Weights of the units

- 2.5.1.6. Mast bracing

- 2.5.1.7. Safe handling of the traction battery

- 2.5.1.8. Traction battery

- 2.5.1.9. Permitted batteries

- 2.5.1.10. Battery commissioning

- 2.5.1.11. Battery lock

- 2.5.1.12. Lithiumion battery socket

- 2.5.2. Daily commissioning

- 2.5.2.1. Preshift checklist

- 2.5.3. Operating devices

- 2.5.3.1. Climbing into or out of the truck

- 2.5.3.2. Entering and leaving

- 2.5.3.3. Drivers seat, seat switch

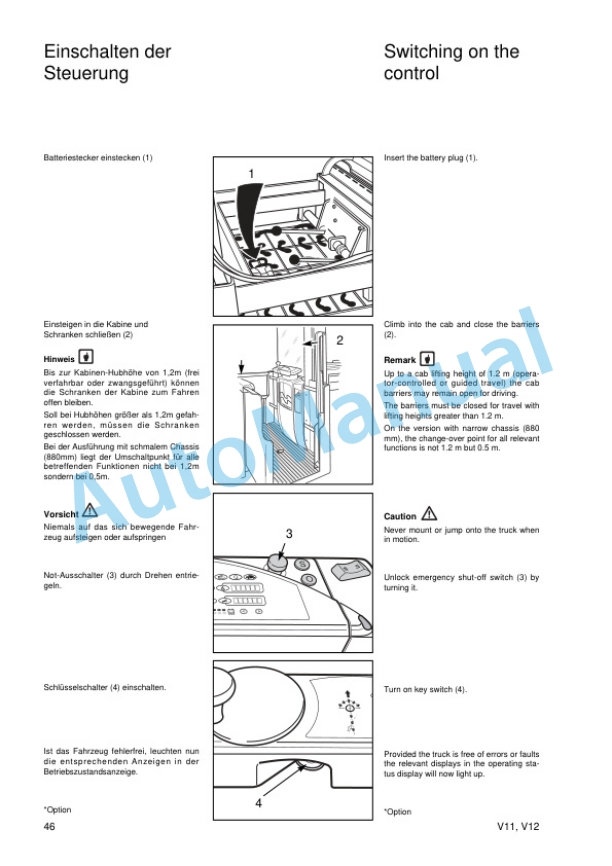

- 2.5.4. Switching on the controller

- 2.5.5. Initial driving exercises

- 2.5.6. Operating the display

- 2.5.7. Display, basic information

- 2.5.8. Operating the display, functions

- 2.5.9. Operating instructions for the display

- 2.5.10. Displays

- 2.5.11. Driving

- 2.5.11.1. Accelerator pedal

- 2.5.11.2. Adjusting the steering column

- 2.5.11.3. Types of guidance

- 2.5.11.4. Mechanical guidance MZF

- 2.5.12. Load pick up

- 2.5.12.1. Picking up a load

- 2.5.12.2. Fork arms, adjustable

- 2.5.13. Emergency operation

- 2.5.13.1. Emergency operation

- 2.5.13.2. Retrieving the truck

- 2.5.14. Parking, decommissioning

- 2.5.14.1. Parking and leaving the industrial truck

- 2.5.14.2. Decommissioning

- 2.6. Regular care and maintenance

- 2.6.1. Regular care and maintenance

- 2.6.2. Special versions, special equipment

- 2.6.3. Regular maintenance

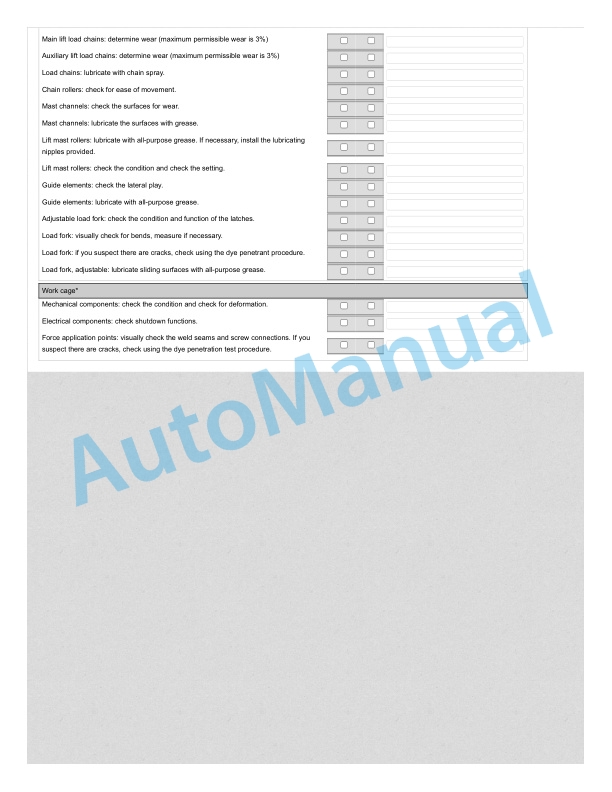

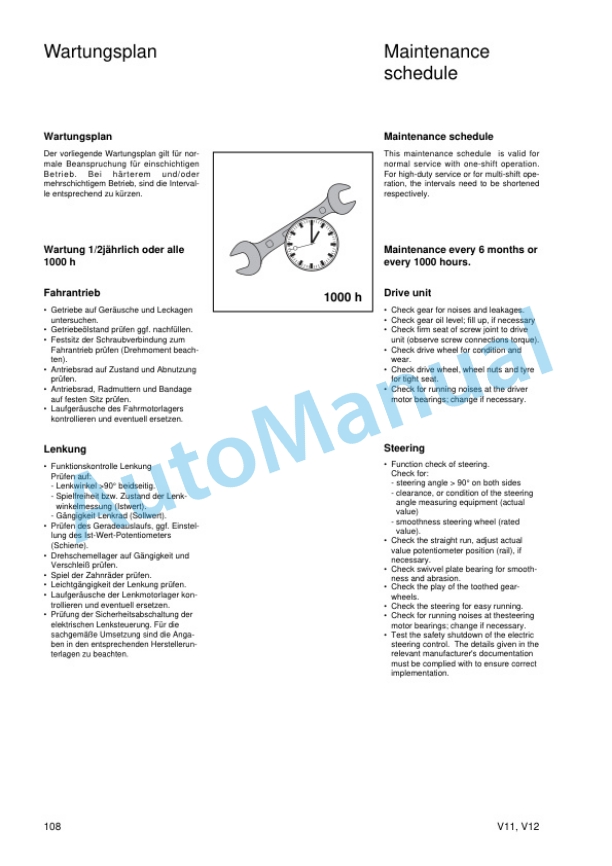

- 2.6.4. Maintenance schedule, 1000 hours

- 2.6.5. hour maintenance schedule

- 2.6.6. Lubricants

- 2.6.7. Fuses

- 2.7. Technical data

- 2.7.1. Ecodesign requirements for electric motors and variable speed drives

- 2.7.2. Technical data

- 2.8. Options

- 2.8.1. Overview of options

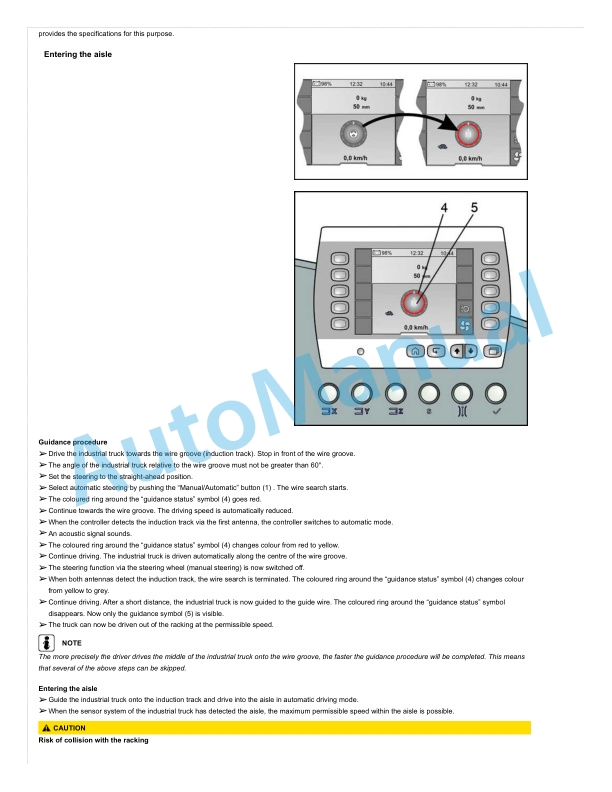

- 2.8.2. Inductive guidance IZF

- 2.8.3. Automatic braking systems

- 2.8.4. Camera system

- 2.8.5. Acoustic warning signal

- 2.8.6. Intermediate lift cutout

- 2.8.7. Traction cutout

- 2.8.8. Dualpedal version

- 2.8.9. Personal protection systemLINDE PSA

- 2.8.10. Personal protection system (MPSE)

- 2.8.11. Safety laser scanner

- 2.8.12. Personal protection system, preparation

- 2.8.13. Working platforms

- 2.8.14. Mirror

- 2.8.15. Working spotlights

- 2.8.16. Overhead guard cover

- 2.8.17. Telescopic table

- 2.8.18. Blue Spot safety headlight

- 2.8.19. Special equipment for cold store application

- 2.8.20. Electrical seat adjustment

- 2.8.21. USB charging station

- 2.8.22. Lift height preselection

- 2.8.23. Clipboard

- 2.8.24. MMS interface

- 2.8.25. Fork cycle

- 2.8.26. Hydraulic fork arm positioner

- 2.8.27. Other attachments

- 2.8.28. Attachments

- 2.8.29. Guard plates on rack rail

Linde Operator Manual PDF

Linde 1111-01 – N20VI, N20VLI Operating Instructions SN 10.09 and up SN up to W41111V00299

Linde Operator Manual PDF

Linde 1103-01 – ETR45 Production site LMH-NA Operating Instructions

Linde Operator Manual PDF

Linde Operator Manual PDF

Linde 033-01 – M25 EX Production site Proplan Operating Instructions

Linde Operator Manual PDF

Linde 1110-01 – N20C, N20VI, N20VLI, V08-01, V08-02 Operating Instructions SN W41110V00529 and up

Linde Operator Manual PDF

Linde 011-01 – K Generation 1 2, K Generation 3, K Generation 4 Operating Instructions

Linde Operator Manual PDF

Linde 1103-02 – ETR50 Production site LMH-NA Operating Instructions SN A11103V00001 and up

Linde Operator Manual PDF

Linde 1110-01 – V08-01, V08-02 Operating Instructions SN 11.09 and up SN up to W41110V00528