Claas ARES 836-816 RZ (A02) Tractor Repair Manual DE

$300.00

- Model: ARES 836-816 RZ (A02) Tractor

- Type Of Manual: Repair Manual

- Language: DE

- Format: PDF(s)

- Size: 178 MB

File List:

– Contents.pdf

– Chapter A0 – CHECKING PROCESS, INJECTION DATA SHEETS.pdf

– Chapter A00 – Overview.pdf

– Chapter A1 – SUPPLY INJECTION engine DPS 6068 HRT 70, engine DPS 6068 HRT 71, engine DPS 6068 HRT 72.pdf

– Chapter A2 – ENGINE TIER II – Engine DPS 6068 HRT 70, Engine DPS 6068 HRT 71, Engine DPS 6068 HRT 72.pdf

– Chapter B00 – Overview.pdf

– Chapter B1 – MANUAL TRANSMISSION GBA 10.pdf

– Chapter B2 – LOW PRESSURE HYDRAULIC CIRCUIT GTA 1040 AND GPA 30.pdf

– Chapter B3 – FULL POWERSHIFT TRANSMISSION GBA 31.pdf

– Chapter B4 – LOW PRESSURE HYDRAULIC CIRCUIT FULL-POWERSHIFT.pdf

– Chapter C00 – Overview.pdf

– Chapter C1 – REAR AXLE GPA 40.pdf

– Chapter C2 – REAR AXLE GPA 30 (The rear axle funnels GPA HD+ and HDE.pdf

– Chapter C3 – SERVICE BRAKE.pdf

– Chapter C4 – AUTOMATIC BRAKE, PARK-LOCK, HAND BRAKE.pdf

– Chapter D00 – Overview.pdf

– Chapter D1 – FRONT AXLE 20.29, 20.29-3, 20.43, 20.43-2.pdf

– Chapter D2 – FRONT AXLE PROACTIVE 20.43 SI, 20.43 SI-2, 20.43 SI-3.pdf

– Chapter D3 – DRIVE HOUSING FOR 4 DRIVE WHEELS GPA 30 AND GPA 40.pdf

– Chapter E00 – Overview.pdf

– Chapter E1 – CLOSED HYDRAULICS (110 l min) (except control circuit, see chapter B2 or B4).pdf

– Chapter E2 – CLOSED HYDRAULICS 100 l min.pdf

– Chapter F00 – Overview.pdf

– Chapter F1 – ELECTRICAL.pdf

– Chapter F2 – CABLE HARNESSES AND CONNECTORS.pdf

– Chapter G00 – Overview.pdf

– Chapter G1 – DASHBOARD.pdf

– Chapter G2 – ELECTRONIC HITCH TCE 15 25 AND TCE 15 T.pdf

– Chapter G3 – MANAGEMENT OF POWER TRANSMISSION AXLE.pdf

– Chapter G4 – ENGINE CONTROL.pdf

– Chapter G5 – INFOTRAC AND ISO CONNECTION.pdf

– Chapter G6 – ELECTROPILOT.pdf

– Chapter G7 – USER MANUAL WIN METADIAG ARES 806.pdf

– Chapter H00 – Overview.pdf

– Chapter H1 – RAISING THE CABIN.pdf

– Chapter H2 – HEATING AIR CONDITIONING.pdf

– Chapter H3 – GLUING THE DISCS.pdf

– Chapter J00 – Overview.pdf

– Chapter J1 – FRONT HITCH AND FRONT PTO.pdf

– Chapter J2 – PNEUMATIC BRAKE.pdf

– Chapter , standardized tightening torques.pdf

Contents.pdf

Table of Content:

1 MR 806 CONTENT

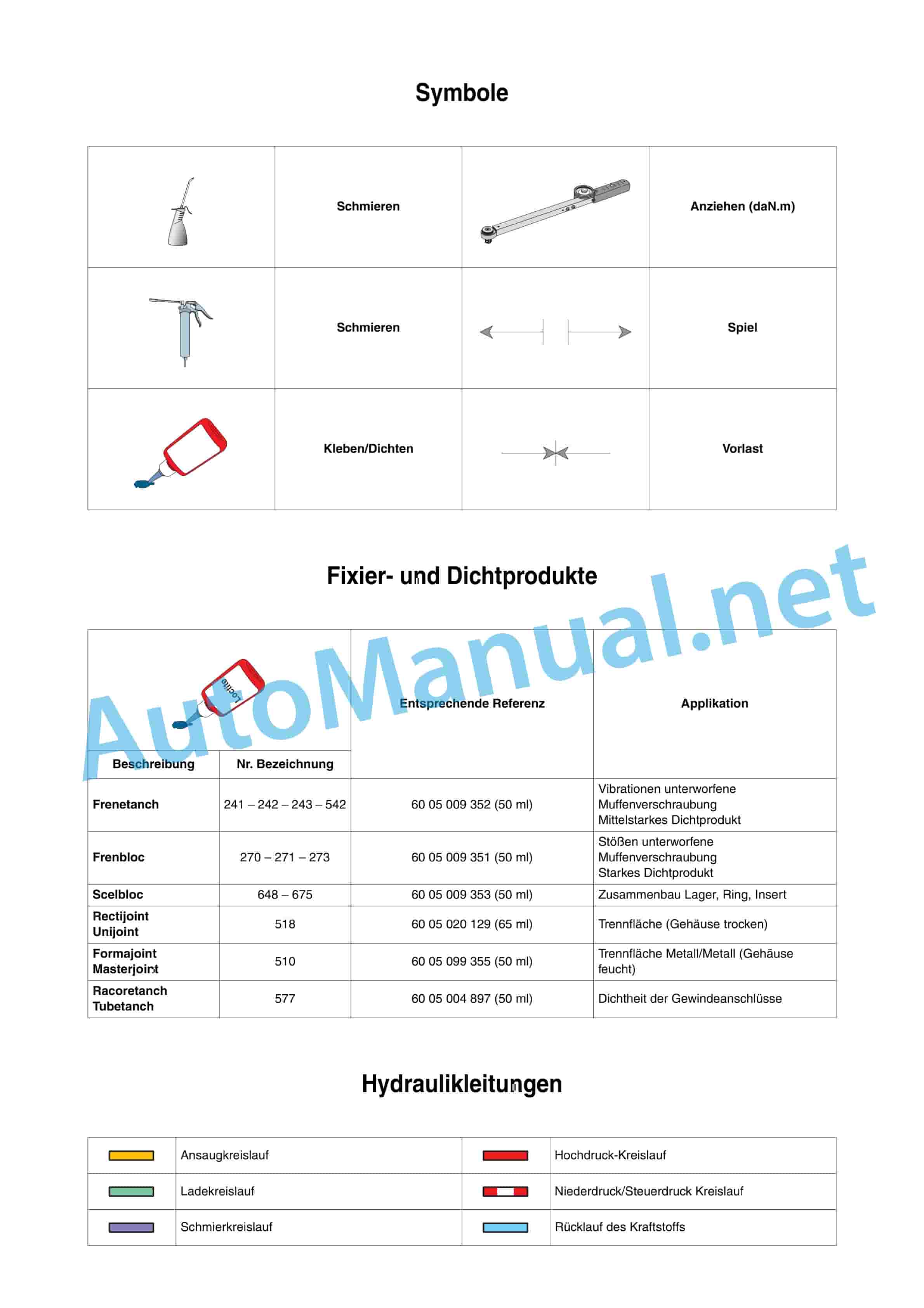

1.1 SYMBOLS

1.2 A0 CHECKING PROCESS INJECTION DATA SHEETS

1.3 A1 SUPPLY INJECTION

1.4 A2 ENGINE TIER II

1.5 B1 “PARK-LOCK”, HANDBRAKE

1.13 D1 FRONT AXLE

1.14 D2 FRONT AXLE PROACTIV

1.15 D3 DRIVE HOUSING FOR 4 DRIVE WHEELS GPA 30 AND GPA 40

1.16 E1 CLOSED HYDRAULICS (110 L/MIN)

1.17 E2 CLOSED HYDRAULICS (100 L/MIN)

1.18 F1 – ELECTRICAL

1.19 F2 – CABLE HARNESSES AND CONNECTORS

1.20 G1 DASHBOARD

1.21 G2 ELECTRONIC HITCH TCE 15/25″Point recording”

1.3 Print acceptance (appendix)

1.4 INJECTION DATA SHEET

2 MR 806 CONTENT

Chapter A00 – Overview.pdf

Table of Content:

1 A0 CHECKING PROCESS INJECTION DATA SHEETS

2 A1 SUPPLY INJECTION

3 A2 ENGINE TIER II

4 MR 806 CONTENTS

Chapter A1 – SUPPLY INJECTION Engine DPS 6068 HRT 70, Engine DPS 6068 HRT 71, Engine DPS 6068 HRT 72.pdf

Table of Content:

1 A1 SUPPLY INJECTION

1.1 Identifier

1.2 Tightening torques (DE 10)

1.3 Tightening torques (VP 44)

1.4 Functional principle

Chapter B00 – Overview.pdf

Table of Content:

1 B1 MANUAL TRANSMISSION GBA 10

2 B2 LOW PRESSURE HYDRAULIC CIRCUIT GTA 1 040 AND GPA 30

3 B3 GEARBOX GBA 31 FULL POWERSHIFT

4 B4 LOW PRESSURE HYDRAULIC CIRCUIT FULL-POWERSHIFT

5 MR 806 CONTENTS

Chapter B1 – MANUAL TRANSMISSION GBA 10.pdf

Table of Content:

1 B1 MANUAL TRANSMISSION GBA 10

1.1 General Specifications

1.2 Tightening torques

1.3 Main Settings

1.4 REVERSHIFT

1.5 front clutch

1.6 Rear clutch

1.7 Quadrishift gearbox

1.8 Switch housing cover

1.9 Guide rods

1.10 Output shaft

1.11 1.5 Measuring points and solenoid valve control

1.6 Measuring points and checking the distribution block GBA 10

1.7 Data sheet “Determination of control values” for hydraulics

1.8 Measuring points and checking lubrication GBA 10

1.9 Data sheet “Determination of control values” for hydraulics

1.10 Measuring points and control LS110 l/min

1.11 Data sheet “Determination of control values” for hydraulics

1.12 Measuring points and control LS100 l/min

1.13 Data sheet “Determination of control values” for hydraulics

2 MR 806 CONTENT

Chapter B3 – FULL POWERSHIFT TRANSMISSION GBA 31.pdf

Table of Content:

1 B3 GEARBOX GBA 31 FULL POWERSHIFT

1.1 General

1.2 Repair

2 MR 806 CONTENT

Chapter B4 – LOW PRESSURE HYDRAULIC CIRCUIT FULL-POWERSHIFT.pdf

Table of Content:

1 B4 LOW PRESSURE HYDRAULIC CIRCUIT FULL-POWERSHIFT

1.1 General

1.2 Overview

1.3 Repair

1.4 Measuring and control points

1.5 Data sheet ?”PARK-LOCK”, HANDBRAKE

5 MR 806 CONTENTS

Chapter C1 – REAR AXLE GPA 40.pdf

Table of Content:

1 C1 REAR AXLE GPA 40

1.1 Tightening torqu”

1.4 Rear axle funnel ND

1.5 Rear axle funnel HD et HD+

1.6 Rear axle funnel HDE

1.7 PTO shaft clutch GPA 40

1.8 Upper shaft PTO shaft GPA 40

1.9 Lower shaft PTO shaft GPA 40

1.10 Proportional PTO

2 MR 806 CONTENT

Chapter C2 – REAR AXLE GPA 30 (The rear axle funnels GPA HD+ and HDE.pdf

Table of Content:

1 C2 REAR AXLE GPA 30

1.1 Tightening”

1.4 PTO shaft clutch GPA 30

1.5 Upper shaft PTO shaftGPA 30

1.6 Lower shaft PTO shaft GPA 30

1.7 Creep speeds GPA 30

2 MR 806 CONTENT

Chapter C3 – SERVICE BRAKE.pdf

Table of Content:

1 C3 SERVICE BRAKE

1.1 Technical features

1.2 Brake pistons and seals

1.3 Amplifier and master cylinder

1.4 Replacing the master cylinders

1.5 Bleeding the brake circuit

2 MR 806 CONTENT

Chapter C4 – AUTOMATIC B”PARK-LOCK”, HANDBRAKE

1.1 Automatic brake

1.2 “Parking lock”

1.3 Handbrake

2 MR 806 CONTENT

Chapter D00 – Overview.pdf

Table of Content:

1 D1 FRONT AXLE

2 D2 FRONT AXLE PROACTIV

3 D3 DRIVE HOUSING FOR 4 DRIVE WHEELS GPA 30 AND GPA 40

4 MR 806 CONTENTS

Chapter D1 – FRONT AXLE 20.29, 20.29-3, 20.43, 20.43-2.pdfChapter D2 – FRONT AXLE PROACTIVE 20.43 SI, 20.43 SI-2, 20.43 SI-3.pdf

Table of Content:

1 D2 FRONT AXLE PROACTIV

1.1 Overview

1.2 Removal/reinstallation

1.3 Removal before intervention in the front axle

1.4 Removal/r”Determination of control values” for hydraulics

1.7 Electrical controls

1.8 Diagnosis in the event of malfunctions

2 MR 806 CONTENT

Chapter D3 – DRIVE HOUSING FOR 4 DRIVE WHEELS GPA 30 AND GPA 40.pdf

Table of Content:

1 D3 DRIVE HOUSING FOR 4 DRIVE WHEELS GPA 30 AND GPA 40

1.1 Overview

1.2 Removing/reinstalling the unit

1.3 Measuring points and controls of the “Determination of control values” for hydraulics

2 MR 806 CONTENT

Chapter E00 – Overview.pdf

Table of Content:

1 E1 CLOSED HYDRAULIC (110 L/MIN)

2 E2 CLOSED HYDRAULICS (100 L/MIN)

3 MR 806 CONTENT

Chapter E1 – CLOSED HYDRAULICS (110 l min) (except control circuit, see chapter B2 or B4).pdf

Table of Content:”Determination of control values” for hydraulics

1.5 Hydraulic measuring and control points

1.6 Data sheet “Determination of control values” for hydraulics

2 MR 806 CONTENT

Chapter E2 – CLOSED HYDRAULICS 100 l min.pdf

Table of Content:

1 E2 CLOSED HYDRAULIC (100 L/MIN)

1.1 Overview

1.2 Removal/reinstalla”Determination of control values” for hydraulics

1.5 Hydraulic measuring and control points

1.6 Data sheet “Determination of control values” for hydraulics

2 MR 806 CONTENT

Chapter F00 – Overview.pdf

Table of Content:

1 F1 – ELECTRICAL

2 F2 – CABLE HARNESSES AND CONNECTORS

3 MR 806 CONTENT

Chapter F1 – ELECTRICAL.pdf

Table of Content:

1 F1 – ELECTRICAL

1.1 FUSE BOX AND RELAY

1.2 CIRCUIT STARTING/LOAD/PRE-Glow DE10

1.3 CIRCUIT STARTING/LOAD/PRE-Glow VP44

1.4 LOW BEAM – HIGH BEAM – HORN – PARKING LIGHT – LIGHTING DASHBOARD

1.5 ALL-ROUND LIGHTS

1.6 WORK LIGHTS FRONT

1.7 REAR WORK LIGHTS

1.8 BRAKE LIGHT – ACTIVATE THE FRONT AXLE – OPERATION SOLENOID VALVE PNEUMATIC BRAKE

1.9 TURN SIGNAL AND HAZARD FLASHER

1.10 CIGAR LIGHTER – CLOCK – RADIO – CEILING LAMP AND SPOTLIGHT

1.11 AIR SUSPENSION SEAT – FRONT PTO CLUTCH

1.12 WIPER / WASHER FRONT AND REAR

1.13 VENTILATION DASHBOARD

1.14 VENTILATION DASHBOARD AND AIR CONDITIONING

1.15 ON-BOARD COMPUTER INFOTRAC / ISO-PLUG

1.16 FUEL LEVEL – ENGINE TEMPERATURE OIL PRESSURE – CLOGGED OIL FILTER

1.17 HANDBRAKE – BRAKE FLUID LEVEL

1.18 ENGINE SPEED

1.19 CALIBRATION DASHBOARD – DIAGNOSTIC CONNECTOR DASHBOARD AND TCE 15T

1.20 DIAGNOSTIC SOCKET ELECTROPILOT/DRIVETRONIC/GTA 103-202/GPA 40

1.21 DIAGNOSTIC CONNECTOR ELECTROPILOT/DRIVETRONIC/FPS

1.22 CONNECTOR 25 A

1.23 HYDRAULIC PRESSURE TRANSMISSION – CLOGGED OIL FILTER (HP) – CLOGGED OIL FILTER (SUCTION)

1.24 THEORETICAL SPEED

1.25 DASHBOARD – REAR PTO SPEED

1.26 POWER LIFT TCE 15T

1.27 ELECTROPILOT (WITH TCE 15T)

1.28 POWER LIFT TCE – 15/25/35 / RADAR

1.29 ELECTROPILOT (WITH TCE 15/25/35)

1.30 OPERATION CLUTCH AND FORWARD DRIVE GTA 103-202 – GPA 40

1.31 AUTOMATIC HANDBRAKE

1.32 OPERATION OF CLUTCH AND FORWARD DRIVE FPS

1.33 PARK LOCK FPS

1.34 QUADRISHIFT II

1.35 QUADRACTIV GTA 103-202 – GPA 40

1.36 QUADRACTIV FPS

1.37 ENGINE MANAGEMENT DE10

1.38 MANAGEMENT ENGINE VP44

1.39 SUSPENSION FRONT AXLE

1.40 SWITCHING ON FRONT AXLE – DIFFERENTIAL AND REAR PTO

1.41 SENSORS OIL TEMPERATURE – ENGINE SPEED – DRIVING SPEED – REAR PTO SPEED – SPEED SENSOR MODULE WS. – DRIVETRONIC

1.42 CROSS-WAY OPERATION WITH ELECTROPILOT

1.43 CROSS-WAY OPERATION

1.44 CAN NET DE10

1.45 CAN NET VP44

2 MR 806 CONTENT

Chapter F2 – CABLE HARNESSES AND CONNECTORS.pdf

Table of Content:

1 F2 – CABLE HARNESSES AND CONNECTORS

1.1 1 – Dashboard cable set

1.2 2 – Cable set for pre-glow control

1.3 3/1 – cable set motor front side

1.4 3/2a – cable set motor front side

1.5 3/2b – cable set injection

1.6 3/2c – cable set for operation injection

1.7 4 – Cable set for front axle suspension control

1.8 5 – Cable set dashboard / cabin upper part

1.9 5a – cable set cabin upper part / front headlights

1.10 5b – Cabin top cable set / rear headlight with air conditioning

1.11 5c – Front and rear headlight cable set

1.12 6 – Rear cable set

1.13 7a – Cable set gearbox closed circuit 110 liters

1.14 7b – Wiring harness gearbox closed circuit 100 liters

1.15 7c – Cable set connection gearbox GTA 303

1.16 7d – Cable set gearbox GTA 303

1.17 8a – Cable set for operation gearbox GTA 103/202 – GPA 40

1.18 8b – Cable set for transmission control Full-Powershift

1.19 8/1 – Cable set ISO socket

1.20 8/2 – cable set display Quadrishift 2/Quadractiv/Full-Powershift

1.21 9a – Cable set operation TCE 15/25/35

1.22 9b – Cable set for operation TCE 15T

1.23 9/1a – cable set TCE 15/25/35

1.24 9/1b – Cable set TCE 15T

1.25 9/2a – cable set cross lever with Electropilot

1.26 9/2b – cable set cross lever

1.27 9/3 – Cable set for electro-hydraulic control valves

1.28 10 – Cable set on-board computer

2 MR 806 CONTENT

Chapter G00 – Overview.pdf

Table of Content:

1 G1 DASHBOARD

2 G2 ELECTRONIC HITCH TCE 15/25 AND TCE 15 T

3 G3 t 6 CONTENT

Chapter G1 – DASHBOARD.pdf

Table of Content:

1 G1 DASHBOARD

1.1 Functional principle

1.2 Technical data

1.3 Removal/reinstallation

1.4 Calibration

2 MR 806 CONTENT

Chapter G2 – ELECTRONIC POWER LIFT TCE 15 25 AND TCE 15 T.pdf

Table of Content:

1 G2 ELECTRONIC HITCH TCE 15/25 AND TCE 15 T

1.1 Overview

1.2 Controls and Settings

2 MR 806 CONTENT

Chapter G3 – MANAGEMENT OF POWER TRANSMISSION AXLE.pdf

Table of Content:

1 G3 POWER TRANSMISSION MANAGEMENT/AXLE

1.1 Drivetronic III

1.2 Drivetronic V

1.3 Full Powershift

2 MR 806 CONTENT

Chapter G4 – ENGINE CONTROL.pdf

Table of Content:

1 G4 MOTontent:

1 G6 ELECTROPILOT

1.1 Overview

“Recording of control values”

2 MR 806 CONTENT

Chapter G7 – USER MANUAL WIN METADIAG ARES 806.pdf

Table of Content:

1 G7 USER MANUAL WIN METADIAG ARES 806

1.1 Connecting Win Mtadiag

1.2 Application Motor

1.3 Application gearbox

1.4 Application rear axle

1.5 Application rear PTO shaft

1.6 Application Dashboard

1.7 Application Electropilot

2 MR 806 CONTENT

Chapter H00 – Overview.pdf

Table of Content:

1 H1 CAB LIFT

2 H2 HEATING/AIR CONDITIONING

Chapter H3 – GLUING THE DISCS.pdf

Table of Content:

1 H3 GLUING THE DISCS

1.1 Removal/reinstallation

2 MR 806 CONTENT

Chapter J00 – Overview.pdf

Table of Content:

1 J1 FRONT HITCH AND FRONT PTO

2 J2 ?”Determination of control values”

1.4 Front PTO

1.5 Measuring and control points

1.6 Data sheet “Determination of control values”

2 MR 806 CONTENT

Chapter J2 – PNEUMATIC BRAKE.pdf

Table of Content:

1 J2 PNEUMATIC BRAKE

1.1 How it works

1.2 Main components

2 MR 806 CONTENT

Chapter symbols, fixing and sealing products, hydraulic lines, standardi

4.9/5 - (376 votes)

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11