Claas Talos 130-120 (A38) Tractors Repair Manual EN

$300.00

- Model: Talos 130-120 (A38) Tractors

- Type Of Manual: Repair Manual

- Language: EN

- Format: PDF(s)

- Size: 78.3 MB

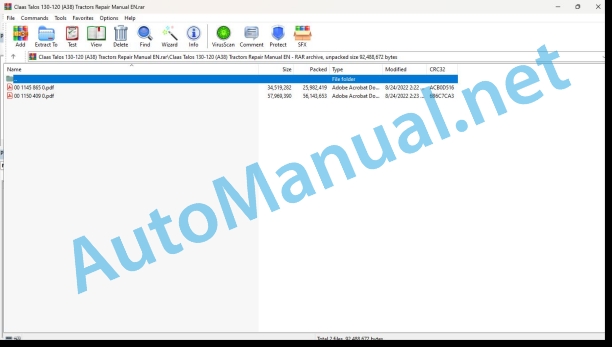

File List:

00 1145 865 0.pdf

00 1150 409 0.pdf

00 1145 865 0.pdf:

TALOS 130-120

Table of contents

Introduction

General Information

Using the repair manual

Scope of the repair manual

General repair instructions

Technical specifications

Cause of damage

Spare parts

Diesel engine

Generator

Welding work

Drive belt/drive chains

Tapered ring assemblies

Self-locking bolts with microencapsulated glue

Threadlock

Lock collar bearing

Collet bearing

Screwed unions with cutting rings on the hydraulic pipes

Progressive ring bolt connectors on hydraulic pipes

Double flare unions screwed onto the hydraulic pipes

Flexible hydraulic hoses

Advice for economical repairs

Torque settings

Standardised tightening torques for metric threaded screws

Tightening torques for DIN 3865 hydraulic unions

Technical specifications

Lubricants

CCN explanation

CCN (CLAAS Component Number)

Electric system standard

Overview

Hydraulic system standard

Overview

CCN Index

General Information

Important note

Identification of warning and danger signs

General Safety and Accident Prevention Regulations

Leaving the machine

Adjusting and maintenance work

Risk of injury through hydraulic liquid

Air conditioner

Hydraulic accumulators

First aid measures

Battery isolating switch

Jacking up the machine

Putting the machine out of operation

01 Engine

0102 Complete component

Introduction

General points

TALOS 120 engine (type S4Q) – Overview

TALOS 130 engine (type S4Q-T) – Overview

Location of the engine serial number

Technical specifications

General instructions

Special tool

Determining when to service the engine

Compression measurement

Precautions for removal and refitting

Fitting oil seals, O-rings and bearings

Tests and adjustments

Dynamometer test (running in)

Maintenance standards

Cylinder block

Cylinder head

Main rotating parts

Timing pinions

Lubrication system

Cooling system

Fuel supply

Electrical system

Tightening torques

Thread sealants

0110 Engine housing

Separating the engine from the clutch housing

Flywheel

Special tool

General view

Inspection

Refitting

0115 Engine unit

Removing the timing pinions, camshaft, balancer shafts and sump

Overview of the assembly

Removing the crankshaft pulley

Removing the timing cover

Checking the clearance between the teeth

Checking the intermediate pinion axial play

Removing the intermediate pinion

Checking the camshaft axial play

Removing the sump and the gasket

Removing the balancer shafts

Removing the oil pump

Removing the camshaft

Removing the front plate

Inspecting the timing pinions, camshaft, balancer shafts and sump

Special tools

Crankshaft pulley

Intermediate pinion

Camshaft

Refitting the timing pinions, camshaft, balancer shafts and sump

Fitting the front plate

Fitting the camshaft

Fitting the oil pump

Fitting the balancer shafts

Fitting the sump

Fitting the intermediate pinion

Checking the clearance between the teeth on the timing pinions

Fitting the oil seal

Fitting the timing cover

Refitting the crankshaft pulley

Removing the pistons, connecting rods, crankshaft and cylinder block

Overview of the assembly

Checking the end clearance of the big end

Removing the connecting rod caps

Removing the pistons

Removing the piston rings

Removing the piston pins

Checking the crankshaft axial play

Removing the main bearing caps

Removing the crankshaft

Inspecting the pistons, connecting rods, crankshaft and cylinder block

Pistons, rings and pins

Checking the connecting rods

Crankshaft

Cylinder block

Pushrods

Refitting the pistons, connecting rods, crankshaft and cylinder block

Special tool

Fitting the pushrods

Fitting the crankshaft

Refitting the piston pins

Refitting the piston rings

Refitting the pistons

Fault finding

Faults and solutions

0120 Cylinder head / Valves / Idler gear

Removing the cylinder head and the valve mechanism

Overview of the assembly

Removing the rocker arm shaft

Removing the rocker arm shaft

Removing the cylinder head

Removing the valves and valve springs

Removing the valve stem seals

Cleaning the cylinder head

Measuring the piston protrusion

Inspecting the cylinder head and the valve mechanism

Special tools

Cylinder head

Rocker arms and rocker arm shaft

Valve springs

Pushrods

Valves, valve guides and valve seats

Replacing the injectors

Refitting the cylinder head and the valve mechanism

Special tool

Fitting the valve stem seals

Fitting the valves and valve springs

Refitting the cylinder head

Refitting the rocker arms and rocker arm shaft

Adjusting the valve clearance

Special tool

Fault finding

Faults and solutions

0125 Injection – / Fuel system

Injection and fuel supply system – General information

Fuel filter (paper cartridge type)

Removal and inspection

Priming the supply system

Fuel filter

Injection pump (turbulence chamber type)

Removing the injection and fuel supply system

Disconnecting the fuel pipes

Removing the injectors

Removing the injection pump

Injection advance

Injection advance setting methods

Checking the injection advance

Setting the injection advance

Injectors

Removing

Refitting

Fault finding

Faults and solutions

0130 Lubricating oil system

Lubrication system – General information

Oil pump

Removing

Inspection

Refitting

Oil filter

Inspection

Discharge valve

Inspection

Fault finding

Faults and solutions

0135 Cooling system

Cooling system – General information

Water pump

Inspection

Thermostat

Fault finding

Faults and solutions

0145 Air intake

Air intake system

General points

Removal, inspection and refitting

Fault finding

Turbocharger

General points

Engine troubleshooting

Faults and solutions

Checks to be carried out according to the symptoms observed

0190 Accessories

Electric starting motor

Removing

Inspection

Refitting

Inspection and test after refitting

Alternator

Removing

Inspection

Refitting

Glow plugs

Inspection

Fault finding

02 Gearbox / Clutch / Universal drive shaft

0202 Complete component

Transmission general view

Removing/refitting the transmission

Transmission inspection

Faults and solutions

Separating the clutch housing from the central housing

Separating the central housing from the rear axle housing

0215 Mechanical clutch

Clutch inspection and repair

Special tools

Clutch operation

Specifications

Clutch cross-sectional view

Clutch disc / Sleeve assembly

Inspection and solutions

Separating the clutch and sleeve

Clutch disc inspection

Inspecting the pressure plate

Refitting the clutch and sleeve

Removing the clutch release fork and bearing

Refitting the clutch release bearing

0218 Clutch control

Checking the clutch pedal setting

0220 Mechanical reverser

Direction reversal system

Clutch housing (direction reverser) – Cross- sectional view

Clutch housing components (direction reverser)

Direction reverser operation

Removing the direction reverser system

0228 Reverser control

Direction reversal system

Forward/reverse gear fork shaft

0230 Mechanical gearbox

Main transmission system

Removing the gearbox

Range box

Cross-sectional view

Removing the range (components)

0238 Gearbox control

Gear lever operation

Inspecting the synchros

Gearbox synchro drive train

Range box

Range lever operation

Drive train

0240 Rear axle housing

Repairing the rear axle housing

Rear axle housing – Cross-sectional view

Removing the brakes

Axle tube – Cross-sectional view

Removing the final drives

Refitting the rear axle

0242 Differential

Rear differential locking system

Special tools

Rear differential lock – Cross-sectional view

Rear differential lock

Removing the differential lock fork

Differential drive pinion shaft – Cross-sectional view

Removing the drive pinion shaft

Refitting the drive pinion shaft

Setting the clearance between the teeth and the drag torque

0252 Electro-hydraulical front axle drive

4-wheel drive transmission

4-wheel drive transmission – Cross-sectional views

4-wheel drive transmission operation

Removing the 4-wheel drive transmission

03 Chassis

0325 Driven steering axle, front

Front axle – General view

Repairing the front axle

Wheel hub – Exploded view

Repairing the wheel hub and pivot

Removing / Refitting the front axle

Removing the steering cylinder

Removing the steering rod

Removing the wheel reduction gear

Removing the wheel shafts

Removing the front axle differential

Refitting the front axle differential

Adjusting the drive pinion and front axle differential

Drive pinion and front axle differential – Cross- sectional view

Calibrating the drive pinion

04 Brake

0405 Service brake

Brake system

Brake system – Cross-sectional view

Operation

Removing the brakes and rear differential

0415 Parking brake

Handbrake

Handbrake operation

05 Steering

0505 Steering

Steering

Hydrostatic steering system

Faults and solutions

Removing the steering gearbox

Refitting the steering gearbox

06 Lift device

0605 Rear power lift

Rear hydraulic lifting system

Linkage cover – Cross-sectional view

Hydraulic linkage control valve block

Cross-sectional view

Arm neutral phase

Arm lifting phase

Arm lowering phase

Tightening torques

Lowering speed adjustment valve and cylinder safety valve

Removing the linkage cover

Removing the linkage

Adjusting the lifting rods

Faults and solutions

08 Drives

0802 Rear PTO

Power take-off

Power take-off (3 speeds) – Cross-sectional view

Power take-off control

Removing the power take-off

09 Hydraulic system

0915 Hydraulic lines

Description of the hydraulic system

Special tools

Hydraulic circuit components

Hydraulic system diagram

Low pressure circuit

Independent power take-off control

Independent power take-off clutch – Cross- sectional view

0920 Valves

Auxiliary spool valves

Auxiliary spool valve control levers

Front electrohydraulic block

Front pressure outlet

Front electrohydraulic block

10 Electrical / Electronic equipment

1015 Wiring harnesses

Key for function diagrams and installation diagrams

Special tools

List of connectors

Harness identification

Harness 1: Engine harness

Engine, front section

Harness 2: Cover

Front lighting

Harnesses 3 and 4: Front section and dashboard harnesses

Front section and dashboard harnesses – Cab version

Front section and dashboard harnesses – Platform version

Harness 5: Under cab / Platform

Under cab harness

Platform harness

Harness 6: Cab

Air conditioning

1080 Electronic circuit diagram

Key for function diagrams and installation diagrams

Special tools

Stopping the engine

Pre-heating

Alternator, Battery

Power take-off

Indicator lights

Lighting

Fuel gauge

Coolant temperature and oil pressure warning lights

Air conditioning

Washer/Wiper

12 Cab / Operator’s platform

1210 Cab

Separating the cab

00 1150 409 0.pdf:

TALOS 130-120

Table of contents

Introduction

General Information

Using this repair manual

Scope of the repair manual

General repair instructions

Technical specifications

Cause of damage

Spare parts

Diesel engine

Generator

Welding work

Drive belt/drive chains

Tapered ring assemblies

Self-locking bolts with microencapsulated glue

Threadlock

Lock collar bearing

Collet bearing

Screwed unions with cutting rings on the hydraulic pipes

Progressive ring bolt connectors on hydraulic pipes

Double flare unions screwed onto the hydraulic pipes

Flexible hydraulic hoses

Advice for economical repairs

Torque settings

Tightening torques for NF E25-030-1 2007-12-01 standard metric threads

Technical specifications

Lubricants

CCN explanation

CCN (CLAAS Component Number)

Electric systems standard

Overview

Hydraulic system standard

Overview

General Information

Of special importance

Identification of warning and danger signs

General safety and accident prevention regulations

Leaving the machine

Adjustment and maintenance operations

Risk of injury from hydraulic fluid

Air conditioner

Hydraulic accumulators

First aid measures

Battery isolating switch

Jacking up the machine

Putting the machine out of operation

01 Engine

0102 Complete component

Introduction

General points

TALOS 120 engine (type S4Q) – Overview

TALOS 130 engine (type S4Q-T) – Overview

Location of the engine serial number

Engine model designation

Technical specifications

General instructions

Special tool

Determining when to service the engine

Compression measurements

Prerequisites

Compression

Precautions for removal and refitting

Refitting

Fitting lip seals, O-rings and bearings

Lip seals

Bearings

Tests and adjustments

Dynamometer test (running in)

Starting procedure

Inspection after starting the engine

Dynamometer test conditions

Inspection after running in

Maintenance standards

Cylinder block

Main bearings

Pushrod bores

Camshaft

Cylinder head

Valves and valve guides

Valve seats

Valve springs

Pushrods

Main rotating parts

Crankshaft

Piston rings

Piston pins

Connecting rods

Flywheel

Timing pinions

Camshaft

Intermediate pinions

Clearance between teeth

Balancer shafts

Lubrication system

Oil pump

Cooling system

Water pump

Thermostat

Fuel supply

Injectors

Electrical system

Electric starting motor

Alternator

Tightening torques

Thread sealants

0110 Engine housing

Separating the engine from the clutch housing

Flywheel

Special tool

General view

Removing the flywheel

Removing the rear cover

Inspection

Flywheel and crown wheel

Refitting

Fitting the rear cover lip seal

Fitting the rear cover

Fitting the flywheel

Checking the surface run out and the bore run out on the flywheel pilot bearing

0115 Engine unit

Removing the timing pinions, camshaft, balancer shafts and sump

Overview of the assembly

Removing the crankshaft pulley

Removing the timing cover

Checking the clearance between the teeth

Checking the intermediate pinion axial play

Removing the intermediate pinion

Checking the camshaft axial play

Removing the sump and the gasket

Removing the balancer shafts

Removing the oil pump

Removing the camshaft

Removing the front plate

Inspecting the timing pinions, camshaft, balancer shafts and sump

Special tools

Crankshaft pulley

Intermediate pinion

Checking the clearance between the intermediate pinion and the shaft

Replacing the intermediate pinion ring

Replacing the intermediate pinion shaft

Camshaft

Checking the cam lift height

Checking the clearance between the camshaft journal and the bore in the cylinder block (or ring)

Checking the deformation

Removing the camshaft pinion

Fitting the camshaft pinion and the stop plate

Checking the deformation of the balancer shafts

Replacing the balancer shaft bearings

Refitting the timing pinions, camshaft, balancer shafts and sump

Fitting the front plate

Fitting the camshaft

Fitting the oil pump

Fitting the balancer shafts

Fitting the sump

Fitting the intermediate pinion

Checking the clearance between the teeth on the timing pinions

Fitting the lip seal

Fitting the timing cover

Refitting the crankshaft pulley

Removing the pistons, connecting rods, crankshaft and cylinder block

Overview of the assembly

Checking the clearance of the big end

Maximum permissible average weight difference between all the connecting rods on the same engine

Removing the connecting rod caps

Removing the pistons

Removing the piston rings

Removing the piston pins

Checking the crankshaft axial play

Removing the main bearings

Removing the crankshaft

Inspecting the pistons, connecting rods, crankshaft and cylinder block

Pistons, rings and pins

Checking the piston diameter

Checking the pistons and piston rings

Checking the clearance between the ends of the piston rings

Checking the clearance between the piston pin and the bore

Checking the clearance between the connecting rod ring and the piston pin

Replacing the connecting rod rings

Checking the connecting rods

Crankshaft

Checking the lubrication clearance of the connecting rod bearing shells

Checking the lubrication clearance for the main bearings

Checking the rotating surface of the lip seal

Checking the run out

Removing the crankshaft pinion

Fitting the crankshaft pinion

Fitting the crankshaft balancer shaft drive pinion

Cylinder block

Checking the bores

Checking the top surface

Pushrods

Checking wear

Checking the clearance between the pushrod and the bore

Refitting the pistons, connecting rods, crankshaft and cylinder block

Special tool

Fitting the pushrods

Fitting the crankshaft

Refitting the piston pins

Refitting the piston rings

Refitting the pistons

Fault finding

Faults and solutions

0120 Cylinder head / Valves / Idler gear

Removing the cylinder head and the valve mechanism

Overview of the assembly

Removing the rocker arm shaft

Removing the rocker arm shaft

Removing the cylinder head

Removing the valves and valve springs

Removing the valve stem seals

Cleaning the cylinder head

Measuring the piston protrusion

Inspecting the cylinder head and the valve mechanism

Special tools

Cylinder head

Rocker arms and rocker arm shaft

Valve springs

Pushrods

Valves, valve guides and valve seats

Measuring the valve rods

Checking the clearance between the rods and the valve guides

Replacing the valve guides

Checking the valves

Replacing the valve seats

Rectifying the valves

Rectifying the valve seats

Grinding in the valves

Replacing the injectors

Refitting the cylinder head and the valve mechanism

Special tool

Fitting the valve stem seals

Fitting the valves and valve springs

Refitting the cylinder head

Tightening the cylinder head bolts

Refitting the rocker arms and rocker arm shaft

Fitting the pushrods

Refitting the rocker arm shaft

Adjusting the valve clearance

Special tool

Fault finding

Faults and solutions

0125 Injection – / Fuel system

Injection and fuel supply system – General information

Fuel filter (paper cartridge type)

Removal and inspection

Priming the supply system

Fuel filter

Injection pump (turbulence chamber type)

Removing the injection and fuel supply system

Disconnecting the fuel pipes

Removing the injectors

Removing the injection pump

Injection advance

Injection advance setting methods

Case 1: Fitting the engine on the assembly chain

Case 2: Replacing only the injection pump

Checking the injection advance

Setting the injection advance

Injectors

Removing

Injection pressure (valve opening pressure)

Dispersal pattern

Refitting

Refitting sequence:

Fault finding

Faults and solutions

0130 Lubricating oil system

Lubrication system – General information

Oil pump

Removing

Inspection

Clearance between the external rotor and the internal rotor

Clearance between the rotors and the cover

Clearance between the external rotor and the unit

Refitting

Oil filter

Inspection

Discharge valve

Inspection

Fault finding

Faults and solutions

0135 Cooling system

Cooling system – General information

Water pump

Inspection

Thermostat

Fault finding

Faults and solutions

0145 Air intake

Air intake system

General points

Removal, inspection and refitting

Fault finding

Faults and solutions

Turbocharger

General points

Common symptoms

Engine troubleshooting

Visual and mechanical checks

Checking the turbine wheel and housing

Checking the compressor wheel and housing

Checking the rotating assembly

Checking the turbocharging pressure limit valve

Faults and solutions

Checks to be carried out according to the symptoms observed

Before removal

During removal

After removal

0190 Accessories

Electric starting motor

Removing

Inspection

Armature

Field winding

Brush and brush holder

One-way clutch

Gearshaft end play

Refitting

Refitting sequence:

Inspection and test after refitting

Setting the pinion clearance

No-load test

Magnetic switch

Alternator

Disassembly

Inspection

Stator coil

Rectifier

Reassembling

Refitting sequence:

Holding the brushes when refitting the rotor

Glow plugs

Inspection

Fault finding

02 Gearbox / Clutch / Universal drive shaft

0202 Complete component

Transmission general view

Removing/refitting the transmission

Transmission inspection

Faults and solutions

Separating the clutch housing from the central housing

Separating the central housing from the rear axle housing

0215 Mechanical clutch

Clutch inspection and repair

Special tools

Clutch operation

Specifications

Clutch cross-sectional view

Clutch disc / Sleeve assembly

Inspection and solutions

Separating the clutch and sleeve

Clutch disc inspection

Inspecting the pressure plate

Refitting the clutch and sleeve

Removing the clutch release fork and bearing

Refitting the clutch release bearing

0218 Clutch control

0220 Mechanical reverser

Direction reversal system

Clutch housing (direction reverser) – Cross-sectional view

Clutch housing components (direction reverser)

Direction reverser operation

Removing the direction reverser system

0228 Reverser control

Direction reversal system

Forward/reverse gear fork shaft

0230 Mechanical gearbox

Main transmission system

Removing the gearbox

Range box

Cross-sectional view

Removing the range box (components)

0238 Gearbox control

Gear lever operation

Inspecting the synchros

Gearbox synchro drive train

1st gear drive

2nd gear drive

3rd gear drive

4th gear drive

Range box

Range lever operation

Drive train

1st range drive

2nd range drive

3rd range drive

4th range drive

0240 Rear axle housing

Repairing the rear axle housing

Rear axle housing – Cross-sectional view

Removing the brakes

Axle tube – Cross-sectional view

Removing the final drives

Reassembling the rear axle

0242 Differential

Rear differential locking system

Special tools

Rear differential lock – Cross-sectional view

Rear differential lock

Removing the differential lock fork

Differential drive pinion shaft – Cross-sectional view

Removing the drive pinion shaft

Refitting the drive pinion shaft

Setting the clearance between the teeth and the drag torque

0252 Electro-hydraulical front axle drive

4-wheel drive transmission

4-wheel drive transmission – Cross-sectional views

4-wheel drive transmission operation

Removing the 4-wheel drive transmission

03 Chassis

0325 Driven steering axle, front

Front axle – General view

Repairing the front axle

Wheel hub – Exploded view

Repairing the wheel hub and pivot

Removing / Refitting the front axle

Removing the steering cylinder

Removing the steering rod

Removing the wheel reduction gear

Removing the wheel shafts

Removing the front axle differential

Refitting the front axle differential

Adjusting the drive pinion and front axle differential

Drive pinion and front axle differential – Cross-sectional view

Setting the position of the drive pinion shaft

Preloading the drive pinion bearing

Clearance between the teeth on the drive pinion and the crown wheel

Calibrating the drive pinion

04 Brake

0405 Service brake

Brake system

Brake system – Cross-sectional view

Operation

Removing the brakes and rear differential

0415 Parking brake

Handbrake

Handbrake operation

05 Steering

0505 Steering

Steering

Hydrostatic steering system

Faults and solutions

Removing the steering gearbox

Refitting the steering gearbox

06 Lift device

0605 Rear power lift

Rear hydraulic lifting system

Linkage cover – Cross-sectional view

Description

Neutral position -> Arm raised

Arm raised -> Neutral position

Neutral position -> Arm lowered

Arm lowered -> Neutral position

Hydraulic linkage control valve block

Cross-sectional view

Arm neutral phase

Arm lifting phase

Arm lowering phase

Tightening torques

Lowering speed adjustment valve and cylinder safety valve

Removing the linkage cover

Removing the linkage

Adjusting the lifting rods

Faults and solutions

08 Drives

0802 Rear PTO

Power take-off

Power take-off (3 speeds) – Cross-sectional view

Power take-off control

Removing the power take-off

09 Hydraulic system

0915 Hydraulic lines

Description of the hydraulic system

Special tools

Hydraulic circuit components

Hydraulic system diagram

Low pressure circuit

Independent power take-off control

Independent power take-off clutch – Cross-sectional view

Power take-off disengagement (lubrication)

Engagement of the power take-off

0920 Valves

Auxiliary hydraulic control valves

Auxiliary hydraulic control valve control

Connections

Operation

Hydraulic circuit diagram

Fitting/removal

Front electrohydraulic block

Front pressure outlet

Front electrohydraulic block

Auxiliary spool valve

10 Electrical / Electronic equipment

1000 General electrical system

Electrical system – General points

Technical specifications

Special tools

Fault finding

Key for function diagrams and installation diagrams

Changing the bulbs

Front lights

Indicators and side lights

Rear lights

Front/rear work lights

Cab interior lighting

1005 Power supply

Starting safety switch

S064 Key-operated ignition

Y015 Engine stop solenoid valve

Engine stop relay

Starting relay

Preheating timer

Preheating relay

Fuse wire

R032 Cigarette lighter

S015 Daytime running lights switch

Cab supply relay

Flashing unit

Power take-off

S114 Rear power take-off on/off switch

Power take-off pressure warning relay

Automatic lift relay (optional)

1012 Modules / sensors

Terminal module A101

Tachometer

Running time counter

Fuel gauge

Coolant temperature

Engine sensors

B045 Coolant temperature sensor

B381 Fuel filter water sensor

R035 Fuel level resistor

Z042 Engine oil pressure switch

Transmission sensors

B123 Transmission fluid temperature sensor

B229 Gearbox speed intermediate sensor

B361 Clutch pedal sensor

Range sensor

Brake sensors

Z126 Left-hand brake pedal switchZ127 Right-hand brake pedal switch

Pedals uncoupled switch

Steering sensor

B117 Wheel angle sensor

B144 Force sensor

B334 Rear linkage position sensorB407 Working depth sensor

1015 Wiring harnesses

Harness identification

Harness 1: Engine harness

Engine, front section

Harness 2: Bonnet

Front lighting

Harnesses 3 and 4: Front section and dashboard harnesses

Cab version

Platform version

Harness 5

Under cab

Under platform

Harness 6 – Cab

Air conditioning

12 Cab / Operator’s platform

1210 Cab

Removing the cab

Removing the fuel tanks

Draining the tanks

Right-hand side of engine

Left-hand side of engine

Left-hand section

Right-hand section

Right-hand console

Refitting

Rear wiper motor

Refitting

Front wiper motor

Refitting

Loudspeaker

Refitting

Audio equipment

Refitting

Refitting

1240 Air condition

Description of the air conditioning/heating system

Components

Heating/air conditioning circuit

Specifications – air conditioning

Maintenance of the air conditioning system

Periodic maintenance operations

Every 6 months

Every year

Every 2 years

Checks and adjustments

Refrigerant

Radiator and condenser harnesses

V-belt tension

Duct connections

Air conditioning and heating – Faults and solutions

Fault finding

Heating/air conditioning controls

Refitting

Air conditioning unit

Preliminary operations

Opening the cab roof

Removing the air conditioning unit

Refitting

Disassembling the air conditioning unit

Reassembling the air conditioning unit

Condenser

Refitting

Compressor

Refitting

Position of components

Electric system

Location of components

Location of components on the engine

Z042 Engine oil pressure switch

B045 Coolant temperature sensor

B381 Fuel fi

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF