Bomag BC 473 EB-3 Soil Compactor Operating and Maintenance Instructions 00820281

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00820281

- Format: PDF

- Size: 5.0MB

- Number of Pages: 208

- Serial Number:

101930151001 and up

-

Model List:

- BC 473 EB-3 Soil Compactor

- 1. Table of contents

- 2. Introduction

- 2.1. Foreword

- 2.2. Machine type plate and engine type plate

- 3. Technical data

- 3.1. Noise and vibration data

- 3.1.1. Noise data

- 3.1.2. Vibration data

- 4. Concerning your safety

- 4.1. General prerequisites

- 4.1.1. General

- 4.1.2. Explanation of signal words used

- 4.1.3. Personal protective equipment

- 4.1.4. Intended use

- 4.1.5. Improper use

- 4.2. Definition of responsible persons

- 4.2.1. Operating company

- 4.2.2. Expert / qualified person

- 4.2.3. Driver / operator

- 4.3. Fundamentals for safe operation

- 4.3.1. Remaining dangers, remaining risks

- 4.3.2. Regular safety inspections

- 4.3.3. Modifications and alterations to the machine

- 4.3.4. Damage, defects, misuse of safety devices

- 4.3.5. Roll Over Protective Structure (ROPS)

- 4.4. Handling fuels and lubricants

- 4.4.1. Preliminary remarks

- 4.4.2. Safety regulations and environmental protection regulations for handling diesel fuel

- 4.4.3. Safety regulations and environmental protection regulations for handling oil

- 4.4.4. Safety regulations and environmental protection regulations for handling hydraulic oil

- 4.4.5. Safety regulations and environmental protection regulations for handling coolants

- 4.4.6. Safety regulations and environmental protection regulations for handling battery acid

- 4.5. Load/transport the machine

- 4.6. Start up procedure

- 4.6.1. Prior to starting up

- 4.6.2. Starting the engine

- 4.6.3. Starting the engine with jump leads

- 4.6.4. Auxiliary heating

- 4.7. Driving the machine, working operation

- 4.7.1. Persons in the danger area

- 4.7.2. Driving the machine

- 4.7.3. Driving on gradients and slopes

- 4.7.4. Parking the machine

- 4.8. Refuelling

- 4.9. What to do in events of emergency

- 4.9.1. Actuating the emergency stop switch

- 4.9.2. Disconnecting the battery

- 4.9.3. Towing the machine

- 4.10. Maintenance work

- 4.10.1. Preliminary remarks

- 4.10.2. Work on hydraulic lines

- 4.10.3. Working on the engine

- 4.10.4. Maintenance work on electric components and battery

- 4.10.5. Working on the air conditioning

- 4.10.6. Cleaning work

- 4.10.7. After maintenance work

- 4.11. Repair

- 4.12. Signage

- 5. Indicators and control elements

- 5.1. Drivers stand

- 5.1.1. Instrument cluster

- 5.1.2. Starter switch

- 5.1.3. Travel pedal

- 5.1.4. Operating console

- 5.1.5. Console for dozer blade control

- 5.1.6. Console for tilt blade control

- 5.1.7. Steering lever console

- 5.2. Cabin

- 5.2.1. Control panel for heating / air conditioning system

- 5.2.2. Control console cabin

- 5.2.3. Hood control panel

- 5.2.4. Control panel for selfregulating air conditioning system

- 5.2.5. Control panel for auxiliary heating

- 5.2.6. Monitor for reversing camera

- 5.3. Outside of machine

- 5.3.1. Main battery switch

- 5.3.2. Reversing camera

- 5.3.3. Fire extinguisher

- 5.3.4. Tilt blade

- 6. Checks prior to start up

- 6.1. Notes on safety

- 6.2. Visual inspections and function tests

- 6.3. Checking the engine oil level

- 6.4. Checking the fuel level, topping up fuel

- 6.4.1. Checking the fuel level

- 6.4.2. Refuelling

- 6.5. Checking the hydraulic oil level

- 6.6. Checking the coolant level

- 6.7. Checking the oil level in the transfer case

- 6.8. Checking the compactor wheels

- 6.9. Check the grease supply in the central lubrication system

- 6.10. Lubricate the tilt blade

- 7. Operation

- 7.1. Setup the work place

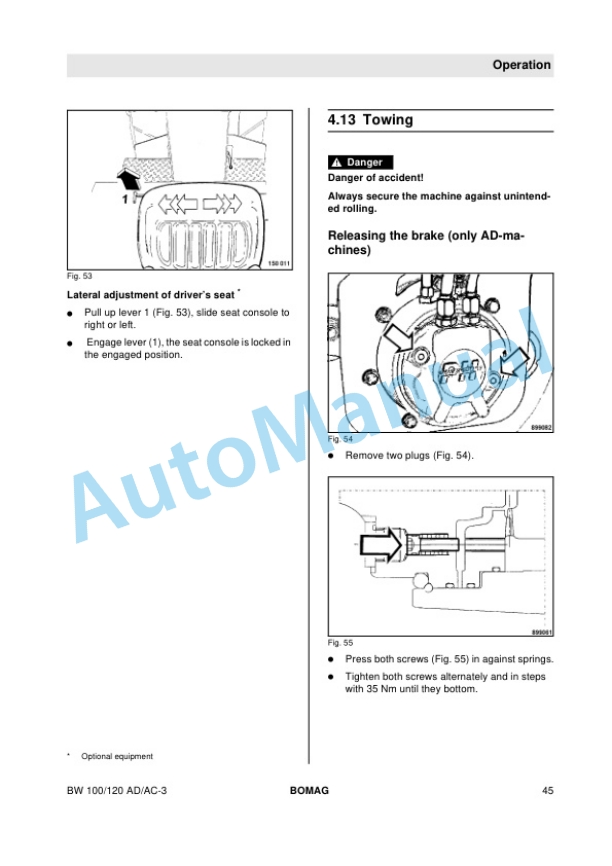

- 7.1.1. Adjust the drivers seat

- 7.2. Electronic immobilizer

- 7.3. Starting the engine

- 7.4. Travel operation

- 7.4.1. Preliminary remarks and safety notes

- 7.4.2. Driving the machine

- 7.4.3. Applying the parking brake

- 7.4.4. Notes on travel operation

- 7.5. Operating the dozer blade

- 7.6. Operating the tilt blade

- 7.7. Parking the machine in secured condition

- 7.8. Heating / air conditioning

- 7.9. Selfregulating air conditioning system

- 7.9.1. Preliminary remarks

- 7.9.2. Buttons and displays

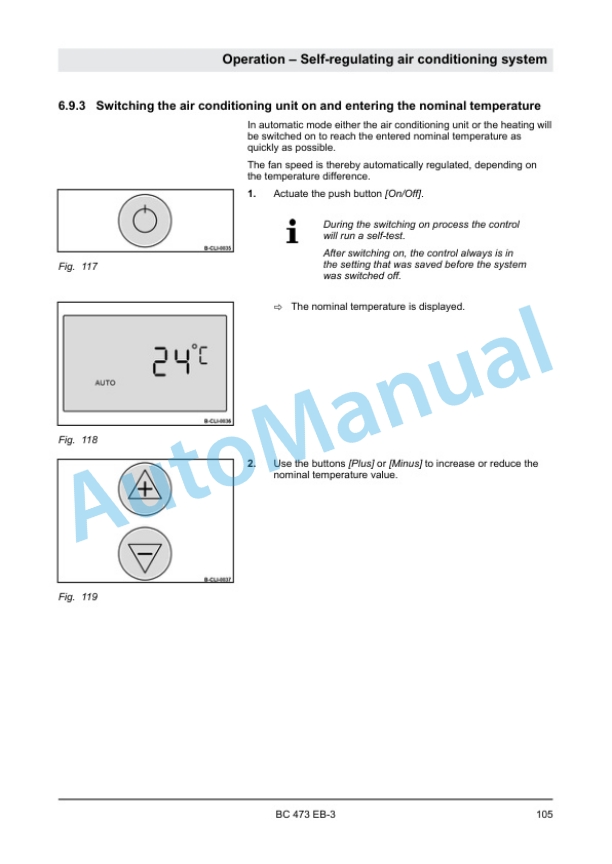

- 7.9.3. Switching the air conditioning unit on and entering the nominal temperature

- 7.9.4. Switching the temperature display between C and F

- 7.9.5. Setting the fan speed manually

- 7.9.6. Reducing the humidity (reheat function)

- 7.10. Operating the auxiliary heating

- 7.10.1. Setting time and weekday

- 7.10.2. Heating operation without preselection (ignition off)

- 7.10.3. Heating operation without preselection (ignition on)

- 7.10.4. Preselecting start of heating

- 7.11. Using the accessing aids

- 7.12. Emergency procedures

- 7.12.1. Actuating the emergency stop switch

- 7.12.2. Emergency exit

- 7.12.3. Disconnect the battery

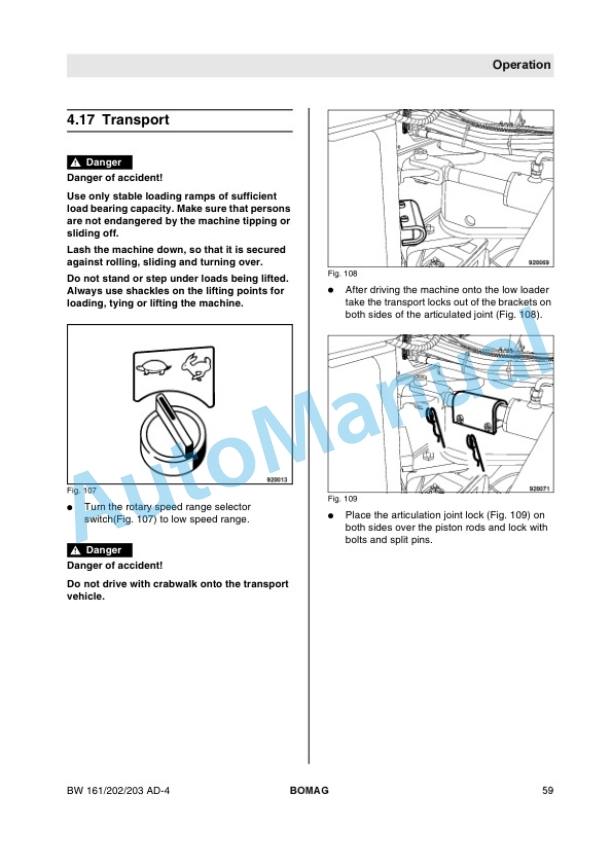

- 8. Loading / transporting the machine

- 8.1. Loading the machine

- 8.2. Lashing the machine to the transport vehicle

- 8.3. Loading by crane

- 8.4. After transport

- 9. Maintenance

- 9.1. Preliminary remarks and safety notes

- 9.2. Preparations / concluding work

- 9.2.1. Overview of maintenance flaps and doors

- 9.2.2. Opening / closing the hood

- 9.2.3. Engaging / releasing the articulation lock

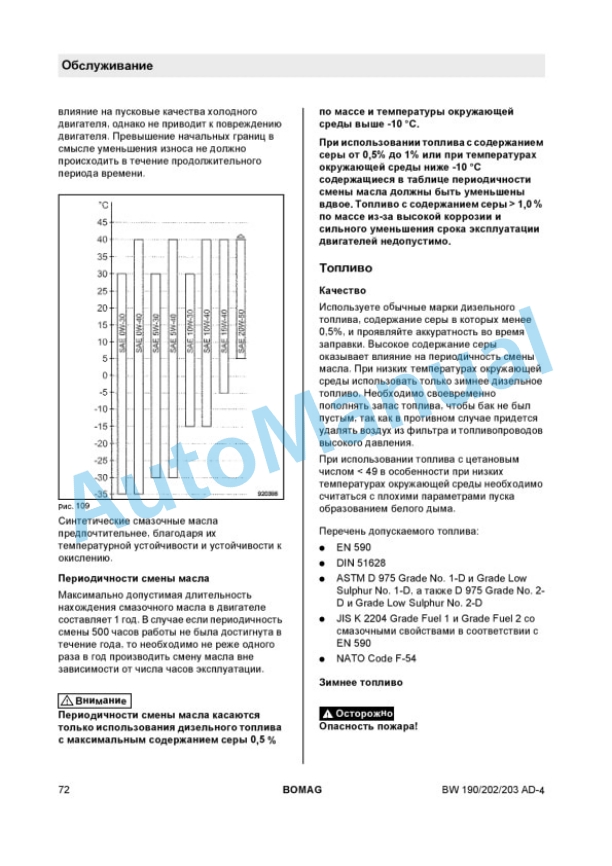

- 9.3. Fuels and lubricants

- 9.3.1. Engine oil

- 9.3.2. Fuel

- 9.3.3. Coolant

- 9.3.4. Hydraulic oil

- 9.3.5. Gear oil SAE 80W140

- 9.3.6. Lubrication grease

- 9.4. List of fuels and lubricants

- 9.5. Runningin instructions

- 9.5.1. General

- 9.5.2. After 50 operating hours

- 9.5.3. After 250 operating hours

- 9.5.4. After 500 operating hours

- 9.5.5. After 1000 operating hours

- 9.5.6. After 2000 operating hours

- 9.6. Maintenance Table

- 9.7. Every 500 operating hours

- 9.7.1. Changing engine oil and oil filter element

- 9.7.2. Replacing the fuel filter, bleeding the fuel system

- 9.7.3. Checking the ribbed Vbelt

- 9.7.4. Checking the antifreeze concentration and the condition of the coolant

- 9.7.5. Checking the hydraulic lines

- 9.7.6. Servicing the battery, checking the battery isolation

- 9.7.7. Checking the engine mounts

- 9.7.8. Servicing the air conditioning system

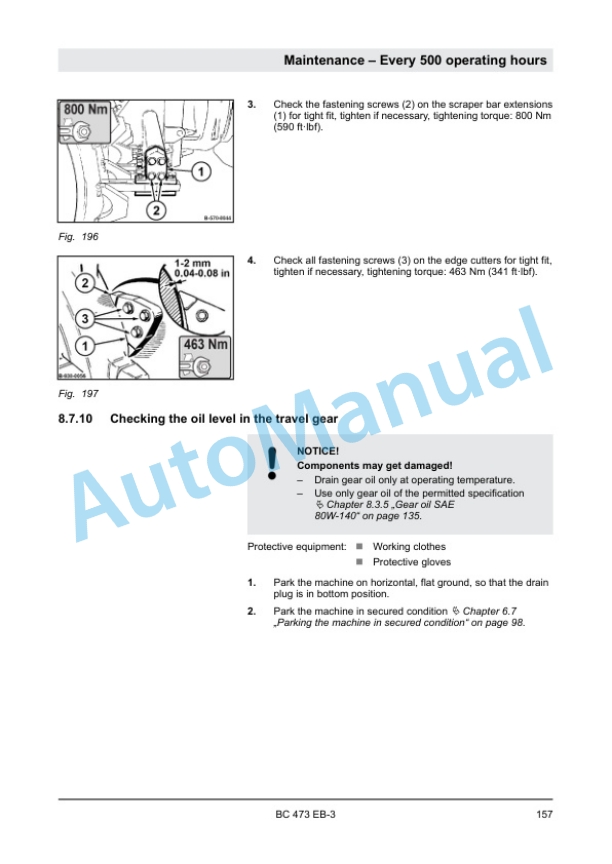

- 9.7.9. Checking the fastening of scrapers and edge cutters

- 9.7.10. Checking the oil level in the travel gear

- 9.7.11. Checking the central lubrication system

- 9.7.12. Changing fresh air filter and circulation air filter

- 9.8. Every 1000 operating hours

- 9.8.1. Checking, adjusting the valve clearance

- 9.8.2. Checking the crankcase ventilation valve

- 9.8.3. Replacing the hydraulic oil filter

- 9.8.4. Changing the oil in the travel gear

- 9.8.5. Checking the ROPS

- 9.8.6. Servicing the auxiliary heating

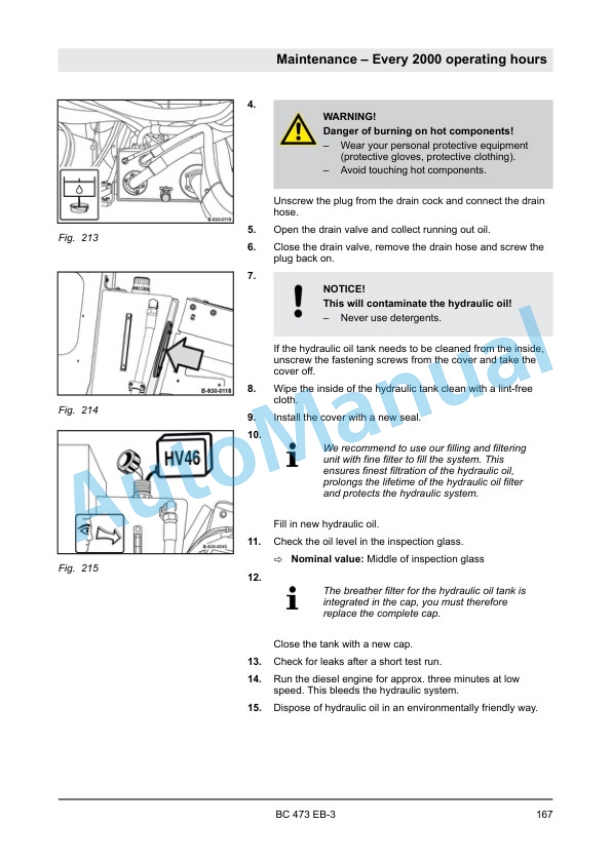

- 9.9. Every 2000 operating hours

- 9.9.1. Changing the hydraulic oil

- 9.9.2. Changing the coolant

- 9.9.3. Changing oil and filter in the transfer case

- 9.9.4. Checking the condition of the oscillating articulated joint

- 9.10. Every 3000 operating hours

- 9.10.1. Replacing ribbed Vbelt and idler pulley

- 9.10.2. Checking the adjusting lever and the gate in the exhaust gas recirculation

- 9.10.3. Replacing the crankcase ventilation valve

- 9.11. As required

- 9.11.1. Checking, cleaning the water separator

- 9.11.2. Air filter maintenance

- 9.11.3. Cleaning the radiator module

- 9.11.4. Filling the provision tank for the windscreen washer system

- 9.11.5. Draining off dirty fluids from front and rear frame

- 9.11.6. Drain the fuel tank sludge

- 9.11.7. Check / adjust scrapers and edge cutters

- 9.11.8. Checking the dozer blade cutting edges

- 9.11.9. Replacing padfpoot caps

- 9.11.10. Weld on new pad foot caps

- 9.11.11. Measures prior to extended shutdown period

- 10. Troubleshooting

- 10.1. Preliminary remarks

- 10.2. Starting the engine with jump leads

- 10.3. Emergency operation of hood

- 10.4. Operating the engine emergency mode

- 10.5. Fuse assignment

- 10.5.1. Notes on safety

- 10.5.2. Central electrics

- 10.5.3. Main fuses

- 10.5.4. Control console cabin

- 10.6. Engine faults

- 11. Disposal

- 11.1. Final shutdown of machine

- 12. List of special tools

Bomag Operator Manual PDF

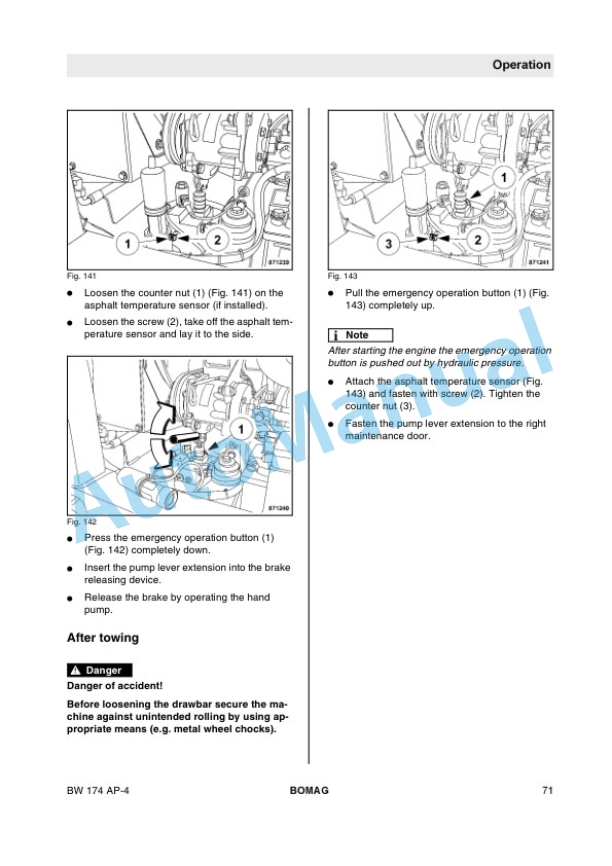

Bomag BW 174 AP-4 Tandem Vibratory Roller Operating and Maintenance Instructions 00806401

Bomag Operator Manual PDF

Bomag Operator Manual PDF

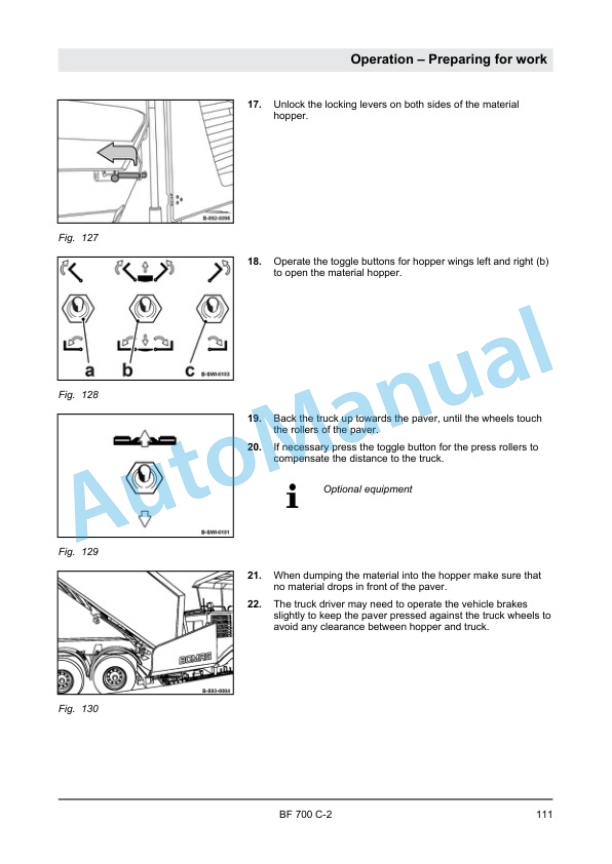

Bomag BF 700 C-2 Paver Operating and Maintenance Instructions 00820031

Bomag Operator Manual PDF

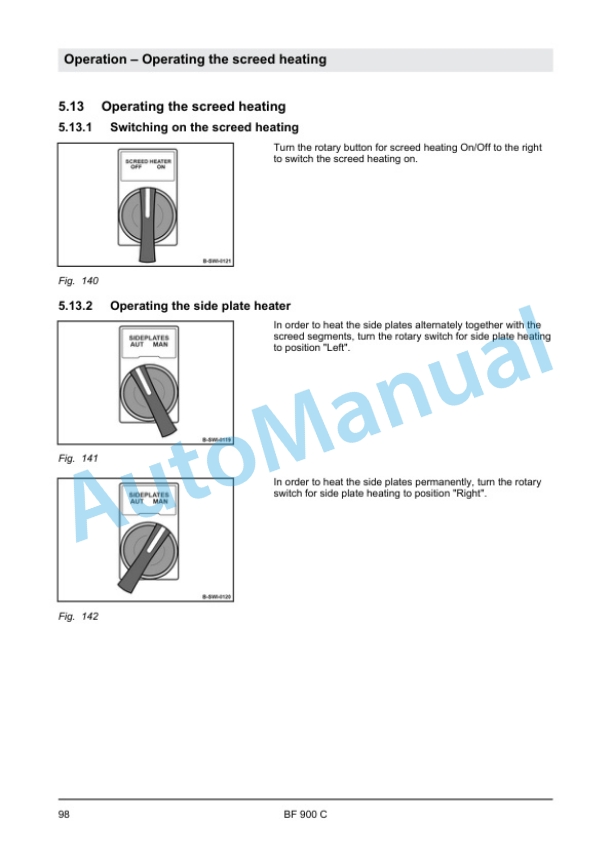

Bomag BF 900 C Paver Operating and Maintenance Instructions 00808181

Bomag Operator Manual PDF

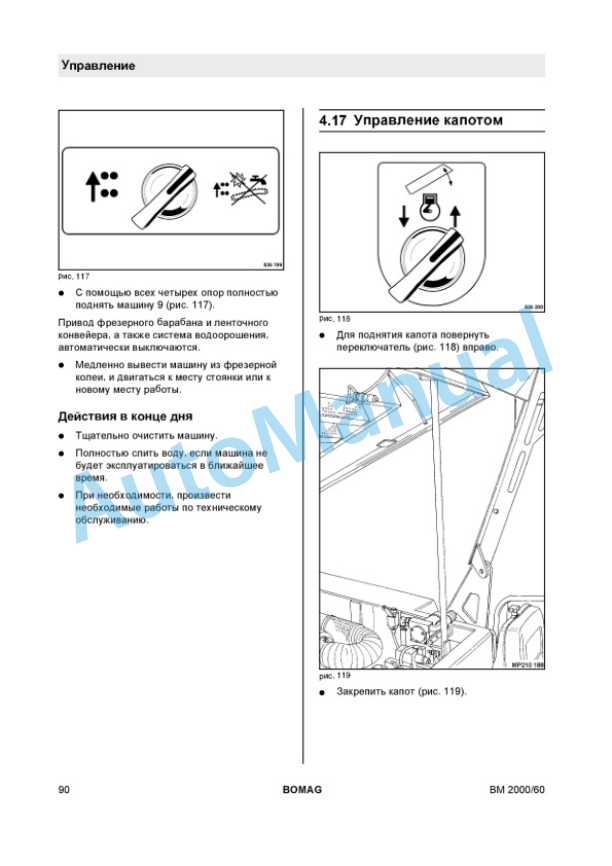

Bomag BM 2000-60 Road Milling Machine Operating and Maintenance Instructions 00804757

Bomag Operator Manual PDF

Bomag BW 135 AD-5 Tandem Vibratory Roller Operating and Maintenance Instructions 00820191

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag BMF 2500 S, BMF 2500 M Feeder Operating and Maintenance Instructions 00890004

Bomag Operator Manual PDF