Bomag BC 473 RB-4, BC 473 RS-4, BC 473 EB-4 Refuse Compactor Service Manual 00840022

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840022

- Format: PDF

- Size: 67.0MB

- Number of Pages: 886

- Serial Number:

101930081001 and up

101930091001 and up

101930111001 and up

Category: Bomag Service Manual PDF

-

Model List:

- BC 473 RB-4 Refuse Compactor

- BC 473 RS-4 Refuse Compactor

- BC 473 EB-4 Refuse Compactor

- 1. Table of contents

- 2. General

- 2.1. Introduction

- 2.2. Concerning your safety

- 2.2.1. Basic prerequisites

- 2.2.2. Definition of responsible persons

- 2.2.3. Fundamentals for safe operation

- 2.2.4. Handling fuels and lubricants

- 2.2.5. Loading / transporting the machine

- 2.2.6. Start up procedure

- 2.2.7. Driving the machine working operation

- 2.2.8. Refuelling

- 2.2.9. Topping up AdBlue/DEF

- 2.2.10. Emergency procedures

- 2.2.11. Maintenance work

- 2.2.12. Repair

- 2.2.13. Signage

- 2.3. Maintenance and repair

- 2.3.1. Notes on repair

- 2.3.2. Preliminary remarks and safety notes

- 2.3.3. Preparations/concluding work

- 2.3.4. Parking the machine in secured condition

- 3. Technical data

- 3.1. Technical data, BC 473 RB 4

- 3.1.1. Technical data

- 3.2. Technical data, BC 473 RS 4

- 3.2.1. Technical data

- 3.3. Technical data, BC 473 EB 4

- 3.3.1. Technical data

- 3.4. Additional technical data

- 3.5. Terms and basis of calculation

- 3.6. Fuels and lubricants

- 3.6.1. Engine oil

- 3.6.2. Fuel

- 3.6.3. AdBlue/DEF

- 3.6.4. Coolant

- 3.6.5. Hydraulic oil

- 3.6.6. Gear oil SAE 80W140

- 3.6.7. Lubrication grease

- 3.7. List of fuels and lubricants

- 4. Overview of machine

- 4.1. General information

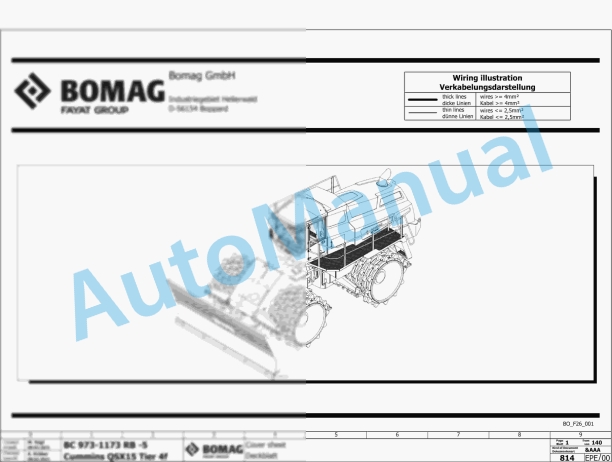

- 4.2. Electric systems

- 4.3. Hydraulic system

- 4.4. Machine assemblies

- 4.4.1. Diesel engine

- 4.4.2. Air conditioning

- 4.4.3. Central lubrication system

- 4.4.4. Overview of maintenance flaps and doors

- 5. Electric systems

- 5.1. Basic principles

- 5.1.1. Measuring method

- 5.1.2. Understanding circuit diagrams

- 5.1.3. Telemecanique switch

- 5.1.4. Deutsch plug, series DT and DTM

- 5.1.5. Magnetic coil plug

- 5.1.6. Clipon technology

- 5.2. Overview of electric system

- 5.2.1. Operators stand

- 5.2.2. Wiring

- 5.2.3. CAN BUS overview

- 5.2.4. Table of fuels and lubricants

- 5.3. Starting the engine with jump leads

- 5.4. Installation locations of control units

- 5.5. Fuse assignment

- 5.5.1. Notes on safety

- 5.5.2. Central electrics

- 5.5.3. Main fuses

- 5.5.4. Control console cabin

- 5.6. Description of electrical components

- 5.6.1. Control console cabin

- 5.6.2. Control unit for air conditioning, A72

- 5.7. Training of electric system

- 5.8. Inspection and maintenance work

- 5.8.1. Maintenance Table

- 5.8.2. Every 500 operating hours

- 5.8.3. As required

- 6. Hydraulic system

- 6.1. Basic principles

- 6.1.1. Open and closed hydraulic circuit

- 6.1.2. Swash plate principle, pump

- 6.1.3. Swash plate principle, motor

- 6.1.4. External gear pumps

- 6.2. Overview of hydraulics

- 6.3. Description of hydraulic components

- 6.3.1. Travel pump, A4VG110 DA

- 6.3.2. Fan pump, A4VG56 EFEP

- 6.3.3. Steering and working pump, A10VO/VSO

- 6.3.4. Travel motor, A6VM HA2T

- 6.3.5. Fan motor

- 6.4. Description of hydraulic circuits

- 6.4.1. Charge circuit, engine hood, brake and travel speed range selection

- 6.4.2. Travel system

- 6.4.3. Cooling system

- 6.4.4. Working hydraulics

- 6.5. Inspection and maintenance work

- 6.5.1. Maintenance Table

- 6.5.2. Checks prior to start up

- 6.5.3. Every 500 operating hours

- 6.5.4. Every 1000 operating hours

- 6.5.5. Every 2000 operating hours

- 7. Machine assemblies

- 7.1. Diesel engine

- 7.1.1. Overview of diesel engine

- 7.1.2. Lubrication oil circuit

- 7.1.3. Cooling circuit

- 7.1.4. Fuel system

- 7.1.5. Crankcase ventilation

- 7.1.6. Charging

- 7.1.7. Exhaust gas recirculation

- 7.1.8. Exhaust gas aftertreatment SCR

- 7.1.9. Engine electrics

- 7.1.10. Inspection and maintenance work

- 7.2. Oscillating articulated joint

- 7.2.1. Repair overview

- 7.2.2. Repairing the articulated joint

- 7.2.3. Inspection and maintenance work

- 7.3. Compactor wheels and dozer blade

- 7.3.1. Inspection and maintenance work

- 7.4. Central lubrication system

- 7.4.1. Overview of central lubrication system

- 7.4.2. Technical description

- 7.4.3. Control board

- 7.4.4. Lubrication process

- 7.4.5. Progressive distributor

- 7.4.6. Lubrication oil pump

- 7.4.7. Inspection and maintenance work

- 7.5. Air conditioning

- 7.5.1. Overview of air conditioning

- 7.5.2. Control unit for air conditioning, A72

- 7.5.3. Physical principles

- 7.5.4. Refrigerant R134a

- 7.5.5. Compressor oil / refrigeration oil

- 7.5.6. Working principle of the air conditioning system

- 7.5.7. Monitoring devices

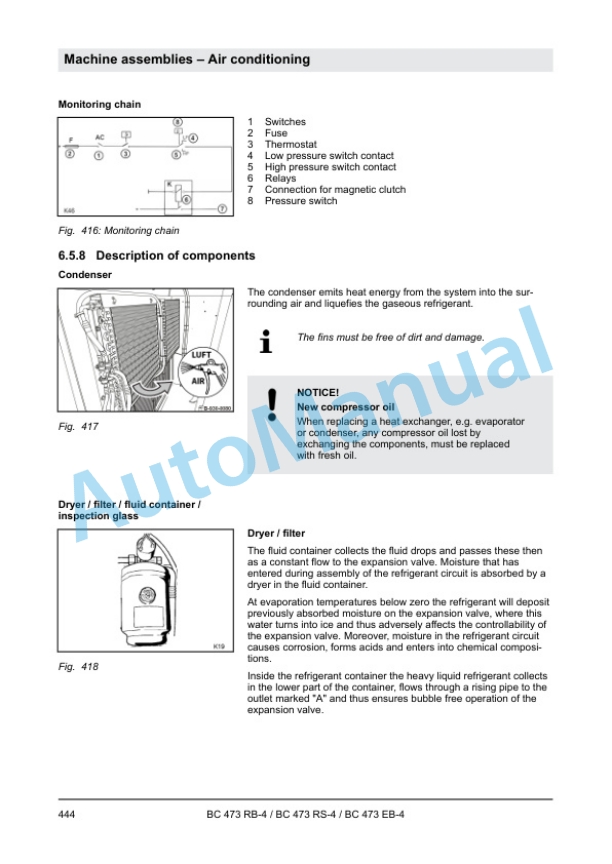

- 7.5.8. Description of components

- 7.5.9. Compressor

- 7.5.10. Emptying in case of repair

- 7.5.11. Drying and evacuation

- 7.5.12. Filling instructions

- 7.5.13. Steam table for R134a

- 7.5.14. Inspection and maintenance work

- 7.6. Auxiliary heating, AIRTRONIC

- 7.6.1. Description of function

- 7.6.2. Fuse assignment

- 7.6.3. Control panel

- 7.6.4. Inspection and maintenance work

- 8. Troubleshooting

- 8.1. Preliminary remarks

- 8.2. Emergency procedures

- 8.2.1. Actuating the emergency stop switch

- 8.2.2. Emergency exit

- 8.2.3. Disconnect the battery

- 8.2.4. Towing the machine

- 8.2.5. After towing

- 8.3. Troubleshooting, electrical systems

- 8.3.1. Preliminary remarks

- 8.3.2. Starting the engine with jump leads

- 8.3.3. Checking the main battery switch

- 8.3.4. Fuse assignment

- 8.3.5. ESX, checking the electric power supply

- 8.3.6. Diagnostics concept

- 8.4. Trouble shooting, diesel engine

- 8.4.1. Fault Cause Remedy

- 8.4.2. Starting the engine with jump leads

- 8.4.3. Operating the engine emergency mode

- 8.4.4. Behaviour of the engine control in case of malfunctions

- 8.4.5. SCR warnings and operation limitations

- 8.4.6. Fault code control units

- 8.5. Trouble shooting, hydraulics

- 8.5.1. Emergency operation of hood

- 8.5.2. Insufficient hydraulic power

- 8.5.3. Troubleshooting axial piston pumps

- 8.5.4. Troubleshooting axial piston motors

- 8.5.5. Troubleshooting table for hydraulic components

- 8.6. Troubleshooting, air conditioning system

- 8.6.1. Trouble shooting in refrigerant circuit, basic principles

- 8.6.2. Trouble shooting procedure

- 8.6.3. Leak test

- 8.6.4. Checking the magnetic clutch

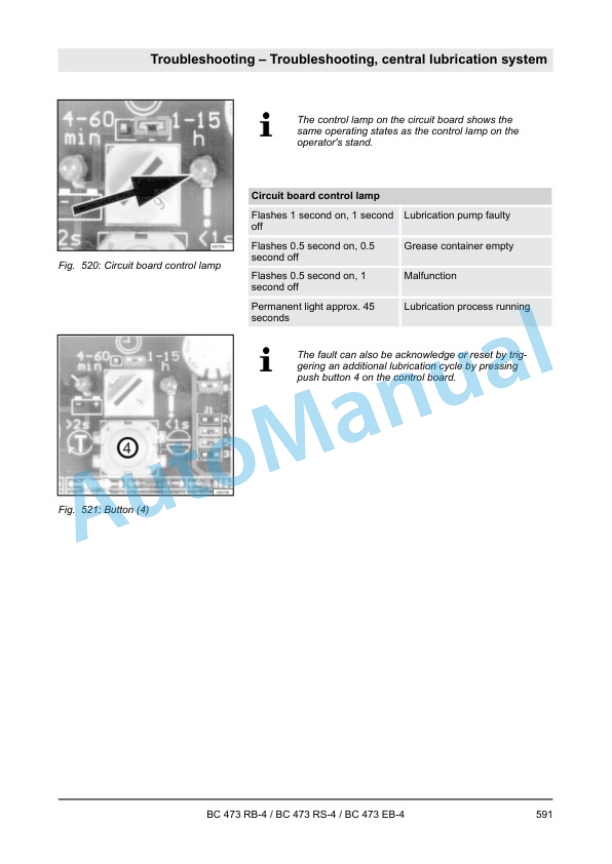

- 8.7. Troubleshooting, central lubrication system

- 8.7.1. Function control

- 8.7.2. Faults and causes

- 8.7.3. Fault Cause Remedy

- 8.7.4. Failure of central lubrication system (grease emerges from relief valve)

- 8.8. Troubleshooting, auxiliary heating

- 8.8.1. Fuse assignment

- 8.8.2. Components

- 8.8.3. Control and safety elements

- 8.8.4. Trouble shooting

- 8.8.5. Diagnostics of control panel, old version

- 8.8.6. Diagnostics of control panel, new version

- 8.8.7. Check the fuel supply

- 8.8.8. Circuit diagram, AIRTRONIC D2/D4

- 9. Special tools

- 9.1. Special tools, electrics

- 9.2. Special tools for hydraulic system

- 9.2.1. Special tools, tests and adjustments

- 10. Measures prior to extended shutdown period

- 10.1. Measures before shutting down

- 10.2. Measures during the shut down period

- 10.3. Battery service during prolonged machine downtimes

- 10.4. Measures before restarting

- 11. Index

- 12. Appendix

- 12.1. Appendices

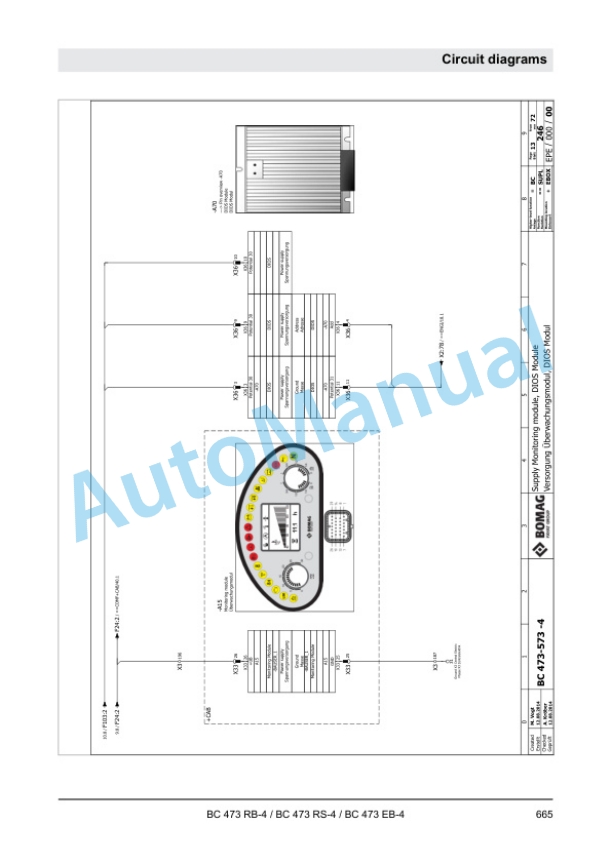

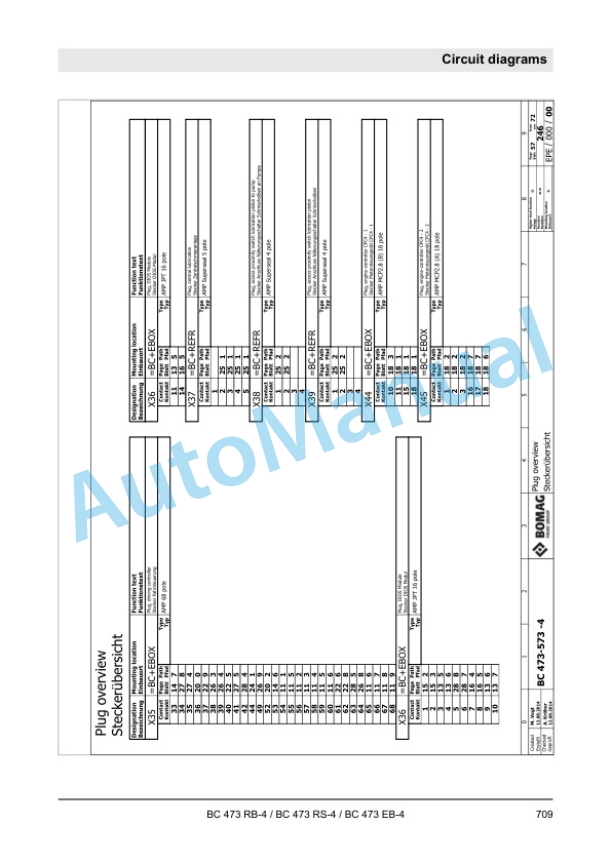

- 12.2. A Circuit diagrams

- 12.2.1. Circuit diagram 246

- 12.2.2. Circuit diagram 329

- 12.2.3. Circuit diagram 514

- 12.2.4. Hydraulic diagram 571 908 27

- 12.2.5. Hydraulic diagram 571 908 28, BC 473 RS4

Rate this product

You may also like

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930021001 – 101930021018

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

$30.00