Bomag BF 700 C-2 Paver Operating and Maintenance Instructions 00820031

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00820031

- Format: PDF

- Size: 8.9MB

- Number of Pages: 220

- Serial Number:

821892061001 and up

Category: Bomag Operator Manual PDF

-

Model List:

- BF 700 C-2 Paver

- 1. Table of contents

- 2. Introduction

- 2.1. Foreword

- 2.2. Machine type plate and engine type plate

- 3. Technical data

- 3.1. Noise and vibration data

- 4. Concerning your safety

- 4.1. General prerequisites

- 4.2. Definition of responsible persons

- 4.3. Basic safety regulations for safe operation

- 4.4. Handling fuels and lubricants

- 4.5. Loading/transporting the machine

- 4.6. Taking the machine into service

- 4.7. Driving the machine, working operation

- 4.8. Refuelling

- 4.9. Topping up AdBlue/DEF

- 4.10. What to do in events of emergency

- 4.11. Maintenance work

- 4.12. Repair

- 4.13. Stickers and decals

- 5. Display and control elements

- 5.1. Operators stand

- 5.2. Outside of machine

- 5.3. Outside control panels

- 5.4. Screed operating console

- 5.5. Operating console for screed heating

- 6. Tests before taking into operation

- 6.1. Notes on safety

- 6.2. Visual inspections and function tests

- 6.3. Checking the engine oil level

- 6.4. Checking the fuel level, topping up fuel

- 6.5. Checking the AdBlue/DEF level, topping up

- 6.6. Checking the hydraulic oil level

- 6.7. Checking the coolant level

- 6.8. Checking the emulsion level, topping up

- 6.9. Lubricating the machine

- 6.10. Check the grease supply in the central lubrication system

- 7. Operation

- 7.1. Settingup the work place

- 7.2. Start the engine

- 7.3. Driving the machine in transport mode

- 7.4. Braking the machine

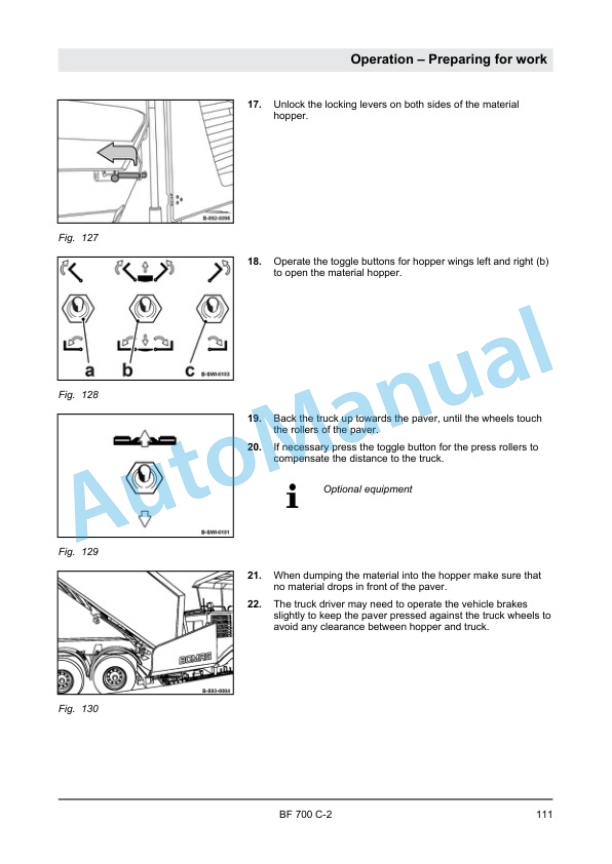

- 7.5. Preparing for work

- 7.6. Operation

- 7.7. Park the machine in secured condition.

- 7.8. Adjusting the auger height

- 7.9. Operating the screed

- 7.10. Operating the screed heating

- 7.11. Operating the protection roof

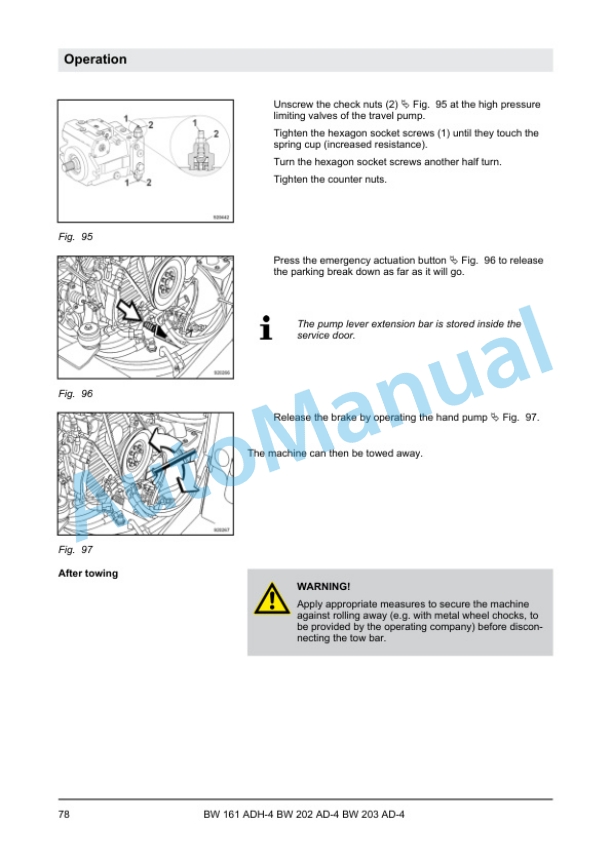

- 7.12. Emergency procedures

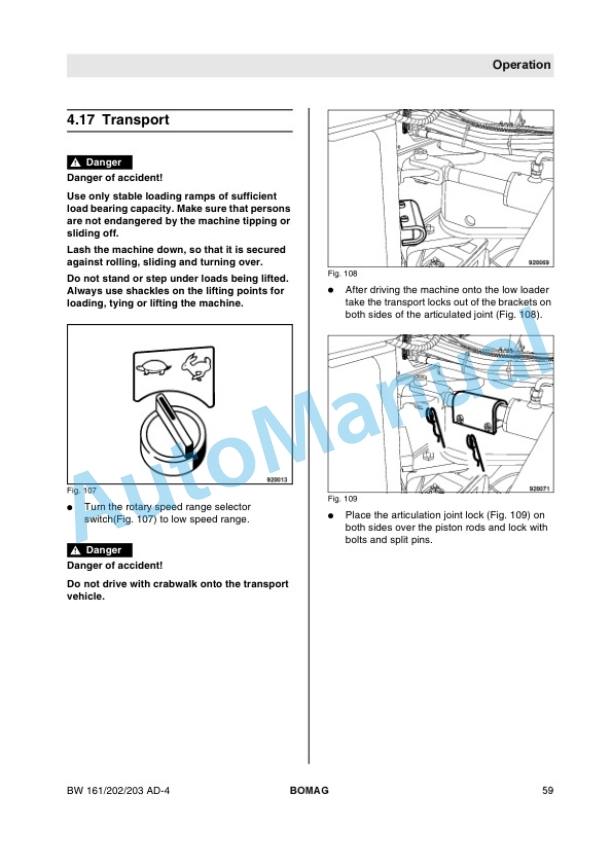

- 8. Loading / transporting the machine

- 8.1. Prepare for transport

- 8.2. Loading the machine

- 8.3. Lashing the machine to the transport vehicle

- 8.4. Loading by crane

- 9. Maintenance

- 9.1. Preliminary remarks and safety notes

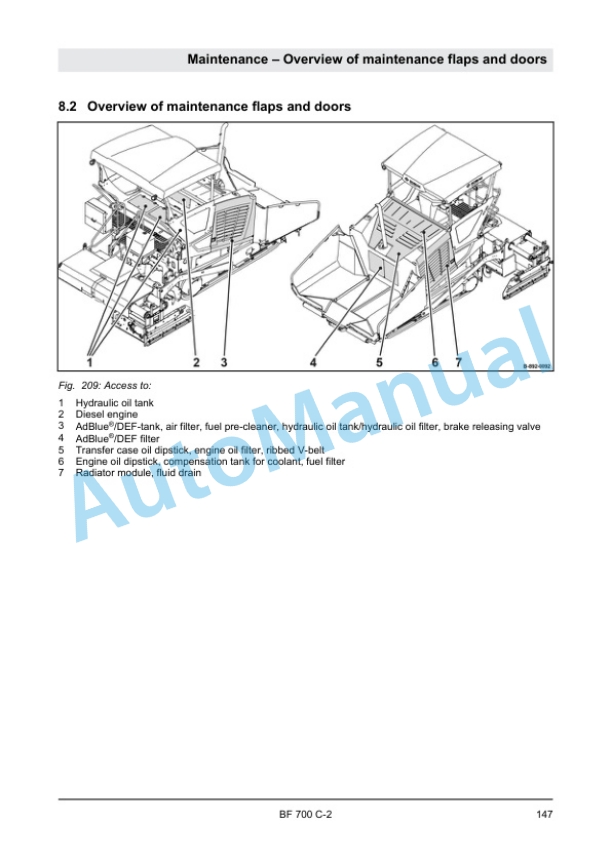

- 9.2. Overview of maintenance flaps and doors

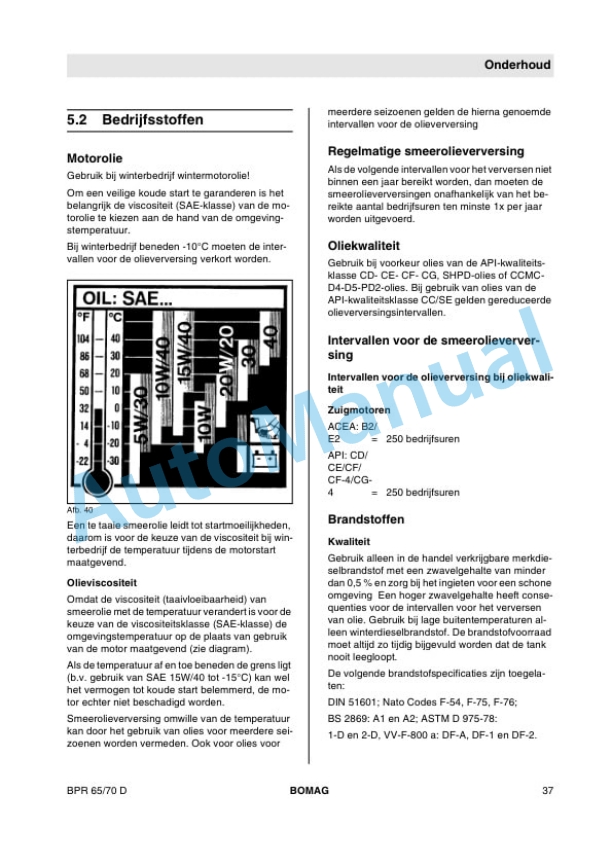

- 9.3. Fuels and lubricants

- 9.4. List of fuels and lubricants

- 9.5. Runningin instructions

- 9.6. Maintenance table

- 9.7. Every 50 operating hours

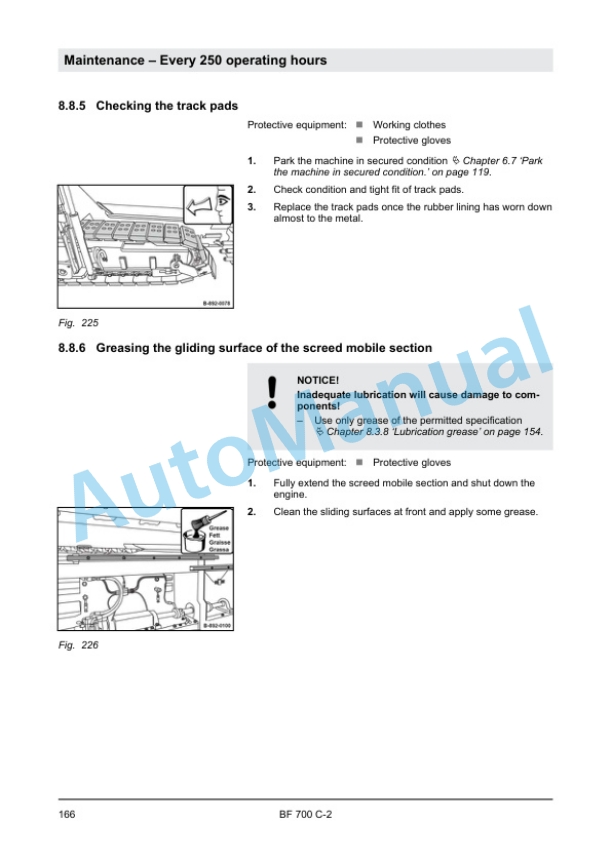

- 9.8. Every 250 operating hours

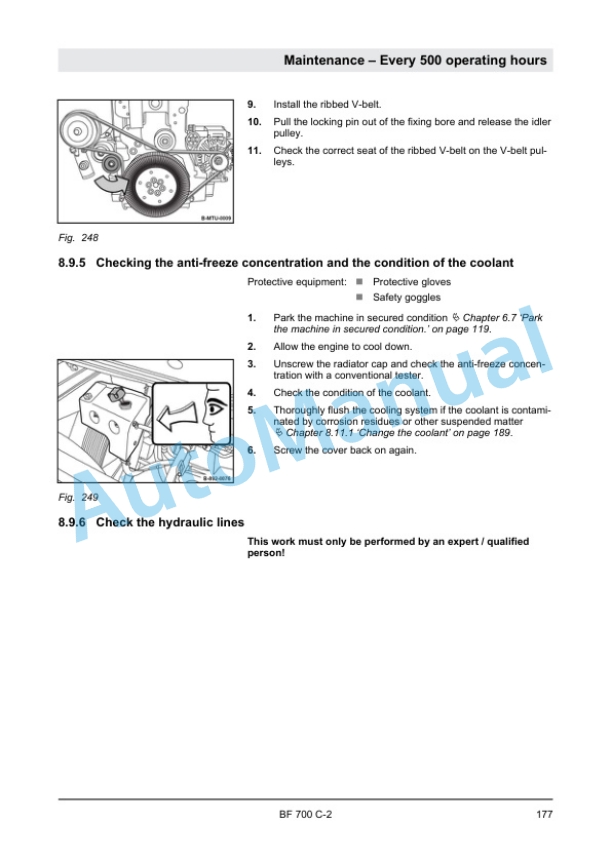

- 9.9. Every 500 operating hours

- 9.10. Every 1000 operating hours

- 9.11. Every 2000 operating hours

- 9.12. As required

- 10. Troubleshooting

- 10.1. Preliminary remarks

- 10.2. Starting the engine with jump leads

- 10.3. Screed heating fault code display

- 10.4. Fuse assignment

- 10.5. Fault code display in the LCDisplay unit

- 10.6. Engine faults

- 11. Waste disposal

- 11.1. Final shutdown of machine

- 12. List of special tools

Rate this product

You may also like

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

Bomag BW 120 AC-5 Combination Roller Operating and Maintenance Instructions 00820131

$20.00

Bomag Operator Manual PDF

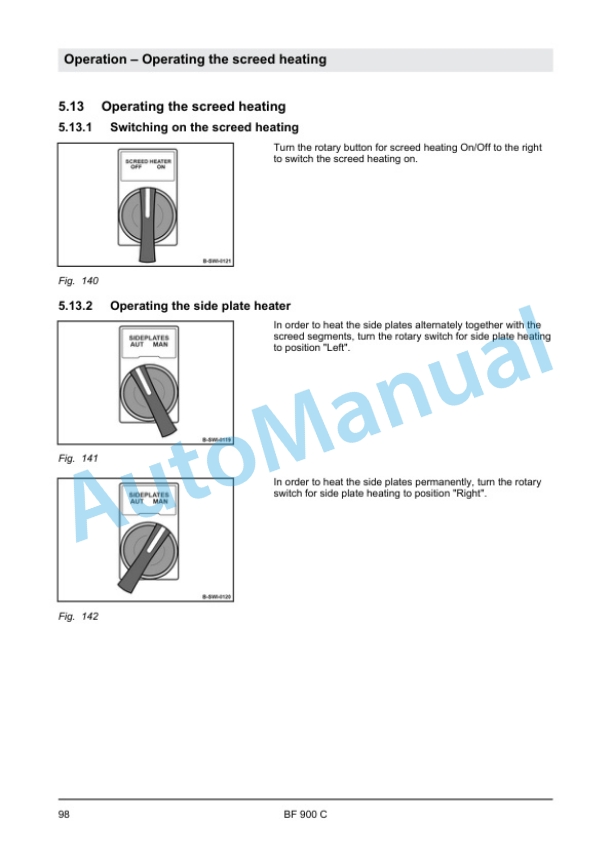

Bomag BF 900 C Paver Operating and Maintenance Instructions 00808181

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

Bomag BPR 70-70 D Reversible Vibrating Plate Operating and Maintenance Instructions 00806761

$20.00

Bomag Operator Manual PDF

Bomag BPR 65-70 D Vibrating Plate Operating and Maintenance Instructions 00805246

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

Bomag BMF 2500 S, BMF 2500 M Feeder Operating and Maintenance Instructions 00890004

$20.00