Bomag BF 900 C Paver Operating and Maintenance Instructions 00808181

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00808181

- Format: PDF

- Size: 8.6MB

- Number of Pages: 194

- Serial Number:

821893081001 and up

821893091001 and up

-

Model List:

- BF 900 C Paver

- 1. Table of contents

- 2. Introduction

- 2.1. Foreword

- 2.2. Machine type plate and engine type plate

- 3. Technical data

- 4. Safety regulations

- 4.1. Stickers and decals

- 5. Display and control elements

- 5.1. Vie of main control panel

- 5.2. Description

- 5.2.1. Quick adjustment lever for screed angle of attack

- 5.3. View of external operator stations

- 5.4. Control elements on external operator stations

- 5.5. Screed operating console

- 5.5.1. Toggle switch for cleaning system

- 5.5.2. Pressure gauge for relief pressure

- 5.5.3. Control lamp screed relieved

- 5.5.4. Potentiometer screed relieve right/left distribution

- 5.5.5. Toggle button protection roof

- 5.5.6. 24 V Universal socket

- 5.5.7. Potentiometer for timer

- 5.5.8. Potentiometer for screed relief machine stopped

- 5.5.9. Potentiometer for screed relief machine in motion

- 5.5.10. Toggle button straight crossfalls adjustment

- 5.6. Operating console for screed heating

- 5.7. View of levelling control

- 6. Operation

- 6.1. General

- 6.2. Tests before taking into operation

- 6.3. Adjusting the drivers seat and displacing the drivers platform

- 6.4. Starting the engine

- 6.5. Driving the machine in transport speed mode

- 6.6. Preparing for work

- 6.7. Operation

- 6.7.1. Preliminary remarks

- 6.7.2. Starting operation

- 6.7.3. During work

- 6.7.3.1. Turning the machine on the spot

- 6.7.3.2. Temporarily interrupting work

- 6.7.3.3. Settings to the screed

- 6.8. Activities at the end of the day

- 6.9. Shutting the engine down

- 6.10. DPFregeneration

- 6.11. Adjusting the auger height

- 6.12. Operating the screed

- 6.12.1. Preliminary remarks

- 6.12.2. Adjusting the straight crossfalls

- 6.12.3. Adjusting the screed width

- 6.12.4. Adjusting the mat thickness

- 6.12.5. Adjusting the mat height for extra thick mat heights

- 6.12.6. Height adjustment of mobile screed sections

- 6.12.7. Adjusting the angle of attack of the mobile screed sections

- 6.12.8. Setting vibration and tamper frequencies

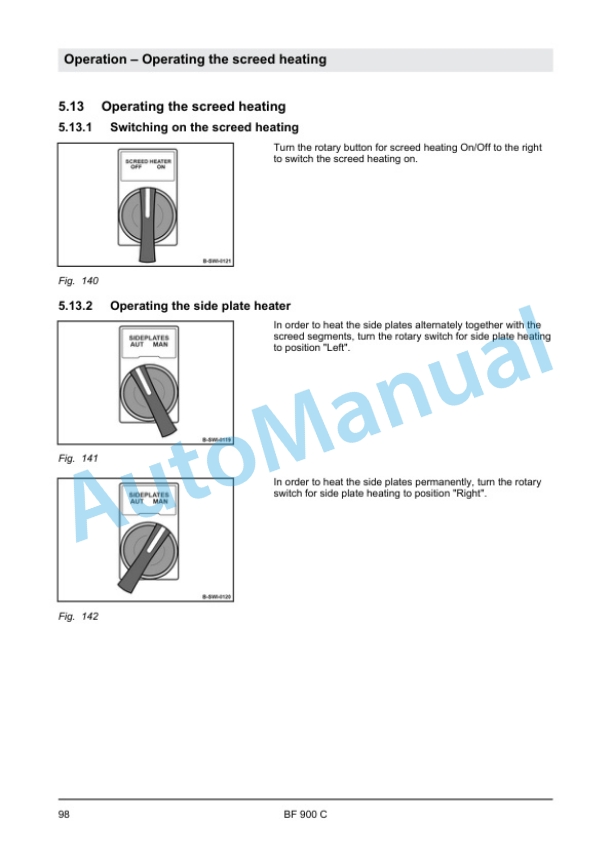

- 6.13. Operating the screed heating

- 6.13.1. Switching on the screed heating

- 6.13.2. Operating the side plate heater

- 6.13.3. Setting the nominal temperature

- 6.13.4. Setting the temperature manually

- 6.13.5. Switching off a screed section

- 6.13.6. Switching off the screed heating

- 6.14. Levelling control MOBAmaticOptional equipment

- 6.15. Hopper lock

- 6.16. Operating the protection roof on the operators stand

- 6.17. What to do in events of emergency

- 6.17.1. Actuate the emergency stop switch

- 6.17.2. Disconnecting the battery

- 6.17.3. Towing the machine

- 6.17.4. After towing

- 6.18. Loading/transport

- 7. Maintenance

- 7.1. General notes on maintenance

- 7.2. Fuels and lubricants

- 7.2.1. Engine oil

- 7.2.1.1. Oil quality

- 7.2.1.2. Oil viscosity

- 7.2.1.3. Oil change intervals

- 7.2.2. Fuel

- 7.2.2.1. Fuel quality

- 7.2.2.2. Winter fuel

- 7.2.2.3. Storage

- 7.2.3. Coolant

- 7.2.3.1. General

- 7.2.3.2. Water quality

- 7.2.3.3. Cooling system protection agent

- 7.2.4. Hydraulic oil

- 7.2.4.1. Mineral oil based hydraulic oil

- 7.2.4.2. Biodegradable hydraulic oil

- 7.2.5. Gear oil SAE 80W140

- 7.2.6. Lubrication grease

- 7.2.7. Hightemperature lubrication grease

- 7.3. Table of fuels and lubricants

- 7.4. Runningin instructions

- 7.4.1. General

- 7.4.2. After 50 operating hours

- 7.4.3. After 250 operating hours

- 7.4.4. After 500 operating hours

- 7.4.5. After 1000 operating hours

- 7.5. Maintenance table

- 7.6. Every 10 operating hours

- 7.6.1. Checking the engine oil level

- 7.6.2. Check the fuel level

- 7.6.3. Check the hydraulic oil level

- 7.6.4. Check the coolant level

- 7.6.5. Checking the emulsion level, topping up

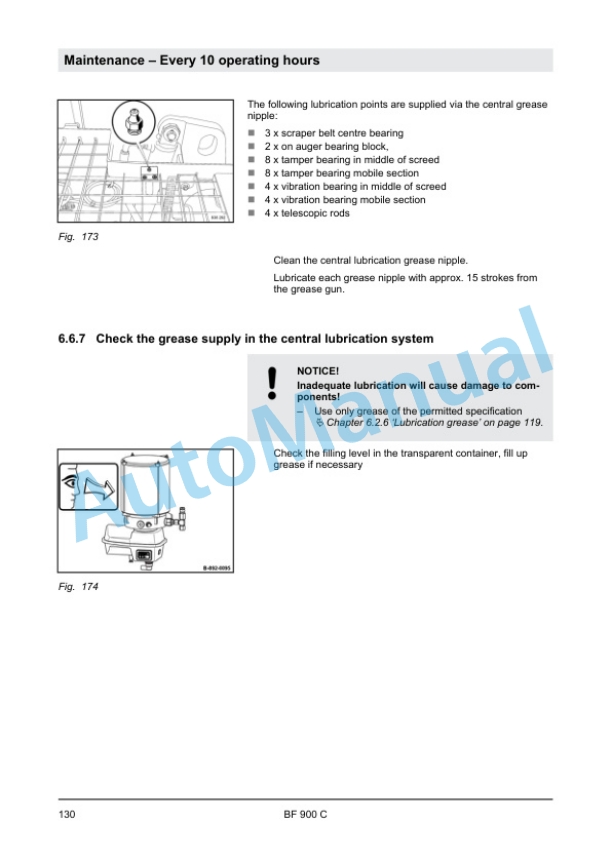

- 7.6.6. Lubricating the machine

- 7.6.7. Check the grease supply in the central lubrication system

- 7.7. Every 250 operating hours

- 7.7.1. Servicing the scraper belt

- 7.7.1.1. Checking the track drive

- 7.7.1.2. Checking/adjusting the chain tension

- 7.7.1.3. Checking the state of the conveyor surface

- 7.7.2. Servicing the scraper belt drive chain

- 7.7.2.1. Checking, adjusting the valve clearance

- 7.7.2.2. Greasing the scraper belt drive chain

- 7.7.3. Servicing the auger

- 7.7.3.1. Checking/adjusting the tension of auger drive chain and greasing the chain

- 7.7.3.2. Greasing the sliding surface for the auger height adjustment.

- 7.7.3.3. Checking the condition of the auger segments

- 7.7.4. Greasing the gliding surface of the screed mobile section

- 7.7.5. Lubricating the machine

- 7.7.6. Checking the central lubrication system

- 7.7.7. Clean the cooling fins on engine and hydraulic oil cooler

- 7.7.8. Check the oil level in the transfer box

- 7.7.9. Checking oil level in travel gear

- 7.7.10. Servicing the Vbelts for the screed heating generator

- 7.7.11. Checking hopper, scrapers and rubber apron

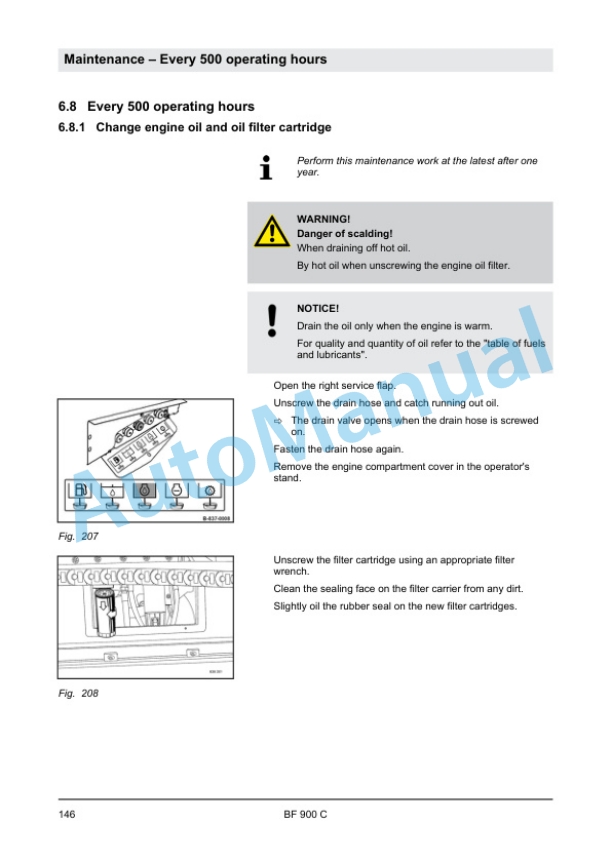

- 7.8. Every 500 operating hours

- 7.8.1. Change engine oil and oil filter cartridge

- 7.8.2. Check the antifreeze concentration and the condition of the coolant

- 7.8.3. Servicing the battery, checking the battery isolation

- 7.8.3.1. Battery service

- 7.8.3.2. Checking the main battery switch

- 7.8.4. Servicing tamper bar and levelling plate

- 7.8.4.1. Checking the state of levelling plates

- 7.8.4.2. Checking the condition of tamper bar, scraper and guide rails

- 7.8.4.3. Checking/adjusting the protrusion of the tamper bar

- 7.8.4.4. Checking, adjusting the tamper bar clearance

- 7.8.5. Checking the track lengthening

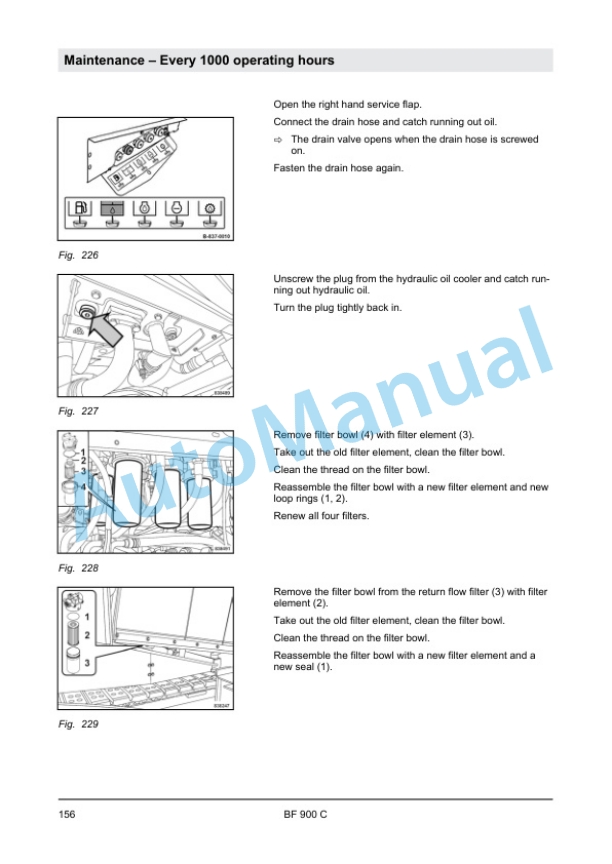

- 7.9. Every 1000 operating hours

- 7.9.1. Checking the ribbed Vbelt, replacing if necessary

- 7.9.2. Replace the fuel filter

- 7.9.3. Replacing the fuel prefilter cartridge, bleed the fuel system

- 7.9.4. Change hydraulic oil and hydraulic oil filter

- 7.9.5. Oil change in transfer case

- 7.9.6. Changing oil in travel gear

- 7.9.7. Intercooler, drain off oil and condensation water

- 7.10. Every 2000 operating hours

- 7.10.1. Adjusting the valve clearance

- 7.10.2. Replacing the coolant

- 7.10.3. Replacing ribbed Vbelt and idler pulley

- 7.10.4. Checking, cleaning the components of the exhaust gas aftertreatment system

- 7.10.5. Checking the DBFburner

- 7.11. Every 4000 operating hours

- 7.11.1. Servicing the DBFburner

- 7.12. Every 6000 operating hours

- 7.12.1. Replace the injection valve

- 7.12.2. Replace the crank case ventilation valve

- 7.13. As required

- 7.13.1. Air filter maintenance

- 7.13.2. Check, clean the water separator

- 7.13.3. Replace heating elements

- 7.13.3.1. Replacing the heating elements for the basic screed

- 7.13.3.2. Replacing the heating elements for the mobile parts

- 7.13.3.3. Replacing the heating element for the tamper

- 7.13.4. Extending auger and tunnel

- 7.13.5. Drain the fuel tank sludge

- 7.13.6. Measures before longer downtimes of the machine

- 7.13.6.1. Measures before shutting down

- 7.13.6.2. Battery service in case of longer machine standstill

- 7.13.6.3. Measures before restarting

- 8. Troubleshooting

- 8.1. Preliminary remarks

- 8.2. Starting the engine with jump leads

- 8.3. Screed heating fault code display

- 8.4. Fuse assignment

- 8.5. Fault code display

- 8.6. Engine faults

- 9. Disposal

- 9.1. Final shutdown of machine

Bomag Operator Manual PDF

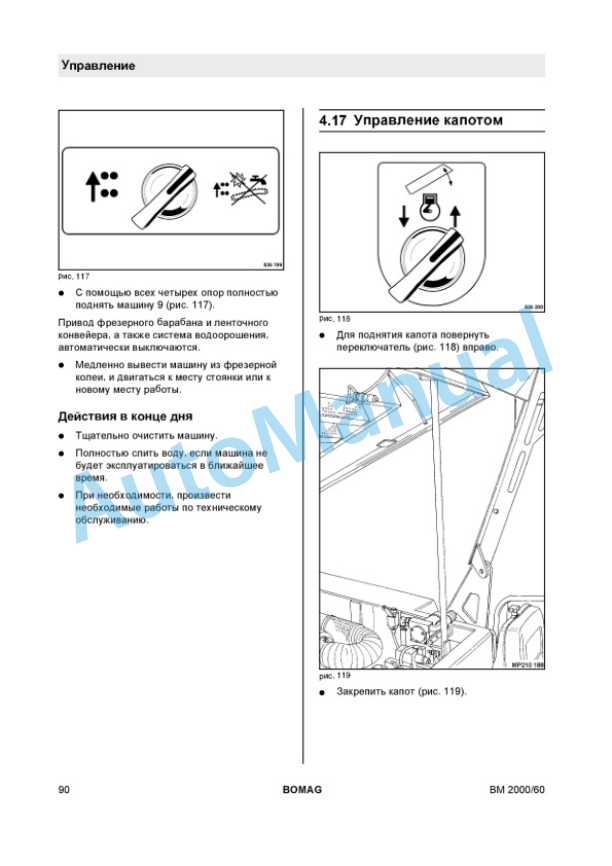

Bomag BM 2000-60 Road Milling Machine Operating and Maintenance Instructions 00804757

Bomag Operator Manual PDF

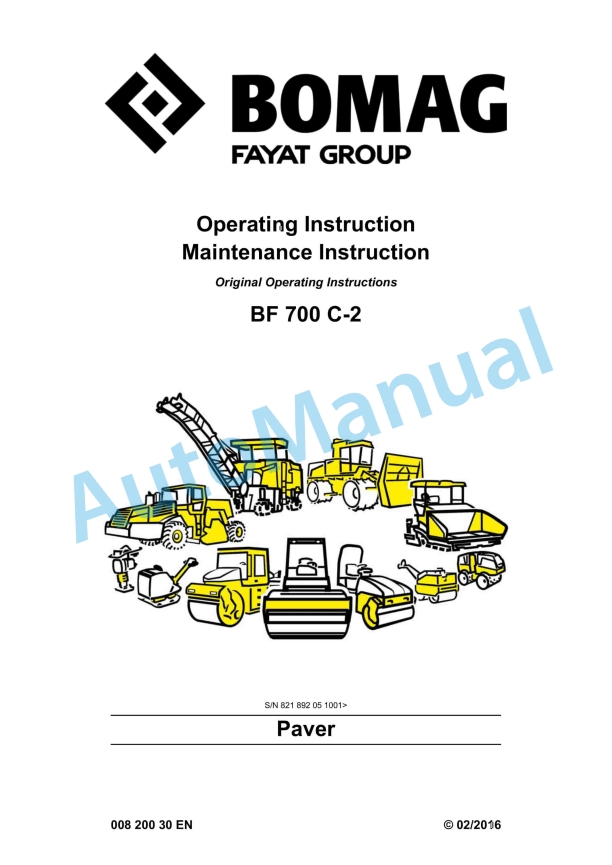

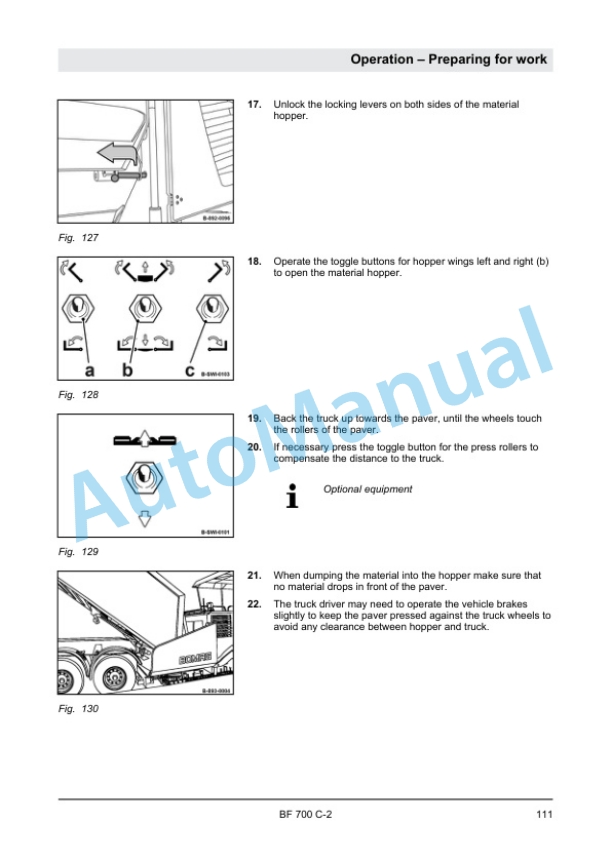

Bomag BF 700 C-2 Paver Operating and Maintenance Instructions 00820030

Bomag Operator Manual PDF

Bomag BM 2000-60 Cold Milling Machine Operating and Maintenance Instructions 00806061

Bomag Operator Manual PDF

Bomag BPR 70-70 D Reversible Vibrating Plate Operating and Maintenance Instructions 00806761

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag BMF 2500 S, BMF 2500 M Feeder Operating and Maintenance Instructions 00890004

Bomag Operator Manual PDF

Bomag BW 174 APO-4i Tandem Vibratory Roller Operating and Maintenance Instructions 00820287

Bomag Operator Manual PDF