Bomag BM 1000-30-2 to BM 1300-30-2-PB Cold Milling Machine Service Manual 00891761

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00891761

- Format: PDF

- Size: 50.1MB

- Number of Pages: 826

- Serial Number:

821836341001, 821836351001, 821836301001, 821836361001, 821836371001, 821836321001

Category: Bomag Service Manual PDF

-

Model List:

- BM 1000-30-2 Cold Milling Machine

- BM 1200-30-2 Cold Milling Machine

- BM 1300-30-2 Cold Milling Machine

- BM 1000-30-2-PB Cold Milling Machine

- BM 1200-30-2-PB Cold Milling Machine

- BM 1300-30-2-PB Cold Milling Machine

- 1. BM 1000/302/1200/302/1300/302

- 1.1. BM 1000/302/1200/302/1300/302

- 2. General

- 2.1. General

- 2.2. Introduction

- 2.3. General

- 2.4. General

- 2.5. Transport work with cranes and lifting tackle

- 2.6. Precautions and codes of conduct for welding work

- 2.7. Operation of highvoltage systems

- 2.8. Old oils

- 2.9. Hydraulics

- 2.10. Hot fuels

- 2.11. Synthetic rubber

- 2.12. Poisonous substances

- 2.13. Battery

- 2.14. Special safety regulations

- 2.15. The values specified in the table apply for screws

- 2.16. The values specified in the table apply for screws

- 2.17. The values specified in the table apply for screws

- 2.18. The values specified in the table apply for screws

- 2.19. The values specified in the table apply for screws

- 2.20. The values specified in the table apply for screws

- 2.21. The values specified in the table apply for screws

- 2.22. The values specified in the table apply for screws

- 2.23. The values specified in the table apply for screws

- 2.24. The values specified in the table apply for screws

- 2.25. The values specified in the table apply for screws

- 2.26. The values specified in the table apply for screws

- 2.27. The values specified in the table apply for screws

- 3. Technical data

- 3.1. Technical data

- 3.2.

- 3.3.

- 4. Maintenance

- 4.1. Maintenance

- 4.2. Fuels and lubricants

- 4.3. Coolant

- 4.4. Mineral oil based hydraulic oil

- 4.5. Gear oil

- 4.6. Lubrication grease

- 5. Electrics

- 5.1. Electrics

- 5.2. DTM Series

- 5.3. DTM Series

- 5.4. DTM Series

- 5.5. DTM Series

- 5.6. DTM Series

- 5.7. DTM Series

- 5.8. DTM Series

- 5.9. DTM Series

- 5.10. DTM Series

- 5.11. DTM Series

- 5.12. DTM Series

- 5.13. DTM Series

- 5.14. DTM Series

- 5.15. DTM Series

- 5.16. DTM Series

- 5.17. DTM Series

- 5.18. DTM Series

- 5.19. Battery service

- 5.20. Battery service

- 5.21. Battery service

- 5.22. Battery service

- 5.23. Battery service

- 5.24. Battery service

- 5.25. Battery service

- 5.26. Starting with jump wires

- 5.27.

- 5.28.

- 5.29.

- 5.30.

- 5.31.

- 5.32. View of operators stand

- 5.33. View of operators stand

- 5.34. B17S3, B17S4, B17S5 Control console travel system

- 5.35. Operating conditions for height regulation

- 5.36. Operating conditions for height regulation

- 5.37. Differential pressure switch for hydraulic oil

- 5.38. Engine speed sensor, C8

- 5.39.

- 5.40.

- 5.41.

- 5.42. Pin assignment for control

- 6. Engine

- 6.1. Engine

- 6.2. Engine attachment parts

- 6.3. Engine attachment parts

- 6.4. Checking the cylinder head ground cable

- 6.5. Checking the cylinder head ground cable

- 6.6. Check the engine oil level

- 6.7. Change engine oil and oil filter cartridge

- 6.8. Check, clean the water separator

- 6.9. Change the fuel prefilter cartridge

- 6.10. Replace the fuel filter cartridge

- 6.11. Checking the combustion air filter

- 6.12. Service the combustion air filter

- 6.13. Check the coolant level

- 6.14. Checking the condition of the coolant hoses

- 6.15. Change the coolant

- 6.16. Clean the cooling fins on engine and hydraulic oil cooler

- 6.17. Checking, tensioning the V belt for the generator system

- 6.18. Cleaning the crankcase ventilation

- 6.19. Check the engine mounts

- 6.20. Checking the valve clearance

- 7. Milling drive, description

- 7.1. Milling drive, description

- 8. Milling drive, repair

- 8.1. Milling drive, repair

- 8.2. Checking, replacing the milling drum Vbelt

- 8.3. Change the oil in the milling drum reduction gear

- 8.4. Oil change in milling drum bearing

- 9. Milling drum, repair

- 9.1. Milling drum, repair

- 9.2. Check/replace cutting tools, scraper

- 9.3. Check/replace cutting tools, scraper

- 9.4. Check/replace cutting tools, scraper

- 10. Milling unit, description

- 10.1. Milling unit, description

- 10.2. Milling unit

- 10.3. Milling unit

- 10.4. Milling drum

- 10.5. Milling housing

- 10.6. Holddown

- 10.7. Scraper

- 10.8. Side plate

- 11. Travel drive, description

- 11.1. Travel drive, description

- 12. Travel drive, repair

- 12.1. Travel drive, repair

- 12.2. Checking the track plates

- 12.3. Retightening the track plate fastening screws

- 12.4. Check the track drive

- 12.5. Oil change in track drive gear

- 12.6. Oil change in track drive gear

- 12.7. Oil change in track drive gear

- 12.8. Oil change in track drive gear

- 13. Conveyor belt, description

- 13.1. Conveyor belt, description

- 13.2. Conveyor belts

- 13.3. Folding / unfolding the loading conveyor belt

- 14. Conveyor belt, repair

- 14.1. Conveyor belt, repair

- 14.2. Checking, tightening the conveyor belts

- 14.3. Checking the safety ropes

- 14.4. Lubricating the conveyor belts

- 15. Hydraulics

- 15.1. Hydraulics

- 15.2. Component overview hydraulics

- 15.3. Component overview hydraulics

- 15.4. Variable displacement pumps, A4VG28EP to A4VG180EP

- 15.5. Variable displacement pumps, A4VG28EP to A4VG180EP

- 15.6. Travel pump viewed on the machine

- 15.7. Travel pump viewed on the machine

- 15.8. Working pump viewed on the machine

- 15.9. Working pump viewed on the machine

- 15.10. Working pump viewed on the machine

- 15.11. Working pump viewed on the machine

- 15.12. Variable displacement pumps, A4VG28EP to A4VG180EP

- 15.13. Variable displacement pumps, A4VG28EP to A4VG180EP

- 15.14. Conveyor belt pump viewed on the machine

- 15.15. Conveyor belt pump viewed on the machine

- 15.16. Swash plate principle

- 15.17. Gear pump WP09

- 15.18. Gear pump WP09

- 15.19. Fan pump viewed on the machine

- 15.20. Fan pump viewed on the machine

- 15.21. Description of function

- 15.22. Description of function

- 15.23. Travel motor viewed on the machine

- 15.24. Travel motor viewed on the machine

- 15.25. Check the hydraulic oil level

- 15.26. Clean the cooling fins on engine and hydraulic oil cooler

- 15.27. Changing hydraulic oil and breather filter

- 15.28. Changing the hydraulic oil filter

- 16. Hydraulics travel circuit

- 16.1. Hydraulics travel circuit

- 16.2. Travel system

- 16.3. Travel system

- 16.4. Levelling

- 16.5. Levelling

- 16.6. Steering

- 16.7. Steering

- 17. Hydraulics milling operation

- 17.1. Hydraulics milling operation

- 17.2. Clutch viewed on the machine

- 17.3. Clutch viewed on the machine

- 17.4. Side plates

- 17.5. Side plates

- 17.6. Holddown

- 17.7. Scraper

- 18. Hydraulic cylinder

- 18.1. Hydraulic cylinder

- 18.2. Repairing hydraulic cylinders

- 19. Tests and adjustments

- 19.1. Tests and adjustments

- 19.2. Checking/adjusting the travel pump

- 19.3. Checking/adjusting the travel pump

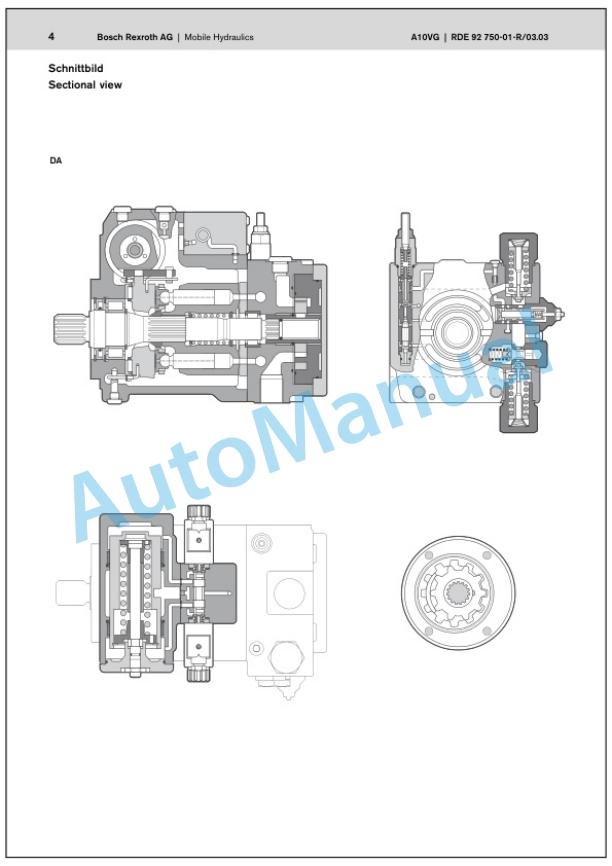

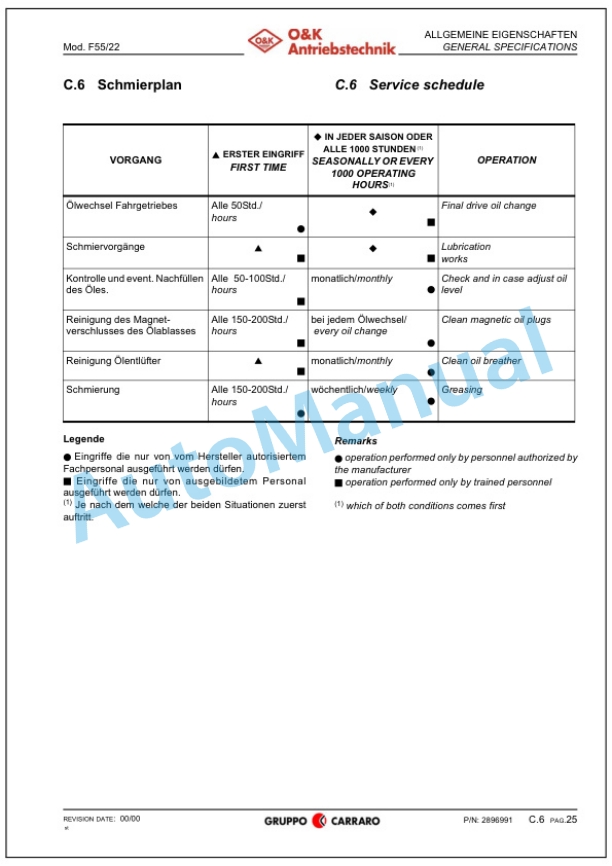

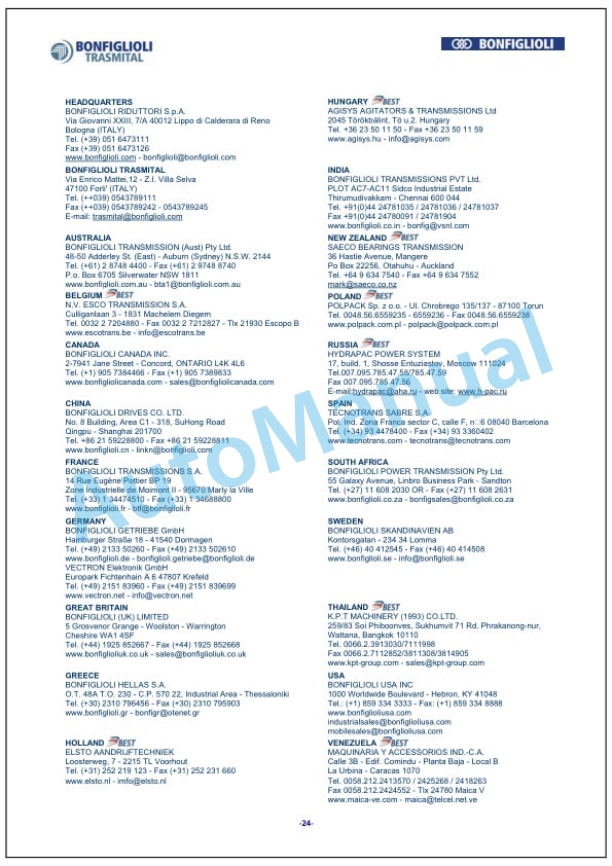

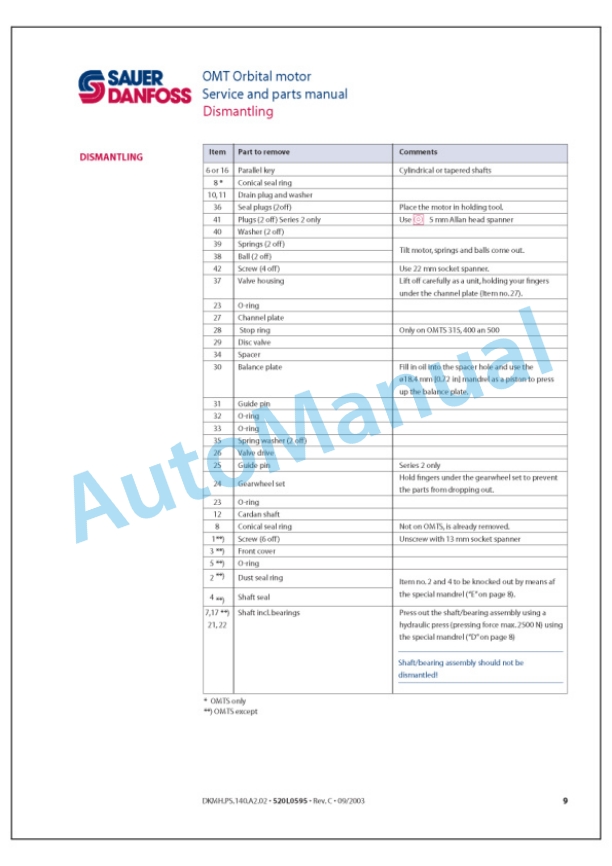

- 20. Suppliers documentation

- 20.1. Suppliers documentation

- 20.2.

- 20.3.

- 20.4.

- 20.5.

- 20.6.

- 20.7.

- 20.8.

- 20.9.

- 20.10.

- 20.11.

- 20.12.

- 20.13.

- 20.14.

- 20.15.

- 20.16.

- 20.17.

- 20.18.

- 20.19.

- 20.20.

- 20.21.

- 20.22.

- 20.23.

- 20.24.

- 20.25.

- 20.26.

- 20.27.

- 21. Circuit diagrams

- 21.1. Circuit diagrams

Rate this product

You may also like

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

$30.00