Bomag BM 1000-35 Cold Planer Service Training 00840003

$30.00

- Type Of Manual: Service Training

- Manual ID: 00840003

- Format: PDF

- Size: 25.2MB

- Number of Pages: 484

- Serial Number:

101883001001 and up

-

Model List:

- BM 1000-35 Cold Planer

- 1. Table of contents

- 2. General service training

- 2.1. Introduction Service Training

- 2.2. Concerning your safety

- 2.2.1. Handling fuels and lubricants

- 2.2.1.1. Preliminary remarks

- 2.2.1.2. Safety regulations and environmental protection regulations for handling diesel fuel

- 2.2.1.3. Safety regulations and environmental protection regulations for handling AdBlue/DEF

- 2.2.1.4. Safety regulations and environmental protection regulations for handling oil

- 2.2.1.5. Safety regulations and environmental protection regulations for handling hydraulic oil

- 2.2.1.6. Safety regulations and environmental protection regulations for handling coolants

- 2.2.1.7. Safety regulations and environmental protection regulations for handling battery acid

- 2.2.2. Park the machine in secured condition.

- 2.3. Fuels and lubricants

- 2.3.1. Engine oil

- 2.3.1.1. Oil quality

- 2.3.1.2. Oil viscosity

- 2.3.1.3. Oil change intervals

- 2.3.2. Fuel

- 2.3.2.1. Fuel quality

- 2.3.2.2. Winter fuel

- 2.3.2.3. Storage

- 2.3.3. AdBlue/DEF

- 2.3.3.1. AdBlue/DEF quality

- 2.3.3.2. Low outside temperatures

- 2.3.3.3. Storage

- 2.3.3.4. Cleanliness

- 2.3.4. Coolant

- 2.3.4.1. General

- 2.3.4.2. Topping up coolant

- 2.3.4.3. Replacing the coolant

- 2.3.5. Hydraulic oil

- 2.3.5.1. Mineral oil based hydraulic oil

- 2.3.5.2. Biodegradable hydraulic oil

- 2.3.6. Gear oil

- 2.3.7. Lubrication grease

- 2.3.8. Hightemperature lubrication grease

- 2.4. Table of fuels and lubricants

- 3. Technical data

- 4. Total overview of machine

- 4.1. Component overview Electrics

- 4.2. Component overview hydraulics

- 5. Trouble shooting

- 5.1. Overviews

- 5.1.1. Overview Travel System

- 5.1.2. Overview Milling drive

- 5.1.3. Overview Height adjustment

- 5.1.4. Overview Steering

- 5.1.5. Overview Conveyor belt functions

- 5.1.6. Overview Swivelling the slewable chassis

- 5.2. Functional conditions

- 5.2.1. Functional conditions introduction

- 5.2.2. Functional conditions Starting the diesel engine

- 5.2.3. Functional conditions Shutting down the diesel engine

- 5.2.4. Functional conditions Release of travel lever

- 5.2.5. Functional conditions Activating transport speed

- 5.2.6. Functional conditions Activating working speed

- 5.2.7. Functional conditions Swivelling the track chain drive

- 5.2.8. Functional condition Switch on the milling drum

- 5.2.9. Functional condition Switch off the milling drum

- 5.2.10. Functional conditions Switch on conveyor belt

- 5.2.11. Functional conditions Switch off conveyor belt

- 5.2.12. Functional condition Moving the conveyor belt

- 5.2.13. Functional condition Unfolding and folding the conveyor belt

- 5.2.14. Functional conditions Activate/deactivate the differential lock

- 5.2.15. Functional conditions Scraper (all functions)

- 5.2.16. Functional conditions Holddown (all functions)

- 5.2.17. Functional conditions Side doors (left right) (all functions)

- 5.2.18. Functional conditions Lifting the machine

- 5.2.19. Functional conditions lowering the rear of the machine

- 5.2.20. Functional conditions Switching the water spraying system on/off

- 5.2.21. Functional conditions Switching the high pressure cleaner on/off

- 5.2.22. Functional conditions Switching the filling pump on/off

- 5.2.23. Functional conditions sunroof up/down

- 5.2.24. Functional conditions Opening/closing engine hood

- 5.2.25. Functional conditions Tool change

- 5.3. Fault codes

- 6. Electric systems

- 6.1. Control units

- 6.2. Display

- 6.2.1. 0Start screen

- 6.2.2. 1Work screen

- 6.2.2.1. 1.3Camera view

- 6.2.3. 2Menu

- 6.2.3.1. 2.1Display settings

- 6.2.3.2. 2.2Diagnose

- 6.2.3.3. 2.3Service

- 6.2.3.3.1. 2.3.1Configuration

- 6.2.3.3.2. 2.3.2Service access

- 6.2.3.3.3. 2.3.3 Actuator test

- 6.2.3.3.4. 2.3.4 Teach procedures

- 6.2.3.4. 2.5Extraction system

- 6.2.4. Fault code display

- 6.3. Reserve wiring

- 7. Engine

- 7.1. General description

- 7.2. Lubrication oil circuit

- 7.3. Cooling circuit

- 7.4. Fuel system

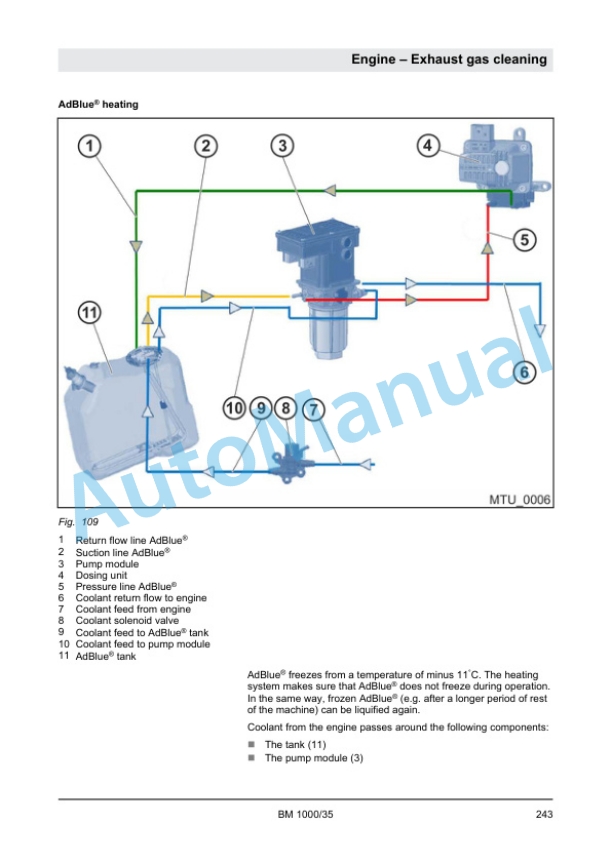

- 7.5. Exhaust gas cleaning

- 7.5.1. Exhaust gas recirculation

- 7.6. Engine electrics

- 7.6.1. Control unit MTU

- 7.6.2. Sensors MTU 6R 1000

- 7.7. Adjusting the valve clearance

- 8. Hydraulic system

- 8.1. Component description

- 8.2. Travel pump

- 8.3. Conveyor belt pump

- 8.4. Fan pump

- 8.5. Working pump

- 8.6. Towing the machine

- 8.7. Trouble shooting axial piston pumps

- 9. Assembly groups

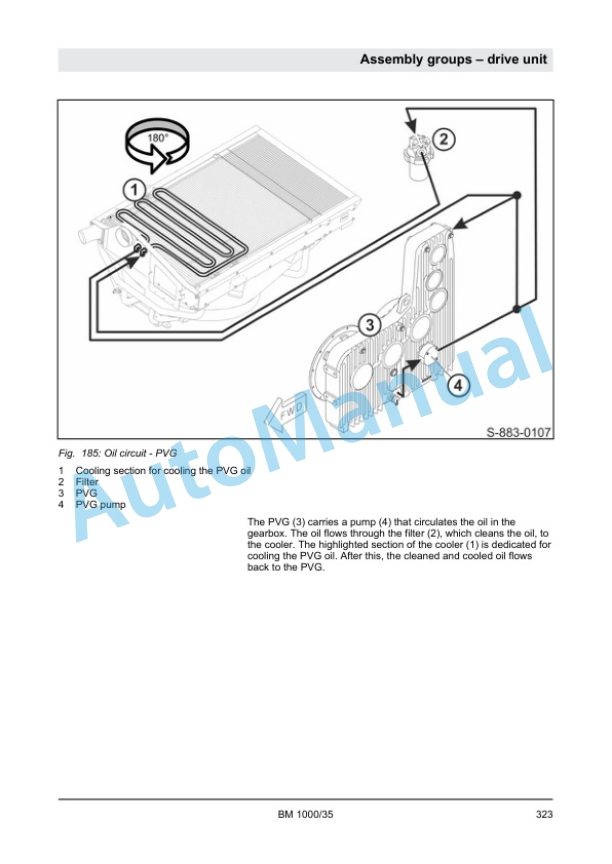

- 9.1. drive unit

- 9.1.1. Description

- 9.2. Milling unit

- 9.2.1. Description

- 9.3. Milling drum

- 9.3.1. Description

- 9.3.2. Repair

- 9.3.2.1. Checking the condition of cutting teeth and exchange holders

- 9.3.2.2. Replace the cutting chisels

- 9.3.2.3. Changing the milling drum

- 9.3.2.4. Change milling gear oil and filter

- 9.4. Conveyor unit

- 9.4.1. Description

- 9.4.2. Repair

- 9.4.2.1. Checking the conveyor belts

- 9.4.2.2. Tensioning the conveyor belt

- 9.4.2.3. Dismount the conveyor belt

- 9.4.2.4. Mounting the conveyor belt

- 9.5. Undercarriage

- 9.5.1. Description

- 9.5.2. Repair

- 9.6. Water system

- 9.6.1. Description

- 9.6.2. Operation

- 9.6.2.1. Checking the water level

- 9.6.2.1.1. Topping up water with the water pump

- 9.6.2.1.2. Topping up water from a hydrant

- 9.6.2.2. Topping up water with the water pump

- 9.6.2.3. Topping up water from a hydrant

- 9.7. Dust extraction

- 9.7.1. Description

- 10. Index

- 11. Appendix

- 11.1. Appendices

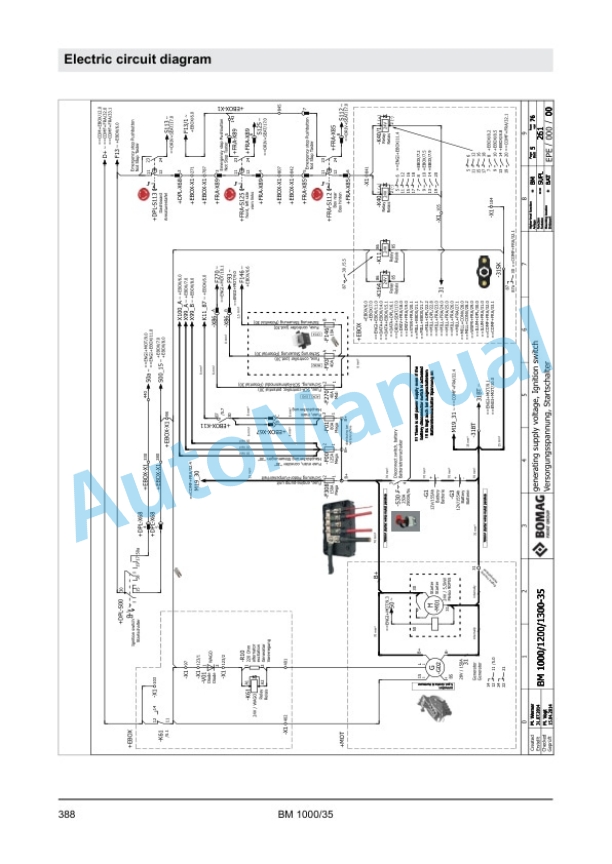

- 11.2. A Electric circuit diagram

- 11.3. B Hydraulic diagram 293

Bomag Service Manual PDF

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930031001 – 101930031042

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

Bomag Service Manual PDF

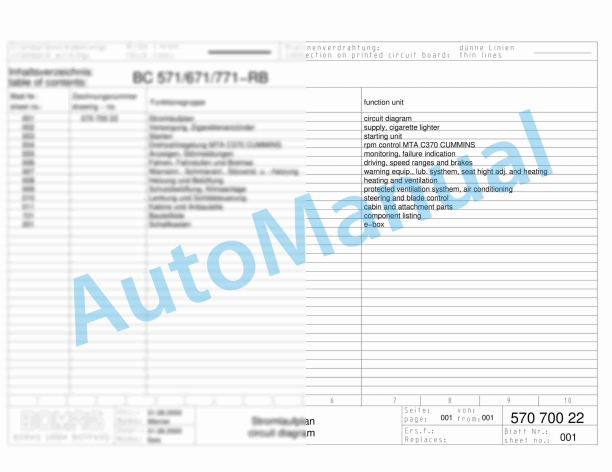

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001