Bomag BW 100 AD-3 to BW 120 AC-3 Tandem Vibratory Rollers Operating and Maintenance Instructions 00812721

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00812721

- Format: PDF

- Size: 2.2MB

- Number of Pages: 88

- Serial Number:

10115051 and up

10117051 and up

10115061 and up

10117053 and up

10117054 and up

10117061 and up

Category: Bomag Operator Manual PDF

-

Model List:

- BW 100 AD-3 Tandem Vibratory Roller

- BW 100 AC-3 Tandem Vibratory Roller

- BW 120 AD-3 Tandem Vibratory Roller

- BW 120 AC-3 Tandem Vibratory Roller

- 1. BW 100 AD3 / BW 120 AD3

- 2. BW 100 AC3 / BW 120 AC3

- 2.1. S/N 101 150 51 …. > / S/N 101 170 51 …. .>

- 2.2. S/N 101 150 61 …. > / S/N 101 170 53 …. >

- 2.3. S/N 101 170 54 …. > / S/N 101 170 61 …. >

- 3. Tandem Vibratory Roller

- 4. Combination Roller

- 4.1. BOMAG machines are products from the wide range of BOMAG compaction equipment.

- 4.2. BOMAGs vast experience in connection with stateoftheart production and testing methods, such …

- 4.3. Please note

- 4.4. For your own personal safety you should only use original spare parts from BOMAG.

- 4.5. In the course of technical development we reserve the right for technical modifications without p…

- 4.6. Please fill in

- 4.7. BW 100 AD3

- 4.8. BW 120 AD3

- 4.9. BW 100 AD3

- 4.10. BW 120 AD3

- 4.11. Weights

- 4.12. Dimensions

- 4.13. Travel characteristics

- 4.14. Steering

- 4.15. Vibration system

- 4.16. Water sprinkler system

- 4.17. BW 100 AC3

- 4.18. BW 120 AC3

- 4.19. BW 100 AC3

- 4.20. BW 120 AC3

- 4.21. Weights

- 4.22. Dimensions

- 4.23. Travel characteristics

- 4.24. Steering

- 4.25. Vibration system

- 4.26. Water sprinkler system

- 4.27. The following noise and vibration values according to the ECdirective for machines, edition (98/…

- 4.28. During operation these values may vary because of the existing operating conditions.

- 4.29. Noise value

- 4.30. Vibration value

- 4.31. General Notes

- 4.32. Intended use

- 4.33. Unintended use

- 4.34. Who has permission to operate the machine

- 4.35. Conversions and changes to the machine

- 4.36. Notes on safety in the operating and maintenance instructions

- 4.37. Information and safety stickers/decals on the machine

- 4.38. Loading the machine

- 4.39. Towing the machine

- 4.40. Checking the roll over protection structure (ROPS)

- 4.41. Starting the machine

- 4.42. Driving the machine

- 4.43. Parking the machine

- 4.44. Filling the fuel tank

- 4.45. Maintenance work

- 5. General notes

- 6. Description of indicators and control elements

- 6.1. Fig. 10

- 6.2. Fig. 11

- 6.3. Fig. 12

- 6.4. Fig. 13

- 6.5. Fig. 14

- 6.6. Fig. 15

- 6.7. Fig. 16

- 6.8. Fig. 17

- 6.9. Fig. 18

- 6.10. Fig. 19

- 6.11. Ball valve for 3stage vibration

- 7. General notes

- 8. Inspections before starting operation

- 9. Starting the engine

- 9.1. Fig. 26

- 9.2. Fig. 27

- 9.3. Fasten/release your seat belt .

- 10. Starting with jump wires

- 10.1. Fig. 34

- 11. Driving the machine

- 11.1. Fig. 35

- 11.2. Fig. 36

- 11.3. Fig. 37

- 12. Stopping the machine / applying the brake

- 12.1. Fig. 38

- 13. Switching the vibration on and off

- 13.1. Preselecting vibration (only AD)

- 13.2. Preselecting vibration (3 stages, only AD)

- 13.3. Switch the vibration on

- 13.4. Switching the vibration off

- 14. Switching the gravity sprinkling system on and off

- 14.1. Fig. 43

- 15. Switching the tire sprinkling system on and off

- 15.1. Fig. 44

- 16. Switching the pressure sprinkler system on or off

- 16.1. Fig. 45

- 16.2. Fig. 46

- 16.3. Fig. 47

- 16.4. Fig. 48

- 17. Stopping the engine/machine

- 17.1. Fig. 49

- 17.2. Fig. 50

- 17.3. Fig. 51

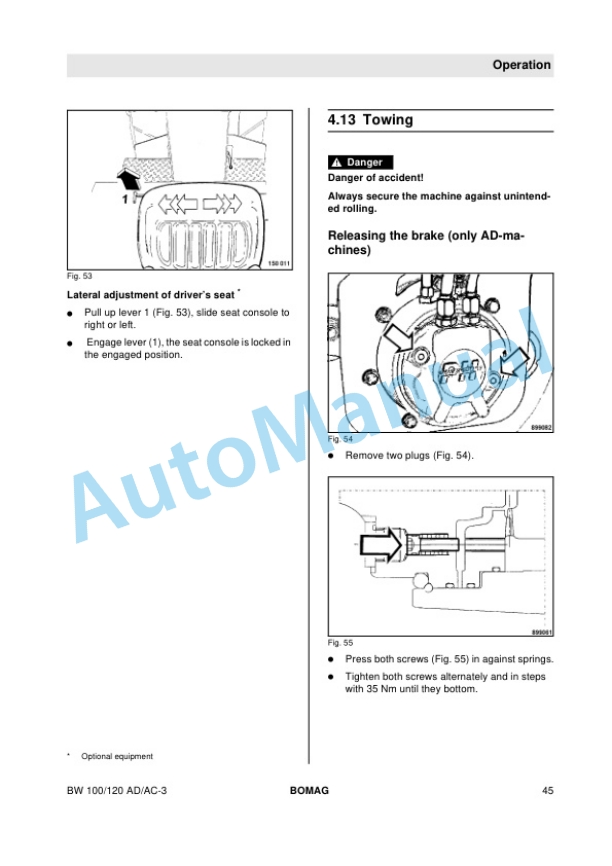

- 18. Adjusting the drivers seat

- 18.1. Fig. 52

- 18.2. Fig. 53

- 18.3. Lateral adjustment of drivers seat

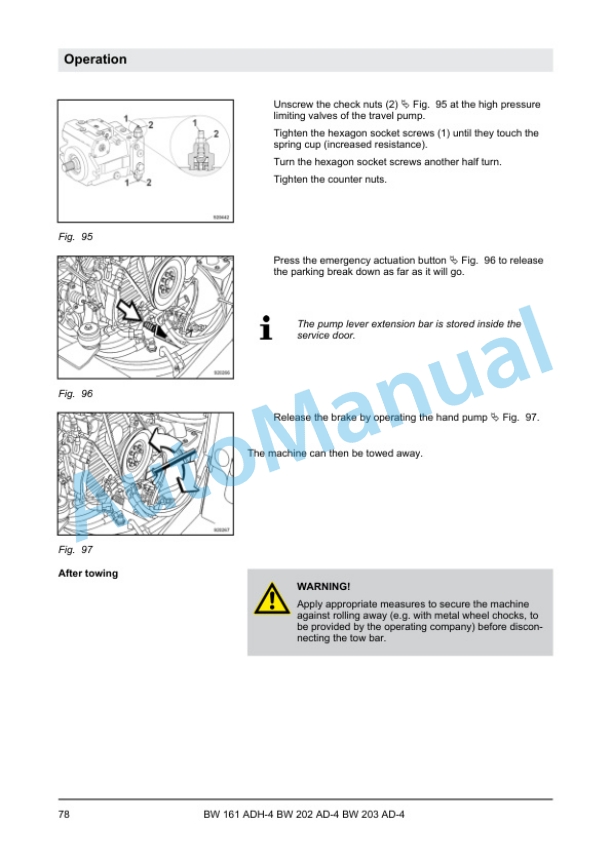

- 19. Towing

- 19.1. Releasing the brake (only ADmachines)

- 19.2. Releasing the brakes on drum and rubber wheels (only ACmachines)

- 19.3. Towing the machine

- 19.4. After towing

- 20. Loading and transport

- 20.1. Fig. 61

- 20.2. Fig. 62

- 20.3. Fig. 63

- 20.4. Loading weight See technical data.

- 20.5. After transport

- 21. Foldable roll over protection structure (ROPS)

- 21.1. Split foldable roll over protection structure (ROPS)

- 21.2. Central fourpoint lifting facility

- 22. General notes on maintenance

- 22.1. Notes on the fuel system

- 22.2. Notes on the engine performance

- 22.3. Notes on the hydraulic system

- 23. Fuels and lubricants

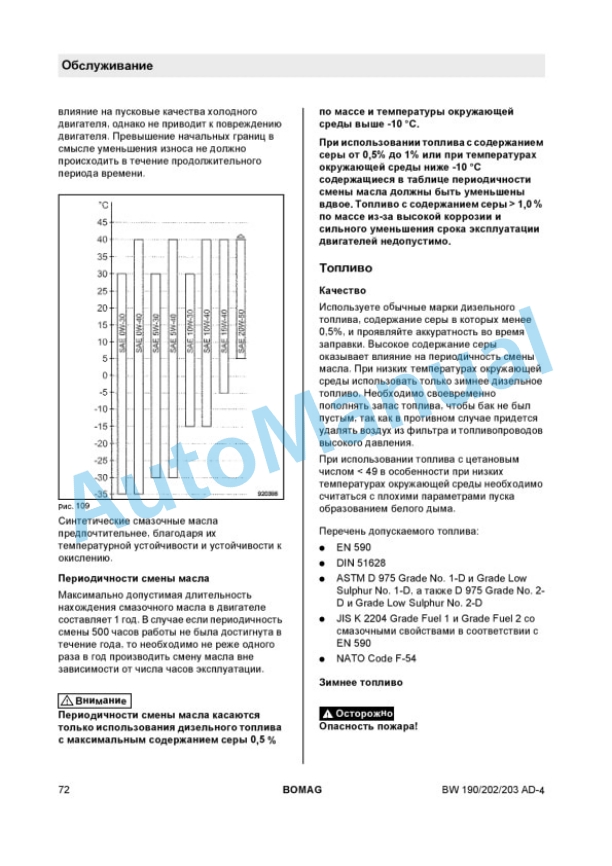

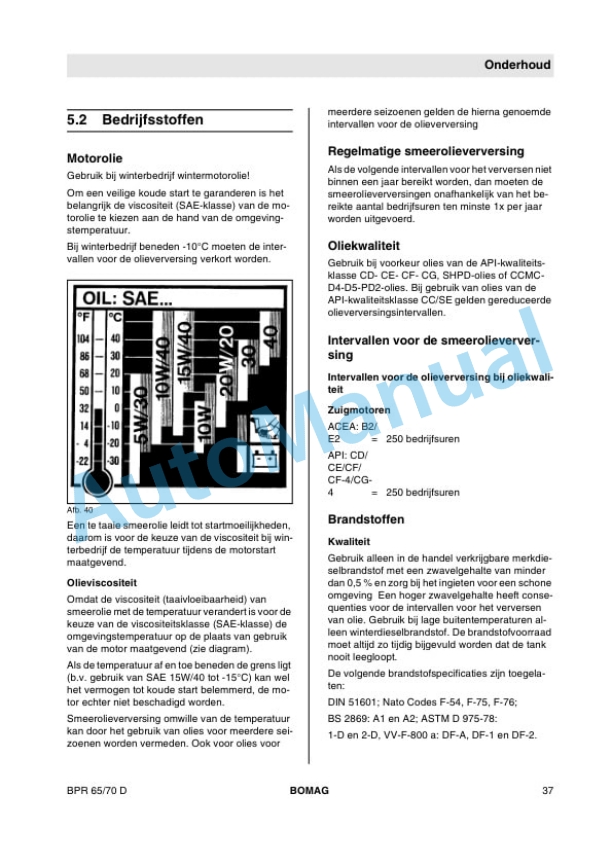

- 23.1. Engine oil

- 23.2. Oil viscosity

- 23.3. Regular lubrication oil changes

- 23.4. Oil quality

- 23.5. Lubrication oil change intervals

- 23.6. Lubrication oil quality classes

- 23.7. Winter fuel

- 23.8. Mineral oil based hydraulic oil

- 23.9. Biodegradable hydraulic oil

- 23.10. Lubrication grease

- 24. Fuels, lubricants and filling capacities

- 24.1. Assembly

- 24.2. Fuel or lubricant

- 24.3. Quantity approx.

- 25. Runningin instructions

- 25.1. The following maintenance work must be performed when running in new machines or overhauled engines

- 25.2. After 50 operating hours

- 26. Maintenance chart

- 26.1. With all maintenance intervals perform also the work for shorter preceding service intervals.

- 26.2. Designation

- 26.3. Every 10 operating hours

- 26.4. Every 50 operating hours

- 26.5. Every 250 operating hours

- 26.6. Every 500 operating hours

- 26.7. Every 1000 operating hours

- 26.8. Every 2000 operating hours

- 26.9. Every 3000 operating hours

- 26.10. Every 5000 operating hours

- 26.11. As required

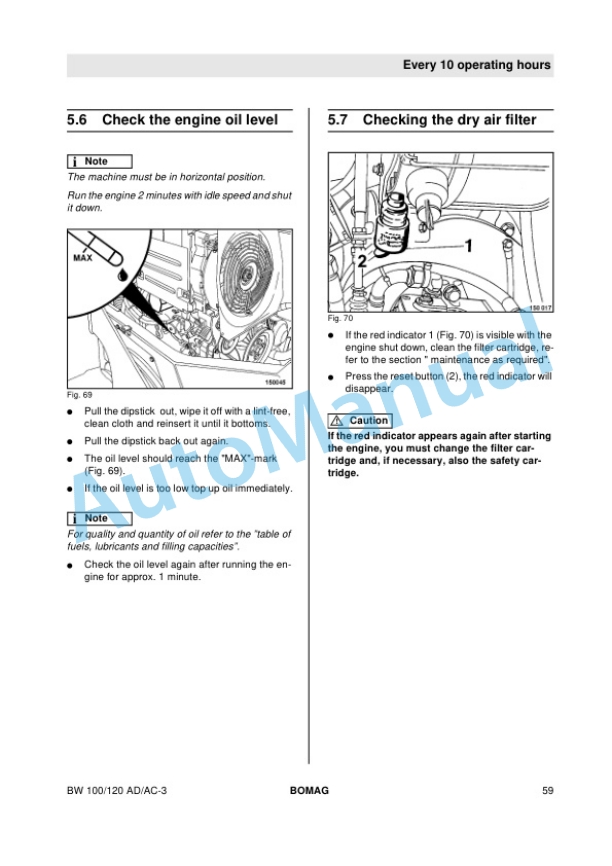

- 27. Check the engine oil level

- 27.1. Fig. 69

- 28. Checking the dry air filter

- 28.1. Fig. 70

- 29. Checking the hydraulic oil level

- 29.1. Fig. 71

- 30. Checking the hydraulic oil filter element

- 30.1. Fig. 72

- 31. Checking the fuel level

- 31.1. Fig. 73

- 32. Checking the water level

- 32.1. Fig. 74

- 33. Checking the emulsion oil level

- 33.1. Fig. 75

- 34. Lubricating the articulated joint

- 34.1. Fig. 76

- 35. Cleaning cooling fins and engine oil cooler

- 35.1. Fig. 77

- 36. Cleaning the hydraulic oil cooler

- 36.1. Fig. 78

- 37. Adjust the scrapers

- 37.1. Fig. 79

- 37.2. Fig. 80

- 38. Checking the battery condition, greasing the poles

- 38.1. Fig. 81

- 38.2. Maintenance free batteries

- 38.3. Serviceable batteries

- 39. Draining the slurry from the fuel tank

- 39.1. Fig. 82

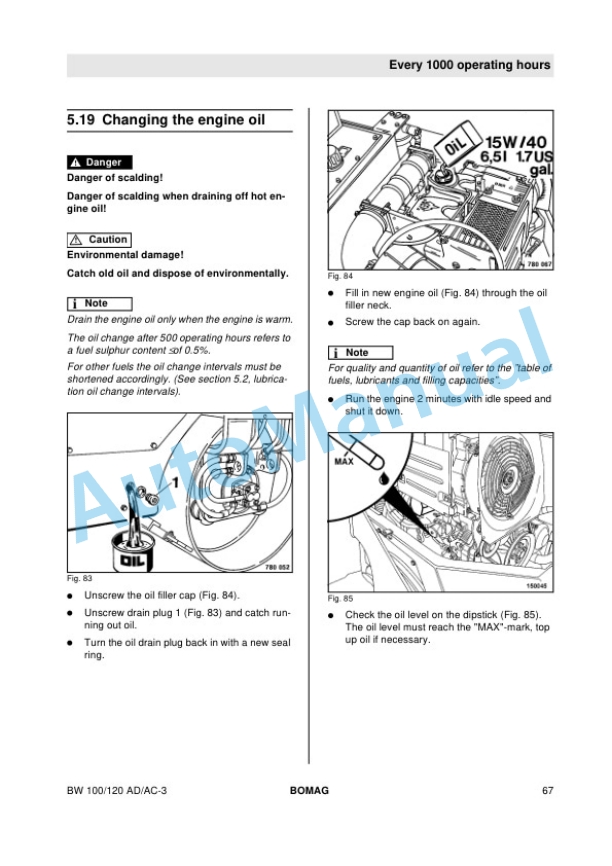

- 40. Changing the engine oil

- 40.1. Fig. 83

- 40.2. Fig. 84

- 40.3. Fig. 85

- 41. Change the engine oil filter cartridge

- 41.1. Fig. 86

- 42. Check, adjust the valve clearance

- 42.1. Valve clearance

- 42.2. Checking the valve clearance

- 42.3. Adjusting the valve clearance

- 43. Checking, tensioning, changing the Vbelt

- 43.1. Checking the Vbelt

- 43.2. Tensioning the Vbelt

- 43.3. Changing the Vbelt

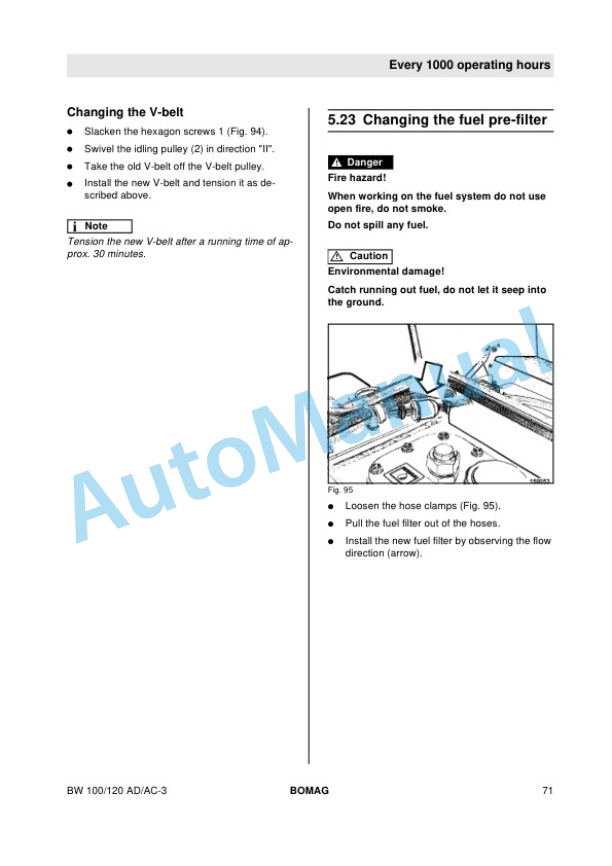

- 44. Changing the fuel prefilter

- 44.1. Fig. 95

- 45. Changing the fuel filter cartridge

- 45.1. Fig. 96

- 46. Changing the hydraulic oil

- 46.1. Fig. 97

- 46.2. Fig. 98

- 46.3. Bleeding the hydraulic system

- 47. Changing the hydraulic oil filter element

- 47.1. Fig. 99

- 48. Checking the injection valves

- 49. Replacing the toothed belt

- 49.1. Fig. 100

- 50. Checking the tire pressure

- 50.1. Fig. 101

- 50.2. Nominal value approx.2.2 bar

- 51. Cleaning, changing the dry air filter

- 51.1. Fig. 102

- 51.2. Fig. 103

- 51.3. Dry cleaning

- 51.4. Wet cleaning

- 52. Cleaning the water tank

- 52.1. Fig. 104

- 53. Water sprinkler system, maintenance in the event of frost

- 53.1. Fig. 105

- 54. Engine conservation

- 54.1. Anticorrosion oils are all oils complying with the specification MILL21260 B or TL 9150 037/2…

- 55. Tightening torques for screws with metric unified thread

- 55.1. Fig. 106

- 56. General notes

- 56.1. The following work must only be carried out by qualified and trained personnel or by the BOMAG sa…

- 56.2. Please observe strictly the safety regulations in chapter 2 of these operating and maintenance in…

- 57. Engine problems

- 57.1. Possible cause

Rate this product

You may also like

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

Bomag BC 473 EB-3 Soil Compactor Operating and Maintenance Instructions 00820281

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

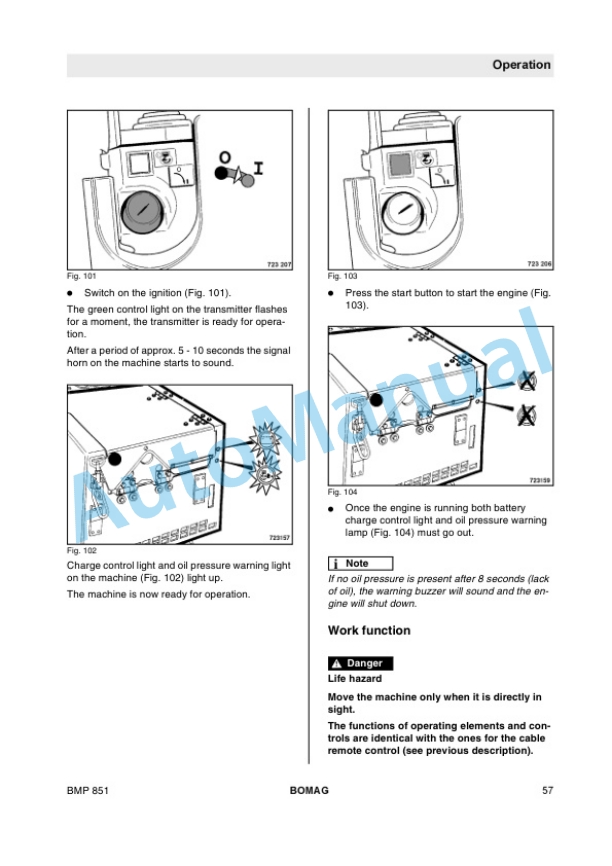

Bomag BMP 851 Multi Purpose Compactor Operating and Maintenance Instructions 00811141

$20.00

Bomag Operator Manual PDF

Bomag BM 2000-60 Cold Milling Machine Operating and Maintenance Instructions 00806061

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

Bomag BPR 65-70 D Vibrating Plate Operating and Maintenance Instructions 00805246

$20.00

Bomag Operator Manual PDF

$20.00