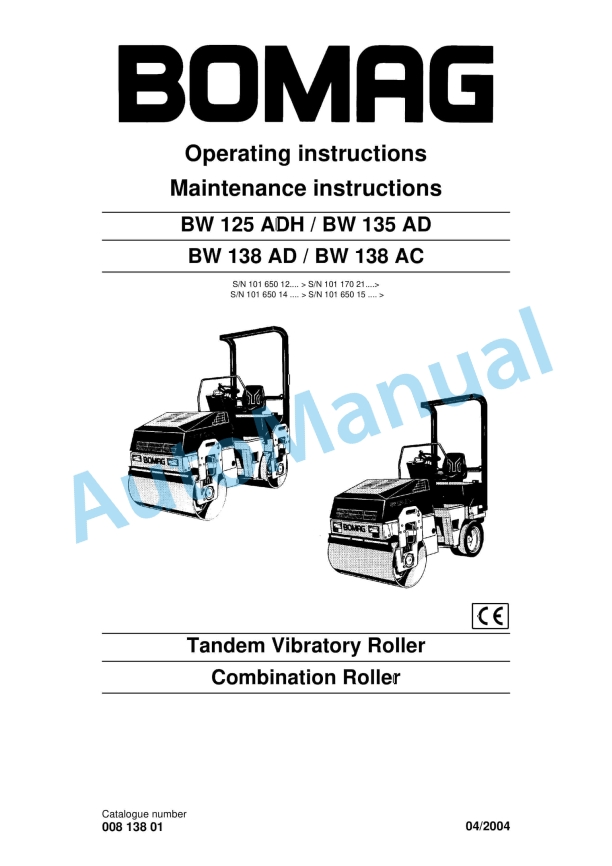

Bomag BW 125 ADH, BW 135 AD, BW 138 AD, BW 138 AC Tandem Vibratory Rollers Operating and Maintenance Instructions 00813801

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00813801

- Format: PDF

- Size: 2.2MB

- Number of Pages: 86

- Serial Number:

10165012 and up

10117021 and up

10165014 and up

10165015 and up

-

Model List:

- BW 125 ADH Tandem Vibratory Roller

- BW 135 AD Tandem Vibratory Roller

- BW 138 AD Tandem Vibratory Roller

- BW 138 AC Tandem Vibratory Roller

- 1. BW 125 ADH / BW 135 AD

- 2. BW 138 AD / BW 138 AC

- 2.1. S/N 101 650 12…. > S/N 101 170 21….>

- 2.2. S/N 101 650 14 …. > S/N 101 650 15 …. >

- 3. Tandem Vibratory Roller

- 4. Combination Roller

- 4.1. BOMAG machines are products from the wide range of BOMAG compaction equipment.

- 4.2. BOMAGs vast experience in connection with stateoftheart production and testing methods, such …

- 4.3. Please note

- 4.4. For your own personal safety you should only use original spare parts from BOMAG.

- 4.5. In the course of technical development we reserve the right for technical modifications without p…

- 4.6. Please fill in

- 4.7. BW 125 ADH

- 4.8. BW 135 AD

- 4.9. BW 138 AD

- 4.10. BW 125 ADH

- 4.11. BW 135 AD

- 4.12. BW 138 AD

- 4.13. Weights

- 4.14. Dimensions

- 4.15. Travel characteristics

- 4.16. Steering

- 4.17. Vibration system

- 4.18. Water sprinkler system

- 4.19. The following noise and vibration values according to the ECdirective for machines, edition (98/…

- 4.20. During operation these values may vary because of the existing operating conditions.

- 4.21. Noise value

- 4.22. Vibration value

- 4.23. Noise value

- 4.24. Vibration value

- 4.25. General Notes

- 4.26. Intended use

- 4.27. Unintended use

- 4.28. Who has permission to operate the machine

- 4.29. Conversions and changes to the machine

- 4.30. Notes on safety in the operating and maintenance instructions

- 4.31. Information and safety stickers/decals on the machine

- 4.32. Loading the machine

- 4.33. Towing the machine

- 4.34. Checking the roll over protection structure (ROPS)

- 4.35. Starting the machine

- 4.36. Driving the machine

- 4.37. Parking the machine

- 4.38. Filling the fuel tank

- 4.39. Maintenance work

- 5. General notes

- 6. Description of indicators and control elements

- 6.1. Fig. 10

- 6.2. Fig. 11

- 6.3. Fig. 12

- 6.4. Fig. 13

- 6.5. Fig. 14

- 6.6. Fig. 15

- 6.7. Fig. 16

- 6.8. Fig. 17

- 6.9. Fig. 18

- 6.10. Fig. 19

- 6.11. Ball valve for 3stage vibration

- 6.12. Foot switch for flow divider (only AD)

- 7. General notes

- 8. Inspections before starting operation

- 9. Starting the engine

- 9.1. Fig. 26

- 9.2. Fig. 27

- 9.3. Fasten/release your seat belt .

- 10. Starting with jump wires

- 10.1. Fig. 34

- 11. Driving the machine

- 11.1. Fig. 35

- 11.2. Fig. 36

- 11.3. Fig. 37

- 12. Stopping the machine / applying the brake

- 12.1. Fig. 38

- 13. Switching the vibration on and off

- 13.1. Preselecting vibration (only AD)

- 13.2. Preselecting vibration (3 stages, only AD)

- 13.3. Switch the vibration on

- 13.4. Switching the vibration off

- 14. Switching the vibration on or off

- 14.1. Fig. 43

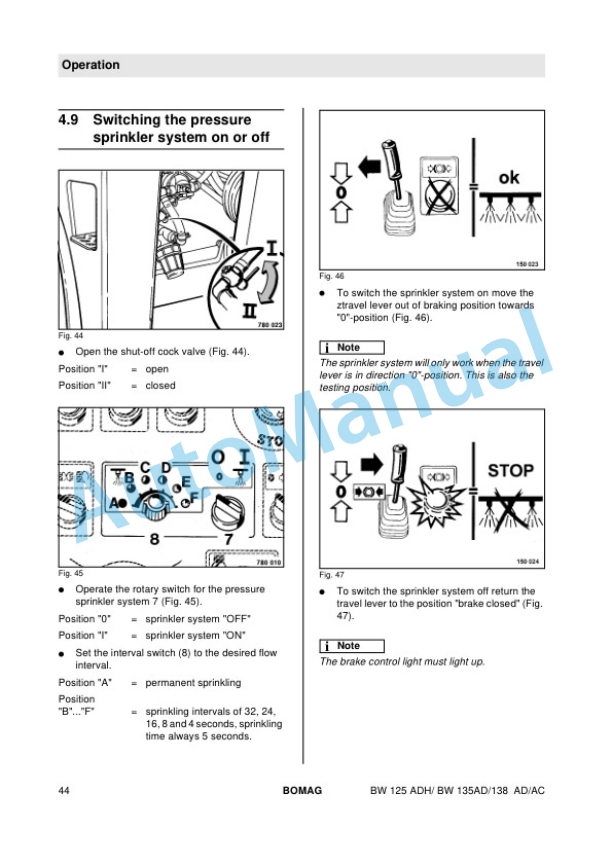

- 15. Switching the pressure sprinkler system on or off

- 15.1. Fig. 44

- 15.2. Fig. 45

- 15.3. Fig. 46

- 15.4. Fig. 47

- 16. Stopping the engine/machine

- 16.1. Fig. 48

- 16.2. Fig. 49

- 16.3. Fig. 50

- 17. Adjusting the drivers seat

- 17.1. Fig. 51

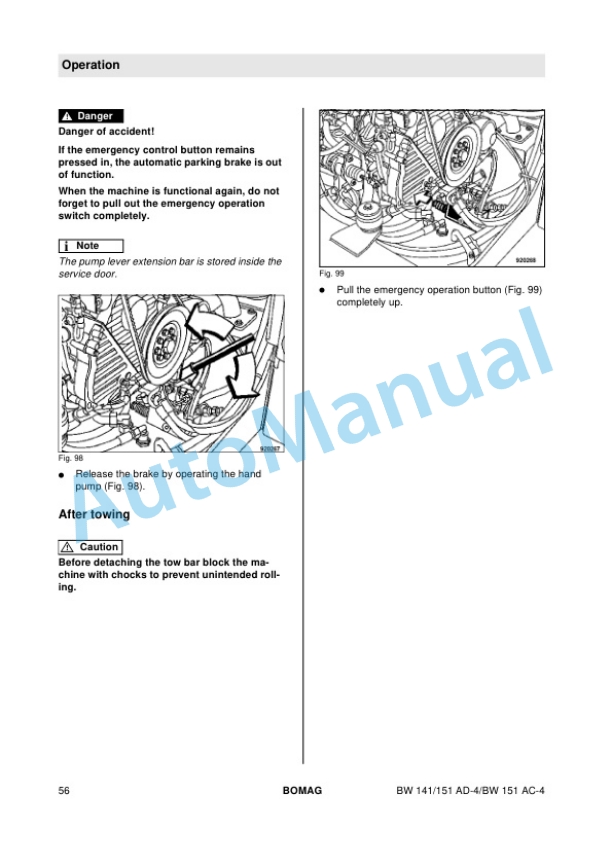

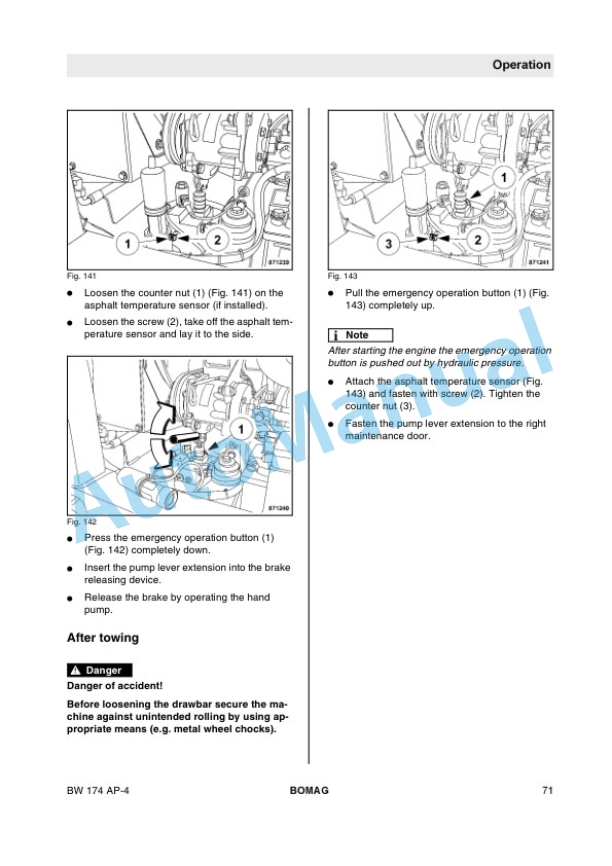

- 18. Towing

- 18.1. Releasing the brakes on front and rear drums mechanically (only ADmachines)

- 18.2. Releasing the brakes on drum and rubber wheels (only ACmachines)

- 18.3. Towing the machine

- 18.4. After towing

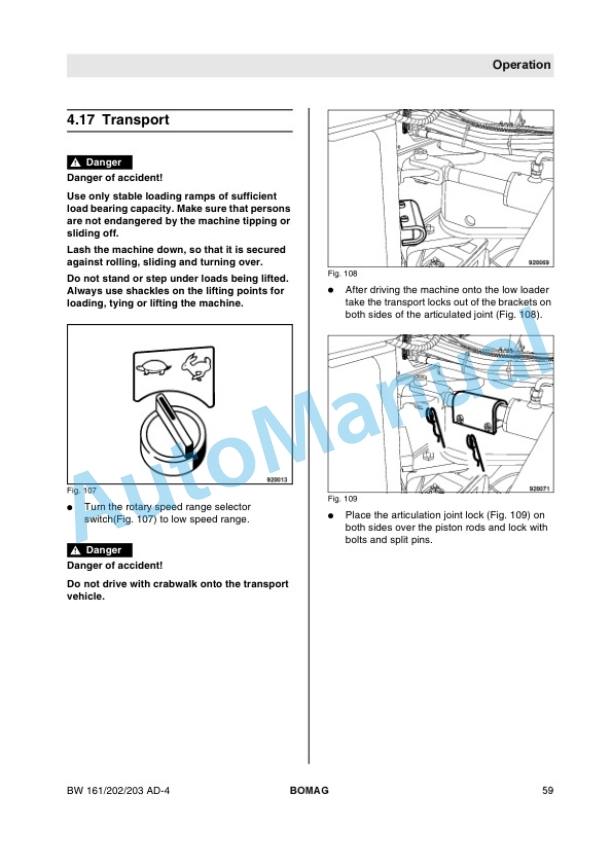

- 19. Loading and transport

- 19.1. Fig. 57

- 19.2. Fig. 58

- 19.3. Fig. 59

- 19.4. Loading weight See technical data

- 19.5. After transport

- 20. Foldable roll over protection structure (ROPS)

- 20.1. Split foldable roll over protection structure (ROPS)

- 21. General notes on maintenance

- 21.1. Notes on the fuel system

- 21.2. Notes on the engine performance

- 21.3. Notes on the hydraulic system

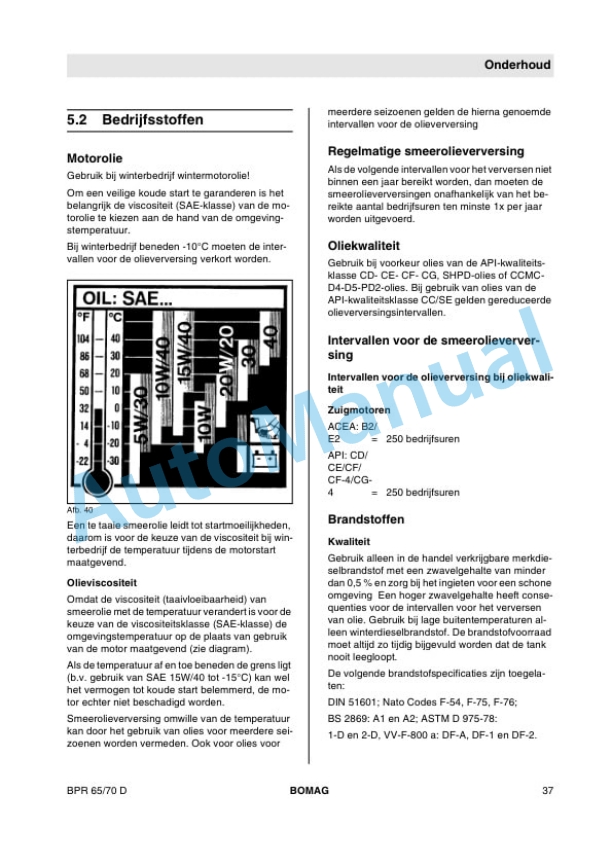

- 22. Fuels and lubricants

- 22.1. Engine oil

- 22.2. Oil viscosity

- 22.3. Regular lubrication oil changes

- 22.4. Oil quality

- 22.5. Lubrication oil change intervals

- 22.6. Lubrication oil quality classes

- 22.7. Winter fuel

- 22.8. Mineral oil based hydraulic oil

- 22.9. Biodegradable hydraulic oil

- 22.10. Lubrication grease

- 23. Table of fuels and lubricants

- 23.1. Assembly

- 23.2. Fuel or lubricant

- 23.3. Quantity approx.

- 24. Runningin instructions

- 24.1. The following maintenance work must be performed when running in new machines or overhauled engines

- 24.2. After 50 operating hours

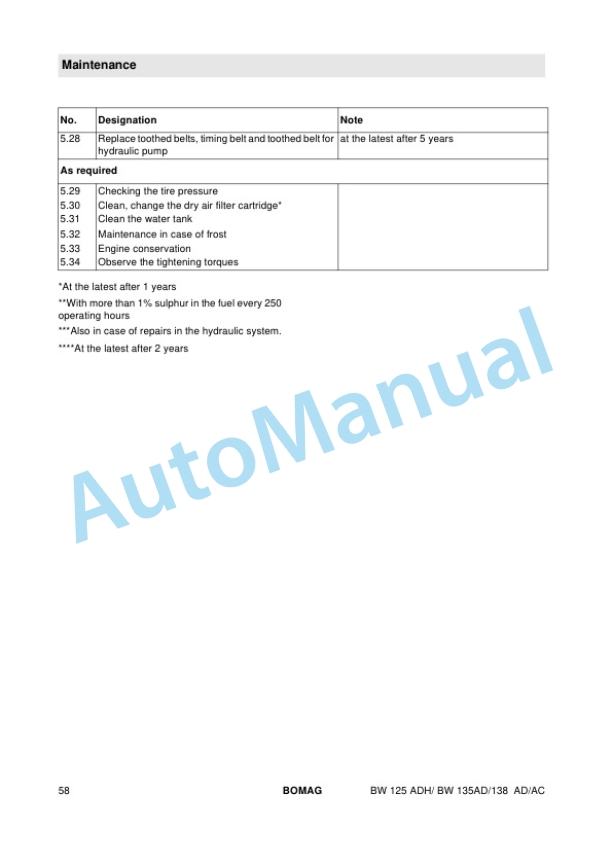

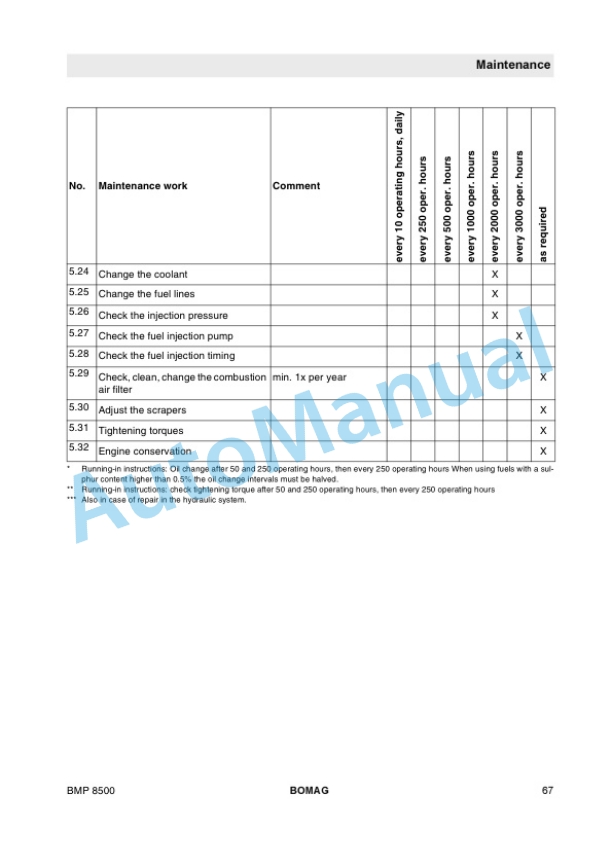

- 25. Maintenance chart

- 25.1. With all maintenance intervals perform also the work for shorter preceding service intervals.

- 25.2. Designation

- 25.3. Every 10 operating hours

- 25.4. Every 50 operating hours

- 25.5. Every 250 operating hours

- 25.6. Every 500 operating hours

- 25.7. Every 1000 operating hours

- 25.8. Every 2000 operating hours

- 25.9. Every 3000 operating hours

- 25.10. Every 5000 operating hours

- 25.11. As required

- 26. Check the engine oil level

- 26.1. Fig. 64

- 27. Checking the dry air filter

- 27.1. Fig. 65

- 28. Checking the hydraulic oil level

- 28.1. Fig. 66

- 29. Checking the hydraulic oil filter element

- 29.1. Fig. 67

- 30. Checking the fuel level

- 30.1. Fig. 68

- 31. Checking the water level

- 31.1. Fig. 69

- 32. Checking the emulsion oil level

- 32.1. Fig. 70

- 33. Lubricating the articulated joint

- 33.1. Fig. 71

- 34. Cleaning cooling fins and engine oil cooler

- 34.1. Fig. 72

- 35. Cleaning the hydraulic oil cooler

- 35.1. Fig. 73

- 36. Adjusting the scrapers

- 36.1. Fig. 74

- 36.2. Fig. 75

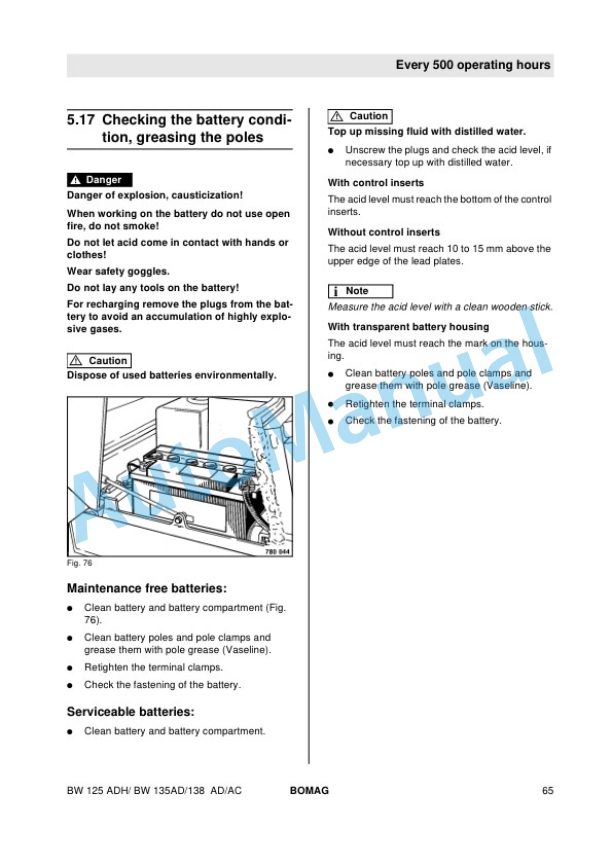

- 37. Checking the battery condition, greasing the poles

- 37.1. Fig. 76

- 37.2. Maintenance free batteries

- 37.3. Serviceable batteries

- 38. Draining the slurry from the fuel tank

- 38.1. Fig. 77

- 39. Changing the engine oil

- 39.1. Fig. 78

- 39.2. Fig. 79

- 39.3. Fig. 80

- 40. Change the engine oil filter cartridge

- 40.1. Fig. 81

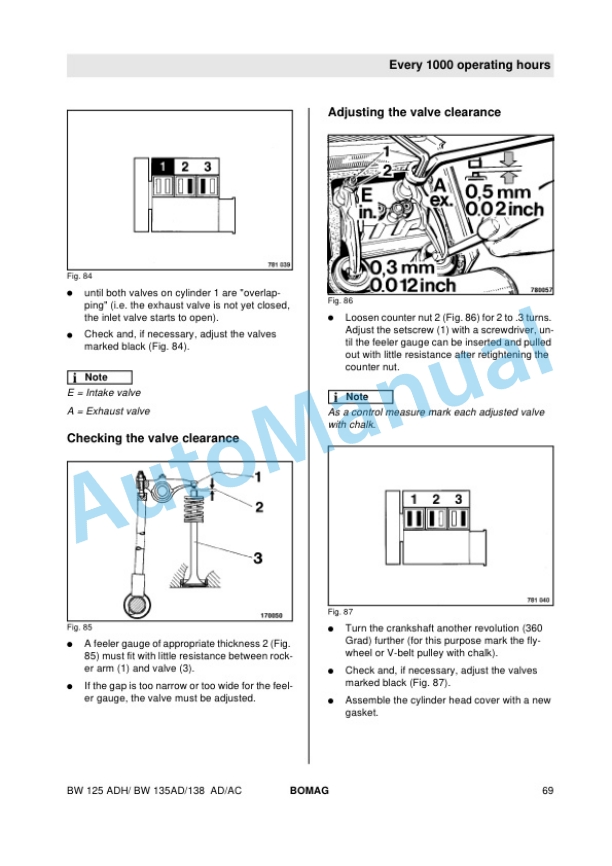

- 41. Check, adjust the valve clearance

- 41.1. Valve clearance

- 41.2. Checking the valve clearance

- 41.3. Adjusting the valve clearance

- 42. Checking, tensioning, changing the Vbelt

- 42.1. Checking the Vbelt

- 42.2. Tensioning the Vbelt

- 42.3. Changing the Vbelt

- 43. Changing the fuel prefilter

- 43.1. Fig. 90

- 44. Change the fuel filter cartridge

- 44.1. Fig. 91

- 45. Changing the hydraulic oil

- 45.1. Fig. 92

- 45.2. Fig. 93

- 45.3. Bleeding the hydraulic system

- 46. Changing the hydraulic oil filter element

- 46.1. Fig. 94

- 47. Checking the injection valves

- 48. Replacing the toothed belt

- 48.1. Fig. 95

- 49. Checking the tire pressure

- 49.1. Fig. 96

- 49.2. Nominal value 2,2 bar (32 psi)

- 50. Cleaning, changing the dry air filter

- 50.1. Fig. 97

- 50.2. Fig. 98

- 50.3. Dry cleaning

- 50.4. Wet cleaning

- 51. Cleaning the water tank

- 51.1. Fig. 99

- 52. Water sprinkler system, maintenance in the event of frost

- 52.1. Fig. 100

- 53. Engine conservation

- 53.1. Anticorrosion oils are all oils complying with the specification MILL21260 B or TL 9150 037/2…

- 54. Tightening torques for screws with metric unified thread

- 54.1. Fig. 101

- 55. General notes

- 55.1. The following work must only be carried out by qualified and trained personnel or by the BOMAG sa…

- 55.2. Please observe strictly the safety regulations in chapter 2 of these operating and maintenance in…

- 56. Engine problems

- 56.1. Possible cause

Bomag Operator Manual PDF

Bomag BPR 65-70 D Vibrating Plate Operating and Maintenance Instructions 00805246

Bomag Operator Manual PDF

Bomag BC 473 EB-3 Soil Compactor Operating and Maintenance Instructions 00820281

Bomag Operator Manual PDF

Bomag BF 700 C-2 Paver Operating and Maintenance Instructions 00820031

Bomag Operator Manual PDF

Bomag BMP 8500 Multi Purpose Compactor Operating and Maintenance Instructions 00805981

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag BW 174 AP-4 Tandem Vibratory Roller Operating and Maintenance Instructions 00806401

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag BC 670 RB Refuse Compactor Operating and Maintenance Instructions 00816061