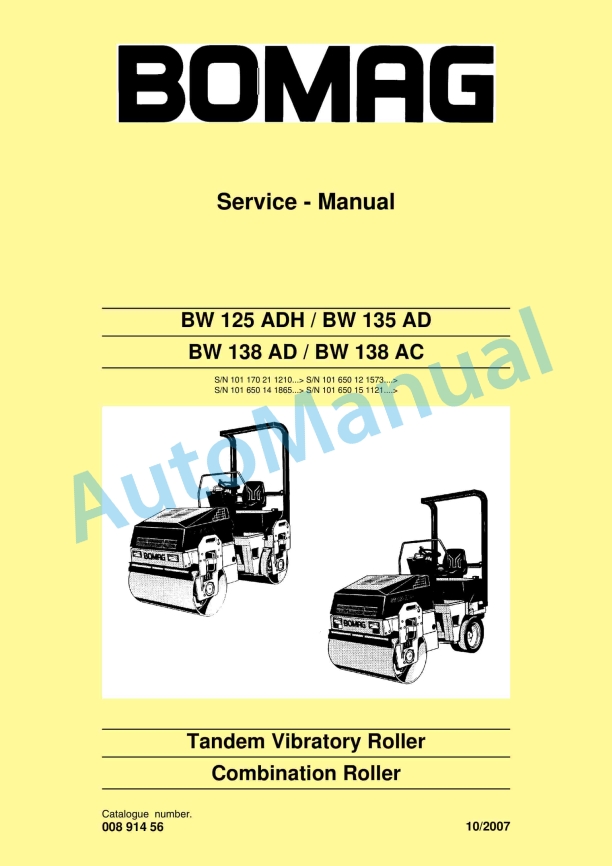

Bomag BW 125 ADH, BW 135 AD, BW 138 AD, BW 138 AC Tandem Vibratory Rollers Service Manual 00891456

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00891456

- Format: PDF

- Size: 24.2MB

- Number of Pages: 462

- Serial Number:

101170211210 and up

101650121573 and up

101650141865 and up

101650151121 and up

-

Model List:

- BW 125 ADH Tandem Vibratory Roller

- BW 135 AD Tandem Vibratory Roller

- BW 138 AD Tandem Vibratory Roller

- BW 138 AC Tandem Vibratory Roller

- 1. BW 125 ADH / BW 135 AD

- 2. BW 138 AD / BW 138 AC

- 2.1. S/N 101 170 21 1210…> S/N 101 650 12 1573….>

- 2.2. S/N 101 650 14 1865…> S/N 101 650 15 1121….>

- 3. Tandem Vibratory Roller

- 4. Combination Roller

- 4.1. General

- 5. Introduction

- 6. Safety regulations

- 6.1. Important notes

- 6.2. General

- 6.3. Precautions and codes of conduct for welding work

- 6.4. Old oils

- 6.5. Hydraulics

- 6.6. Hot fuels

- 6.7. Synthetic rubber

- 6.8. Poisonous substances

- 6.9. Battery

- 6.10. Special safety regulations

- 7. General repair instructions

- 7.1. General

- 7.2. Electrics

- 7.3. Battery

- 7.4. Hydraulic system

- 7.5. Fuel hoses

- 7.6. Gaskets and mating surfaces

- 7.7. Feather keys and keyways

- 7.8. Ball and roller bearings

- 7.9. Screws and nuts

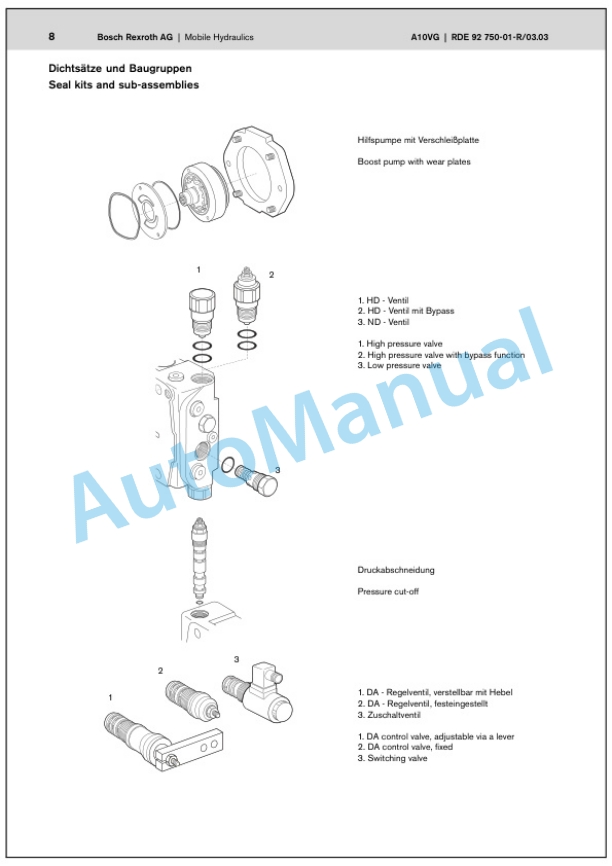

- 8. Tightening torques

- 8.1. Maintenance

- 9. General notes on maintenance

- 9.1. Notes on the fuel system

- 9.2. Notes on the engine performance

- 9.3. Notes on the hydraulic system

- 10. Fuels and lubricants

- 10.1. Engine oil

- 10.2. Oil viscosity

- 10.3. Regular lubrication oil changes

- 10.4. Oil quality

- 10.5. Lubrication oil change intervals

- 10.6. Lubrication oil quality classes

- 10.7. Winter fuel

- 10.8. Mineral oil based hydraulic oil

- 10.9. Biodegradable hydraulic oil

- 10.10. Lubrication grease

- 11. Table of fuels and lubricants

- 12. Runningin instructions

- 13. Maintenance chart

- 13.1. Technical data

- 13.2. Technical data

- 13.3. Fig. 11

- 13.4. Fig. 12

- 13.5. Noise value

- 13.6. Vibration value

- 14. Special tools, tests and adjustments

- 15. Checking the rotation speeds

- 15.1. Check the engine speed

- 15.2. Checking the exciter shaft speed

- 16. Pressure tests in the travel circuit

- 17. Checking / adjusting the neutral positions of the travel pump (Sauer pump)

- 18. Pressure tests in the vibration circuit

- 19. Checking the leakage rate of the vibration motor

- 20. Pressure test in steering circuit

- 21. General

- 21.1. General notes on trouble shooting in hydraulic systems

- 21.2. Important points for trouble shooting and fault rectification

- 22. Trouble shooting diagram

- 22.1. Fundamental electrics

- 22.2. Understanding circuit diagrams

- 22.3. Terminal designations

- 22.4. Current and voltage

- 22.5. Resistance

- 22.6. Series / parallel connection

- 22.7. Ohms law

- 22.8. Electrical energy

- 22.9. Formula diagram

- 22.10. Metrology

- 22.11. Diodes, relays, fuses

- 22.12. Batteries

- 22.13. Threephase generator

- 22.14. Electric starter

- 22.15. Telemecanique switch

- 22.16. Inductive proximity switches

- 22.17. Angle sensor with current output

- 22.18. Plug connectors

- 22.19. Deutsch plug, series DT and DTM

- 22.20. Plugs and terminals in spring clamping technology

- 23. Special tools, electrics

- 23.1. Fig. 10

- 23.2. Fig. 11

- 23.3. Fig. 12

- 23.4. Fig. 13

- 23.5. Fig. 14

- 23.6. Fig. 15

- 23.7. Fig. 16

- 23.8. Fig. 17

- 23.9. Fig. 18

- 23.10. Fig. 19

- 23.11. Fig. 20

- 23.12. Fig. 21

- 23.13. Fig. 22

- 23.14. Fig. 23

- 23.15. Fig. 24

- 23.16. Fig. 25

- 23.17. Fig. 26

- 23.18. Fig. 27

- 23.19. Fig. 28

- 23.20. Fig. 29

- 23.21. Fig. 30

- 23.22. Fig. 31

- 23.23. Fig. 32

- 23.24. Fig. 33

- 23.25. Fig. 34

- 23.26. Fig. 35

- 23.27. Fig. 36

- 23.28. Fig. 37

- 23.29. Fig. 38

- 23.30. Fig. 39

- 23.31. Fig. 40

- 23.32. Fig. 41

- 24. Vibration module

- 25. Module A68

- 25.1. Flushing and bleeding

- 26. Special tools for flushing

- 26.1. Fig. 10

- 26.2. Fig. 11

- 26.3. Fig. 12

- 26.4. Fig. 13

- 26.5. Fig. 14

- 26.6. Fig. 15

- 26.7. Fig. 16

- 26.8. Fig. 17

- 26.9. Fig. 18

- 26.10. Fig. 19

- 27. Flushing general

- 27.1. Changing a component

- 27.2. Chips (abrasion) in the oil

- 27.3. Before flushing

- 27.4. Bleeding

- 27.5. Servicing the flushing filter kit

- 28. Flushing schematic for front drum drive

- 28.1. Travel pump

- 28.2. Pipe joint (tool)

- 28.3. Reducing fitting (tool)

- 28.4. Connecting union (tool)

- 28.5. Rear drum drive motor

- 28.6. Flushing hose (tool) 20S 25S

- 28.7. Screw socket (tool) R1 25S

- 28.8. Flushing filter 1m (tool)

- 28.9. Front drum drive motor

- 28.10. Connecting union (tool)

- 28.11. Elbow union (tool)

- 28.12. Connecting union (tool)

- 28.13. Reducing fitting (tool)

- 28.14. High pressure hose

- 28.15. Flushing hose (tool) 20S 25S

- 29. Flushing the front drum drive

- 29.1. Fig. 10

- 30. Flushing schematic for rear drum drive system

- 30.1. Connecting union (tool)

- 30.2. Reducing fitting (tool)

- 30.3. Pipe joint (tool)

- 30.4. Rear drum drive motor

- 30.5. Flushing hose 20S 25S (tool)

- 30.6. Screw socket (tool) R1 25S

- 30.7. Flushing filter (tool)

- 30.8. Front drum drive motor

- 30.9. Connecting union (tool)

- 30.10. Reducing fitting (tool)

- 30.11. Elbow union (tool)

- 30.12. Connecting union (tool)

- 30.13. Travel pump

- 30.14. High pressure hose

- 30.15. Flushing hose 20S 25S (tool)

- 31. Flushing the rear drum drive

- 31.1. Fig. 10

- 32. Flushing schematic, rear wheel drive motors

- 32.1. Connecting union (tool)

- 32.2. Reducing fitting (tool)

- 32.3. Pipe joint (tool)

- 32.4. Rear wheel drive motors

- 32.5. Flushing hose 20S 25S (tool)

- 32.6. Screw socket (tool) R1 25S

- 32.7. Flushing filter 1m (tool)

- 32.8. Front drum drive motor

- 32.9. Connecting union (tool)

- 32.10. Reducing fitting (tool)

- 32.11. Elbow union (tool)

- 32.12. Connecting union (tool)

- 32.13. Travel pump

- 32.14. High pressure hose

- 32.15. Flushing hose 20S 25S (tool)

- 33. Flushing the rear wheel drive

- 33.1. Fig. 10

- 34. Flushing schematic for vibration drive

- 34.1. Screw fitting 3/4 15L (tool)

- 34.2. Flushing hose (tool)

- 34.3. Vibration valve

- 34.4. Vibration motor, rear (only ADmachine)

- 34.5. Vibration pump

- 34.6. Hydraulic oil tank

- 34.7. Front vibration motor

- 34.8. Connecting union (tool)

- 34.9. Flushing filter (tool)

- 34.10. Hydraulic hose

- 34.11. Flushing hose (tool)

- 35. Flushing the vibration circuit

- 36. Bleeding the travel circuit

- 37. Special tools

- 38. Repair overview for drum

- 39. Removing and installing the drum

- 39.1. Removing the drum

- 39.2. Installing the drum

- 40. Dismantling the drum

- 40.1. Removing the drum drive motor

- 40.2. Remove the vibration motor

- 40.3. Disassembling the bearing cover

- 40.4. Disassembling the exciter shaft

- 40.5. Dismantling the exciter shaft

- 40.6. Removing the cover

- 41. Assembling the drum

- 41.1. Installing the bearing cover

- 41.2. Assembling the exciter shaft

- 41.3. Installing the exciter shaft

- 41.4. Measuring the end float

- 41.5. Assembling the bearing plate

- 41.6. Installing the vibration motor

- 41.7. Installing the drum drive motor

- 42. Special tools, oscillating articulated joint (BW100/120 family)

- 43. Repair overview Oscillating articulated joint

- 43.1. Tensioning nut

- 43.2. Oscillation axle

- 43.3. Bearing housing

- 43.4. Carrier

- 43.5. Bearing block

- 43.6. Cylinder eye for steering cylinder

- 44. Removing and installing the oscillating articulated joint

- 45. Dismantling the oscillating articulated joint

- 45.1. Fig. 10

- 45.2. Fig. 11

- 46. Assembling the oscillating articulated joint

- 46.1. Fig. 10

- 46.2. Fig. 11

- 46.3. Fig. 12

- 46.4. Fig. 13

- 46.5. Fig. 14

- 46.6. Fig. 15

- 46.7. Fig. 16

- 46.8. Fig. 17

- 46.9. Fig. 18

- 46.10. Fig. 19

- 47. Travel pump A10VG28 ….63

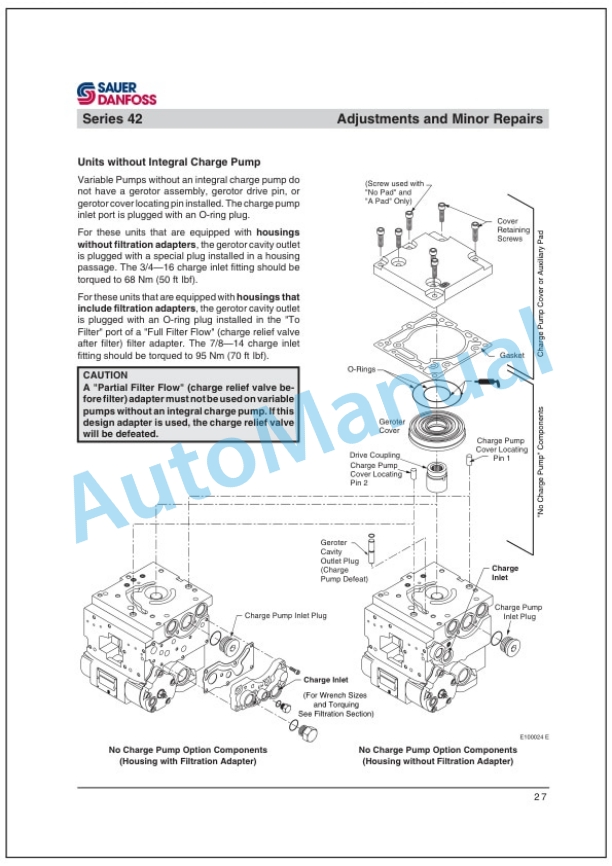

- 48. Travel pump series 42

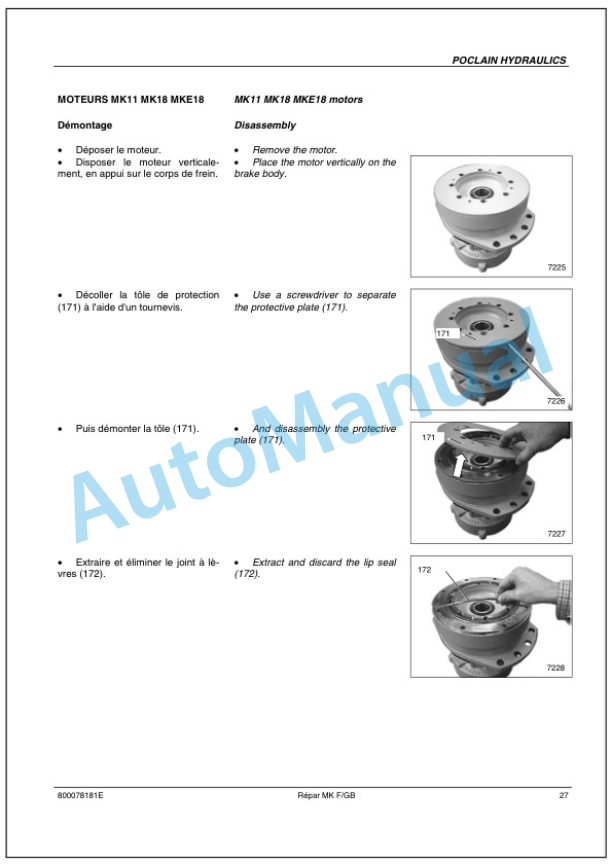

- 49. Drum drive MK05/08/11/18

- 50. Wheel drive MS/MSE 02…18

- 50.1. Circuit diagrams

- 51. Wiring diagram

- 52. Hydraulic diagram

- 53. Hydraulic diagram

- 54. Hydraulic diagram

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

Bomag Service Manual PDF

Bomag Service Manual PDF

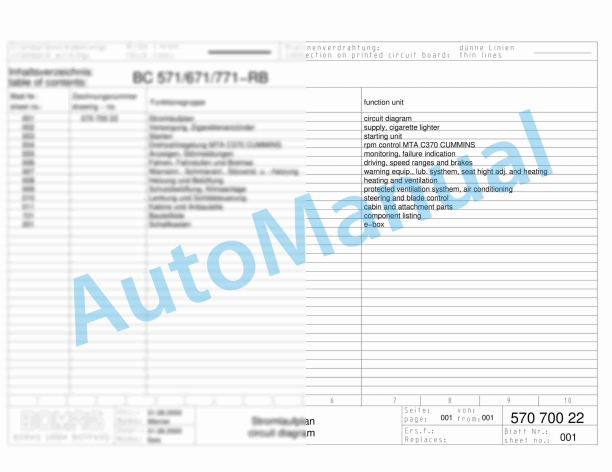

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930071001 – 101930071002

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930021001 – 101930021018

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999