Bomag BW 135 AD-5 Tandem Vibratory Roller Operating and Maintenance Instructions 00820191

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00820191

- Format: PDF

- Size: 7.9MB

- Number of Pages: 244

- Serial Number:

101650361015 and up

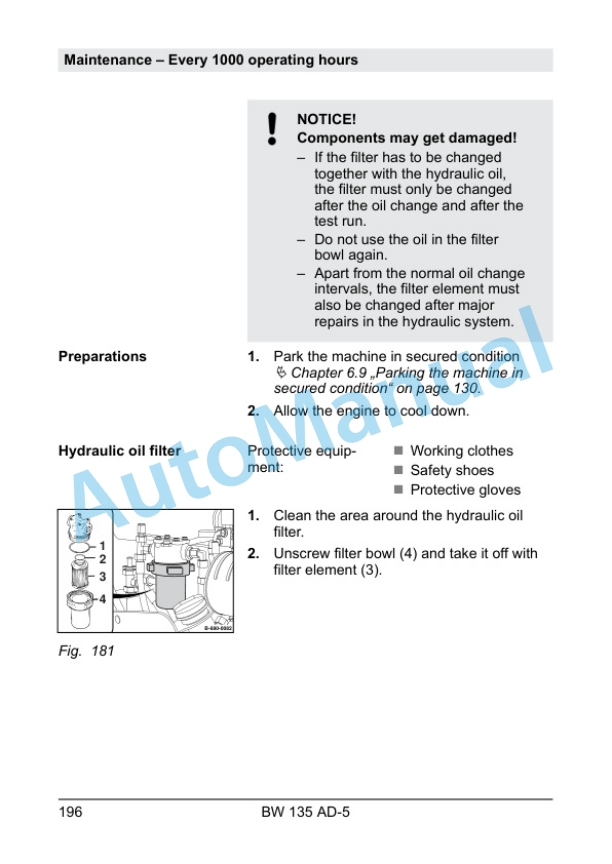

Category: Bomag Operator Manual PDF

-

Model List:

- BW 135 AD-5 Tandem Vibratory Roller

- 1. Table of contents

- 2. Introduction

- 2.1. Foreword

- 2.2. Machine type plate and engine type plate

- 3. Technical data

- 3.1. Noise and vibration data

- 3.1.1. Noise data

- 3.1.2. Vibration data

- 4. Concerning your safety

- 4.1. Basic prerequisites

- 4.1.1. General

- 4.1.2. Explanation of signal words used

- 4.1.3. Personal protective equipment

- 4.1.4. Intended use

- 4.1.5. Improper use

- 4.2. Definition of responsible persons

- 4.2.1. Operating company

- 4.2.2. Expert / qualified person

- 4.2.3. Driver / operator

- 4.3. Fundamentals for safe operation

- 4.3.1. Remaining dangers, remaining risks

- 4.3.2. Regular safety inspections

- 4.3.3. Modifications and alterations to the machine

- 4.3.4. Damage, defects, misuse of safety devices

- 4.3.5. Roll Over Protective Structure (ROPS)

- 4.4. Handling fuels and lubricants

- 4.4.1. Preliminary remarks

- 4.4.2. Safety regulations and environmental protection regulations for handling diesel fuel

- 4.4.3. Safety regulations and environmental protection regulations for handling oil

- 4.4.4. Safety regulations and environmental protection regulations for handling hydraulic oil

- 4.4.5. Safety regulations and environmental protection regulations for handling coolants

- 4.4.6. Safety regulations and environmental protection regulations for handling battery acid

- 4.5. Loading / transporting the machine

- 4.6. Startup procedure

- 4.6.1. Prior to starting up

- 4.6.2. Starting the engine

- 4.6.3. Starting the engine with jump leads

- 4.7. Driving the machine working operation

- 4.7.1. Persons in the danger area

- 4.7.2. Driving the machine

- 4.7.3. Driving up and down slopes

- 4.7.4. Cross slope

- 4.7.5. Working with vibration

- 4.7.6. Working with the chip spreader

- 4.7.7. Parking the machine

- 4.8. Refuelling

- 4.9. Regeneration of exhaust gas aftertreatment system

- 4.10. Emergency procedures

- 4.10.1. Actuating the emergency stop switch

- 4.10.2. Disconnecting the battery

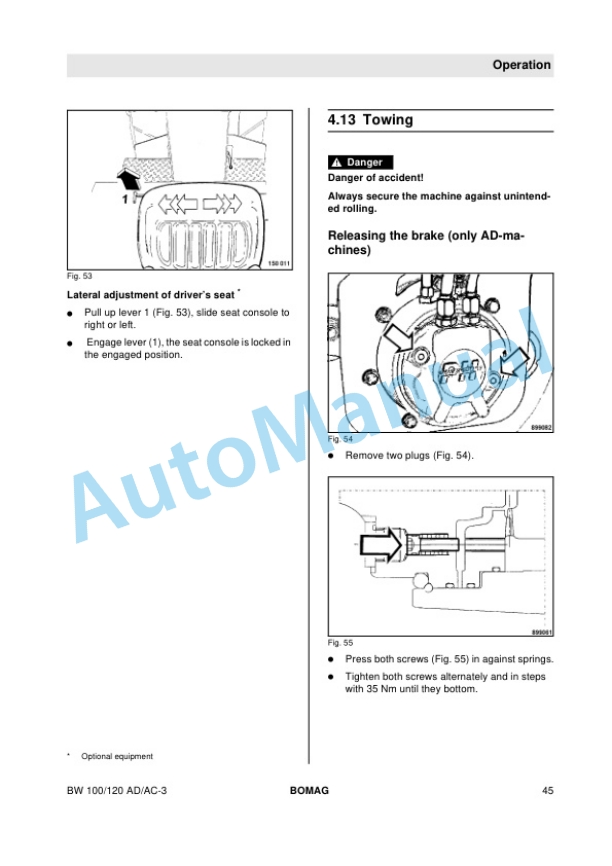

- 4.10.3. Towing the machine

- 4.11. Maintenance work

- 4.11.1. Preliminary remarks

- 4.11.2. Working on hydraulic lines

- 4.11.3. Working on the engine

- 4.11.4. Maintenance work on electric components and battery

- 4.11.5. Cleaning work

- 4.11.6. After maintenance work

- 4.12. Repair

- 4.13. Signage

- 5. Indicators and control elements

- 5.1. Drivers stand

- 5.1.1. Operating console

- 5.1.2. Starter switch

- 5.1.3. 12 V DIN socket

- 5.1.4. Travel lever

- 5.2. Outside of machine

- 5.2.1. Adjustment lever for chip quantity

- 5.3. Engine compartment

- 5.3.1. Main battery switch

- 6. Checks prior to start up

- 6.1. Notes on safety

- 6.2. Visual inspections and function tests

- 6.3. Checking the engine oil level

- 6.4. Checking the fuel level topping up fuel

- 6.4.1. Checking the fuel level

- 6.4.2. Refuelling

- 6.5. Checking the hydraulic oil level

- 6.6. Checking the hydraulic oil filter

- 6.7. Checking the coolant level

- 6.8. Checking the air filter

- 6.9. Checking the water level, topping up

- 6.10. Checking, adjusting the scrapers

- 7. Operation

- 7.1. Settingup the work place

- 7.1.1. Adjust the drivers seat

- 7.1.2. Sliding the drivers seat sideways

- 7.2. Electronic immobilizer

- 7.3. Starting the engine

- 7.4. Travel operation

- 7.4.1. Preliminary remarks and safety notes

- 7.4.2. Driving the machine

- 7.4.3. Stopping the machine, applying the parking brake

- 7.5. Working with vibration

- 7.5.1. Preliminary remarks and safety notes

- 7.5.2. Preparing to work with vibration

- 7.5.3. Manual vibration

- 7.5.4. Vibration in automatic mode

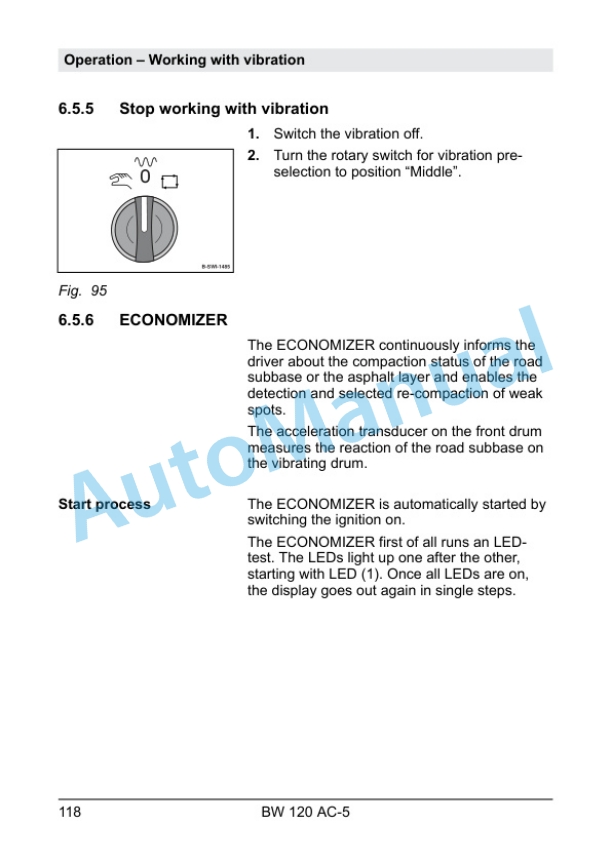

- 7.5.5. Stop working with vibration

- 7.5.6. ECONOMIZER

- 7.6. Water spraying system

- 7.7. Crabwalk

- 7.7.1. Operating the crabwalk via the travel lever

- 7.8. Regeneration of exhaust gas aftertreatment system

- 7.8.1. Preliminary remarks and safety notes

- 7.8.2. Suppressing regeneration

- 7.8.3. Running regeneration at standstill

- 7.9. Parking the machine in secured condition

- 7.10. Edge cutter

- 7.10.1. Lifting / lowering the edge cutter

- 7.11. Chip spreader

- 7.11.1. Filling the chip spreader

- 7.11.2. Emptying the chip spreader

- 7.11.3. Working with chip spreader

- 7.12. Emergency procedures

- 7.12.1. Actuating the emergency stop switch

- 7.12.2. Disconnecting the battery

- 7.12.3. Towing the machine

- 7.12.4. After towing

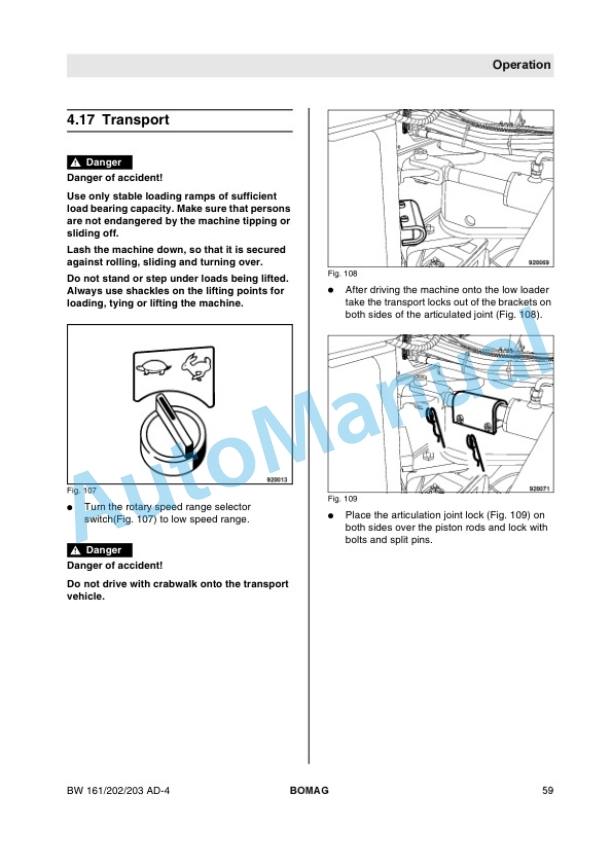

- 8. Loading / transporting the machine

- 8.1. Prepare for transport

- 8.2. Loading the machine

- 8.2.1. Folding down the foldable ROPS

- 8.2.2. Folding down the foldable ROPS with protective roof

- 8.3. Lashing the machine to the transport vehicle

- 8.4. Loading by crane

- 8.5. After transport

- 8.5.1. Erecting the foldable ROPS

- 8.5.2. Erecting the foldable ROPS with protective roof

- 9. Maintenance

- 9.1. Preliminary remarks and safety notes

- 9.2. Preparations/concluding work

- 9.2.1. Engine hood

- 9.2.2. Articulation lock

- 9.3. Fuels and lubricants

- 9.3.1. Engine oil

- 9.3.2. Fuel

- 9.3.3. Coolant

- 9.3.4. Hydraulic oil

- 9.4. List of fuels and lubricants

- 9.5. Runningin instructions

- 9.5.1. General

- 9.5.2. After 50 operating hours

- 9.5.3. After 250 operating hours

- 9.6. Maintenance Table

- 9.7. Every 50 operating hours

- 9.7.1. Checking radiator hoses and hose clamps

- 9.7.2. Checking and cleaning the water separator

- 9.7.3. Lubricating the chip spreader

- 9.8. Every 250 operating hours

- 9.8.1. Checking, tensioning the Vbelt

- 9.8.2. Check the air intake lines

- 9.8.3. Checking radiator hoses and hose clamps

- 9.8.4. Cleaning the radiator module

- 9.8.5. Battery service

- 9.8.6. Check the parking brake

- 9.8.7. Checking the protective canopies

- 9.9. Every 500 operating hours

- 9.9.1. Change engine oil and oil filter cartridge

- 9.9.2. Replacing the fuel filter bleeding the fuel system

- 9.9.3. Replacing the Vbelt

- 9.9.4. Checking the antifreeze concentration and the condition of the coolant

- 9.9.5. Checking the hydraulic lines

- 9.10. Every 1000 operating hours

- 9.10.1. Checking, adjusting the valve clearance

- 9.10.2. Checking the lines on the diesel engine

- 9.10.3. Checking the exhaust manifold

- 9.10.4. Checking the engine mounts

- 9.10.5. Checking the ROPS

- 9.10.6. Checking the travel control

- 9.10.7. Replacing the hydraulic oil filter

- 9.11. Every 2000 operating hours

- 9.11.1. Changing the hydraulic oil

- 9.11.2. Changing the coolant

- 9.11.3. Replacing the oil separator element

- 9.11.4. Checking the exhaust gas recirculation cooler

- 9.11.5. Replacing hoses

- 9.12. Every 3000 operating hours

- 9.12.1. Checking the turbo charger

- 9.12.2. Cleaning the DPF

- 9.12.3. Checking the exhaust gas recirculation system

- 9.13. As required

- 9.13.1. Air filter maintenance

- 9.13.2. Checking the water spraying system

- 9.13.3. Cleaning the water spraying system

- 9.13.4. Measures if there is a risk of frost

- 9.13.5. Draining the fuel tank sludge

- 9.13.6. Measures prior to extended shutdown period

- 10. Setting up / refitting

- 10.1. Manually adjusting the crabwalk

- 10.2. Edge cutter installing tool

- 10.3. Mounting / removing the chip spreader

- 10.3.1. Preliminary remarks and safety notes

- 10.3.2. Mounting the chip spreader

- 10.3.3. Removing the chip spreader

- 11. Troubleshooting

- 11.1. Preliminary remarks

- 11.2. Starting the engine with jump leads

- 11.3. Fuse assignment

- 11.3.1. Notes on safety

- 11.3.2. Fuses in engine compartment

- 11.3.3. Central electrics

- 11.4. Fault code display

- 11.5. Engine faults

- 11.6. Trouble shooting ECONOMIZER

- 12. Disposal

- 12.1. Final shutdown of machine

Rate this product

You may also like

Bomag Operator Manual PDF

Bomag BW 120 AC-5 Combination Roller Operating and Maintenance Instructions 00820131

$20.00

Bomag Operator Manual PDF

Bomag BPR 70-70 D Reversible Vibrating Plate Operating and Maintenance Instructions 00806761

$20.00

Bomag Operator Manual PDF

Bomag BM 2000-60 Cold Milling Machine Operating and Maintenance Instructions 00806061

$20.00

Bomag Operator Manual PDF

Bomag BC 670 RB Refuse Compactor Operating and Maintenance Instructions 00816061

$20.00

Bomag Operator Manual PDF

Bomag BMP 851 Multi Purpose Compactor Operating and Maintenance Instructions 00811141

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

$20.00

Bomag Operator Manual PDF

$20.00