Bomag BW 145 D-3, BW 145 DH-3, BW 145 PDH-3 Single Drum Rollers Operating and Maintenance Instructions 00815708

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00815708

- Format: PDF

- Size: 1.6MB

- Number of Pages: 92

- Serial Number:

10158121, 90158147

10158122, 90158148

10158123, 90158149

-

Model List:

- BW 145 D-3 Single Drum Roller

- BW 145 DH-3 Single Drum Roller

- BW 145 PDH-3 Single Drum Roller

- 1. BW 145 D3 / DH3 / PDH3

- 1.1. S/N 101 581 21…. 901 581 47 ….

- 1.2. S/N 101 581 22…. 901 581 48 ….

- 1.3. S/N 101 581 23 …. 901 581 49 ….

- 2. Single drum roller

- 2.1. BOMAG machines are products from the wide range of BOMAG compaction equipment.

- 2.2. BOMAGs vast experience, together with the most uptodate production and testing methods, includ…

- 2.3. Please note

- 2.4. For your own safety you should only use BOMAGspare parts.

- 2.5. We reserve the right for technical modifications without prior notification.

- 2.6. Please fill in

- 2.7. BW 145 D3

- 2.8. BW 145 DH3

- 2.9. BW 145 PDH3

- 2.10. BW 145 D3

- 2.11. BW 145 DH3

- 2.12. BW 145 PDH3

- 2.13. Weights

- 2.14. Travel characteristics

- 2.15. Steering

- 2.16. Vibration

- 2.17. Tank contents

- 2.18. The following noise and vibration values according to the ECdirective for machines, edition (91/…

- 2.19. During operation these values may vary because of the existing operating conditions.

- 2.20. Noise value

- 2.21. Vibration value

- 2.22. General

- 2.23. Intended use

- 2.24. Unintended use

- 2.25. Who is allowed to work with the machine

- 2.26. Conversions and alterations to the machine

- 2.27. Safety notes in the operating and maintenance instructions

- 2.28. Information and safety stickers/decals on the machine

- 2.29. Loading the machine

- 2.30. Towing the machine

- 2.31. Checking the rollover protection structure (ROPS)

- 2.32. Starting the machine

- 2.33. Driving the machine

- 2.34. Parking the machine

- 2.35. Filling the fuel tank

- 2.36. Maintenance work

- 3. General notes

- 3.1. The control and warning lamps light up while the engine is running

- 4. General notes

- 5. Tests before taking into operation

- 6. Starting the engine

- 6.1. Fig. 25

- 6.2. Fig. 26

- 6.3. Fig. 27

- 6.4. Fig. 28

- 6.5. Fig. 29

- 6.6. Fig. 30

- 6.7. Fig. 31

- 6.8. Fig. 32

- 6.9. Fig. 33

- 7. Starting with jump leads

- 7.1. Fig. 34

- 8. Driving the machine

- 8.1. Fig. 35

- 8.2. Fig. 36

- 8.3. Fig. 37

- 8.4. Important notes on travel operation

- 9. Emergency exit

- 10. Operating the parking brake, stopping the machine

- 10.1. Fig. 38

- 11. Shutting the engine down

- 11.1. Fig. 39

- 11.2. Fig. 40

- 11.3. Fig. 41

- 12. Switching the vibration on and off

- 12.1. Preselecting the vibration

- 12.2. Switching the vibration on

- 12.3. Switching the vibration off

- 13. Adjusting the seat

- 13.1. Fig. 45

- 14. Operating the hood

- 14.1. Fig. 46

- 14.2. Fig. 47

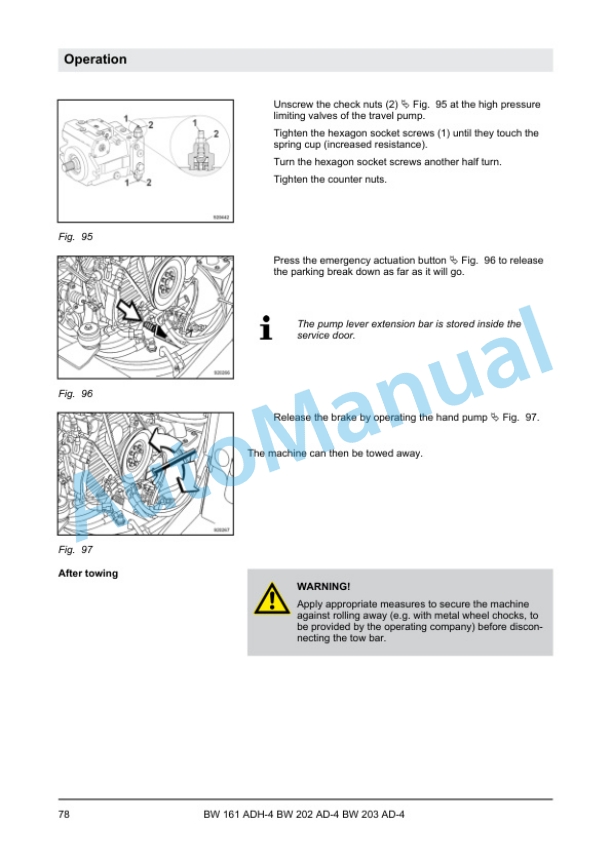

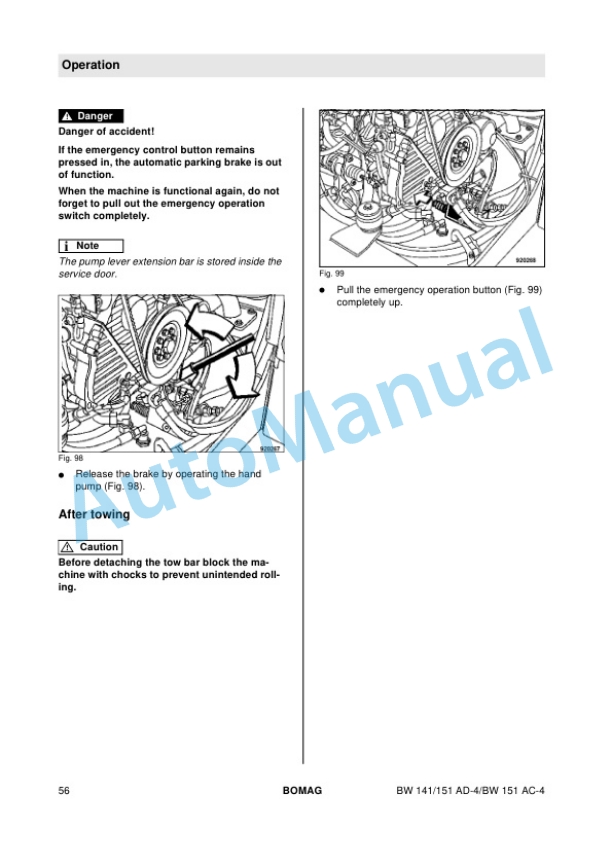

- 15. Towing in case of an engine failure

- 15.1. Fig. 48

- 15.2. Fig. 49

- 15.3. Fig. 50

- 15.4. After towing

- 16. Transport

- 16.1. Fig. 53

- 16.2. Fig. 54

- 16.3. Fig. 55

- 16.4. Weights See technical data

- 17. General notes on maintenance

- 17.1. Notes on the fuel system

- 17.2. Notes on the performance of the engine

- 17.3. Notes on the hydraulic system

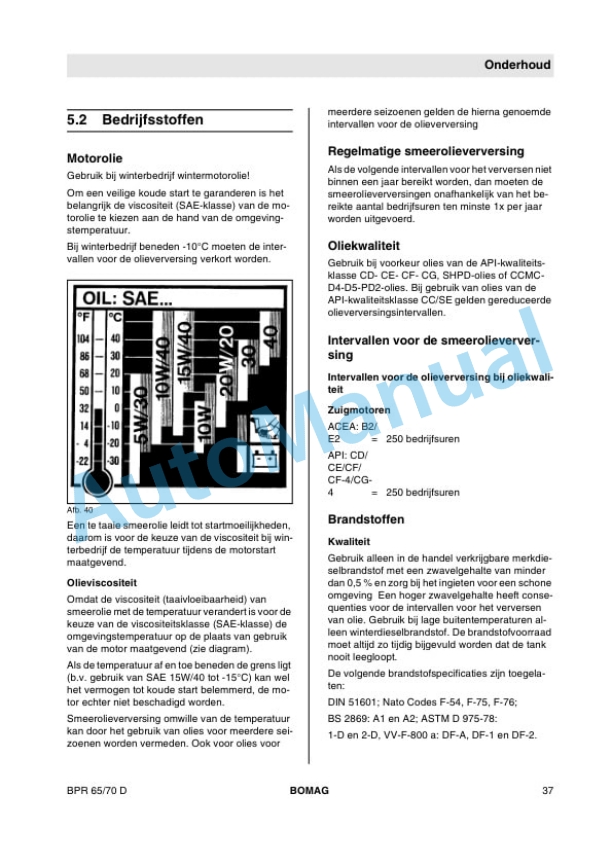

- 18. Fuels and lubricants

- 18.1. Engine oil

- 18.2. Hydraulic oil

- 18.3. Oil for drive axle

- 18.4. Lubrication grease

- 19. Table of fuels and lubricants

- 19.1. Assembly

- 19.2. Fuel or lubricant

- 19.3. Quantity approx.

- 20. Runningin instructions

- 20.1. The following maintenance work must be performed when running in new machines or overhauled engines

- 20.2. After 50 operating hours

- 20.3. After 500 operating hours

- 21. Maintenance chart

- 21.1. With all maintenance intervals perform also the work for shorter preceding service intervals.

- 21.2. Designation

- 21.3. Every 10 operating hours

- 21.4. Every 250 operating hours

- 21.5. Every 500 operating hours

- 21.6. Every 1000 operating hours

- 21.7. Every 2000 operating hours

- 21.8. Every 3000 operating hours

- 21.9. Every 5000 operating hours

- 21.10. As required

- 22. Checking the engine oil level

- 22.1. Fig. 57

- 22.2. For quality and quantity of oil refer to the table of fuels and lubricants

- 23. Checking the fuel filter water separator

- 23.1. Fig. 58

- 24. Checking the fuel level

- 24.1. Fig. 59

- 24.2. Fig. 60

- 24.3. For quality of fuel refer to the table of fuels and lubricants.

- 25. Checking the hydraulic oil level

- 25.1. Fig. 61

- 25.2. Normal level

- 25.3. Minimum level

- 25.4. For quality and quantity of oil refer to the table of fuels and lubricants.

- 26. Checking the tire pressure

- 26.1. Fig. 63

- 26.2. Nominal value see technical data.

- 27. Cleaning the cooling fins on the radiator

- 27.1. Cleaning with compressed air

- 27.2. Cleaning with cold cleansing agent

- 28. Cleaning the cooling fins on the hydraulic oil cooler

- 28.1. Cleaning with compressed air

- 28.2. Cleaning with cold cleansing agent

- 29. Check the oil level in the drive axle

- 29.1. Fig. 66

- 29.2. For quality of oil refer to the table of fuels and lubricants.

- 30. Checking the oil level in left/ right wheel hubs

- 30.1. Fig. 67

- 30.2. For quality of oil refer to the table of fuels and lubricants.

- 31. Checking the oil level in the vibration bearings

- 31.1. Fig. 68

- 31.2. For quality of oil refer to the table of fuels and lubricants.

- 32. Servicing the battery

- 32.1. Fig. 69

- 32.2. Fig. 70

- 33. Draining the sludge from the fuel tank

- 33.1. Fig. 71

- 34. Change engine oil and oil filter cartridge

- 34.1. Fig. 72

- 34.2. Fig. 73

- 34.3. Fig. 74

- 34.4. For quality and quantity of oil refer to the table of fuels and lubricants.

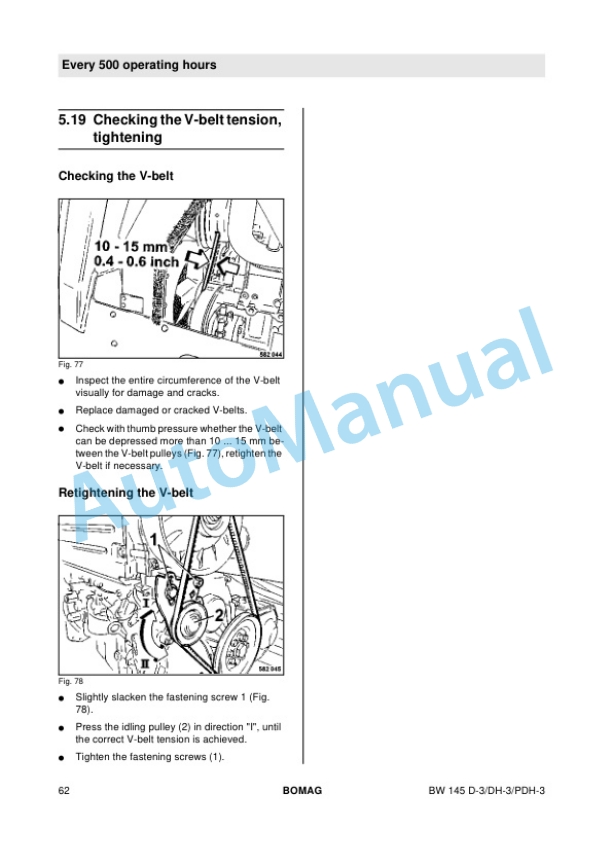

- 35. Checking the Vbelt tension, tightening

- 35.1. Checking the Vbelt

- 35.2. Retightening the Vbelt

- 36. Checking, adjusting the valve clearance

- 36.1. Valve clearance

- 36.2. Adjusting the valve clearance

- 37. Changing the oil in the vibration bearings

- 37.1. Fig. 84

- 37.2. Fig. 85

- 37.3. For quality and quantity of oil refer to the table of fuels and lubricants.

- 38. Change the oil in the drive axle

- 38.1. Fig. 86

- 38.2. Fig. 87

- 38.3. For quality and quantity of oil refer to the table of fuels and lubricants.

- 39. Change the oil in the wheel hubs

- 39.1. Fig. 88

- 39.2. Fig. 89

- 39.3. For quality and quantity of oil refer to the table of fuels and lubricants.

- 40. Changing the fuel prefilter

- 40.1. Fig. 90

- 41. Changing the fuel filter cartridge

- 41.1. Fig. 91

- 42. Checking the fastenings on the diesel engine

- 42.1. Fig. 92

- 42.2. Fig. 93

- 43. Tightening the fastening of the axle on the frame

- 43.1. Fig. 94

- 44. Tightening the wheel nuts

- 44.1. Fig. 95

- 44.2. Tightening torques 550 Nm (405 ftlb) (M22x1,5)

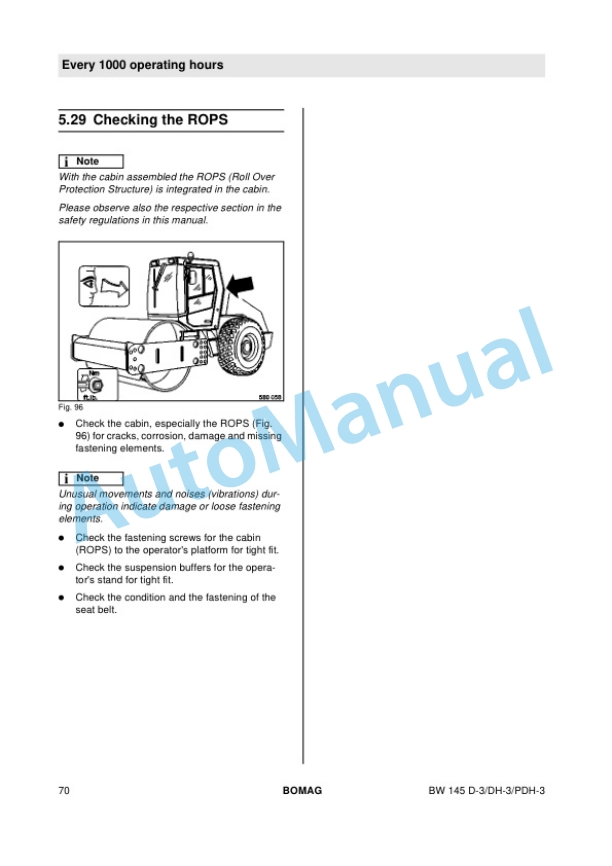

- 45. Checking the ROPS

- 45.1. Fig. 96

- 46. Changing hydraulic oil and breather filter

- 46.1. Fig. 97

- 46.2. Fig. 98

- 46.3. Nominal value

- 46.4. For quality and quantity of oil refer to the table of fuels and lubricants.

- 47. Changing the hydraulic oil filter

- 47.1. Fig. 99

- 48. Checking the injection valves

- 49. Replacing the toothed belt

- 49.1. Fig. 100

- 50. Checking, cleaning, changing the combustion air filter

- 50.1. Fig. 101

- 50.2. Fig. 102

- 50.3. Fig. 103

- 50.4. Fig. 104

- 50.5. Fig. 105

- 50.6. Fig. 106

- 50.7. Fig. 107

- 50.8. Dry cleaning of the main filter element

- 50.9. Changing the safety filter element

- 51. Adjusting the parking brake

- 51.1. Fig. 110

- 51.2. Fig. 111

- 51.3. Fig. 112

- 52. Changing the tires

- 52.1. Fig. 113

- 53. Adjusting the scrapers

- 53.1. smooth drum only

- 53.2. padfoot drum only

- 54. Changing the fresh air filter in the cabin

- 54.1. Fig. 116

- 55. Tightening torques

- 55.1. Fig. 117

- 56. Engine conservation

- 56.1. Anticorrosion oils are those that comply with the specification MILL21260 B or TL 9150 037/2 …

- 56.2. A machine with a conserved engine must be marked by attaching a clearly visible warning tag.

- 57. General notes

- 57.1. The following work must only be carried out by qualified and trained personnel or by the sales se…

- 57.2. Please observe strictly the safety regulations in chapter 2 of these operating and maintenance in…

- 58. Engine

- 58.1. Possible cause

Bomag Operator Manual PDF

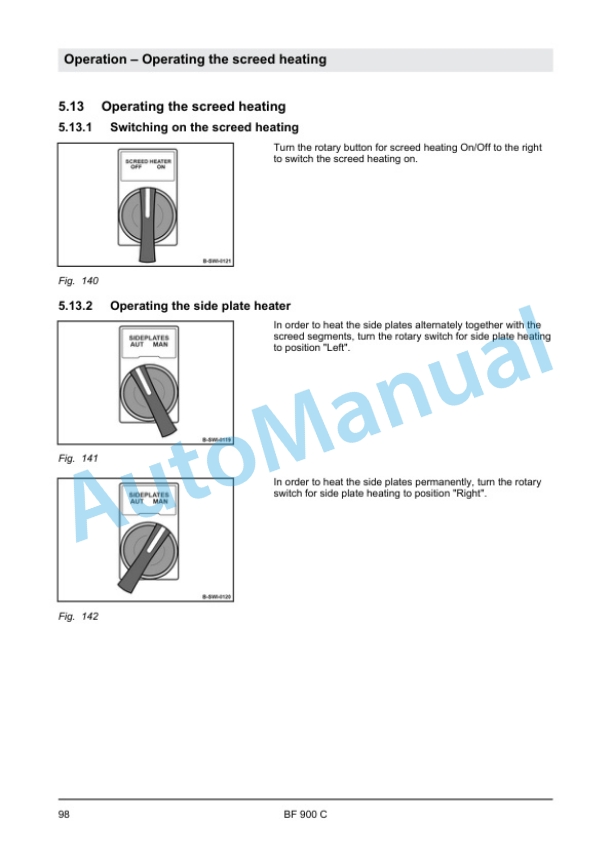

Bomag BF 900 C Paver Operating and Maintenance Instructions 00808181

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag BW 120 AC-5 Combination Roller Operating and Maintenance Instructions 00820131

Bomag Operator Manual PDF

Bomag Operator Manual PDF

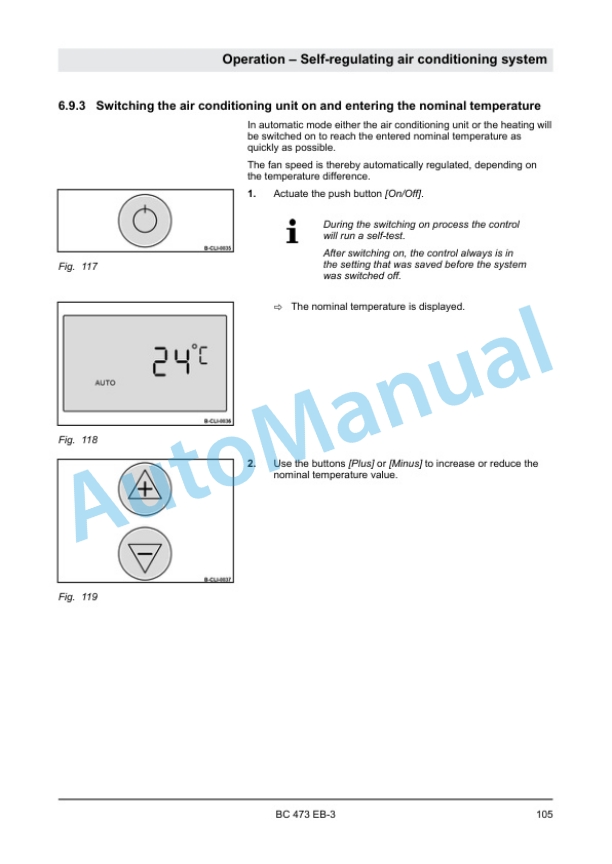

Bomag BC 473 EB-3 Soil Compactor Operating and Maintenance Instructions 00820281

Bomag Operator Manual PDF

Bomag Operator Manual PDF

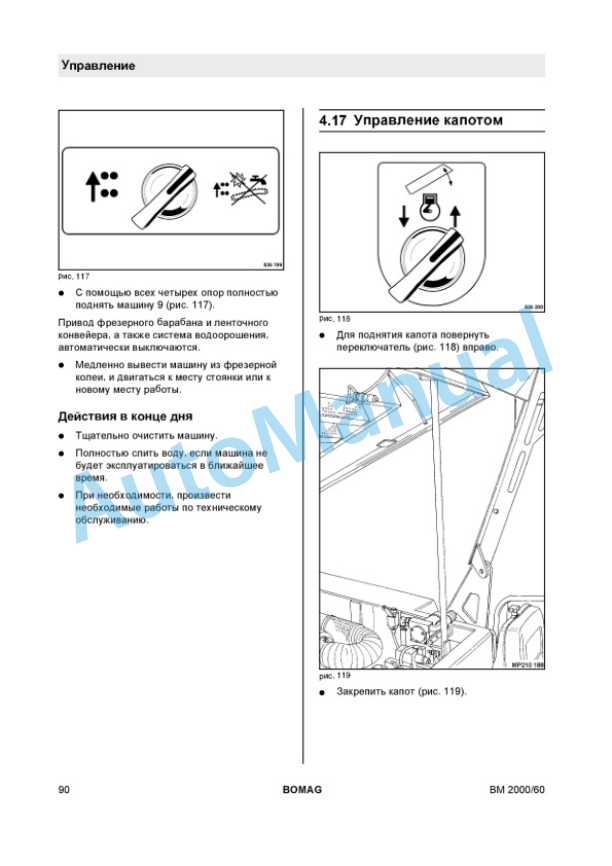

Bomag BM 2000-60 Road Milling Machine Operating and Maintenance Instructions 00804757

Bomag Operator Manual PDF

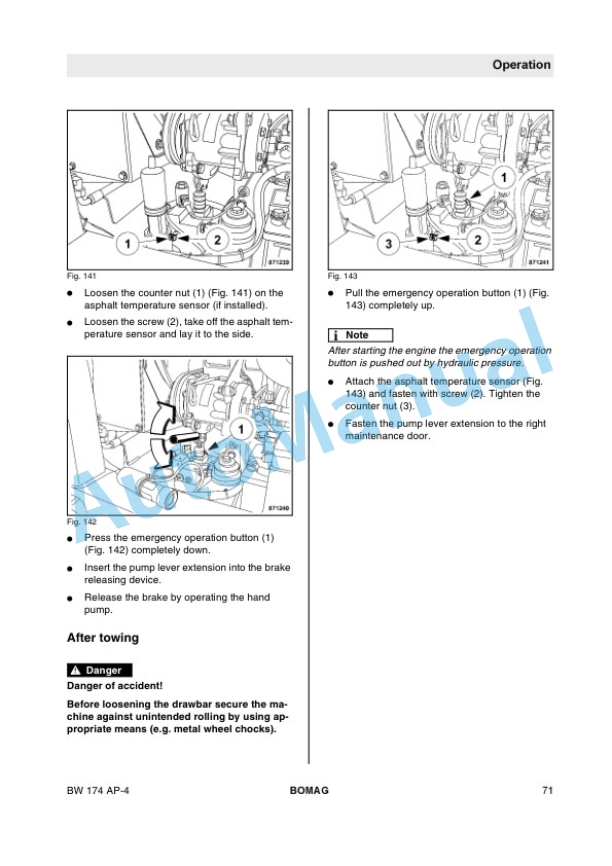

Bomag BW 174 AP-4 Tandem Vibratory Roller Operating and Maintenance Instructions 00806401

Bomag Operator Manual PDF

Bomag BM 2000-60 Cold Milling Machine Operating and Maintenance Instructions 00806061

Bomag Operator Manual PDF

Bomag BPR 65-70 D Vibrating Plate Operating and Maintenance Instructions 00805246