Bomag BW 202 AD-50, BW 206 AD-50, BW 202 ADO-50 Tandem Vibratory Roller Service Manual 00840030

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840030

- Format: PDF

- Size: 74.3MB

- Number of Pages: 904

- Serial Number:

101921191001 and up

101921281001 and up

101921381001 and up

-

Model List:

- BW 202 AD-50 Tandem Vibratory Roller

- BW 206 AD-50 Tandem Vibratory Roller

- BW 202 ADO-50 Tandem Vibratory Roller

- 1. Table of contents

- 2. General

- 2.1. Introduction

- 2.2. Concerning your safety

- 2.3. Maintenance and repair

- 3. Technical data

- 3.1. Technical data, BW 202 AD50

- 3.2. Technical data, BW 202 ADO50

- 3.3. Technical data, BW 206 AD50

- 3.4. Additional technical data

- 3.5. Terms and basis of calculation

- 4. Fuels and lubricants

- 4.1. Fuels and lubricants

- 4.2. List of fuels and lubricants, BW 202 AD50

- 4.3. List of fuels and lubricants, BW 161/202 ADO

- 4.4. List of fuels and lubricants, BW 206 AD50

- 5. Overview of machine

- 5.1. Electric systems

- 5.2. Diesel engine

- 5.3. Hydraulic system

- 5.4. Water spraying system

- 5.5. Air conditioning

- 5.6. Drum

- 6. Electric systems

- 6.1. Overview of electric system

- 6.2. Table of fuels and lubricants

- 6.3. Wiring

- 6.4. CAN BUS overview

- 6.5. Power board

- 6.6. Control console cabin

- 6.7. Fuse assignment

- 6.8. Operators stand

- 6.9. Starting the engine with jump leads

- 6.10. Asphalt temperature sensor, B106

- 6.11. Acceleration transducer, B84 B85

- 6.12. Switching on the pressurized spraying system

- 6.13. Data collector, A80

- 6.14. Differential pressure switch for hydraulic oil filter, B21

- 6.15. Air filter vacuum switch, B03

- 6.16. Sensor, water in fuel, B124

- 6.17. Float switch coolant tank, B55

- 6.18. Oil pressure switch, B06

- 6.19. Coolant temperature switch, B53

- 6.20. Removing and assembling the coolant temperature switch

- 6.21. Boost fuel solenoid valve, Y01

- 6.22. Solenoid actuator to shut down the engine, Y58

- 6.23. Electric throttle control, Y120

- 6.24. Heating flange on engine

- 6.25. Checking the heating flange control

- 6.26. Charge control lamp

- 6.27. Electric module, A108

- 6.28. Telemecanique switch

- 6.29. Deutsch plug, series DT and DTM

- 6.30. Old version of instrument cluster, A15

- 6.31. Inspection and maintenance work

- 7. Diesel engine

- 7.1. Overview of diesel engine

- 7.2. Service side

- 7.3. Starter side

- 7.4. Lubrication oil circuit

- 7.5. Coolant circuit

- 7.6. Replacing the thermostat

- 7.7. Fuel supply

- 7.8. Injection system

- 7.9. Injection pump replacement during service

- 7.10. Injection valve replacement during service

- 7.11. Checking / repairing injection valves

- 7.12. Checking the compression

- 7.13. Inspection and maintenance work

- 8. Hydraulic system

- 8.1. Overview of hydraulics

- 8.2. Open and closed hydraulic circuit

- 8.3. Hydraulic units

- 8.4. Charge circuit and fan circuit

- 8.5. Travel circuit

- 8.6. Vibration circuit

- 8.7. Steering and crabwalk

- 8.8. Edge cutter

- 8.9. Tests and adjustments

- 8.10. Flushing and bleeding

- 8.11. Inspection and maintenance work

- 9. Water spraying system

- 9.1. Overview of water spraying system

- 9.2. Inspection and maintenance work

- 10. Air conditioning

- 10.1. Overview of air conditioning system

- 10.2. Physical principles

- 10.3. Refrigerant R134a

- 10.4. Compressor oil / refrigeration oil

- 10.5. Working principle of the air conditioning system

- 10.6. Monitoring devices

- 10.7. Description of components

- 10.8. Compressor

- 10.9. Emptying in case of repair

- 10.10. Drying and evacuation

- 10.11. Filling instructions

- 10.12. Steam table for R134a

- 10.13. Inspection and maintenance work

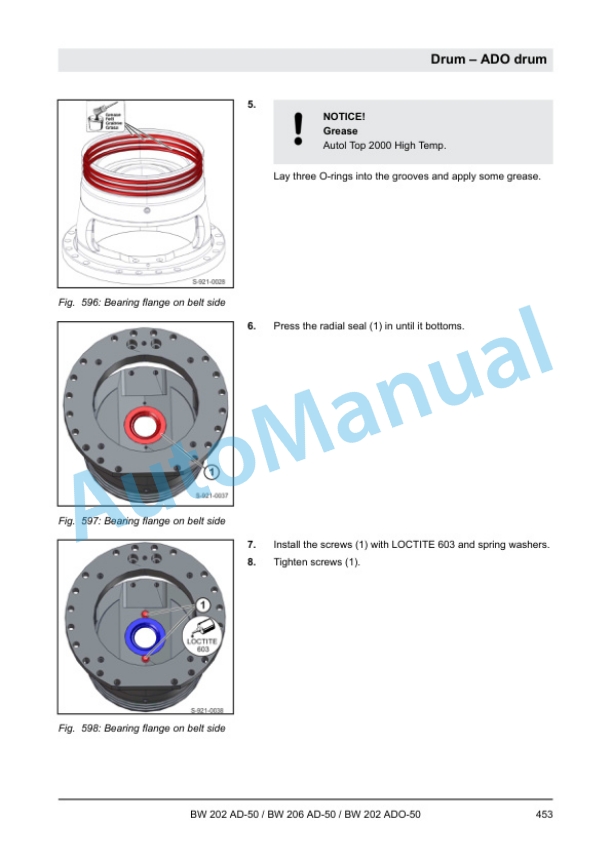

- 11. Drum

- 11.1. Overview, AD drum

- 11.2. ADO drum

- 11.3. Edge cutter

- 11.4. Inspection and maintenance work

- 12. Cabin assembly

- 12.1. Preparations

- 12.2. Cabin assembly

- 12.3. Final function tests and checks

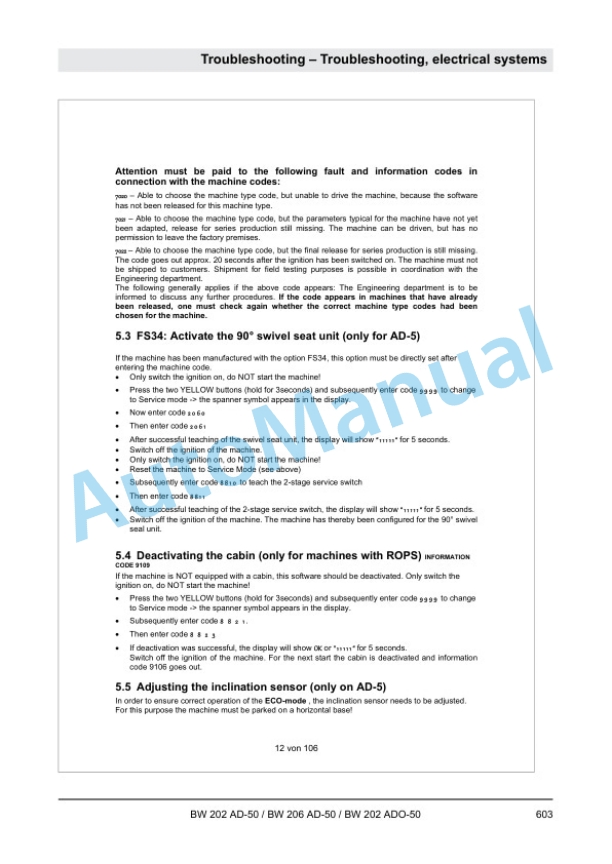

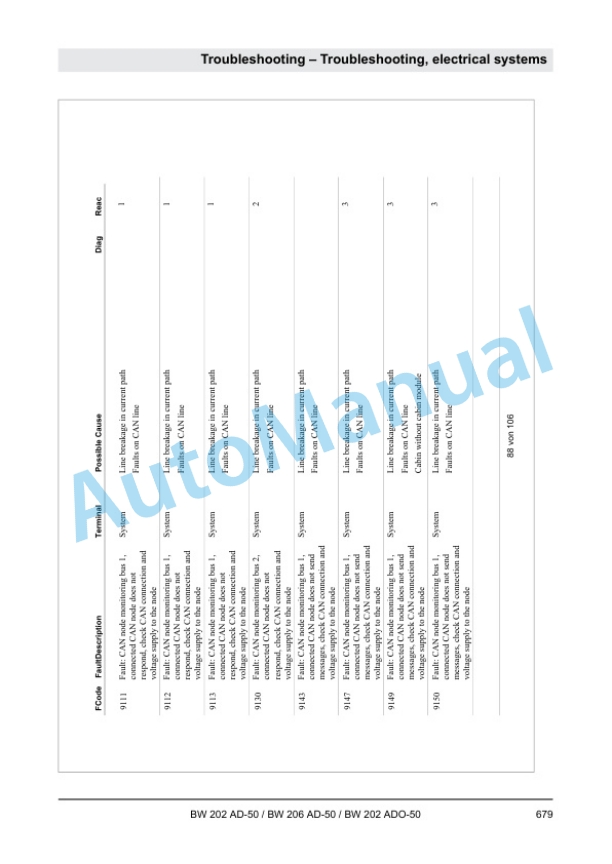

- 13. Troubleshooting

- 13.1. Preliminary remarks

- 13.2. Emergency procedures

- 13.3. Troubleshooting, electrical systems

- 13.4. Trouble shooting, diesel engine

- 13.5. Trouble shooting, hydraulics

- 13.6. Trouble shooting, air conditioning system

- 14. Disposal

- 14.1. Final shutdown of machine

- 15. Special tools

- 15.1. Special tools, electrics

- 15.2. Special tools, hydraulic system

- 15.3. Special tools for ADO drum

- 15.4. List of special tools

- 16. Index

- 17. Appendix

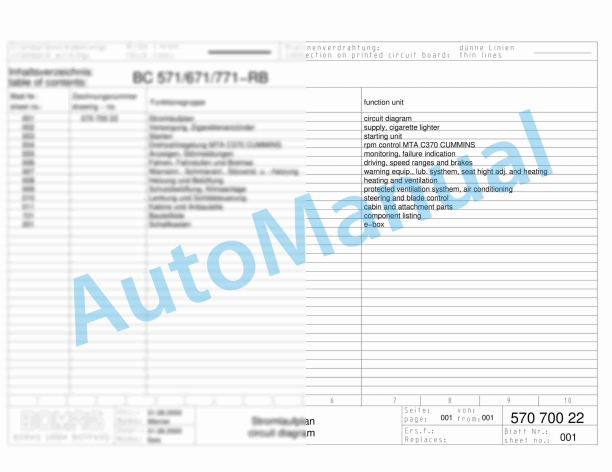

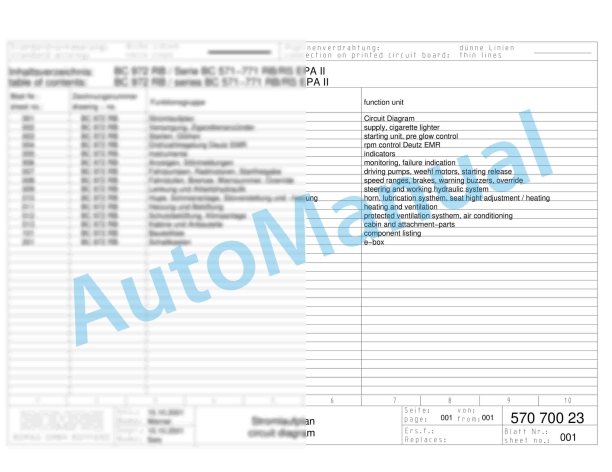

- 17.1. A Circuit diagrams

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

Bomag Service Manual PDF

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

Bomag Service Manual PDF

Bomag BC 572 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570631001 – 101570631163

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999