Bomag BW 216 DHC-4, BW 216 PDHC-4 Single Drum Roller Service Training 00891905

$30.00

- Type Of Manual: Service Training

- Manual ID: 00891905

- Format: PDF

- Size: 28.0MB

- Number of Pages: 596

- Serial Number:

10158321, 10158322

-

Model List:

- BW 216 DHC-4 Single Drum Roller

- BW 216 PDHC-4 Single Drum Roller

- 1. BW 216 DHC4 / BW 216 PDHC4

- 1.1. BW 216 DHC4 / BW 216 PDHC4

- 2.

- 2.1.

- 3. General

- 3.1. General

- 3.2. Introduction

- 3.3. General

- 3.4. General

- 3.5. Transport work with cranes and lifting tackle

- 3.6. Precautions and codes of conduct for welding work

- 3.7. Old oils

- 3.8. Hydraulics

- 3.9. Hot fuels

- 3.10. Synthetic rubber

- 3.11. Poisonous substances

- 3.12. Air conditioning system

- 3.13. Battery

- 3.14. Special safety regulations

- 3.15. The values specified in the table apply for screws

- 3.16. The values specified in the table apply for screws

- 3.17. The values specified in the table apply for screws

- 3.18. The values specified in the table apply for screws

- 3.19. The values specified in the table apply for screws

- 3.20. The values specified in the table apply for screws

- 3.21. The values specified in the table apply for screws

- 3.22. The values specified in the table apply for screws

- 3.23. The values specified in the table apply for screws

- 3.24. The values specified in the table apply for screws

- 3.25. The values specified in the table apply for screws

- 3.26. The values specified in the table apply for screws

- 3.27. The values specified in the table apply for screws

- 3.28. The values specified in the table apply for screws

- 3.29. The values specified in the table apply for screws

- 4. Technical data

- 4.1. Technical data

- 4.2.

- 4.3.

- 4.4.

- 5. Maintenance

- 5.1. Maintenance

- 5.2. General notes on maintenance

- 5.3. Fuels and lubricants

- 6. Connection overview

- 6.1. Connection overview

- 7. Tests and adjustments

- 7.1. Tests and adjustments

- 7.2. Checking the rotation speeds

- 7.3. Checking the rotation speeds

- 7.4. Checking / adjusting the neutral positions of the travel pump

- 7.5. Pressure tests in the travel circuit

- 7.6. Checking / adjusting the vibrator shaft speeds

- 7.7. Pressure measurements in the vibration circuit

- 7.8. Check the leakage rate of the vibration motor

- 7.9. Pressure test in steering circuit

- 8. Flushing and bleeding

- 8.1. Flushing and bleeding

- 8.2. Special tools for flushing

- 8.3. Bleeding the vibration circuit

- 8.4. Bleeding the vibration circuit

- 8.5. Bleeding the vibration circuit

- 9. Caddy wiring diagrams

- 9.1. Caddy wiring diagrams

- 10. Electrics

- 10.1. Electrics

- 10.2. Service the battery

- 10.3. Service the battery

- 10.4. Service the battery

- 10.5. Service the battery

- 10.6.

- 10.7.

- 10.8. Starting with jump wires

- 10.9.

- 10.10.

- 10.11.

- 10.12. S00, start switch

- 10.13.

- 10.14.

- 10.15.

- 10.16.

- 10.17.

- 10.18.

- 10.19.

- 11. Engine electrics

- 11.1. Engine electrics

- 12. Electronic modules

- 12.1. Electronic modules

- 12.2.

- 12.3.

- 12.4.

- 12.5.

- 12.6.

- 12.7.

- 12.8.

- 12.9.

- 12.10.

- 12.11.

- 12.12.

- 12.13.

- 12.14.

- 12.15.

- 12.16.

- 12.17.

- 12.18.

- 12.19.

- 13. Speedometer Module

- 13.1. Speedometer Module

- 14. Service Training

- 14.1. Service Training

- 14.2.

- 14.3.

- 14.4.

- 14.5.

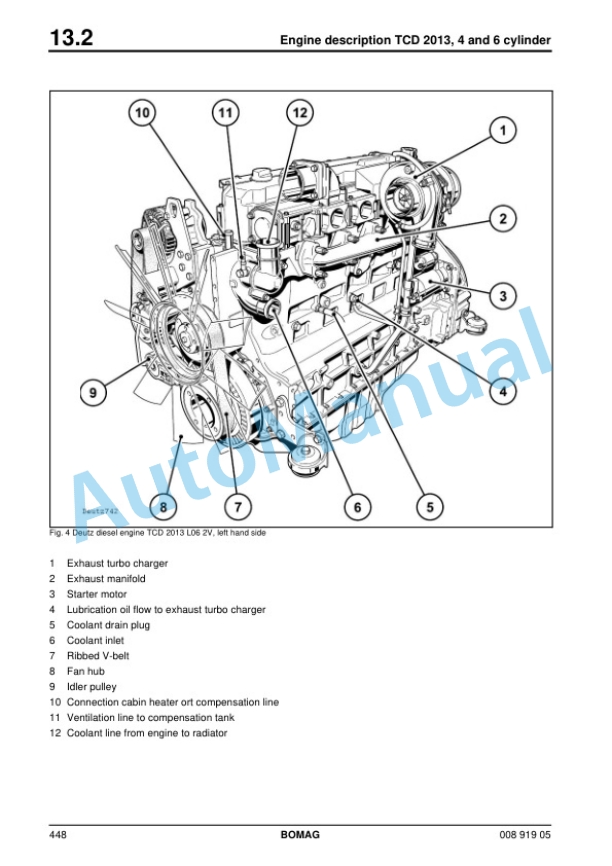

- 15. Engine

- 15.1. Engine

- 15.2. Check the engine oil level

- 15.3. Check the engine oil level

- 15.4. Changing engine oil and oil filter cartridges

- 15.5. Change the fuel prefilter cartridge

- 15.6. Change the fuel filter cartridge

- 15.7. Check, clean the water separator

- 15.8. Check the coolant level

- 15.9. Change the coolant

- 15.10. Combustion air filter service

- 15.11. Check the dust separator

- 15.12. Cleaning the oil bath air filter

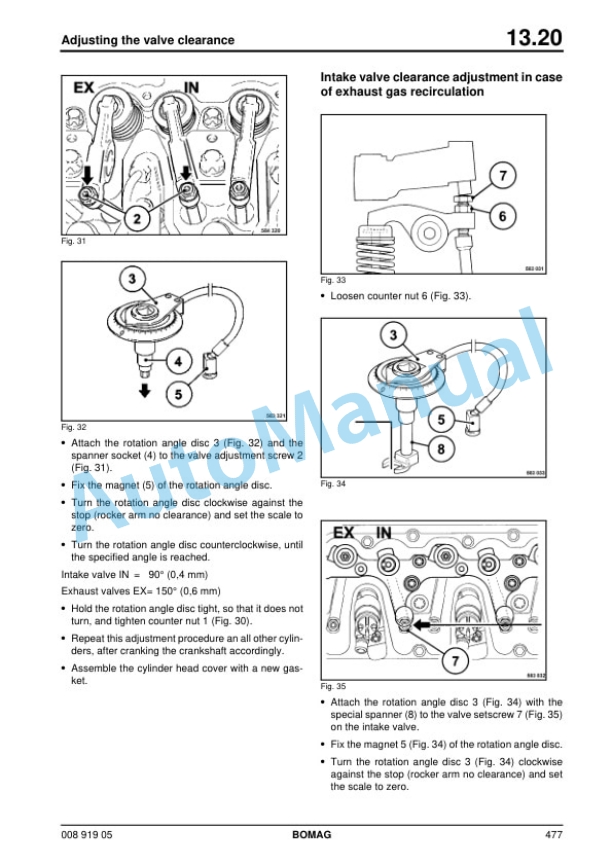

- 15.13. Adjusting the valve clearance

- 15.14. Adjusting the control piston play

- 15.15. Checking / replacing the ribbed Vbelt

- 15.16. Check the engine mounts

- 15.17. Replacing the crank case ventilation valve

- 15.18. Engine conservation

- 16. Air conditioning system

- 16.1. Air conditioning system

- 16.2. Checking, replacing the refrigerant compressor Vbelt

- 16.3. Checking, replacing the refrigerant compressor Vbelt

- 16.4. Checking, replacing the refrigerant compressor Vbelt

- 16.5. Checking, replacing the refrigerant compressor Vbelt

- 16.6. Service the air conditioning

- 17. Drum

- 17.1. Drum

- 18. Circuit diagrams

- 18.1. Circuit diagrams

- 18.2.

- 18.3.

- 18.4.

- 18.5.

- 19.

- 19.1.

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

Bomag Service Manual PDF

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930071001 – 101930071002

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

Bomag Service Manual PDF

Bomag BC 473 EB-3 Refuse Compactor Electric Schematics Diagram 101930151001 – 101930159999

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930021001 – 101930021018