Bomag BW 27 RH-4i Rubber Tire Roller Service Manual 00892289

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00892289

- Format: PDF

- Size: 32.5MB

- Number of Pages: 706

- Serial Number:

10153812, 86153823, 86153824, 86153825

-

Model List:

- BW 27 RH-4i Rubber Tire Roller

- 1. BW 27 RH4i

- 2. Rubber tire roller

- 3. Introduction

- 4. Safety regulations

- 5. General repair instructions

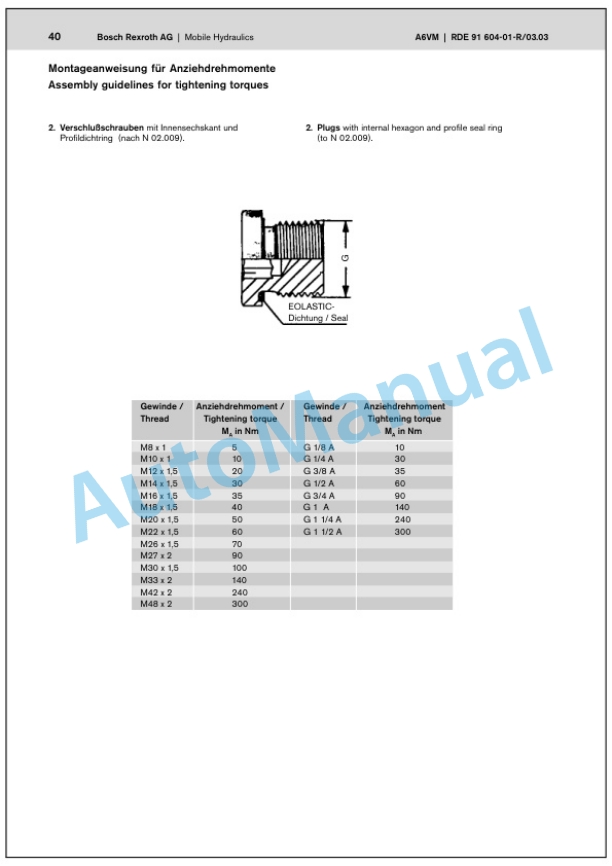

- 6. Tightening torques

- 7. Rubber tire roller

- 8. Technical data

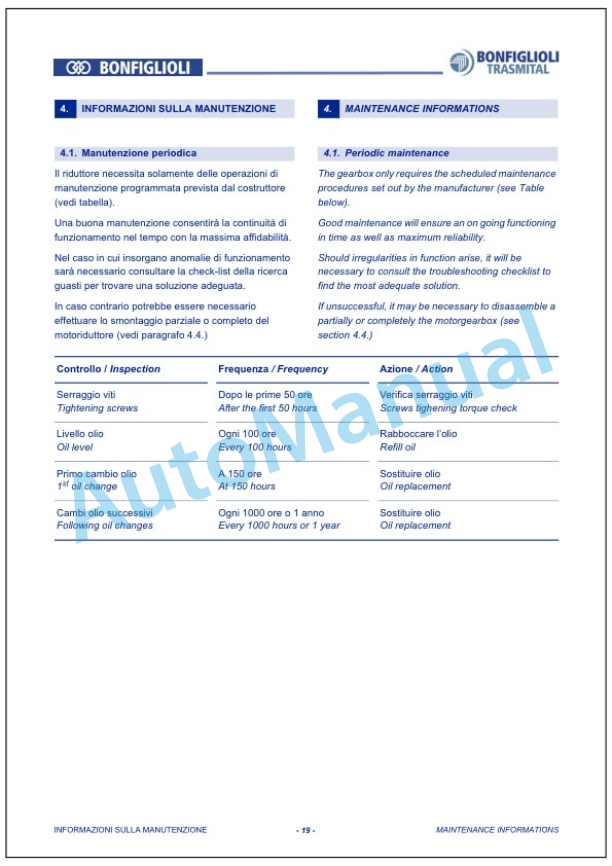

- 9. General notes on maintenance

- 10. Fuels and lubricants

- 11. Table of fuels and lubricants

- 12. Runningin instructions

- 13. Maintenance table

- 14. Overview

- 15. Service the battery, check the main battery switch

- 16. Main battery switch

- 17. Starting with jump wires

- 18. Level sensor in diesel tank (R03)

- 19. Differential pressure switches hydraulic oil filter, B21and B22

- 20. Brake oil temperature switch, B148

- 21. Brake pressure switches, B12 and B102

- 22. Float switch in water tank, B33

- 23. Air filter vacuum switch

- 24. Description of indicators and control elements

- 25. Fuse assignment

- 26. Overview of electric components

- 27. Steering column locking module, A100

- 28. Speedometer module

- 29. EMR4 system overview

- 30. EMR4 system components

- 31. Exhaust gas aftertreatment

- 32. Fuel control unit (FCU)

- 33. Injector

- 34. Crankshaft speed sensor

- 35. Camshaft speed sensor

- 36. Rail pressure sensor

- 37. EMR coolant temperature sensor

- 38. Fuel pressure sensor

- 39. Charge air temperature charge air pressure sensor

- 40. Oil pressure sensor

- 41. Sensor, water in fuel

- 42. Fuel preheating

- 43. Heating flange on engine

- 44. Charge control light, operating hour meter

- 45. System faults per flashing code

- 46. Overview

- 47. Diesel engine

- 48. Engine description TCD 4.1

- 49. Lubrication oil circuit TCD 4.1 / 6.1

- 50. Coolant circuit TCD 4.1 / 6.1

- 51. Common Rail System (CRS) TCD 4.1 / 6.1

- 52. Exhaust gas aftertreatment

- 53. Adjust the valve clearance

- 54. Check the engine oil level

- 55. Changing engine oil and oil filter cartridge

- 56. Check the coolant level

- 57. Change the coolant

- 58. Check the antifreeze concentration and the condition of the coolant

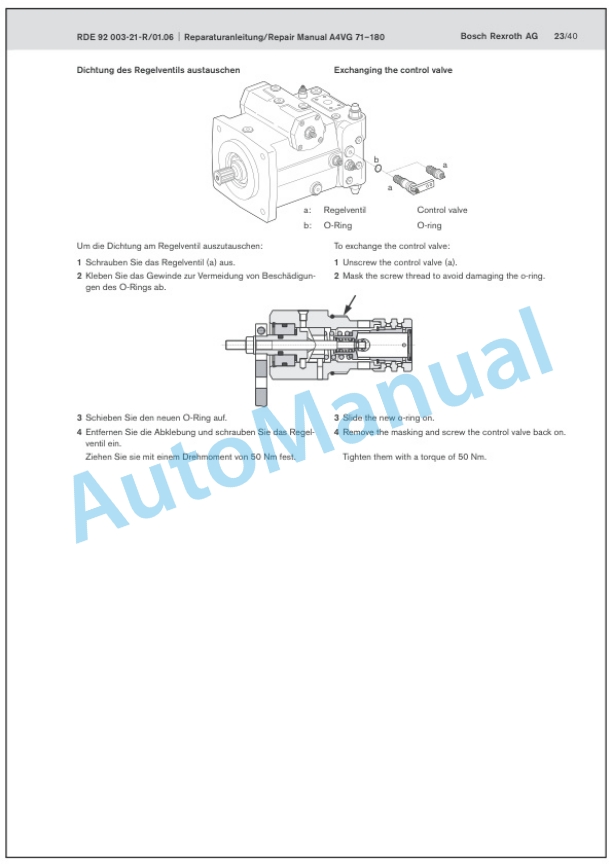

- 59. Clean the cooling fins on engine and hydraulic oil cooler

- 60. Check, clean the water separator

- 61. Replacing the fuel filter cartridge

- 62. Change the fuel filter, bleed the fuel system

- 63. Checking the ribbed Vbelt

- 64. Replacing ribbed Vbelt and idler pulley

- 65. Air filter maintenance

- 66. Check the engine mounts

- 67. Engine problems

- 68. Overview

- 69. Hydraulic circuit

- 70. Travel pumps, A4VG105 DA

- 71. Troubleshooting axial piston pumps

- 72. External gear pumps

- 73. Travel motor, A6VM 107HA2R1

- 74. Trouble shooting, variable displacement axial piston motor

- 75. Steering valve

- 76. Travel circuit

- 77. Steering circuit

- 78. Cooling and crossflushing of the brake housing

- 79. Edge cutter

- 80. Check the hydraulic oil level

- 81. Replace hydraulic oil and breather filter.

- 82. Replace hydraulic oil filter

- 83. Replacing the bypass filter

- 84. Overview

- 85. Brake system

- 86. Stopping the machine, operating the parking brake

- 87. Driving the machine / braking the machine

- 88. Multidisc brake, function test

- 89. Towing in case of an engine failure

- 90. Overview

- 91. Pneumatic system

- 92. Operating the tire inflation system

- 93. Draining the air pressure vessel

- 94. Change the air drier for the brake system

- 95. Check the supply lines for the compressor

- 96. Overview

- 97. Operating the pressure sprinkler system

- 98. Service the water sprinkling system

- 99. Maintenance in case of frost

- 100. Overview

- 101. Physical basics

- 102. Refrigerant R134a

- 103. Compressor oil / refrigeration oil

- 104. Working principle of the air conditioning system

- 105. Monitoring devices

- 106. Description of components

- 107. Measuring the compressor oil level

- 108. Checking the magnetic clutch

- 109. Inspection and maintenance work

- 110. Servicing the Vbelt for the refrigerant compressor

- 111. Service the air conditioning

- 112. Drying and evacuation

- 113. Emptying in case of repair

- 114. Leak test

- 115. Filling instructions

- 116. Trouble shooting in refrigerant circuit, basic principles

- 117. Trouble shooting, refrigerant circuit diagram

- 118. Trouble shooting procedure

- 119. Steam table for R134a

- 120. Repair overview for front axle

- 121. Dismantling the front axle

- 122. Assembling the front axle

Bomag Service Manual PDF

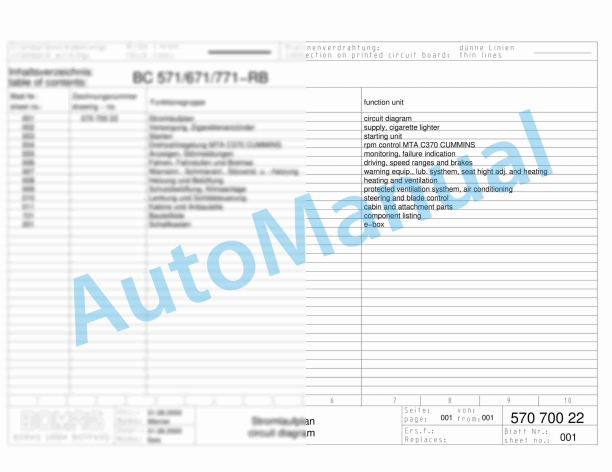

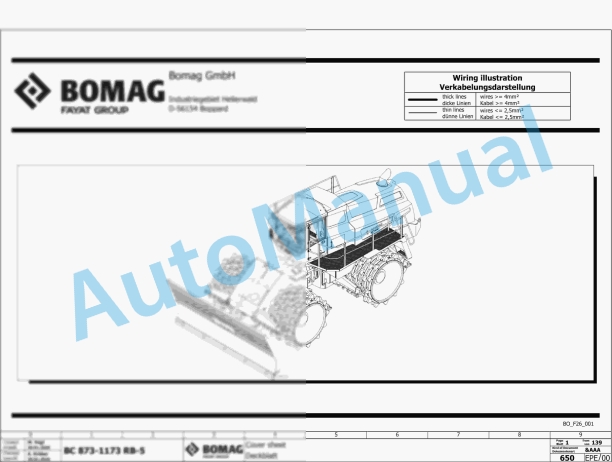

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

Bomag Service Manual PDF

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930031001 – 101930031042

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF