Bomag BW 27 RH Rubber Tire Roller Service Training 00891822

$30.00

- Type Of Manual: Service Training

- Manual ID: 00891822

- Format: PDF

- Size: 37.8MB

- Number of Pages: 470

- Serial Number:

10153811, 10153831, 86153822

-

Model List:

- BW 27 RH Rubber Tire Roller

- 1. BW 27 RH

- 1.1. BW 27 RH

- 2. General

- 2.1. General

- 2.2. Introduction

- 2.3. General

- 2.4. General

- 2.5. Transport work with cranes and lifting tackle

- 2.6. Precautions and codes of conduct for welding work

- 2.7. Operation of highvoltage systems

- 2.8. Old oils

- 2.9. Hydraulics

- 2.10. Hot fuels

- 2.11. Synthetic rubber

- 2.12. Poisonous substances

- 2.13. Air conditioning system

- 2.14. Battery

- 2.15. Special safety regulations

- 2.16. The values specified in the table apply for screws

- 2.17. The values specified in the table apply for screws

- 2.18. The values specified in the table apply for screws

- 2.19. The values specified in the table apply for screws

- 2.20. The values specified in the table apply for screws

- 2.21. The values specified in the table apply for screws

- 2.22. The values specified in the table apply for screws

- 2.23. The values specified in the table apply for screws

- 2.24. The values specified in the table apply for screws

- 2.25. The values specified in the table apply for screws

- 2.26. The values specified in the table apply for screws

- 2.27. The values specified in the table apply for screws

- 2.28. The values specified in the table apply for screws

- 2.29. The values specified in the table apply for screws

- 2.30. The values specified in the table apply for screws

- 3. Pneumatic tires rollers

- 3.1. Pneumatic tires rollers

- 4. Technical data

- 4.1. Technical data

- 4.2.

- 4.3.

- 4.4.

- 5. Maintenance

- 5.1. Maintenance

- 5.2. General notes on maintenance

- 5.3. Fuels and lubricants

- 5.4. Coolant

- 5.5. Mineral oil based hydraulic oil

- 5.6. Biodegradable hydraulic oil

- 5.7. Gear oil

- 5.8. Lubrication grease

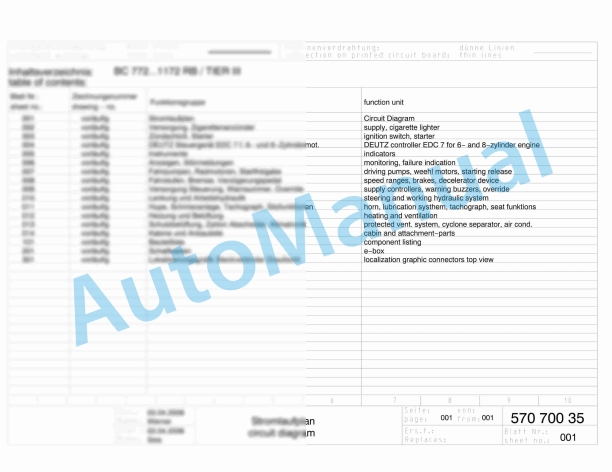

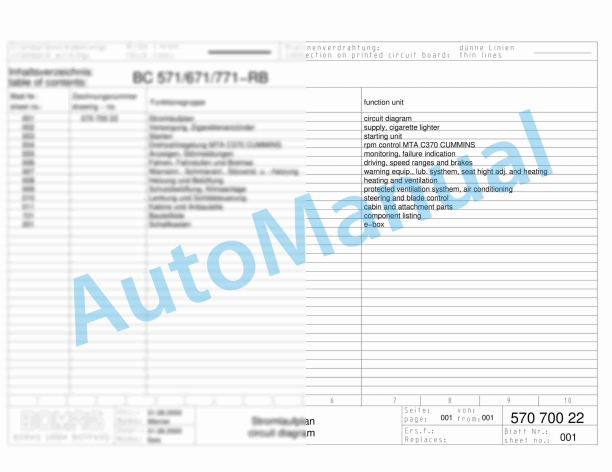

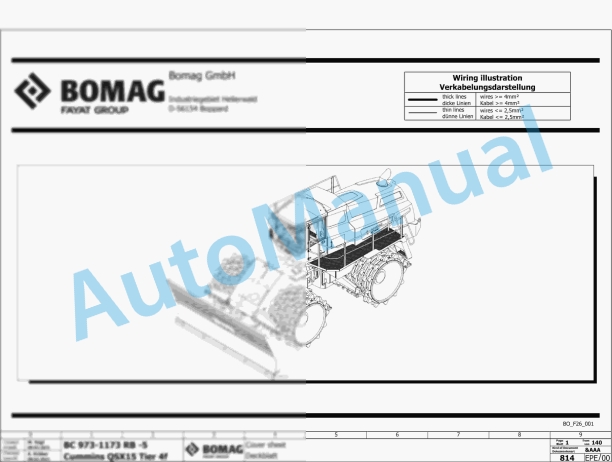

- 6. EPlan wiring diagrams

- 6.1. EPlan wiring diagrams

- 7. Electrics

- 7.1. Electrics

- 7.2. Charge condition with hydrometer

- 7.3. Charge condition with hydrometer

- 7.4. Charge condition with hydrometer

- 7.5. Charge condition with hydrometer

- 7.6. Charge condition with hydrometer

- 7.7. Charge condition with hydrometer

- 7.8. Charge condition with hydrometer

- 7.9. Charge condition with hydrometer

- 7.10. Charge condition with hydrometer

- 7.11. Battery service, checking the main battery switch

- 7.12.

- 7.13.

- 7.14.

- 7.15.

- 7.16. S31 / S184 Travel lever

- 7.17.

- 7.18.

- 7.19.

- 7.20.

- 7.21.

- 7.22.

- 7.23.

- 7.24.

- 7.25.

- 8. Electronic modules

- 8.1. Electronic modules

- 8.2.

- 8.3.

- 8.4.

- 8.5.

- 8.6.

- 8.7.

- 8.8.

- 8.9.

- 9. Module description A100

- 9.1. Module description A100

- 10. Speedometer Module

- 10.1. Speedometer Module

- 11. Engine electrics

- 11.1. Engine electrics

- 12. Hydraulics

- 12.1. Hydraulics

- 12.2. Variable displacement pumps, A4VG105 DA

- 12.3. Variable displacement pumps, A4VG105 DA

- 12.4. Variable displacement pumps, A4VG105 DA

- 12.5. Swash plate principle

- 12.6. External gear pumps

- 12.7. External gear pumps

- 12.8. Description of function

- 12.9. Description of function

- 12.10. HA2R control

- 12.11. Flushing valve

- 12.12. OSP steering valve

- 12.13. OSP steering valve

- 12.14. Check the hydraulic oil level

- 12.15. Check the hydraulic oil level

- 12.16. Check the hydraulic oil level

- 12.17. Check the hydraulic oil level

- 12.18. Replace hydraulic oil and breather filter.

- 12.19. Replace hydraulic oil filter

- 13. Brake

- 13.1. Brake

- 13.2. Stopping the machine, operating the parking brake

- 13.3. Stopping the machine, operating the parking brake

- 13.4. Driving the machine / braking the machine

- 13.5. Multidisc brake, function test

- 13.6. Towing in case of an engine failure

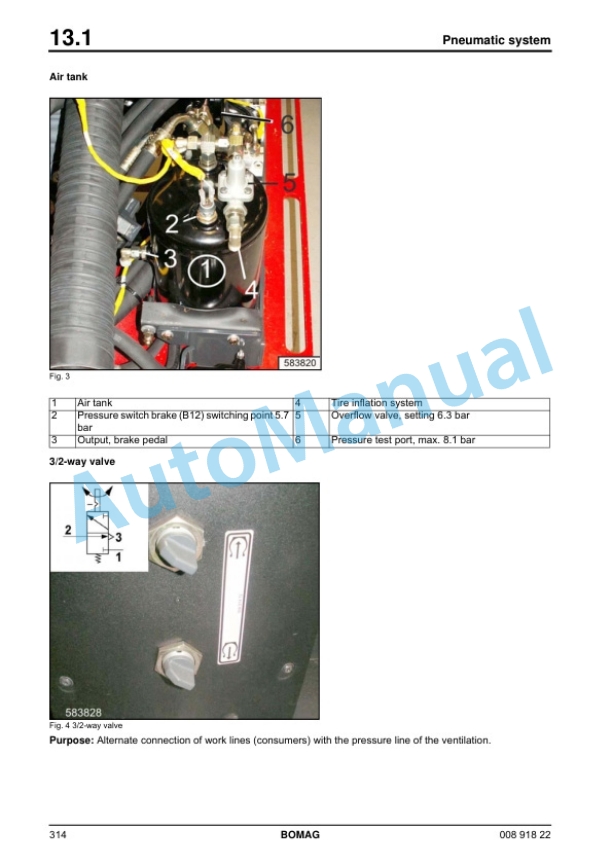

- 14. Pneumatics

- 14.1. Pneumatics

- 14.2. Air drier

- 14.3. Compressor

- 14.4. Overflow valve

- 14.5. Check valve

- 14.6. Operating the tire inflation

- 14.7. Draining the air pressure vessel

- 14.8. Changing the air drier for the brake system

- 14.9. Checking the supply lines for the compressor

- 15. Engine

- 15.1. Engine

- 15.2. Adjusting the valve clearance

- 15.3. Adjusting the valve clearance

- 15.4. Adjusting the valve clearance

- 15.5. Adjusting the valve clearance

- 15.6. Adjusting the valve clearance

- 15.7. Adjusting the valve clearance

- 15.8. Adjusting the control piston play

- 15.9. Check the engine oil level

- 15.10. Changing engine oil and oil filter cartridges

- 15.11. Replace the fuel filter cartridge

- 15.12. Check, clean the water separator

- 15.13. Change the fuel prefilter cartridge

- 15.14. Check the coolant level

- 15.15. Checking the antifreeze concentration

- 15.16. Replacing the coolant

- 15.17. Checking / replacing the ribbed Vbelt

- 15.18. Air filter maintenance

- 15.19. Replacing the crank case ventilation valve

- 15.20. Check the engine mounts

- 15.21. Electronic injector test EMR

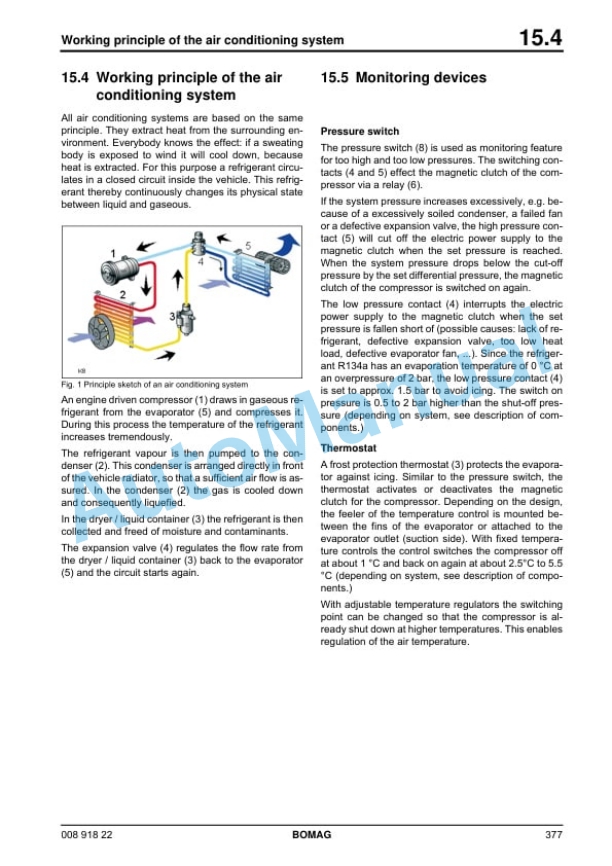

- 16. Air conditioning system

- 16.1. Air conditioning system

- 16.2. Description of components

- 16.3. Description of components

- 16.4. Description of components

- 16.5. Description of components

- 16.6. Description of components

- 16.7. Checking, replacing the refrigerant compressor Vbelt

- 16.8. Checking, replacing the refrigerant compressor Vbelt

- 16.9. Checking, replacing the refrigerant compressor Vbelt

- 16.10. Checking, replacing the refrigerant compressor Vbelt

- 16.11. Service the air conditioning

- 17. Front axle

- 17.1. Front axle

- 17.2. Repair overview for front axle

- 18. Circuit diagrams

- 18.1. Circuit diagrams

- 18.2. S/N Wiring diagram 27

- 18.3. S/N Wiring diagram 27

- 18.4. S/N Wiring diagram 27

- 18.5. S/N Wiring diagram 27

- 18.6. S/N Wiring diagram 27

- 18.7. S/N Wiring diagram 27

- 18.8. S/N Wiring diagram 27

- 18.9. S/N Wiring diagram 27

- 18.10. S/N Wiring diagram 27

- 18.11. S/N Wiring diagram 27

- 18.12. S/N Wiring diagram 27

- 18.13. S/N Wiring diagram 27

- 19.

- 19.1.

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

Bomag Service Manual PDF

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

Bomag Service Manual PDF

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

Bomag Service Manual PDF

Bomag Service Manual PDF