Bomag BW 28 RH Pneumatic Tyred Roller Operating and Maintenance Instructions 00820205

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00820205

- Format: PDF

- Size: 4.9MB

- Number of Pages: 256

- Serial Number:

101538401001 and up

-

Model List:

- BW 28 RH Pneumatic Tyred Roller

- 1. Table of contents

- 2. Introduction

- 2.1. Foreword

- 2.2. Machine type plate and engine type plate

- 3. Technical data

- 3.1. Noise and vibration data

- 3.1.1. Noise data

- 3.1.2. Vibration data

- 4. Concerning your safety

- 4.1. Basic prerequisites

- 4.1.1. General

- 4.1.2. Explanation of signal words used

- 4.1.3. Personal protective equipment

- 4.1.4. Intended use

- 4.1.5. Improper use

- 4.2. Definition of responsible persons

- 4.2.1. Operating company

- 4.2.2. Expert / qualified person

- 4.2.3. Driver / operator

- 4.3. Basic safety regulations for safe operation

- 4.3.1. Remaining dangers, remaining risks

- 4.3.2. Regular safety inspections

- 4.3.3. Modifications and alterations to the machine

- 4.3.4. Damage, defects, misuse of safety devices

- 4.3.5. Roll Over Protective Structure (ROPS)

- 4.4. Handling fuels and lubricants

- 4.4.1. Preliminary remarks

- 4.4.2. Safety regulations and environmental protection regulations for handling diesel fuel

- 4.4.3. Safety regulations and environmental protection regulations for handling AdBlue/DEF

- 4.4.4. Safety regulations and environmental protection regulations for handling oil

- 4.4.5. Safety regulations and environmental protection regulations for handling hydraulic oil

- 4.4.6. Safety regulations and environmental protection regulations for handling coolants

- 4.4.7. Safety regulations and environmental protection regulations for handling battery acid

- 4.5. Loading / transporting the machine

- 4.6. Startup procedure

- 4.6.1. Prior to starting up

- 4.6.2. Starting the engine

- 4.6.3. Starting the engine with jump leads

- 4.7. Driving the machine, working operation

- 4.7.1. Persons in the danger area

- 4.7.2. Driving the machine

- 4.7.3. Driving on gradients and slopes

- 4.7.4. Cross slope

- 4.7.5. Parking the machine

- 4.8. Refuelling

- 4.9. Topping up AdBlue/DEF

- 4.10. Emergency procedures

- 4.10.1. Actuating the emergency stop switch

- 4.10.2. Disconnecting the battery

- 4.10.3. Towing the machine

- 4.11. Maintenance work

- 4.11.1. Preliminary remarks

- 4.11.2. Work on hydraulic lines

- 4.11.3. Working on the engine

- 4.11.4. Exhaust gas aftertreatment system, regeneration at standstill

- 4.11.5. Maintenance work on electric components and battery

- 4.11.6. Working on the air conditioning

- 4.11.7. Working on wheels and tyres

- 4.11.8. Cleaning work

- 4.11.9. After maintenance work

- 4.12. Repair

- 4.13. Signage

- 5. Indicators and control elements

- 5.1. Drivers stand

- 5.1.1. Instrument cluster

- 5.1.2. Operating console

- 5.1.3. Travel lever console

- 5.1.4. Brake pedal

- 5.2. Cabin

- 5.2.1. Control console cabin

- 5.2.2. Heating / air conditioning

- 5.2.3. 12 V DIN socket

- 5.2.4. Monitor for reversing camera

- 5.3. Engine compartment

- 5.3.1. Main battery switch

- 5.4. Outside of machine

- 5.4.1. Lever for scraper position

- 5.4.2. Reversing camera

- 5.5. Fire extinguisher

- 6. Checks prior to start up

- 6.1. Notes on safety

- 6.2. Visual inspections and function tests

- 6.3. Checking the engine oil level

- 6.4. Checking the fuel level, topping up fuel

- 6.4.1. Checking the fuel level

- 6.4.2. Refuelling

- 6.5. Checking the AdBlue/DEF level, topping up

- 6.5.1. Checking the AdBlue/DEF level

- 6.5.2. Topping up AdBlue/DEF

- 6.6. Checking the hydraulic oil level

- 6.7. Checking the coolant level

- 6.8. Checking the water level, topping up

- 6.9. Checking the release agent supply

- 6.10. Checking scrapers and coco mats or brushes

- 6.11. Checking wheels and tyres

- 6.12. Compressor for tyre inflation system checking the oil level

- 7. Operation

- 7.1. Setting up the work place

- 7.1.1. Adjusting the drivers seat

- 7.1.2. Sliding the drivers seat sideways

- 7.1.3. Swivelling the drivers seat

- 7.1.4. Seat heating

- 7.2. Starting the engine

- 7.3. Travel operation

- 7.3.1. Preliminary remarks and safety notes

- 7.3.2. Driving the machine

- 7.4. Water spraying system

- 7.5. Spraying system with emulsion mixing system

- 7.6. Parking the machine in secured condition

- 7.7. Operating the heating / air conditioning system

- 7.8. Tyre inflation system

- 7.9. Ballasting of machine

- 7.10. Emergency procedures

- 7.10.1. Actuating the emergency stop switch

- 7.10.2. Disconnecting the battery

- 7.10.3. Towing the machine

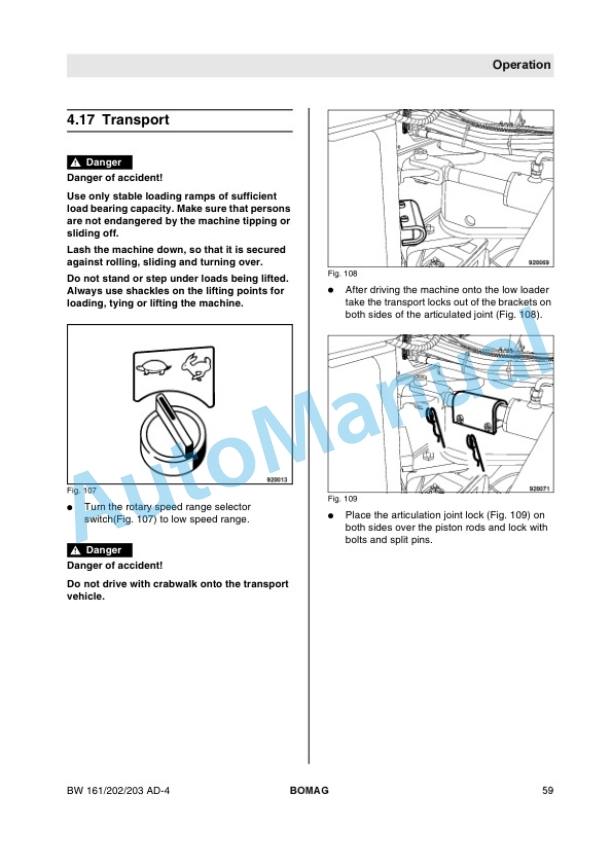

- 8. Loading / transporting the machine

- 8.1. Preparation for transport

- 8.2. Loading the machine

- 8.3. Lashing the machine to the transport vehicle

- 8.4. Loading by crane

- 8.5. After transport

- 9. Maintenance

- 9.1. Preliminary remarks and safety notes

- 9.2. Preparations / concluding work

- 9.2.1. Open and secure the engine hood

- 9.3. Fuels and lubricants

- 9.3.1. Engine oil

- 9.3.2. Fuel

- 9.3.3. AdBlue/DEF

- 9.3.4. Coolant

- 9.3.5. Hydraulic oil

- 9.3.6. Gear oil SAE 80W140

- 9.4. List of fuels and lubricants

- 9.5. Runningin instructions

- 9.5.1. General

- 9.5.2. After 250 operating hours

- 9.5.3. After 500 operating hours

- 9.5.4. After 1000 operating hours

- 9.6. Maintenance Table

- 9.7. Every 250 operating hours

- 9.7.1. Cleaning the radiator module

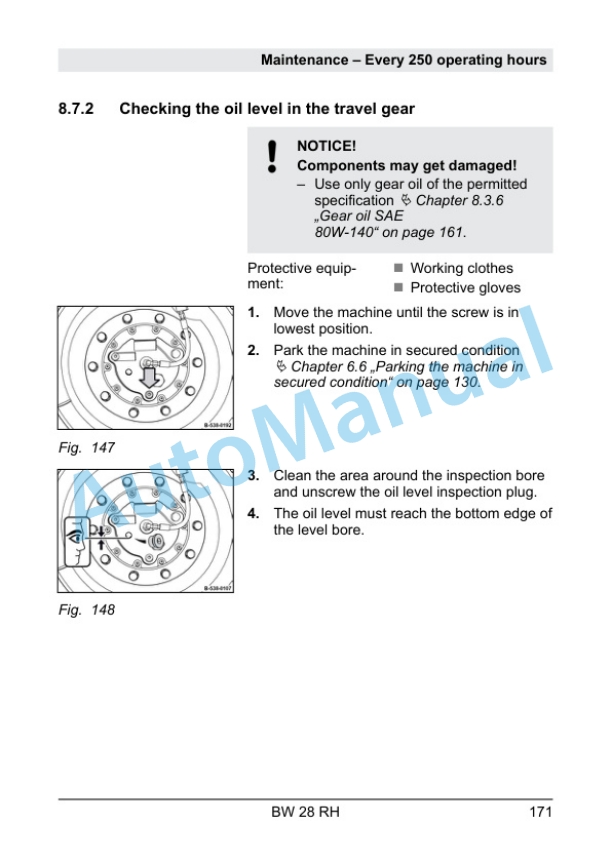

- 9.7.2. Checking the oil level in the travel gear

- 9.7.3. Check the parking brake

- 9.7.4. Compressor for tyre inflation system air filter maintenance

- 9.8. Every 500 operating hours

- 9.8.1. Running regeneration at standstill

- 9.8.2. Change engine oil and oil filter cartridge

- 9.8.3. Replacing the fuel filter, bleeding the fuel system

- 9.8.4. Renewing the AdBlue/DEF filter

- 9.8.5. Service the belt drive

- 9.8.6. Checking the antifreeze concentration and the condition of the coolant

- 9.8.7. Checking the hydraulic lines

- 9.8.8. Servicing the battery, checking the main battery isolation

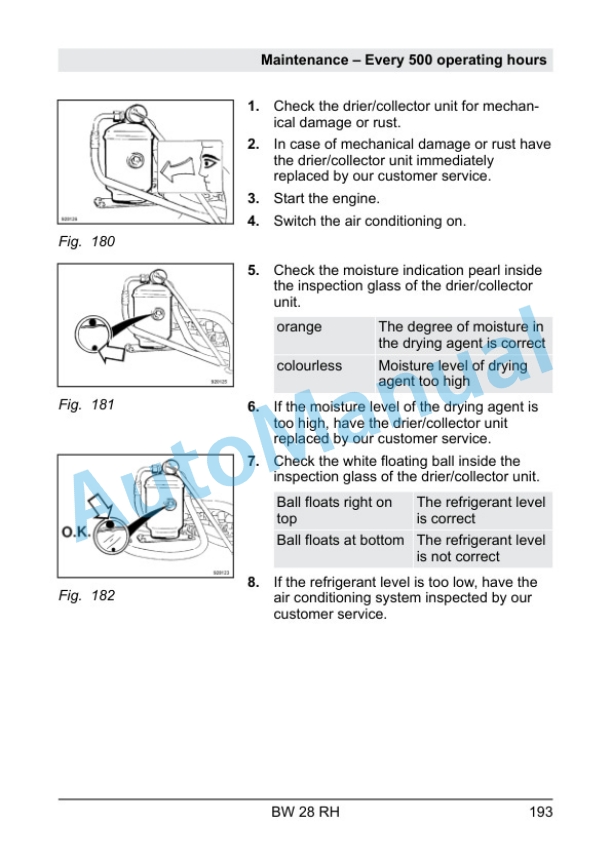

- 9.8.9. Service the air conditioning

- 9.8.10. Check steering for wear

- 9.8.11. Compressor for tyre inflation system changing the oil

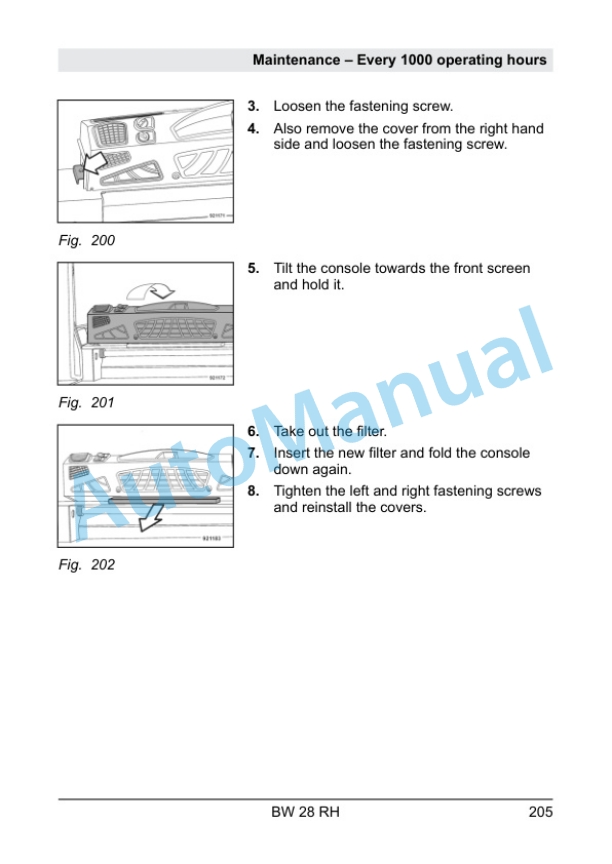

- 9.9. Every 1000 operating hours

- 9.9.1. Replacing the Vbelt

- 9.9.2. Checking the engine mounts

- 9.9.3. Replacing the hydraulic oil filter

- 9.9.4. Retighten the wheel studs

- 9.9.5. Checking the ROPS

- 9.9.6. Checking the travel control

- 9.9.7. Cleaning the circulation air filter of the heating

- 9.9.8. Changing the fresh air filter in the cabin

- 9.10. Every 2000 operating hours

- 9.10.1. Changing the hydraulic oil

- 9.10.2. Changing the coolant

- 9.10.3. Changing the oil in the travel gear

- 9.11. As required

- 9.11.1. Air filter maintenance

- 9.11.2. Checking, cleaning the water separator

- 9.11.3. Servicing the water spraying system

- 9.11.4. Filling the provision tank for the windscreen washer system

- 9.11.5. Measures if there is a risk of frost

- 9.11.6. Draining the fuel tank sludge

- 9.11.7. Measures prior to extended shutdown period

- 10. Troubleshooting

- 10.1. Preliminary remarks

- 10.2. Starting the engine with jump leads

- 10.3. Fuse assignment

- 10.3.1. Notes on safety

- 10.3.2. Central electrics

- 10.3.3. Main fuses

- 10.3.4. Control console cabin

- 10.4. Fault code display

- 10.5. Purging the emulsion mixing system

- 10.6. Engine malfunctions

- 11. Disposal

- 11.1. Final shutdown of machine

- 12. List of special tools

Bomag Operator Manual PDF

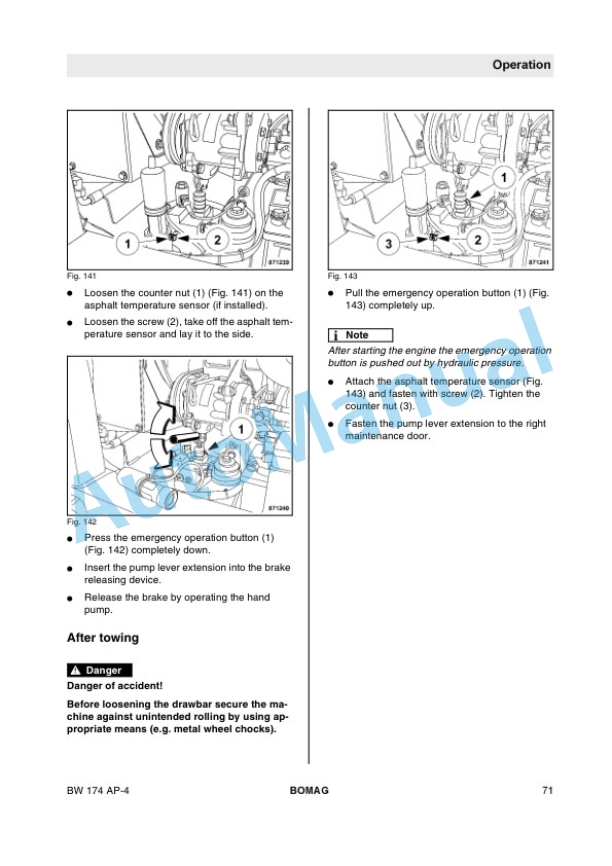

Bomag BW 174 AP-4 Tandem Vibratory Roller Operating and Maintenance Instructions 00806401

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag Operator Manual PDF

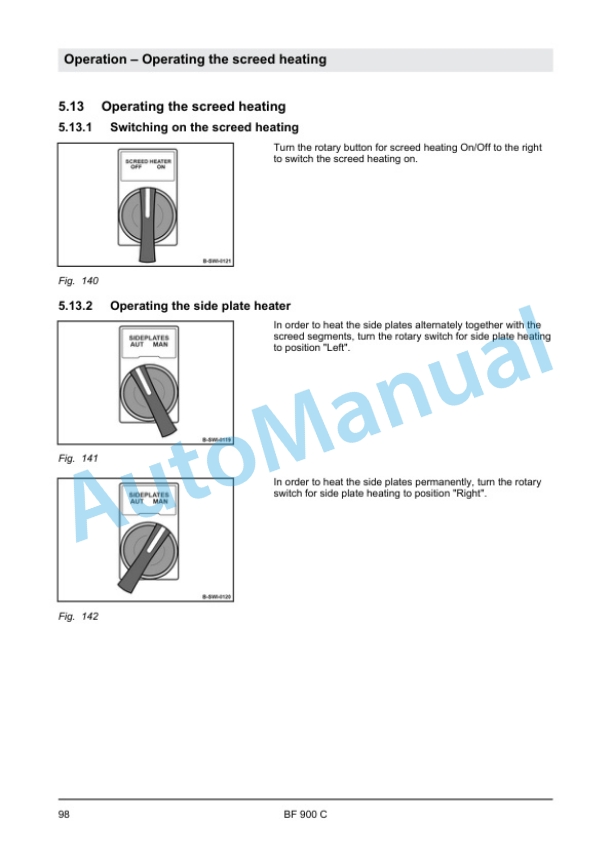

Bomag BF 900 C Paver Operating and Maintenance Instructions 00808181

Bomag Operator Manual PDF

Bomag BC 670 RB Refuse Compactor Operating and Maintenance Instructions 00816061

Bomag Operator Manual PDF

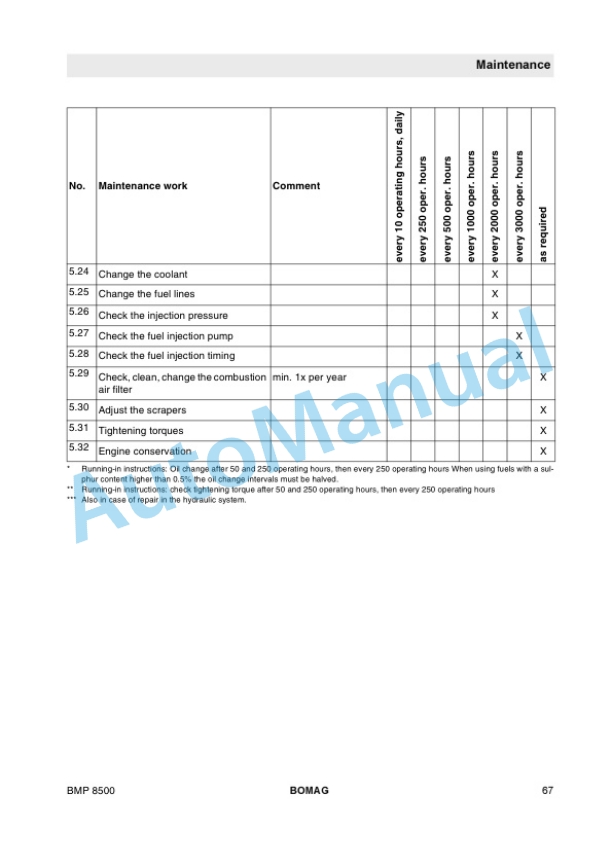

Bomag BMP 8500 Multi Purpose Compactor Operating and Maintenance Instructions 00805981

Bomag Operator Manual PDF

Bomag Operator Manual PDF

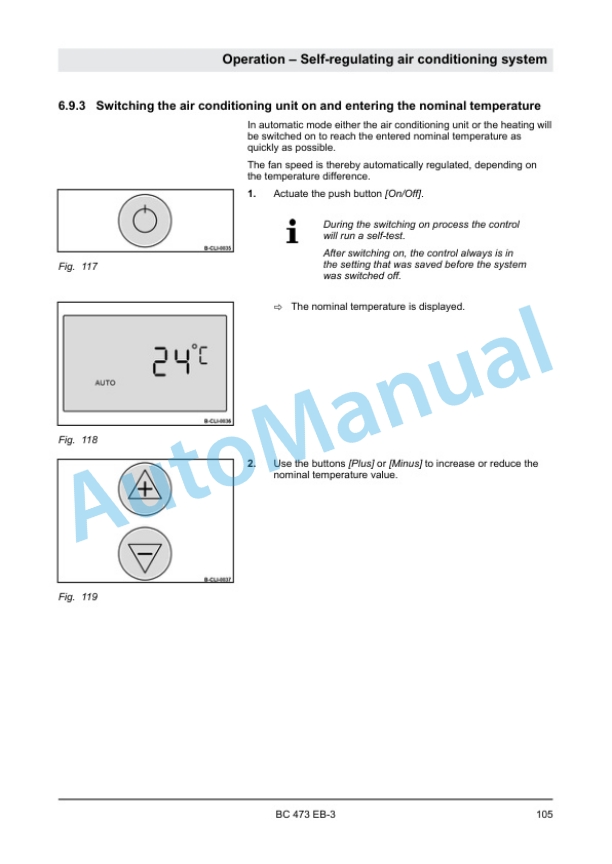

Bomag BC 473 EB-3 Soil Compactor Operating and Maintenance Instructions 00820281

Bomag Operator Manual PDF

Bomag BMP 851 Multi Purpose Compactor Operating and Maintenance Instructions 00811141