Bomag BW 80 AD-5 to BW 100 SCC-5 Tandem Vibratory Roller Operating and Maintenance Instructions 00806701 2017

$20.00

- Type Of Manual: Operating and Maintenance Instructions

- Manual ID: 00806701

- Date: 2017

- Format: PDF

- Size: 4.6MB

- Number of Pages: 216

- Serial Number:

101462003159 and up

101462011943 and up

101462032126 and up

101462041199 and up

101462051196 and up

101462061075 and up

101462071090 and up

-

Model List:

- BW 80 AD-5 Tandem Vibratory Roller

- BW 90 AD-5 Tandem Vibratory Roller

- BW 100 ADM-5 Tandem Vibratory Roller

- BW 100 ACM-5 Tandem Vibratory Roller

- BW 90 SC-5 Tandem Vibratory Roller

- BW 100 SC-5 Tandem Vibratory Roller

- BW 100 SCC-5 Tandem Vibratory Roller

- 1. Table of contents

- 2. Foreword

- 2.1. Machine type plate and engine type plate

- 3. Technical data

- 3.1. Technical data BW 80 AD5

- 3.1.1. Noise and vibration data

- 3.1.1.1. Noise data

- 3.1.1.2. Vibration data

- 3.2. Technical data BW 90 AD5

- 3.2.1. Noise and vibration data

- 3.2.1.1. Noise data

- 3.2.1.2. Vibration data

- 3.3. Technical data BW 100 ADM5

- 3.3.1. Noise and vibration data

- 3.3.1.1. Noise data

- 3.3.1.2. Vibration data

- 3.4. Technical data BW 90 SC5

- 3.4.1. Noise and vibration data

- 3.4.1.1. Noise data

- 3.4.1.2. Vibration data

- 3.5. Technical data BW 100 SC5

- 3.5.1. Noise and vibration data

- 3.5.1.1. Noise data

- 3.5.1.2. Vibration data

- 3.6. Technical data BW 100 ACM5

- 3.6.1. Noise and vibration data

- 3.6.1.1. Noise data

- 3.6.1.2. Vibration data

- 3.7. Technical data BW 100 SCC5

- 3.7.1. Noise and vibration data

- 3.7.1.1. Noise data

- 3.7.1.2. Vibration data

- 4. Safety regulations

- 5. Indicators and control elements

- 5.1. General notes

- 5.2. Description of indicators and control elements

- 5.3. Instrument cluster

- 6. Operation

- 6.1. General

- 6.2. Checks prior to start up

- 6.3. Electronic immobilizer

- 6.4. Adjusting the drivers seat

- 6.5. Starting the engine

- 6.6. Driving the machine

- 6.6.1. Seat contact switch

- 6.7. Stopping the machine, operating the parking brake

- 6.8. Shutting down the engine

- 6.9. Switching the vibration on/off

- 6.9.1. Preliminary remarks and safety notes

- 6.9.2. Vibration in manual mode

- 6.9.3. Vibration in automatic mode

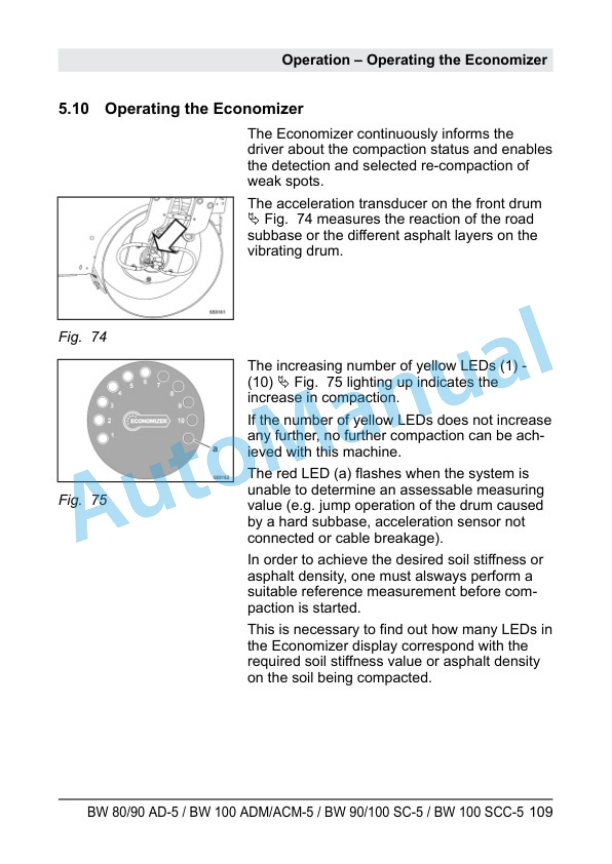

- 6.10. Operating the Economizer

- 6.11. Switching the pressure sprinkling system on and off

- 6.12. Switching emulsion sprinkling on/off

- 6.13. Setting the crabwalk

- 6.14. What to do in events of emergency

- 6.15. Mounting the edge cutter tool

- 6.16. Lifting / lowering the edge cutter

- 6.17. Connecting/disconnecting the hydraulic breakerOptional equipment

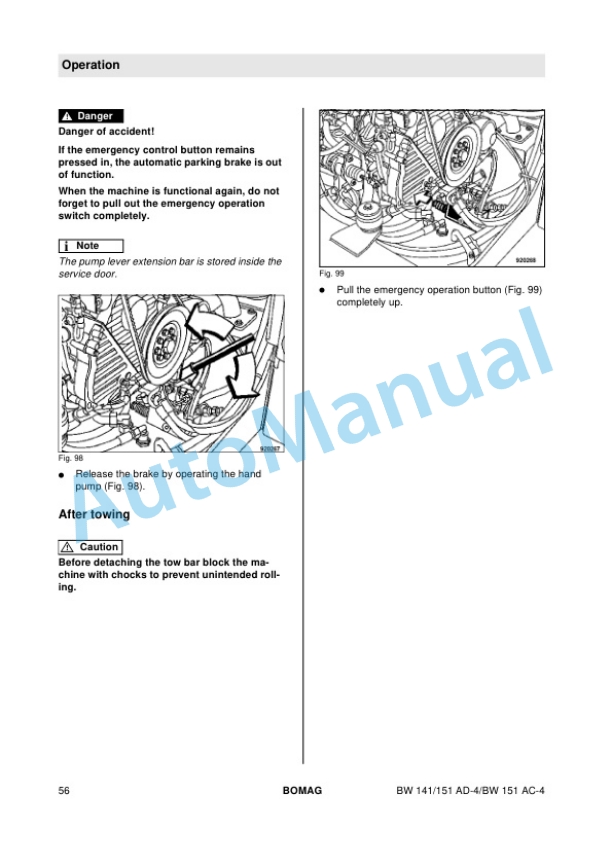

- 6.18. Towing

- 6.18.1. Towing AD/ADM/SCmachines

- 6.18.2. Towing ACM/SCCmachines

- 6.19. Loading/transport

- 7. Maintenance

- 7.1. General notes on maintenance

- 7.2. Fuels and lubricants

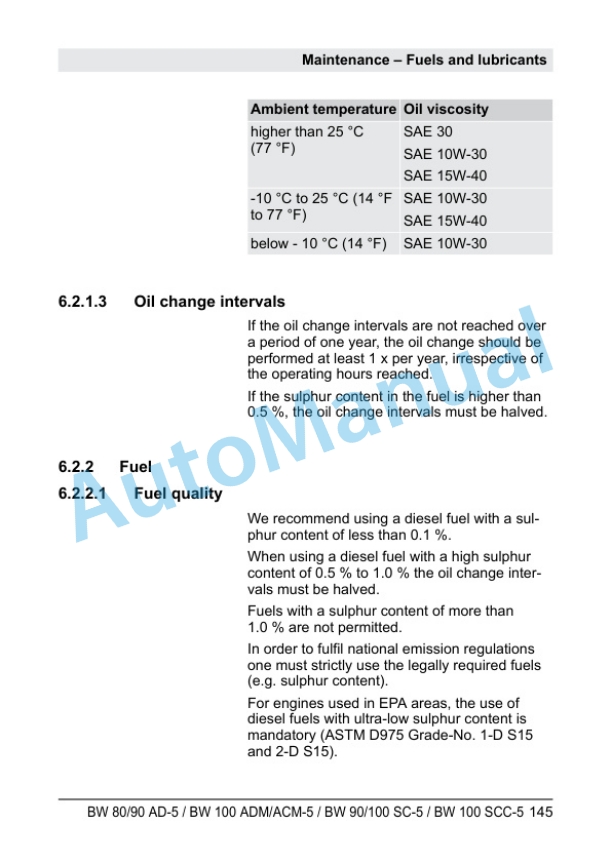

- 7.2.1. Engine oil

- 7.2.1.1. Oil quality

- 7.2.1.2. Oil viscosity

- 7.2.1.3. Oil change intervals

- 7.2.2. Fuel

- 7.2.2.1. Fuel quality

- 7.2.2.2. Winter fuel

- 7.2.2.3. Storage

- 7.2.3. Coolant

- 7.2.4. Hydraulic oil

- 7.2.4.1. Mineral oil based hydraulic oil

- 7.2.4.2. Biodegradable hydraulic oil

- 7.3. List of fuels and lubricants

- 7.4. Runningin instructions

- 7.5. Maintenance Table

- 7.6. Every 10 operating hours

- 7.6.1. Check the engine oil level

- 7.6.2. Check the fuel level

- 7.6.3. Checking the hydraulic oil level

- 7.6.4. Checking the hydraulic oil filter element

- 7.6.5. Checking the coolant level

- 7.6.6. Checking the water level

- 7.6.7. Check the emulsion level

- 7.7. Every 50 operating hours

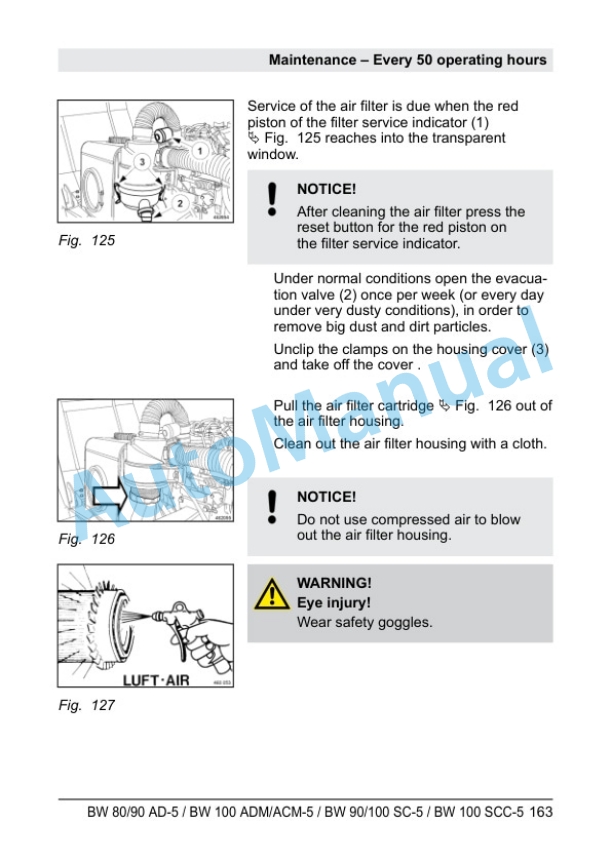

- 7.7.1. Checking, cleaning the air filter, replacing if necessary

- 7.7.2. Check fuel lines and clamps

- 7.7.3. Checking, cleaning the water separator

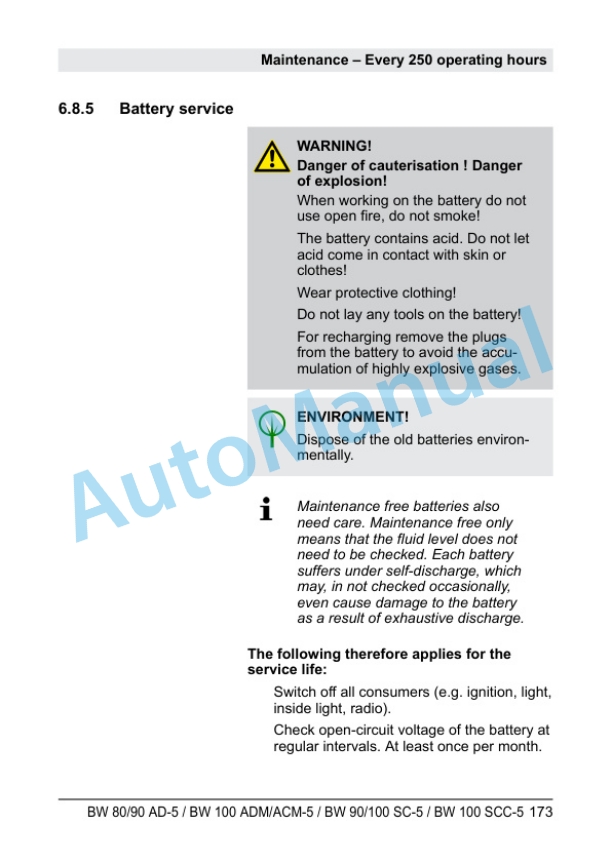

- 7.8. Every 250 operating hours

- 7.8.1. Changing engine oil and oil filter cartridge

- 7.8.2. Checking, tensioning, replacing the Vbelt

- 7.8.3. Checking the air intake lines

- 7.8.4. Cleaning radiator and hydraulic oil cooler

- 7.8.5. Battery service

- 7.8.6. Checking radiator hoses and hose clamps

- 7.8.7. Check scrapers, adjust if necessary

- 7.9. Every 500 operating hours

- 7.9.1. Drain the fuel tank sludge

- 7.9.2. Change the fuel filter

- 7.9.3. Check the antifreeze concentration and the condition of the coolant

- 7.10. Every 1000 operating hours

- 7.10.1. Checking, adjusting the valve clearance

- 7.10.2. Check the engine mounts

- 7.10.3. Check the travel control

- 7.11. Every 2000 operating hours

- 7.11.1. Changing hydraulic oil and breather filter

- 7.11.2. Replacing the hydraulic oil filter

- 7.11.3. Changing the coolant

- 7.11.4. Replacing the fuel lines

- 7.11.5. Check the injection nozzles

- 7.12. Every 3000 operating hours

- 7.12.1. Check the fuel injection pump

- 7.13. As required

- 7.13.1. Checking the air pressure in the rubber tires

- 7.13.2. Water sprinkler system, maintenance in case of frost

- 7.13.3. Tightening torques for screws with metric unified thread

- 7.13.4. Measures to be applied for longer periods of rest

- 8. Trouble shooting

- 8.1. General notes

- 8.2. Starting with jump wires

- 8.3. Engine problems

- 8.4. Fuse assignment

- 8.4.1. Notes on safety

- 8.4.2. Central electrics

- 8.4.3. Main battery fuse

- 9. Disposal

- 9.1. Final shutdown of machine

Bomag Operator Manual PDF

Bomag Operator Manual PDF

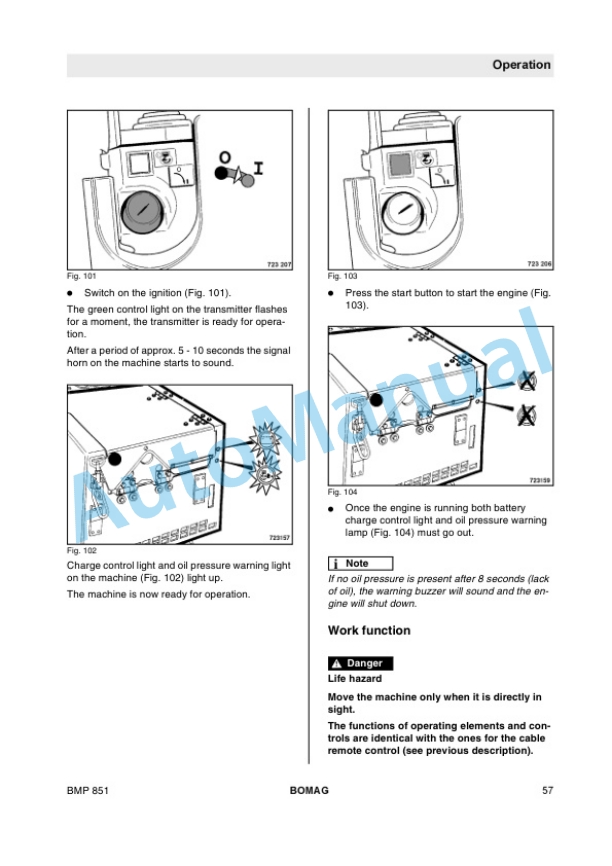

Bomag BMP 851 Multi Purpose Compactor Operating and Maintenance Instructions 00811141

Bomag Operator Manual PDF

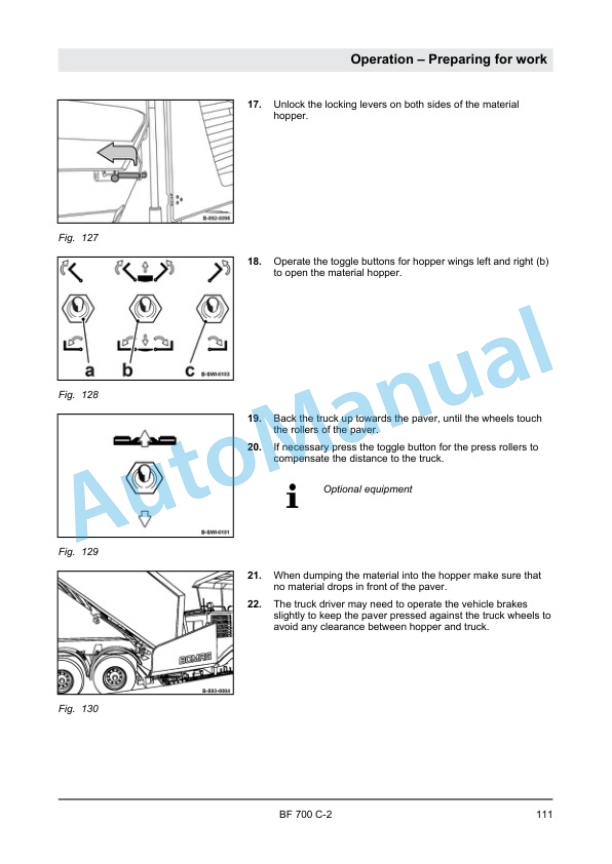

Bomag BF 700 C-2 Paver Operating and Maintenance Instructions 00820031

Bomag Operator Manual PDF

Bomag BPR 70-70 D Reversible Vibrating Plate Operating and Maintenance Instructions 00806761

Bomag Operator Manual PDF

Bomag Operator Manual PDF

Bomag BW 135 AD-5 Tandem Vibratory Roller Operating and Maintenance Instructions 00820191

Bomag Operator Manual PDF

Bomag BM 2000-60 Cold Milling Machine Operating and Maintenance Instructions 00806061

Bomag Operator Manual PDF

Bomag BC 473 EB-3 Soil Compactor Operating and Maintenance Instructions 00820281

Bomag Operator Manual PDF

Bomag BF 900 C Paver Operating and Maintenance Instructions 00808181