Bomag BW 80 AD-5 to BW 100 SCC-5 Tandem Vibratory Roller Service Manual 00892560

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00892560

- Format: PDF

- Size: 44.8MB

- Number of Pages: 458

- Serial Number:

101462001797 and up

101462011323 and up

101462031443 and up

101462051087 and up

101462071054 and up

101462041104 and up

101462061015 and up

Category: Bomag Service Manual PDF

-

Model List:

- BW 80 AD-5 Tandem Vibratory Roller

- BW 90 AD-5 Tandem Vibratory Roller

- BW 100 ADM-5 Tandem Vibratory Roller

- BW 100 ACM-5 Tandem Vibratory Roller

- BW 90 SC-5 Tandem Vibratory Roller

- BW 100 SC-5 Tandem Vibratory Roller

- BW 100 SCC-5 Tandem Vibratory Roller

- 1. Table of contents

- 2. General

- 2.1. Introduction

- 2.2. Safety regulations

- 2.3. Maintenance and repair

- 2.3.1. Notes on repair

- 2.3.1.1. General repair instructions

- 2.3.1.2. Tightening torques

- 2.3.2. General notes on maintenance

- 3. Technical data

- 3.1. BW 80 AD5

- 3.1.1. Noise and vibration data

- 3.1.1.1. Noise data

- 3.1.1.2. Vibration data

- 3.2. BW 90 AD5

- 3.2.1. Noise and vibration data

- 3.2.1.1. Noise data

- 3.2.1.2. Vibration data

- 3.3. BW 90 AC5

- 3.3.1. Noise and vibration data

- 3.3.1.1. Noise data

- 3.3.1.2. Vibration data

- 3.4. BW 100 ADM5

- 3.4.1. Noise and vibration data

- 3.4.1.1. Noise data

- 3.4.1.2. Vibration data

- 3.5. BW 90 SC5

- 3.5.1. Noise and vibration data

- 3.5.1.1. Noise data

- 3.5.1.2. Vibration data

- 3.6. BW 100 SC5

- 3.6.1. Noise and vibration data

- 3.6.1.1. Noise data

- 3.6.1.2. Vibration data

- 3.7. BW 100 ACM5

- 3.7.1. Noise and vibration data

- 3.7.1.1. Noise data

- 3.7.1.2. Vibration data

- 3.8. BW 100 SCC5

- 3.8.1. Noise and vibration data

- 3.8.1.1. Noise data

- 3.8.1.2. Vibration data

- 3.9. Additional technical data

- 3.10. Terms and basis of calculation

- 3.11. Fuels and lubricants

- 3.11.1. Engine oil

- 3.11.1.1. Oil quality

- 3.11.1.2. Oil viscosity

- 3.11.1.3. Oil change intervals

- 3.11.2. Fuel

- 3.11.2.1. Fuel quality

- 3.11.2.2. Winter fuel

- 3.11.2.3. Storage

- 3.11.3. Coolant

- 3.11.4. Hydraulic oil

- 3.11.4.1. Mineral oil based hydraulic oil

- 3.11.4.2. Biodegradable hydraulic oil

- 3.12. List of fuels and lubricants

- 4. Overview of machine

- 4.1. General information

- 4.2. Overviews

- 4.3. Electric systems

- 4.4. Hydraulic system

- 4.5. Machine assemblies

- 4.5.1. Diesel engine

- 4.5.2. Oscillating articulated joint

- 4.5.3. Drum

- 5. Electric systems

- 5.1. Basic principles

- 5.1.1. Measuring method

- 5.1.2. Understanding circuit diagrams

- 5.1.2.1. Circuit diagrams

- 5.1.2.2. Circuit symbols in EPlan

- 5.1.2.3. Identification of switch blocks

- 5.1.3. Telemecanique switch

- 5.1.4. Deutsch plug, series DT and DTM

- 5.1.5. Magnetic coil plug

- 5.2. Overview of electric system

- 5.2.1. Drivers stand, old version

- 5.2.1.1. Control elements

- 5.2.2. Drivers stand, new version

- 5.2.2.1. Control elements

- 5.2.3. Wiring

- 5.2.4. CAN BUS overview

- 5.2.5. Table of fuels and lubricants

- 5.3. Starting with jump wires

- 5.4. Central electrics

- 5.5. Fuse assignment

- 5.5.1. Central electrics

- 5.5.2. Main battery fuse

- 5.6. Description of electrical components

- 5.6.1. Angle sensor on travel lever, B39

- 5.6.2. Inductive proximity switch, B63

- 5.6.3. Switching the vibration on, old version

- 5.6.4. Switching the vibration on, new version

- 5.6.5. Switching the pressurized spraying system on, old version

- 5.6.6. Switching the pressurized spraying system on, new version

- 5.6.7. Sensor, water in fuel filter, B124

- 5.6.8. Engine oil pressure monitoring

- 5.6.9. Coolant temperature monitoring

- 5.6.10. Level sensor in diesel tank, R03

- 5.6.11. Charge control light and operating hour meter

- 5.6.12. Glow plugs, R81, R82 R83

- 5.6.13. Engine solenoid, Y13

- 5.6.14. Instrument cluster, old version

- 5.6.15. Instrument cluster, new version

- 5.6.16. Seat contact control

- 5.7. Repairs

- 5.7.1. Generator repair

- 5.7.2. Repair of starter

- 5.8. Inspection and maintenance work

- 5.8.1. Maintenance Table

- 5.8.2. Every 250 operating hours

- 5.8.2.1. Battery service

- 5.8.3. As required

- 5.8.3.1. Battery service during prolonged machine downtimes

- 6. Hydraulic system

- 6.1. Basic principles

- 6.1.1. Open and closed hydraulic circuit

- 6.1.2. Swash plate principle, pump

- 6.1.3. External gear pumps

- 6.1.4. Reversible external gear motor

- 6.2. Overview of hydraulics

- 6.2.1. Pump overview

- 6.3. Description of hydraulic components

- 6.3.1. Travel pump, A10VG18 HW

- 6.3.1.1. Variable displacement pumps, A10VG18 HW A10VG28 HW

- 6.3.2. Drum drive motor MK 04

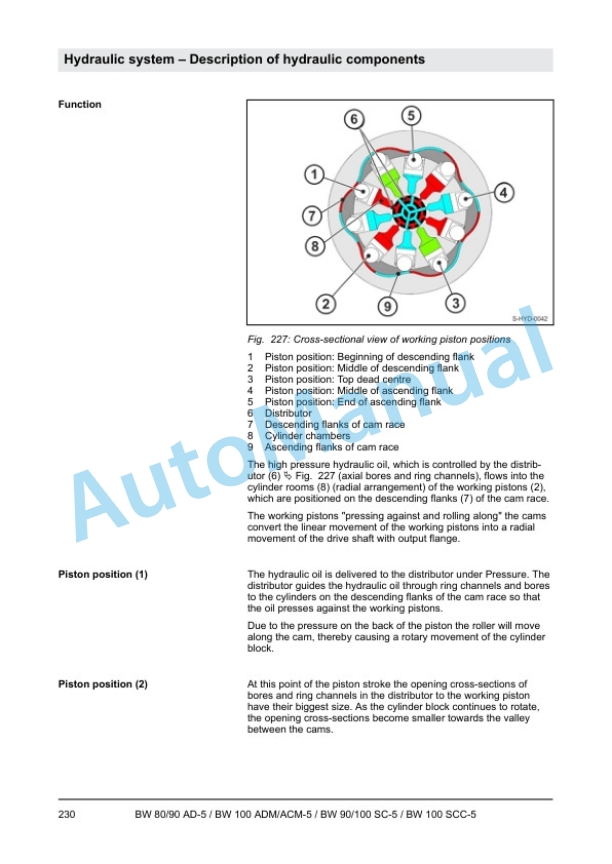

- 6.3.2.1. Radial piston motor

- 6.3.3. Wheel drive motor, MS/MSE

- 6.3.3.1. Radial piston motor with multidisc brake

- 6.3.4. Steering valve

- 6.4. Description of hydraulic circuits

- 6.4.1. Travel circuit

- 6.4.2. Vibration circuit

- 6.4.3. Steering circuit

- 6.4.4. Edge cutter

- 6.4.5. Hydraulic cutting tool

- 6.5. Tests and adjustments

- 6.5.1. Pump overview

- 6.5.2. Checking the rotation speeds

- 6.5.3. Pressure tests in the travel circuit

- 6.5.4. Checking / adjusting the neutral positions of the travel pump

- 6.5.5. Pressure test in the vibration circuit

- 6.5.6. Checking the leakage rate of the vibration motor

- 6.6. Flushing and bleeding

- 6.6.1. Flushing general

- 6.6.2. Flushing schematic for travel system, AD/SCmachine

- 6.6.3. Travel system, flushing AD/SCmachine

- 6.6.4. Flushing schematic for travel system, ACmachine

- 6.6.5. Travel system, flushing ACmachine

- 6.6.6. Bleeding the travel circuit

- 6.7. Inspection and maintenance work

- 6.7.1. Maintenance Table

- 6.7.2. Checks prior to start up

- 6.7.2.1. Checking the hydraulic oil level

- 6.7.2.2. Checking the hydraulic oil filter element

- 6.7.3. Every 500 operating hours

- 6.7.3.1. Checking the hydraulic lines

- 6.7.4. Every 2000 operating hours

- 6.7.4.1. Changing hydraulic oil and breather filter

- 6.7.4.2. Replacing the hydraulic oil filter

- 7. Machine assemblies

- 7.1. Diesel engine

- 7.1.1. Overview of diesel engine

- 7.1.2. Kubota diesel engine

- 7.1.3. Check the injection valves

- 7.1.4. Checking the fuel injection pump

- 7.1.5. Inspection and maintenance work

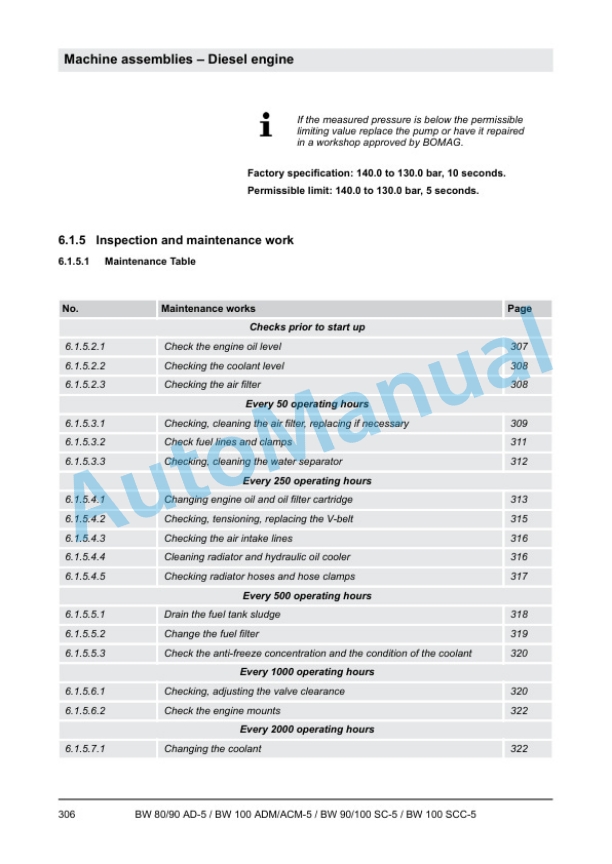

- 7.1.5.1. Maintenance Table

- 7.1.5.2. Checks prior to start up

- 7.1.5.3. Every 50 operating hours

- 7.1.5.4. Every 250 operating hours

- 7.1.5.5. Every 500 operating hours

- 7.1.5.6. Every 1000 operating hours

- 7.1.5.7. Every 2000 operating hours

- 7.1.5.8. Every 3000 operating hours

- 7.1.5.9. As required

- 7.2. Oscillating articulated joint

- 7.2.1. Overview oscillating articulated joint

- 7.2.2. Removing and installing the oscillating articulated joint

- 7.2.3. Repairing the oscillating articulated joint

- 7.3. Drum

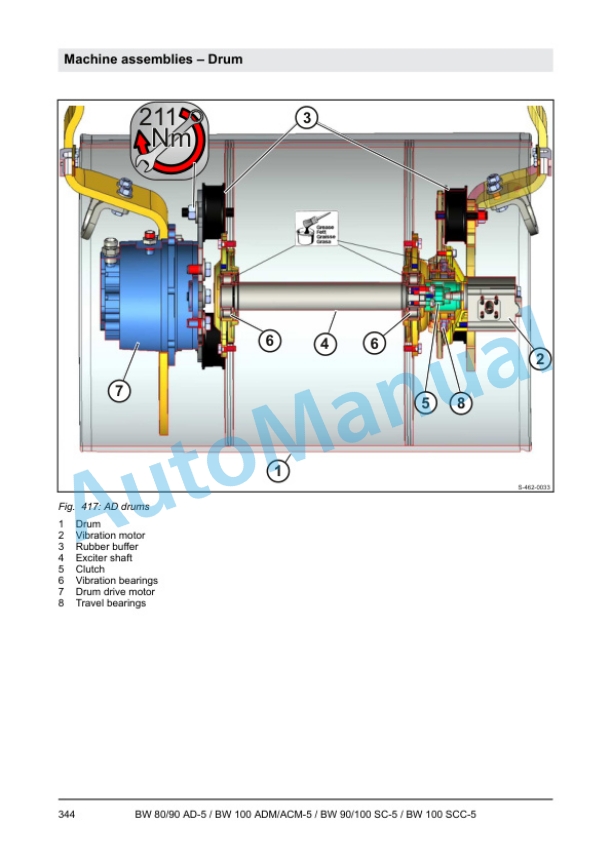

- 7.3.1. Overview drum

- 7.3.2. Removing and installing the ADdrum

- 7.3.3. Dismantling the ADdrum

- 7.3.4. Assembling the ADdrum

- 8. Troubleshooting

- 8.1. Preliminary remarks

- 8.2. Emergency procedures

- 8.2.1. Actuating the emergency stop switch

- 8.2.2. Disconnecting the battery

- 8.2.3. Towing the machine

- 8.3. Towing tandem vibratory roller

- 8.4. Towing combination roller

- 8.5. Troubleshooting, electrical systems

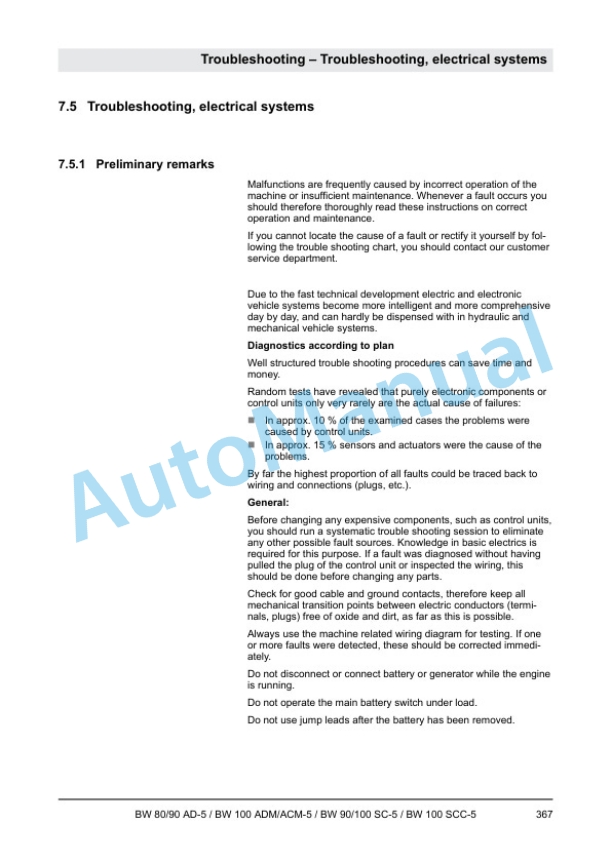

- 8.5.1. Preliminary remarks

- 8.5.2. Starting with jump wires

- 8.5.3. Fuse assignment

- 8.5.3.1. Central electrics

- 8.5.3.2. Main battery fuse

- 8.5.4. Trouble shooting Starter

- 8.5.5. Fault detection via instrument cluster, A15

- 8.5.6. Trouble shooting ECONOMIZER

- 8.5.7. The machine does not drive

- 8.5.8. Seat contact control

- 8.5.9. Check the parking brake

- 8.6. Trouble shooting, hydraulics

- 8.6.1. Insufficient hydraulic power

- 8.6.2. Troubleshooting axial piston pumps

- 8.6.3. The machine does not drive

- 8.6.4. Insufficient travel power

- 8.6.5. Check the parking brake

- 8.7. Trouble shooting, diesel engine

- 8.7.1. Engine problems

- 9. Special tools

- 9.1. Special tools, hydraulic system

- 9.1.1. Special tools, tests and adjustments

- 9.1.2. Special tools for flushing

- 9.2. Special tools, electrics

- 10. Index

- 11. Appendix

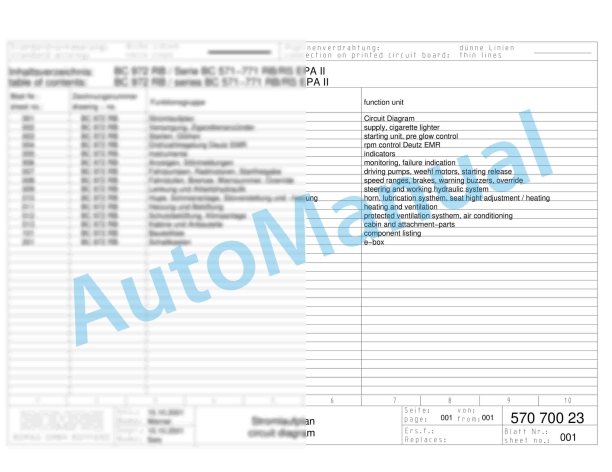

- 11.1. A Circuit diagrams

- 11.1.1. Circuit diagram 368

- 11.1.2. Hydraulic diagram 289

Rate this product

You may also like

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930021001 – 101930021018

$30.00

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930071001 – 101930071002

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

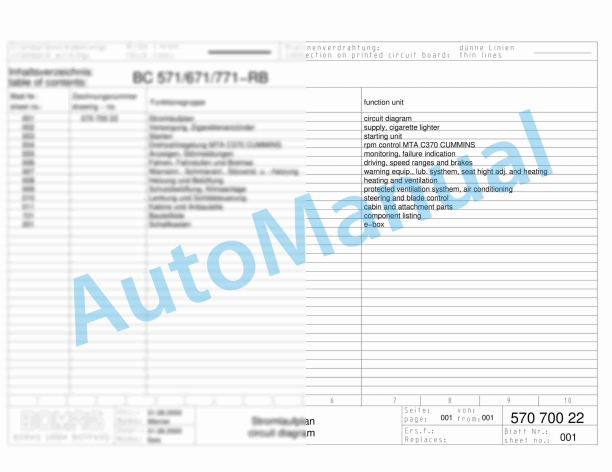

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

$30.00

Bomag Service Manual PDF

Bomag BC 572 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570631001 – 101570631163

$30.00

Bomag Service Manual PDF

$30.00