Bomag MPH 122-2 Soil Stabilizer Service Training 00891787

$30.00

- Type Of Manual: Service Training

- Manual ID: 00891787

- Format: PDF

- Size: 45.5MB

- Number of Pages: 658

- Serial Number:

10159006 and up

10159007 and up

-

Model List:

- MPH 122-2 Soil Stabilizer

- 1. MPH 1222

- 1.1. MPH 1222

- 2. General

- 2.1. General

- 2.2. Introduction

- 2.3. General

- 2.4. General

- 2.5. Transport work with cranes and lifting tackle

- 2.6. Precautions and codes of conduct for welding work

- 2.7. Operation of highvoltage systems

- 2.8. Old oils

- 2.9. Hydraulics

- 2.10. Hot fuels

- 2.11. Synthetic rubber

- 2.12. Poisonous substances

- 2.13. Air conditioning system

- 2.14. Battery

- 2.15. Special safety regulations

- 2.16. The values specified in the table apply for screws

- 2.17. The values specified in the table apply for screws

- 2.18. The values specified in the table apply for screws

- 2.19. The values specified in the table apply for screws

- 2.20. The values specified in the table apply for screws

- 2.21. The values specified in the table apply for screws

- 2.22. The values specified in the table apply for screws

- 2.23. The values specified in the table apply for screws

- 2.24. The values specified in the table apply for screws

- 2.25. The values specified in the table apply for screws

- 2.26. The values specified in the table apply for screws

- 2.27. The values specified in the table apply for screws

- 2.28. The values specified in the table apply for screws

- 2.29. The values specified in the table apply for screws

- 3. BOMAG Stabilizer / Recycler

- 3.1. BOMAG Stabilizer / Recycler

- 4. Technical data

- 4.1. Technical data

- 4.2.

- 4.3.

- 4.4.

- 5. Maintenance

- 5.1. Maintenance

- 5.2. General notes on maintenance

- 5.3. Fuels and lubricants

- 5.4. Coolant

- 5.5. Mineral oil based hydraulic oil

- 5.6. Biodegradable hydraulic oil

- 5.7. Gear oil

- 5.8. Milling gear oil

- 5.9. Lubrication grease

- 5.10. Thermal oil

- 5.11. Compressor service unit

- 6. EPlan wiring diagrams

- 6.1. EPlan wiring diagrams

- 7. Electrics

- 7.1. Electrics

- 7.2. Battery service, checking the main battery switch

- 7.3. Battery service, checking the main battery switch

- 7.4. Battery service, checking the main battery switch

- 7.5. Battery service, checking the main battery switch

- 7.6. Starting with jump wires

- 7.7.

- 7.8.

- 7.9.

- 7.10.

- 7.11.

- 7.12.

- 7.13.

- 7.14.

- 7.15.

- 7.16.

- 7.17.

- 7.18.

- 8. Electronic control

- 8.1. Electronic control

- 9. Engine electrics

- 9.1. Engine electrics

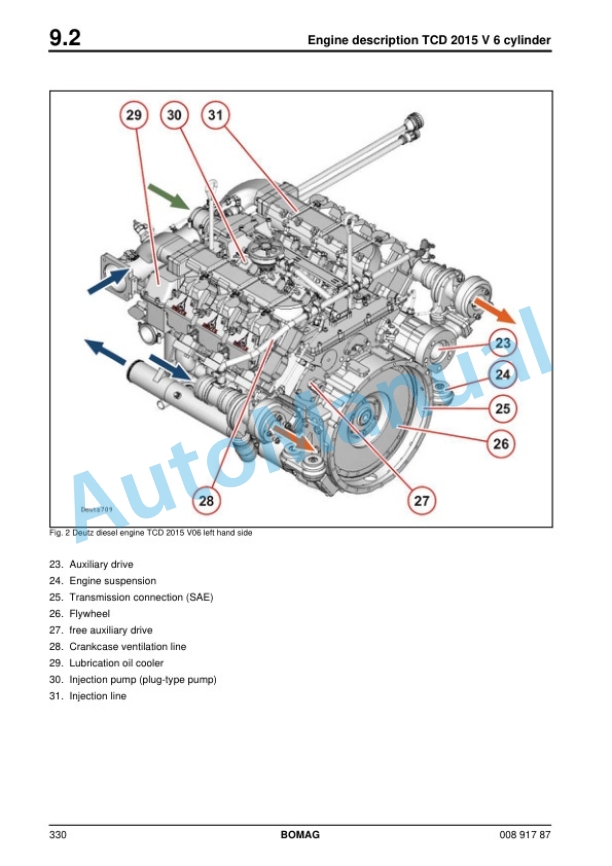

- 10. Engine

- 10.1. Engine

- 10.2. Check, adjust the valve clearance

- 10.3. Check, adjust the valve clearance

- 10.4. Check, adjust the valve clearance

- 10.5. Check, adjust the valve clearance

- 10.6. Check, adjust the valve clearance

- 10.7. Check, adjust the valve clearance

- 10.8. Check, adjust the valve clearance

- 10.9. Check, adjust the valve clearance

- 10.10. Check, adjust the valve clearance

- 10.11. Checking the engine oil level

- 10.12. Changing engine oil and oil filter cartridge

- 10.13. Check the coolant level

- 10.14. Checking the condition of the coolant

- 10.15. Checking/changing the coolant

- 10.16. Check, clean the water separator

- 10.17. Changing the fuel filter

- 10.18. Replacing the fuel prefilter cartridge, bleed the fuel system

- 10.19. Cleaning, changing the dry air filter cartridge

- 10.20. Servicing the generator Vbelt

- 10.21. Check the engine mounts

- 10.22. Check the fastening of engine / turbocharger / combustion air hoses

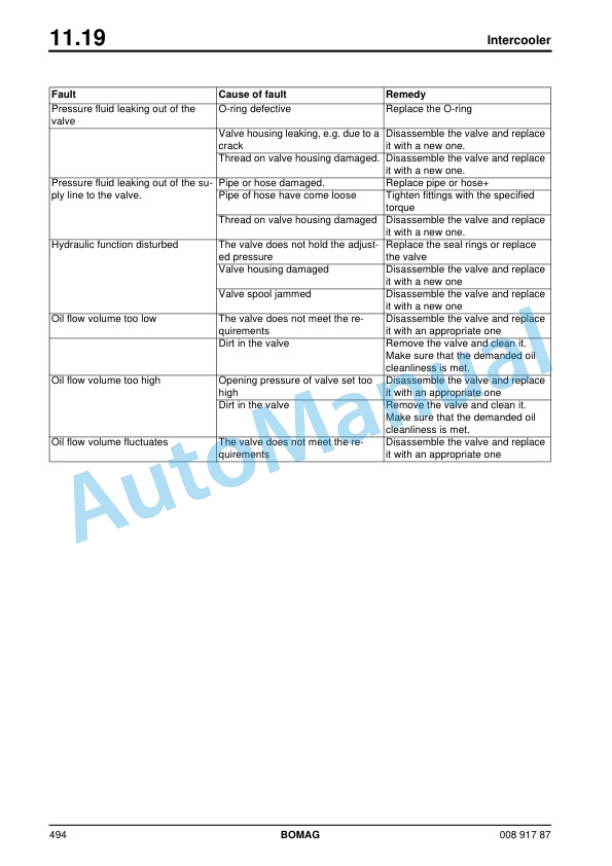

- 10.23. Cleaning the intercooler

- 10.24. Intercooler, draining off oil/ condensation water

- 10.25. Checking the crankcase pressure

- 10.26. Replacing the crankcase ventilation valve

- 11. Air conditioning system

- 11.1. Air conditioning system

- 11.2. Servicing the air conditioning compressor

- 11.3. Servicing the air conditioning compressor

- 11.4. Servicing the air conditioning compressor

- 11.5. Servicing the air conditioning compressor

- 11.6. Service the air conditioning

- 12. Hydraulics

- 12.1. Hydraulics

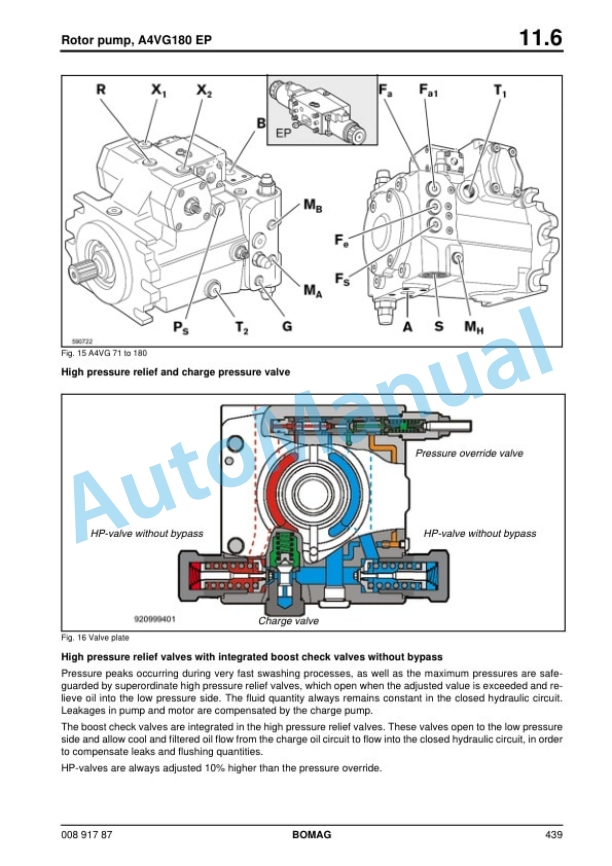

- 12.2. Variable displacement pumps, A4VG28EP to A4VG180EP

- 12.3. Variable displacement pumps, A4VG28EP to A4VG180EP

- 12.4. Variable displacement pumps, A4VG28EP to A4VG180EP

- 12.5. Variable displacement pumps, A4VG28EP to A4VG180EP

- 12.6. Swash plate principle

- 12.7. Swash plate principle

- 12.8. External gear pumps

- 12.9. External gear pumps

- 12.10. Multiple gear pumps

- 12.11. Description of function

- 12.12.

- 12.13.

- 12.14. Function logic of the rotor drive

- 12.15. Plugin fixed displacement motors A2FE and A2FM

- 12.16. OSP steering valve

- 12.17. OSP steering valve

- 12.18. Control valve blocks SP08

- 12.19. Control valve blocks SP08

- 12.20. Raising/lowering the cabin

- 12.21. Raising/lowering the cabin

- 12.22. Towing

- 12.23. External gear motors

- 12.24. External gear motors

- 12.25. way flow control valve, adjustable

- 12.26. Cleaning the intercooler

- 12.27. Checking the hydraulic oil level

- 12.28. Changing hydraulic oil and breather filter

- 12.29. Checking the contamination of the hydraulic oil filters

- 12.30. Change the hydraulic oil fine filter

- 13. Water injection

- 13.1. Water injection

- 13.2.

- 13.3. External gear motors

- 13.4. External gear motors

- 13.5. External gear motors

- 13.6. Water dosing system

- 13.7. Water sprinkler system, maintenance in the event of frost

- 14. Bitumen dosing system

- 14.1. Bitumen dosing system

- 14.2.

- 14.3.

- 14.4.

- 14.5.

- 14.6.

- 14.7.

- 14.8.

- 14.9.

- 14.10.

- 14.11. Checking the reaction water level

- 14.12. Checking the reaction water level

- 14.13. Checking the reaction water level

- 14.14. Reaction water tank

- 14.15. Checking the oil level for the reaction water pump

- 14.16. Checking the oil level in compressor and service unit

- 14.17. Checking the thermal oil

- 14.18. Checking the contamination of the hydraulic oil filters

- 14.19. Checking the binder pump

- 14.20. Checking the spraying sections

- 14.21. Checking, cleaning the additional fuel filter

- 14.22. Change the additional fuel filter

- 14.23. Changing the thermal oil

- 14.24. Compressor oil change

- 14.25. Cleaning the bitumen filter

- 15. Circuit diagrams

- 15.1. Circuit diagrams

- 15.2. S/N Wiring diagram 42

- 15.3. S/N Wiring diagram 42

- 15.4. S/N Wiring diagram 42

- 15.5. S/N Wiring diagram 42

- 15.6. S/N Wiring diagram 42

- 15.7. S/N Wiring diagram 42

- 15.8. S/N Wiring diagram 42

- 15.9. S/N Wiring diagram 42

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 463 RB-3 Refuse Compactor Electric Schematics Diagram 101930121001 – 101930129999

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930031001 – 101930031042

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930021001 – 101930021018