Claas AXOS 340-310 (A22) Tractor Repair Manual DE

$300.00

- Model: AXOS 340-310 (A22) Tractor

- Type Of Manual: Repair Manual

- Language: DE

- Format: PDF(s)

- Size: 192 MB

File List:

– 00 1138 049 0.pdf

– 00 1171 913 X.pdf

– Size(0.3 MB) 10.4.2010.pdf

– Size(0.3 MB) 12/11/2009.pdf

– Size(1.3 MB) 10.4.2010.pdf

– Size(1.6 MB) 10.4.2010.pdf

– Size(1.8 MB) 9.27.2010.pdf

– Size(11.4 MB) 10.4.2010.pdf

– Size(11.6 MB) 10.4.2010.pdf

– Size(14.7 MB) 7.25.2013.pdf

– Size(17.4 MB) 10.4.2010.pdf

– Size(26 MB) 10.4.2010.pdf

– Size(3.3 MB) 10.4.2010.pdf

– Size(3.5 MB) 9.27.2010.pdf

– Size(3.7 MB) 10.4.2010.pdf

– Size(33.9 MB) 7.29.2013.pdf

– Size(37.7 MB) 3.28.2013.pdf

– Size(4.2 MB) 4.29.2013.pdf

– Size(4.3 MB) 10.4.2010.pdf

– Size(5 MB) 12/11/2009.pdf

– Size(6.2 MB) 12/11/2009.pdf

– Size(7.2 MB) 4.1.2013.pnts

3 CCN (CLAAS COMPONENT NUMBER)

4 Introduction

4.1 General information

4.2 Hydraulic line

4.3 Pneumatic line

4.4 General repair instructions

4.5 Tightening torques

4.6 Technical data

5.1 Tools by chapter

5.2 Tool according to order numbers

6 Fasteners and sealants

8 Security

8.1 General information

9 01 Motor

9.1 0102 Complete component

9.2 0110 Motor housing

9.3 0115 Motor engine

9.4 0120 cylinder head / valves / distributor wheel

9.5 0125 Injection / Fuel System

9.6 0130 Lubricating oil system

9.7 0135 cooling system

9.8 0140 exhaust system

10 02 Gearbox / clutch / cardan shaft

10.1 0202 Complete component

10.2 0215 Mechanical clutch

10.3 0218 Control / actuation clutch

10.4 0220 Mechanical reversing

10.5 0222 Hydraulic reversing

10.6 0230 Mechanical gears

10.7 0234 powershift transmission

10.8 0238 Control / actuation gearbox

10.9 0240 rear axle housing

10.10 0242 Differential

10.11 0252 Electro-hydraulic front axle drive

11 03 Chassis

11.1 Attachment point

11.2 0320 Steering axle

11.3 0325 Front steering drive axle

12 04 Brake

12.1 0405 Service brake

12.2 0415 parking brake

12.3 0420 Compressed air trailer brake system

12.4 0425 Hydraulic trailer brake

13 05 Steering

13.1 0505 Steering

14 06 Lifting device

14.1 0605 rear power lift

14.2 0610 Front power lift

15 07 Trailer hitch

15.1 0705 hitch bracket

16 08 Drives

16.1 0802 Rear PTO

16.2 0804 Front PTO

17 09 Hydraulics

17.1 0910 Pumps

17.2 0920 Valves

18 12 Cab / Driver’s cab

18.1 1205 Cab suspension

18.2 1210 Cabin

18.3 1215 Driver’s cab

18.4 1235 Cabin heater

18.5 1240 Air conditioning

19 80 attachments, machine housing

19.1 8005 frame / trough

19.2 8025 fairings / hoods

19.3 8035 Ballast / additional weight

20.120.2 A

Size(0.3 MB) 10.4.2010.pdf

Table of Content:

1 10 Error Codes

1.1 Error codes – rear linkage

1.2 Error codes

Size(0.3 MB) 12/11/2009.pdf

Table of Content:

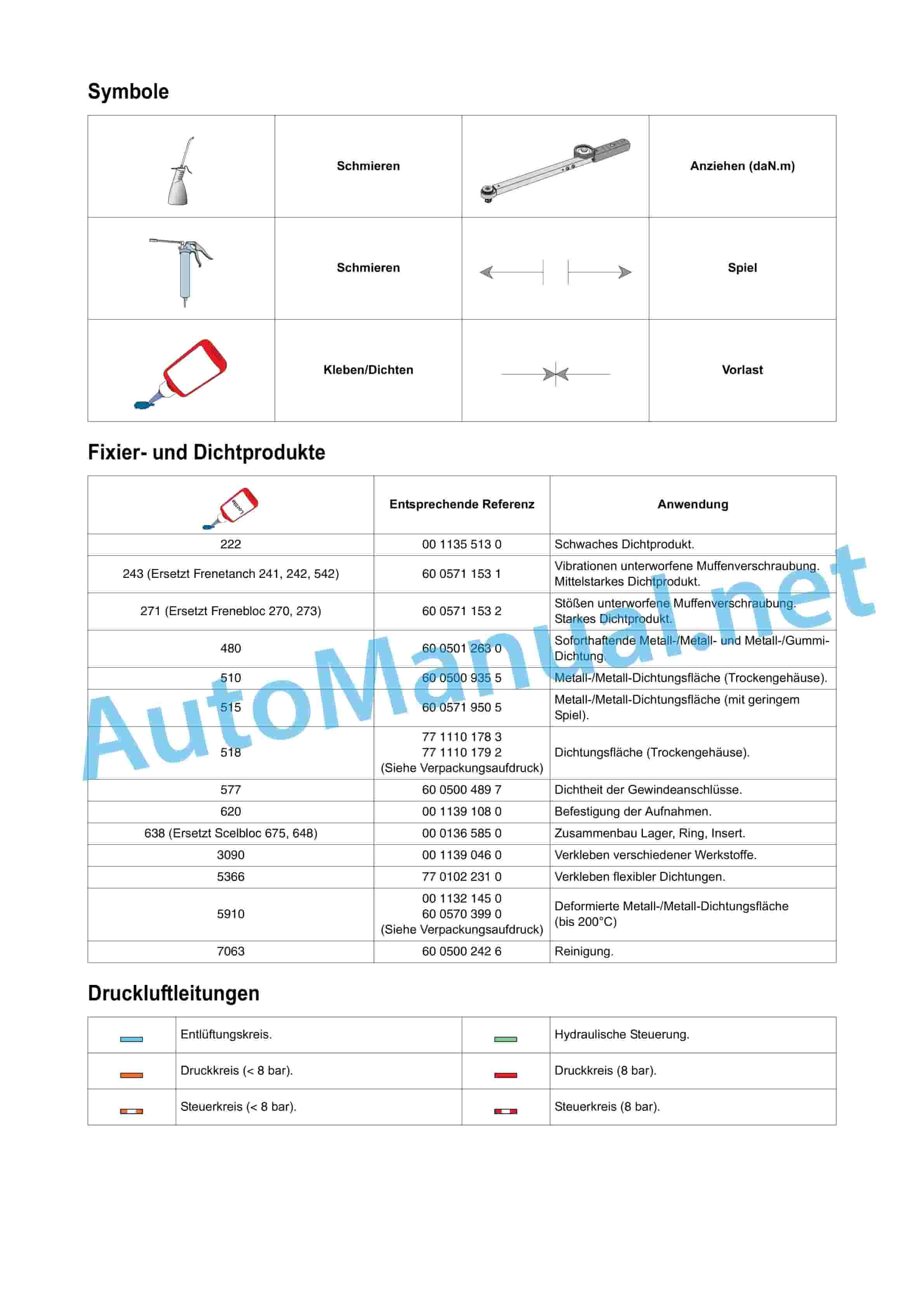

2 fixing and sealing products

3 compressed air lines

4 hydraulic lines

5 Standardized tightening torques (except specific tightening torques from technical support)

5.1 Screws

5.2 Hydraulic connections – standard DIN 3865

Size(1.3 MB) 10.4.2010.pdf

Table of Content:

1 03 Chassis

1.1 Content

1.2 Rigid front axle

Size(1.6 MB) 10.4.2010.pdf

Table of Content:

1 05 Steering

1.1 Content

1.2 Setting

1.3 Specific torques and sealants

1.4 Measurements ah2>

Table of Content:

1 08 OPERATION

1.1 Content

1.2 08 Operation

Size(11.4 MB) 10.4.2010.pdf

Table of Content:

1 Numbering of the components CLAAS

2 Gearbox module TR1 A57

2.1 Overview

2.2 Measurement”A58″

3.1 Overview

3.2 Measurements and controls

4 module dashboard DBD A101

4.1 Overview

4.2 Meas”B45″

5.1 Overview

5.2 Measurements and controls

6 Coolant temperature sensor – cold start “B46”

6.1 Overview

6.2 Measurements and controls

7 Transmission oil temperature sender “B123”

7.1 Overview

7.2 Measurements and controls

8 Rear Hitch Position Sensor “B139”

8.1 Overview

8.2 Setting

8.3 Measurements and controls

9 dynamometers “B144”

9.1 Overview

9.2 Setting

9.3 Measurements and controls

10 sensors for the theoretical speed “B227”

10.1 Overview

10.2 Measurements and controls

11 Intermediate speed sensor gearbox “B229”

11.1 Overview

11.2 Setting

11.3 Measurement and control

12 Fuel level “R35”

12.1 Overview

12.2 Measurements and controls

13 Angle position sensor pedal “R73”

13.1 Overview

13.2 Setting

13.3 Measurements and controls

14 Switch 4 wheel drive “S1”

14.1 Overview

14.2 Measurements and controls

15 ignition key “S64”

15.1 Overview

15.2 Measurements and controls

16 Switch on/off of the front PTO shaft “S113″

16.1 Measurements and controls

17 Torque converter switch Revershift S171

17.1 Overview

17.2 Measurements and controls

17.3 Checking the supply voltage

18 Gear switch +/- and clutch switch S184

18.1 Overview

18.2 Measurements and controls

19 Rear hitch switch ?”Y1″

21.1 Overview

21.2 Measurements and controls

22 Solenoid valve stopping the engine Y15

22.1 Overview

22.2 Measurements and controls

22.3 Che”Y326”

23.1 Overview

23.2 Test methods

23.3 Measurements and controls

24 solenoid valves of the power-shiftable reversing system “Revershift”, “Y327” and “Y328”

24.1 Overview

24.2 Measurements and controls

24.3 Checking the resistance

24.4 Checking the current strength

25 solenoid valve for powershift stages “Y335″

25.1 Overview

25.2 Measurements and controls

26 Rear hitch raising/lowering solenoid valve Y336, Y337?”Z12”

27.1 Overview

27.2 Measurements and controls

28 Air conditioning gas pressure switch “Z21”

28.1 Overview

28.2 Measurements and controls

29 Air conditioning thermostat “Z24”

29.1 Overview

29.2 Measurements and controls

30 pressure switch engine oil “Z42”

30.1 Overview

30.2 Measurements and controls

31 Air filter clogging contactor “Z69”

31.1 Overview

31.2 Measurements and controls

32 Idle switch of the gearbox “Z77”

32.1 Overview

32.2 Measurements and controls

32.3 Continuity control

33 Left brake pedal switch “Z126”

33.1 Overview

33.2 Measurements and controls

33.3 Setting

34 Right brake pedal switch “Z127″

34.1 Overview

34.2 Measurements and controls

34.3 Setting

35 Pedal switch in lower position Z152

35.1 Overview

35.2 Settings

35.3 Measuremen”Z160”

36.1 Overview

36.2 Measurements and controls

37 Switch-Rear PTO 540 rpm “Z161”

37.1 Overview

37.2 Measurements and controls

38 Rear PTO control circuit pressure switch “Z175”

38.1 Overview

38.2 Measurements and controls

39 Pressure contact transmission control circuit “Z184”

39.1 Overview

39.2 Measurements and controls

40 Switch – PTO shaft engaged “Z185”

40.1 Overview

40.2 Setting

40.3 Measurements and controls

41 Idle switch rear PTO shaft “Z186”

41.1 Overview

41.2 Measurements and controls

42 Rear PTO speed switch 540 rpm economy mode “Z187”

42.1 Overview

42.2 Measurements and controls

Size(11.6 MB) 10.4.2010.pdf

Table of Content:

1.1 F1 – Functional circuit diagrams

2 work lights on rear fender

3 position lights and license plate lighting

4 low beam

5 high beam

6 brake lights

7 rotating lights

9 direction indicators and hazard warning lights

10 Dashboard lighting

11 Front PTO – Powershiftable shuttle

12 Front PTO – Mechanical shuttle

13 Rear PTO – Mechanical shuttle

14 Rear PTO – Powershiftable shuttle

15 Starter and load circuit – mechanical reversing circuit

16 Starter and Load Circuit – Revershift

17 Pre-glow

18 Forward gear – Reverse gear

19 Bed. 4-wheel drive

20 Hydraulic pressure (data) – Mechanical shuttle

21 Hydraulic pressure (data) – Powershift shuttle

22 Gearbox temperature

23 Dual powershift

24 Network CAN

25 Supply before production d. Contacts

26 Supply after production d. Contacts

30 Supply module gearbox

31 Diagnostechanical reversing circuit

32 Diagnostic connection – load-switchable reversing circuit

33 Supply module dashboard

34 Socket 25 A

35 Connection loader

36 Handbrake

37 Theoretical travel speed and speed gearbox

38 Fuel level

39 Oil pressure, air filter blockage, engine temperature

40 Fuel – Pump

41 Calibration, display dashboard

42 F0_001_022_AXOS_PLF_0509_DIAGNOSTIC_DE.pdf

42.1 HELP USING TECHNICAL SUPPORT

42.2 List of CLAAS COMPONENT NUMBERS (CCN)

42.3 List of connections

42.4 General cabling

42.5 List of cable sets

42.6 List of ground points

42.7 Fuse and electronic boards

42.8 Notes

43 F2_001-064_AXOS_PLF_0509_DIAGNOSTIC_DE.pdf

43.1 F2 connection diagrams

43.2 Content

44 F3_001_016_AXOS_PLF_0509_DIAGNOSTIC_DE.pdf

44.1 Content

44.2 Notes

45 F0_001_022_AXOS_PLF_0509_DIAGNOSTIC_DE.pdf

45.1 HELP USING TECHNICAL SUPPORT

45.2 List of CLAAS COMPONENT NUMBERS (CCN)

45.3 List of connections

45.4 General cabling

45.5 List of cable sets

45.6 List of ground points

45.7 Fuse and electronic boards

Size(14.7 MB) 7.25.2013.pdf

Table of Content:

1 02_001-004_AXOS_340-310_DIAGNOSTIC_TDM_DE.pdf

1.1 Content

2 02_005-052_AXOS_340-310_DIAGNOSTIC_DE.pdf

2.1 02 Gearbox/Clutch

3 02_007-026_AXOS_340-310_DIAGNOSTIC_A3_DE.pdf

3.1 Power transmission Transmission with powershiftable shuttle

3.2 Power transmission transmission with mechanical shuttle

3.3 Most important settings

3.4 Tightening torques of the hydraulic block with power-shiftable shuttle

3.5 Hydraulic control circuit with power-shiftable shuttle

Size(17.4 MB) 10.4.2010.pdf

Table of Content:

1 HELP USING TECHNICAL SUPPORT

1.1 F0 General

1.2 This section applies to all parts numbered in Chapter F. Each board is initially shown in a 2D view with the list of relays and fuses. They are then shown schematically in one or more views.

1.3 F1 functional circuit diagrams

1.4 Each wiring dirds and their connections responsible for a specific use function, such as the control of the front linkage or the fuel level gauges (see below).

1.5 F2 connection diagrams

1.6 This section lists all connectors, intermediate connections and splices. For each part there is a list with the numbers of the channels and the associated cables (see below).

1.7 F3 Installation plans

1.8 This section allows precise knowledge of the location of the individual electrical parts in the vehicle.

1.9 Content

2 ListCLAAS COMPONENT NUMBERS (CCN)

3 List of connections

4 General wiring

5 List of cable sets

6 List of ground points

7 fuse and electronic boards

7.1 Fuse board primary consumer V21

9 F1_001-060_TS_AXOS_CAB_0409_DIAGNOSTIC_DE.pdf

9.1 Content

9.2 Work lights at the top of the cab at the front

9.3 Work lights at the top of the cab at the rear – (roof below)

9.4 Work lights at the rear at the top of the cab – (top roof)

9.5 Position lights and license plate lighting

9.6 Low beam

9.7 High beam

9.8 Brake lights

9.9 Rotating beacon

9.11 Direction indicators and hazard warning lights

9.12 Dashboard lighting

9.13 Operation ventilation

9.14 Manual air conditioning

9.15 Rear power lift TCE 9

9.16 Front PTO

9.17 Rear PTO shaft (reversing gear under torque)

9.18 Rear PTO (mechanical reversing switch)

9.19 Starter and load circuit – (mechanical reversing switch)

9.20 Starter and load circuit – (reversing circuit under torque)

9.21 Preheating

9.22 Forward gear – Reverse gear

9.23 Condition 4-wheel drive

9.24 Hydraulic pressures and filter clogging

9.25 Transmission temperature – Powershiftable shuttle

9.26 Hydraulic doubler “Twinshift”

9.27 Cigar lighter

9.28 Car radio – Clock

9.29 Ceiling light

9.30 Windshield Wiper/Windshield Washer with Adjustable Steering Column

9.31 Front windshield wiper/washer with fixed steering column

9.32 Rear windshield wiper/washer

9.33 Lines K and L

9.34 Network CAN

9.35 Supply before production d. Contacts

9.36 Supply after production d. Contacts

9.40 Supply module gearbox “TR1”

9.41 Supply module for rear power lift “REH” and control panel V22

9.42 Supply diagnostic connection

9.43 Supply module dashboard “DBD”

9.44 Socket 25 A – (cabin)

9.45 On-board computer and event counter

9.46 Loader connection

9.47 Handbrake

9.48 Air seat

9.49 Theoretical travel speed and speed gearbox

9.50 fuel level

9.51 Oil pressure, air filter blockage, engine temperature

9.52 Fuel – Pump

9.53 Calibration, Dashboard Display (Adjustable Steering Column)

9.54 Calibration, dashboard display (fixed steering column)

9.55 Notes

10 F2_001-110_AXOS_CAB_0409_DIAGNOSTIC_DE.pdf

10.1 F2 connection diagrams

10.2 Content

10.3 Notes

11 F3_001-030_AXOS_CAB_0409_DIAGNOSTIC_DE.pdf

11.1 Content

11.2 01 – Cabin bottom cable set

11.3 02 – Dashboard cable set – Mechanical shuttle – With air conditioning

11.4 02 – Dashboard cable set – Mechanical shuttle – Without air conditioning

11.5 02 – Dashboard cable set – Powershift shuttle – With air conditioning

11.6 02 – Dashboard cable set – Powershift shuttle – Without air conditioning

11.7 03 – Cable set fender

11.8 03 – Cable set fender – electro-hydraulic power lift

11.9 04 – Cable set above the cabin roof below

11.10 04 – Cable set above the cabin roof below

11.11 07 – Cabin supply cable set

11.12 09 – Gearbox cable set – Mechanical shuttle

11.13 09 – Gearbox cable set – Powershiftable shuttle

11.14 09 – Transmission cable set – Powershiftable shuttle – Electro-hydraulic power lift

11.15 10 – Engine cable set – 4 cylinders

11.16 11 – Radiator grille cable set

11.17 13 – Transmission control cable set – Mechanical shuttle

11.18 13 – Transmission control cable set – Powershiftable shuttle

11.19 13 – Transmission control cable set – Powershiftable shuttle – Electro-hydraulic power lift

11.20 27 – Cable set power supply cabin interior

11.21 49 – Cable set for device connection cabin

11.22 52 – Cigarette lighter cable set

11.23 66 – Cable set – windshield wiper/washer – dashboard display

11.24 C2 – Cable safety switch

11.25 C3 – Positive start cable

11.26 C4 – Positive start cable

11.27 C6 – Negative start cable

12 F2_001-110_AXOS_CAB_0409_DIAGNOSTIC_DE.pdf

12.1 F2 connection diagrams

12.2 Content

12.3 Notes

Size(26 MB) 10.4.2010.pdf

Table of Content:

1.1 12 10 Cabin

1.2 12 15 Platform / roll bar

1.3 12 35 Heating

1.4 12 40 Air conditioning

Size(3.3 MB) 10.4.2010.pdf

Table of Content:

1.1 08 02 Rear PTO (2 and 3 speed ranges)

1.2 08 04 Front PTO

Size(3.5 MB) 9.27.2010.pdf

Table of Content:

1 08 PTO SHAFT DRIVE AND OPERATION

1.1 Content

1.2 08 02 Rear PTO (2 and 3 speed ranges)

1.3 08 04 Front PTO

Size(3.7 MB) 10.4.2010.pdf

Table of Content:

1 06 lifting device

1.1 Content

1.2 Rear power lift

1.3 Front power lift

Size(33.9 MB) 7.29.2013.pdf

Table of Content:

1 02 TRANSMISSION/CLUTCH

1.1 Content

1.2 02 00 General

d mechanical reversing switch

1.6 02 22 Hydraulic shuttle

1.7 02 30 mechanical gear

1.8 02 34 Powershift Transmission

1.9 02 38 Controls of the reduction gear s

1.10 02 40 Rear axle housing and final reductions

1.11 02 42 Differential

1.12 02 52 Electro-hydraulic power take-off

Size(37.7 MB) 3.28.2013.pdf

Table of Content:

1 01 MOTOR

1.1 Content

1.2 01 00 General

1.3 01 02 COMPLETE ASSEMBLY

1.4 01 10 Motor housing

1.5 01 15 Rotating parts

1.6 01 20 Cylinder head, valves and valve control

1.7 01 25 Fuel injection and supply system

1.8 01 30 Lubrication system

1.9 01 35 Cooling System

1.10 01 40 Exhaust device

Size(4.2 MB) 4.29.2013.pdf

Table of Content:

1 04 Brake

1.1 Content

1.2 Service brake

1.3 Trailer air brake

1.4 Trailer oil pressure brake

Size(4.3 MB) 10.4.2010.pdf

Table of Content:

1.1 05 00 General

1.2 05 0Table of Content:

1 tools per chapter

2 tools per reference number

3 tools per reference number

4 tools per reference number

5 tools per reference number

6 tools per reference number

7 tools per reference number

8 tools per reference number

9 tools per reference number

10 tools per reference number

11 tools per reference number

12 tools per reference number

13 tools per reference number

14 tools per reference number

Size(6.2 MB) 12/11/2009.pdf

Table of Content:

1.1 03 00 General

1.2 03 25 Front steering axle with drive wheels

Size(7.2 MB) 4.1.2013.pdf

Table of Content:

1 01 MOTOR

1.1 Content

1.2 01 Motor

Size(7.2 MB) 4.8.2013.pdf

Table of Content:

1.1 09 00 General

1.2 09 10 Pumps

1.3 09 20 valves

Size(7.3 MB) 10.4.2010.pdf.crdownload

Table ofear power lift

1.3 06 10 Front power lift

Size(7.3 MB) 4.29.2013.pdf

Table of Content:

1.1 04 05 Service brake

1.2 04 15 Handbrake

1.3 04 20 Trailer air brake

1.4 04 25 Trailer oil pressure brake

Size(8.1 MB) 7.25.2013.pdf

Table of Content:

1 09_001_004_AXOS_340-310_DIAGNOSTIC_TDM_DE.pdf

1.1 Content

2 09_005_030_AXOS_340-310_DIAGNOSTIC_DE.pdf

2.1 09 Hydraulic System

3 09_013_016_AXOS_340-310_DIAGNOSTIC_

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF