Claas Crop Sensor Isaria (B61) Digital Solutions Operator Manual EN

$50.00

- Model: Crop Sensor Isaria (B61) Digital Solutions

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 53.4 MB

File List:

00 0018 584 4.pdf

00 0019 424 0.pdf

00 0301 051 0.pdf

00 0303 482 0.pdf

00 1400 243 0.pdf

00 1400 244 0.pdf

00 1400 341 3.pdf

00 1400 347 5.pdf

00 1402 771 3.pdf

00 2348 427 0.pdf

00 0018 584 4.pdf:

EASY on board app

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Information about this Operator’s Manual

1.1.2 Symbols and notes

1.1.3 Notes regarding warranty

1.1.4 Technical requirements

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

1.3 Softwareupdate

1.3.1 Installing updates

1.3.2 Updating the operating system

1.4 Faults and remedies

1.4.1

1.4.2 Fault message: Screen locked

1.5 Technical terms and abbreviations

1.5.1 Technical terms

1.5.2 Units

1.5.3 Abbreviations

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Requirements made on all persons working with the product

2.2.3 Hazard areas

2.2.4 Check interactions with self-propelled machines / tractors and implements

2.2.5 Structural changes

2.2.6 Optional equipment and spare parts

2.2.7 Technical status

2.2.8 Hazard caused by damage to the product

2.2.9 Visibility of work area

2.2.10 Glare and reflections

2.2.11 Unintentional triggering of functions

2.2.12 Hazards caused by signal tones

2.2.13 Unauthorised use

2.2.14 Use of mobile terminal outside the cab

2.2.15 Follow the safety instructions

2.2.16 Respecting technical limit values

2.2.17 Preparing the product for road travel

2.2.18 Hazards when driving on the road and on the field

2.2.19 Hazards when driving on the road with an ISOBUS implement

2.2.20 Hazards caused by switching off the app while driving

2.2.21 Hazards from disturbance of WLAN environment

2.2.22 Hazards from covering up the App

2.2.23 Hazards caused by malfunctions of the app

2.2.24 Lifted machine parts and loads

3 EASY on board App

3.1 Operating and display elements

3.1.1 Overview of the EASY on board App

3.1.2 Overview of function bar

3.1.3 Cockpit bar overview

3.1.4 Functions of the EASY on board App

3.1.5 Using the number pad

3.1.6 Using the keyboard

3.2 Operation

3.2.1 Selecting a module

3.2.2 Activating or deactivating modules

3.2.3 Activating or changing the licence

3.2.4 Setting the volume

3.2.5 Closing the app

4 Documentation

4.1 Product description

4.1.1 Requirements

4.1.2 Task data

4.1.3 Product options

4.1.4 App operation in the background

4.2 Operating and display elements

4.2.1

4.2.2 Tasks

4.2.3 Fields

4.2.4 Harvesting

4.2.5 Seeds

4.2.6 Consumables

4.2.7 Machines and implements

4.2.8 Persons

4.2.9 Remark

4.2.10

4.2.11 Entering quantities

4.3 Creating a task

4.3.1 Creating a task

4.3.2 Copying a task

4.3.3 Selecting fields

4.3.4 Creating a new field

4.3.5 Selecting the harvest type

4.3.6 Selecting seeds

4.3.7 Select consumables

4.3.8 Selecting machines and implements

4.3.9 Selecting persons

4.3.10 Save task

4.4 Documentation

4.4.1 Starting the task

4.4.2 Stopping the task

4.4.3 Completing the task

4.4.4 Synchronising an task

4.4.5 Exporting data

4.4.6 Deleting settings

5 ISO terminal

5.1 Product description

5.1.1

5.1.2 Connecting the ISO terminal

5.2 Operating and display elements

5.2.1 Overview of the ISO terminal

5.2.2

5.2.3 Controlling the machine without a USB connection to the CWI

5.3 Programmable keys

5.3.1 Assigning a key assignment

5.3.2 Programming the key assignment

5.3.3 Editing a key assignment

5.3.4 Deleting key assignments

6 Adjustments

6.1 Operating and display elements

6.1.1 Settings

6.2 Adjustments

6.2.1 Resetting the data source

6.2.2 Activating ISOBUS communication

6.2.3 Checking the synchronisation status

6.2.4 Sending an error report

7.1 Adjustments

7.1.1 Where do I find the version number?

7.1.2 Can I change to another app while this app is running?

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0303 482 0.pdf:

PROFI CAM 4

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Structural changes

2.2.3 Optional equipment and spare parts

2.2.4 Operation only following proper putting into operation

2.2.5 Technical status

2.2.6 Respecting technical limit values

Respecting technical limit values

2.2.7 Hazards when driving on roads and fields

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Identification plates

3.3 Information on the product

3.3.1 CE marking

4 Operating and display elements

4.1 Camera system

4.1.1 Camera system monitor

4.1.2 CEBIS

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

6 Preparing the product

6.1 Switching off and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to putting into operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electric and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Putting out of operation and disposal

10.1 General information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 1400 243 0.pdf:

AGROCOM MAP quick start guidefor importing a new machine description

! Please note: Please read the manual carefully and follow the instructions.

Step 1: Write data to the memory card on the PC in AGROCOM MAP

Step 2: On MOBILE CEBIS ��� e work record with CROP SENSOR

Step 3: Import the machine description on the PC into AGROCOM MAP

00 1400 244 0.pdf:

AGROCOM NET quick start guidefor importing a new machine description

! Please note: Please read the manual carefully and follow the instructions.

Step 1: Write data to the memory card on the PC in AGROCOM NET

Step 2: On MOBILE CEBIS ��� set up the work record with CROP SENSOR

Step 3: Import the machine description on the PC into AGROCOM NET

00 1400 347 5.pdf:

CROP SENSOR ISARIA

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of Manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment 1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonamisuse

2.1 Identifying warnings

2.1.1 Hazard signs

Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Requirements made on all persons working with the product

2.2.4 Hazard areas

2.2.5 Standing between machine and front attachment

2.2.6 Interaction between CROP SENSOR ISARIA and the machine or tractor

2.2.7 Structural changes

2.2.8 Optional equipment and spare parts

2.2.9 Operation only following proper putting into operation

2.2.10 Technical status

2.2.11 Hazard from damage on the product

2.2.12 Respecting technical limit values

Respecting technical limit values

2.2.13 Keeping the safety devices functional

2.2.14 Personal protective equipment

2.2.15 Preparing the product for road travel

2.2.16 Hazards when driving on the road and in the field with the CROP SENSOR ISARIA

2.2.17 Hazards when driving on the road and in the field

2.2.18 Unsuitable operating materials

2.2.19 Safe handling of operating materials and auxiliary materials

2.2.20 Environmental protection and disposal

2.2.21 Electrocution by electrical system

2.2.22 Only carry out work on the machine when it is stopped

2.2.23 Maintenance operations and repair work

2.2.24 Raised machine parts and loads

2.2.25 Welding work prohibited

2.2.26 Check interactions with self-propelled machines / tractors and implements

2.3 Safety marking

2.3.1 Layout of safety decals

2.3.2 CROP SENSOR ISARIA safety decals

3 Product description

3.1 Overview and method of operation

3.1.1 CROP SENSOR ISARIA

3.2 Safety devices

3.2.1 Safety features on the CROP SENSOR ISARIA

3.3 Optional equipment

3.3.1 Country-specific equipment*

Warning plates

3.4 Identification plates and identification number

3.4.1 Position of the CROP SENSOR ISARIA identification plate

4 Operating and display elements

4.1 Terminal

4.1.1 Different display values may result from using different terminals

4.1.2 Overview of the S10 terminal

4.2 Monitor

4.2.1 Overview of operating screen

4.2.2 Menu bar

4.2.3 Status messages

4.3

4.3.1

4.4

4.4.1

4.4.2

4.4.3 <1-point mode> menu

4.4.4 <2-point mode> menu

4.4.5

4.4.6

4.5

4.5.1

4.5.2

4.6

4.6.1

5 Technical specifications

5.1 CROP SENSOR ISARIA

5.1.1 CROP SENSOR ISARIA

5.1.2 Tightening torque

6 Mounting

6.1 Package list

6.1.1 CROP SENSOR ISARIA system

6.2 3-point fitting support

6.2.1 Installing the three-point fitting support

Fitting to three-point support

Fitting to the three-point implement hitch

Work preparation

6.3 Universal adapter

6.3.1 Fitting the universal adapter

6.4 CROP SENSOR ISARIA

6.4.1 Unpacking

6.4.2 Assembling the base frame

6.4.3 Installing the side arms

Assigning the side arms

Fastening the side arms to the base frame

Installing the measuring head adjustment

Fastening the lifting cylinder

Connecting side arm 1

Connecting side arm 2

6.4.4 Connecting the CROP SENSOR ISARIA electrically

6.5 Country-specific equipment

6.5.1 Country-specific equipment*

Shipping package

Pre-assembling the lateral warning plates

Pre-assembling the front warning plates

Fitting the warning plates to the CROP SENSOR

7 Machine preparation

7.1 Switching off and securing the machine

7.1.1 Shut down and secure the machine

7.2 Checklists

7.2.1 Putting the CROP SENSOR ISARIA into operation

7.2.2 Moving the CROP SENSOR ISARIA to transport position

7.3 CROP SENSOR ISARIA

7.3.1 Working with illumination

7.3.2 Set the installation height and working height

7.3.3 Connecting the implement terminal

8 Operation

8.1 Transport

8.1.1 Road travel with CROP SENSOR ISARIA

Obstructed view due to side arms / sensor heads

8.1.2 Parking the CROP SENSOR ISARIA

8.2 CROP SENSOR ISARIA

8.2.1 Folding the CROP SENSOR ISARIA out or in

Folding the CROP SENSOR ISARIA out or in manually

8.3 Adjustments

8.3.1 Adjusting a basic setting

8.3.2 Adjusting the quantity settings

Setting the minimum and maximum quantity

Setting the control range.

8.3.3 Setting the biomass threshold value

Setting the biomass threshold value

Calibrating the biomass threshold value

8.3.4 Changing UT over to a second ISOBUS terminal

8.3.5 Changing TC over to a second ISOBUS terminal

8.4 Fertilising modes

8.4.1 Using mapping mode

8.4.2 Setting auto mode

8.4.3 Setting 1-point mode

8.4.4 Setting 2-point mode

8.4.5 Performing the calibration run for 1- or 2-point mode

8.4.6 Setting the ISARIA fertiliser system

8.5 Yield potential map

8.5.1 Yield potential map with CROP SENSOR ISARIA

8.5.2 Using the yield potential map in free calibration

8.5.3 Using the yield potential map with the ISARIA fertiliser system

8.6 ISARIA Expert mode

8.6.1 Activating and deactivating the expert mode

8.6.2 Displaying information for calculating the fertilizer quantities

8.6.3 ISARIA fertiliser system with expert mode

8.7 TELEMATICS

8.7.1 Using TELEMATICS

8.8 Task Management

8.8.1 Job management with the S10 terminal

Opening the job management

Starting a task

Pausing in task

Stopping the job

9 Faults and remedies

9.1 CROP SENSOR ISARIA

9.1.1 CROP SENSOR ISARIA

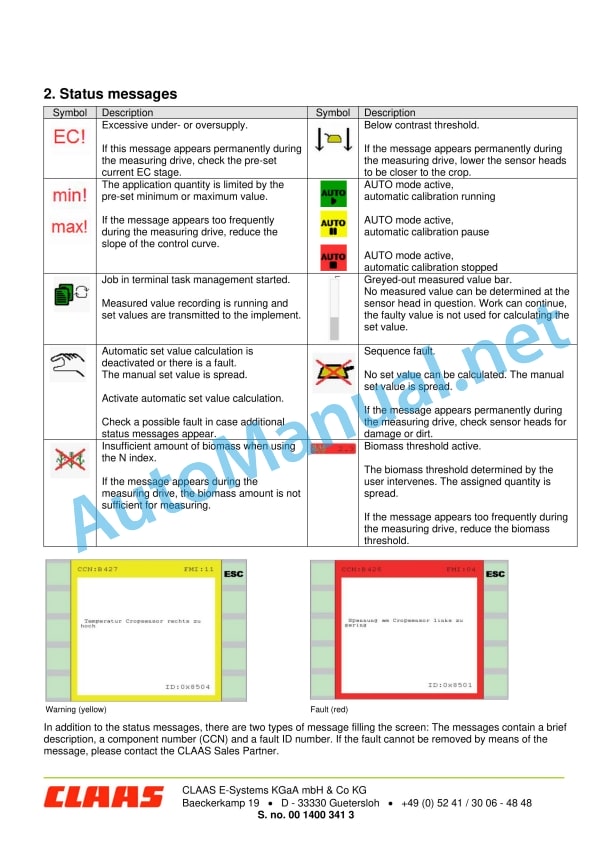

9.1.2 Status messages

9.1.3 Set value transmission

10 Maintenance

10.1 Maintenance schedules

10.1.1 Every 10 operating hours or daily

10.1.2 Every 50 operating hours or monthly

10.1.3 Every 100 operating hours or after the fertilising season

10.2 Cleaning system

10.2.1 Cleaning the measuring heads

10.2.2 Cleaning the CROP SENSOR ISARIA

10.3 Lubrication plan

10.3.1 Lubrication points

11 Putting out of operation and disposal

11.1 General information

11.1.1 Decommissioning and disposal

12 EC declaration of conformity

12.1 CROP SENSOR ISARIA

12.1.1 EC Declaration of conformity

13 Technical terms and abbreviations

13.1 Terms and explanations

13.1.1 Abbreviations

13.1.2 Units

00 1402 771 3.pdf:

CEBIS MOBILE

Table of contents

1 To this Operator’s Manual

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Notes on the Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Notes on maintenance

1.1.7 Notes on warranty

1.1.8 Technical specifications

1.1.9 Spare parts and technical questions

2.1 Intended use

2.1.1 Intended use

2.1.2 Reasonably foreseeable misuse

2.2 Safety rules

2.2.1 Operator’s Manual and other sources of information

Importance of Operator’s Manual

2.2.2 Personnel qualification and organisation

Requirements made on all persons working with the product

2.2.3 Changes on the product

Structural changes

2.2.4 Additional equipment and spare parts

Additional equipment and spare parts

2.2.5 Technically flawless condition

Technically flawless condition of product

Hazard from damage on the product

Respecting technical limit values

2.2.6 Hazard areas

Hazard areas

2.2.7 Sources of hazards on the product

Electrocution from electric system

Noise can cause health damage

2.2.8 Hazards while working on the machine

Working only on the shut-down machine

Maintenance and repair work

Lifted machine parts and loads

Hazards from welding work

2.2.9 Check interactions between self-propelled machines / tractors and implements

2.2.10 Road travel with the CEBIS MOBILE ISOBUS

2.2.11 Operating the terminal while driving

Switching off the terminal during fieldwork

Operating the terminal during road travel

2.3 Safety instructions in this manual

2.3.1 Identification of warning and danger signs

3 Product description

3.1 Overview and method of operation

3.1.1 CEBIS MOBILE on-board computer

3.1.2 Overview of CEBIS MOBILE terminal

3.1.3 Function of ISOBUS application

3.2 Optional equipment

3.2.1 GPS antenna A100

3.2.2 Power supply cable

3.2.3 Serial connecting cables

3.2.4 Serial/CAN converter LH 5000 – ISOBUS (SCU-L)

3.2.5 Serial/CAN converter NMEA 2000 (SCU-N)

3.2.6 ISOBUS basic equipment

3.3 Identification plates and identification number

3.3.1 CEBIS MOBILE identification plate position

3.3.2 CEBIS MOBILE identification plate explanation

4 Operating and control elements

4.1 CEBIS MOBILE onboard computer

4.1.1 Terminal

4.1.2 Terminal program

4.2 Universal terminal menu structure (service)

4.2.1 Main menu of universal terminal

4.2.2

4.2.3

4.2.4

4.2.5

4.3 Job processing (task) menu structure

4.3.1 Job processing main menu

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

5 Technical specifications

5.1 CEBIS MOBILE

5.1.1 Specification

5.2 GPS source

5.2.1 GPS antenna A100

5.2.2 Serial/CAN converter NMEA 2000 (SCU-N)

5.2.3 GPS serial (NMEA0183)

5.3 Serial connection

5.3.1 Specification of serial connection

5.3.2 Serial/CAN converter LH5000 – ISOBUS (SCU-L)*

6 Mounting

6.1 Package list

6.1.1 Shipping package of CEBIS MOBILE ISOBUS / VA

6.1.2 Shipping package of GPS antenna A100*

6.2 Installation of ISOBUS components

6.2.1 Installation of operating terminal

6.2.2 Connection of operating terminal

Power supply and data connection through the ISOBUS cab connector

Power supply by 12V socket

6.2.3 Installation of ISOBUS basic equipment*

Connection of ISOBUS basic equipment

6.2.4 Implement / terminal connection

Connection through the ISOBUS

Connection through the serial interface

Connection of serial/CAN converter LH 5000 – ISOBUS (SCU-L)*

6.3 Installation of GPS source

6.3.1 Installation of GPS antenna A100*

6.3.2 Installation of serial/CAN converter NMEA2000 (SCU-N)*

6.3.3 Installation of serial GPS

7 Preparing the product

7.1 Shutting down and securing the machine

7.1.1 Shut down and secure the machine

7.2 Prior to operation

7.2.1 Carry out prior to initial operation or after a software update

7.2.2 Every time before putting into operation

8 Operation

8.1 CEBIS MOBILE onboard computer

8.1.1 Starting the application

8.1.2 Activating the application

8.1.3 Job management with GPS PILOT

8.2 Switching CEBIS MOBILE on/off

8.2.1 Switching on CEBIS MOBILE

8.2.2 Selecting an ISOBUS application

8.2.3 Switching off CEBIS MOBILE

8.3 Programmable keys

8.3.1 Displaying the key assignment

8.3.2 Creating a key assignment

Step 1: Selecting the control and the key

Option 1:

00 2348 427 0.pdf:

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 700

3.1.2 Function principle of CEMIS 700

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 700

4 Information on the product

4.1 Software version

5 Operating and display elements

5.1 CEMIS 700

5.1.1 User interface

5.1.2 Terminal program

6 Technical specifications

6.1 CEMIS 700

6.1.1 Specification

7 Operation

7.1 CEMIS 700

7.1.1 Operating the CEMIS 700

7.1.2 Switching CEMIS 700 on

7.1.3 Switching CEMIS 700 off

7.2 Terminal settings

7.2.1 Making settings

Making settings with the rotary button

Making settings with the touch function

7.2.2 Setting the screen lighting

Daytime mode

Nighttime mode

Activating automatic key lighting

7.2.3 Setting the time and date

7.2.4 Displaying diagnosis information

On-board power supply voltage display

Display of CLAAS ISOBUS ECU address and name

7.2.5 Setting the language and display formats

Setting the language

Setting display formats

7.2.6 Setting the volume

7.2.7 Deleting an ISOBUS implement

8 Maintenance

8.1 Maintenance

8.1.1 Daily

9 Putting out of operation and disposal

9.1 General information

9.1.1 Removal from service and disposal

10 Technical terms and abbreviations

10.1 Terms and explanations

10.1.1 Technical words

10.1.2 Abbreviations

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

New Holland Service Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20