- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Claas Disco 2650 C (620) Mower Operator Manual EN

$50.00

- Model: Disco 2650 C (620) Mower

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 45.5 MB

File List:

00 0293 857 6.pdf

00 0299 720 4.pdf

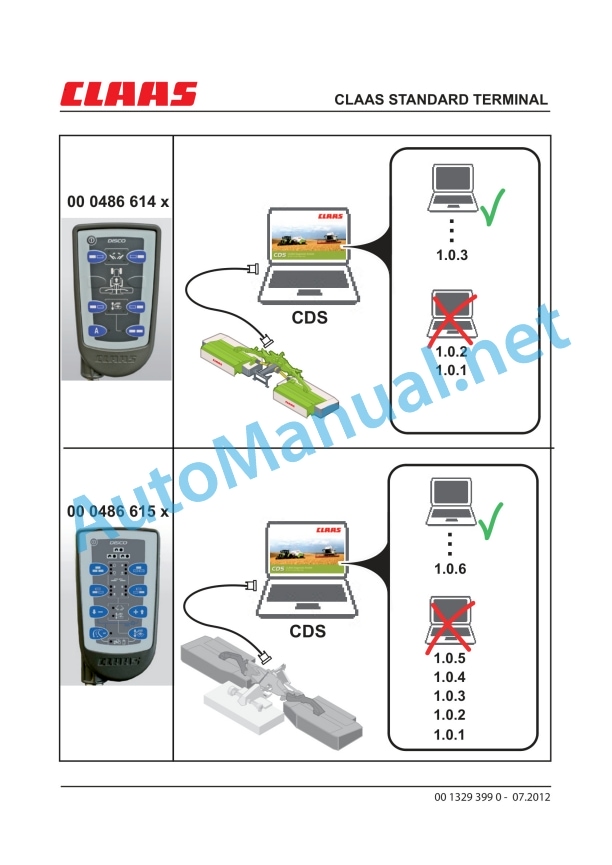

00 1329 399 0.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 0293 857 6.pdf:

1 Introduction

Introduction

VALIDITY

2 Table of contents

3 Preface

Of special importance

Identification plate

4 Safety Rules

Identification of warning and danger signs

Designated use

Avoidable incorrect applications

General safety and accident prevention regulations

Attached machines

Trailed machines

PTO operation

Hydraulic system

Maintenance

Sound pressure level

De-commissioning and disposal

Safety decals with pictorials

5 Specifications

Specifications

Axial loading, minimum ballast and total weight calculation

Noise pressure level of the disc mowers DISCO 3450 / 3050 / 3050 C / 2650 / 2650 C

6 Prior to operation

Loading / unloading the machine DISCO 3450 / 3050 / 3050 C / 2650 / 2650 C

Check and observe the following before putting into operation!

Attachment to the tractor

Adjusting the hitch

Adjust universal drive shaft

Fitting the universal drive shaft

Universal drive shaft – conditioner

Hydraulics

Fitting the machine

Prior to transportation

Driving on public roads

Identification of the machine for road traffic

7 Operation

Operation

Working position

Safety devices

Transport position

Setting the cutting height

Collision protection

Recommendations for environmental protection

Suspension springs

Swath device Right hand swath disc

Left hand swath disc (Optional equipment DISCO 2650 Plus / 2650)

Left hand swath disc (Optional equipment DISCO 3050 Plus / 3050)

Conditioner DISCO 3050 C / 2650 C

Swath plates DISCO 3050 C / 2650 C

Wide distribution hood (Optional equipment DISCO 3050 C Plus / 2650 C Plus)

Additional equipment

High cutting runners B03 0020

Additional runners C03 0030

Collision protection and safety frame S03 0070

Left hand swath disc G03 0020

Left hand swath plate G03 0030

Changeover kit for PTO speed 1000 rpm P09 0010

Wide distribution hood G03 0010

Slip yoke kit M03 0010

Slip yoke kit M03 0020

Hydraulic connecting parts for tractor R03/ 0010

Lighting adapter (USA, R03/0500)

8 Maintenance

Important maintenance instructions

Hydraulic system

Energy accumulators

Lubrication

Safety device (safety frame)

Drive systems

Tensioning the drive belts

Conditioner gearbox

Mower head

Knife sections

Knife section box

Changing the cutting knives

Blade replacement DISCO 3050 / 2650

Mower discs

Replacing cutting discs

Mower head suspension

Conditioner tines

Fitting/removing tines

Universal drive shaft

Hydraulic system

Hydraulic hose connections

Hydraulic cylinders

Connecting elements

Screw connections

Cleaning and care

Winter storage

Malfunctions

9 Lubrication chart

Safety rules

Lubricants

Lubrication

0501.pdf

5 Specifications

Specifications

Axial loading, minimum ballast and total weight calculation

Noise pressure level of the disc mowers DISCO 3450 / 3050 / 3050 C / 2650 / 2650 C

00 0299 720 4.pdf:

1 Introduction

Introduction

Validity

2 Contents

3 Preface

Of special importance

Identification plate

4 Safety Instructions

Designated use

Identification of warnings and dangers

General Safety and Accident Prevention Instructions

Attached machines

Machines as trailors

PTO Operation

Hydraulic system

Maintenance

Sound pressure level

Safety decals with warning symbols

5 Specifications

DISCO 2650 RC Plus / 2650 RC

Noise level

Calculating axle loads, minimum ballasting and total weight

Calculation of the minimum ballasting front

Calculation of the minimum ballasting rear

Calculation of the actual front axle load

Calculation of the actual total weight

Calculation of the actual rear axle load

Tyre payload

6 Assembly

Loading and unloading machine

Initial assembly of machine

7 Before Operation

Check and observe the following before putting into operation

Attachment to the tractor

Hitch pin

Drive shaft

Adapting the PTO shaft length

Mounting universal drive shaft

Attaching the universal drive shaft

Wide angle synchronised joint

Universal drive shaft – roller conditioner

Hydraulic system

Prop stand

Pull rope

Storing the machine

Prior to transportation

Driving on public roads

8 Operation

Operation

Working position

Transport position

Adjusting the working height

Suspension spring

Securing against driving off

Using the mower unit

Instructions for mowing

Environmental recommendations

Poor conditions

Changing the swathe width

Mowing without a conditioner

OPTIONAL EQUIPMENT

High cutting runners

Push-on runners

Driving off protection and the safety frame

Kit for detachable forks

Hydraulic connector for tractors

9 Maintenance

Important Maintenance Instructions

Hydraulic system

Lubrication

Guards (safety frame)

DRIVE SYSTEMS

Gearbox lubrication

Angle drive

Conditioner gearbox

Checking V-belts

Tensioning V-belts

Mower head

Mower blades

Mower blade box

Replacing mower blades

Mower blade quick replacement system

Mower blade bracket (Mower blade quick replacement system)

Screw-mounted mower blades

Mower blade attachment (screw-mounted version)

Cutting discs

Replacing cutting discs

Conditioner

Synchronised running of the conditioning rollers

Setting the roller clearance

Spring adjustment

Adjusting the roller tension

Suspension spring

Drive shaft

General information on universal drive shafts

Hydraulic system

Hydraulic hose connections

Hydraulic cylinder

Dismantling or fitting the cylinder:

Cleaning and care

Screw connections

Connecting elements

End of season storage

Lubricants chart

10 Lubrication Chart

Safety Rules

Lubricants

Lubrication

00 2348 408 0.pdf:

CEMIS 100

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 100

3.1.2 Function principle of CEMIS 100

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 100

4 Operating and display elements

4.1 CEMIS 100

4.1.1 User interface for LINER

4.1.2 User interface for ROLLANT

4.1.3 User interface for UNIWRAP

5 Technical specifications

5.1 CEMIS 100

5.1.1 Specification

6 Operation

6.1 CEMIS 100

6.1.1 Operating the CEMIS 100

6.1.2 Switching CEMIS 100 on

6.1.3 Switching CEMIS 100 off

7 Maintenance

7.1 CEMIS 100

7.1.1 Daily

8 Putting out of operation and disposal

8.1 General information

8.1.1 Removal from service and disposal

9 Technical terms and abbreviations

9.1 Terms and explanations

9.1.1 Technical words

9.1.2 Abbreviations

00 2348 427 0.pdf:

CEMIS 700

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 700

3.1.2 Function principle of CEMIS 700

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 700

4 Information on the product

4.1 Software version

5 Operating and display elements

5.1 CEMIS 700

5.1.1 User interface

5.1.2 Terminal program

6 Technical specifications

6.1 CEMIS 700

6.1.1 Specification

7 Operation

7.1 CEMIS 700

7.1.1 Operating the CEMIS 700

7.1.2 Switching CEMIS 700 on

7.1.3 Switching CEMIS 700 off

7.2 Terminal settings

7.2.1 Making settings

Making settings with the rotary button

Making settings with the touch function

7.2.2 Setting the screen lighting

Daytime mode

Nighttime mode

Activating automatic key lighting

7.2.3 Setting the time and date

7.2.4 Displaying diagnosis information

On-board power supply voltage display

Display of CLAAS ISOBUS ECU address and name

7.2.5 Setting the language and display formats

Setting the language

Setting display formats

7.2.6 Setting the volume

7.2.7 Deleting an ISOBUS implement

8 Maintenance

8.1 Maintenance

8.1.1 Daily

9 Putting out of operation and disposal

9.1 General information

9.1.1 Removal from service and disposal

10 Technical terms and abbreviations

10.1 Terms and explanations

10.1.1 Technical words

10.1.2 Abbreviations

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF