Claas Disco 9100 Cas (F60) Mower Operator Manual EN

$50.00

- Model: Disco 9100 Cas (F60) Mower

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 79.0 MB

File List:

00 0291 473 2.pdf

00 0292 618 2.pdf

00 0296 253 1.pdf

00 0296 634 1.pdf

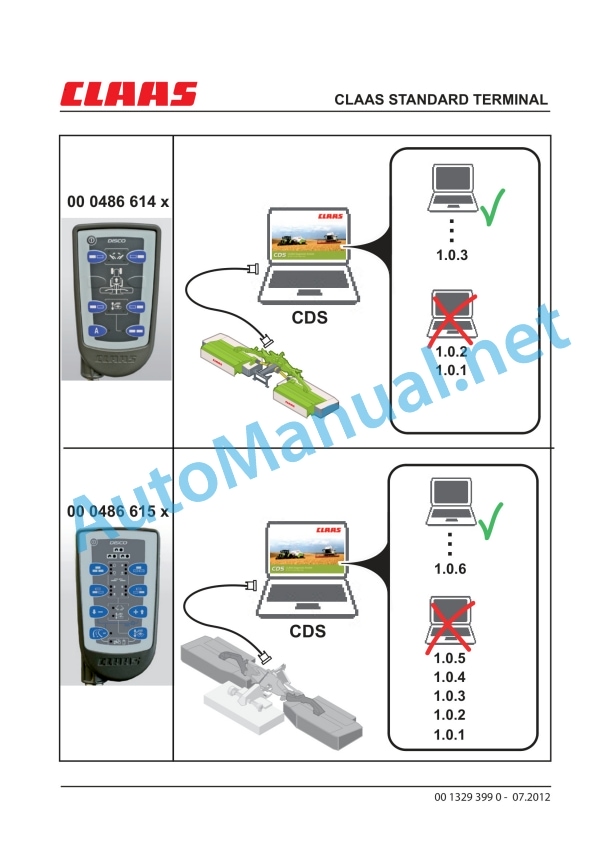

00 1329 399 0.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 0291 473 2.pdf:

DISCO 9100 C AUTOSWATHER

Table of contents

1 To this Operator’s Manual

1.1 Notes on the manual

1.1.1 General instructions

1.1.2 Validity of manual

1.1.3 Technical specifications

1.1.4 Symbols and notes

1.1.5 Using the manual

Directions

2 Safety

2.1 Safety rules

2.1.1 Particularly important

2.1.2 Qualification of drivers and maintenance personnel

2.1.3 Intended use

2.1.4 Reasonably foreseeable misuse

2.1.5 Safety and accident prevention regulations

2.1.6 First aid measures

2.1.7 Danger of injury from hydraulic liquid

2.2 Safety decals on the machine

2.2.1 Safety decals

2.2.2 Position of hazard warning signs

3 Machine description

3.1 Overview and method of operation

3.1.1 Overview of DISCO 9100 C AUTOSWATHER

3.1.2 Overview: cross conveyors

3.1.3 Function of DISCO 9100 C AUTOSWATHER

3.2 Optional machine equipment

3.2.1 Optional machine equipment

3.2.2 High-cut skids

3.2.3 Wear skids

3.2.4 Slip-on yoke for 8-piece universal drive shaft

3.2.5 ISOBUS connecting cable

3.2.6 Hydraulic safety guards

3.2.7 On-board hydraulics

3.2.8 Hydraulic connection for AXION 900

3.2.9 DISCO 3100 FC speed sensor

3.2.10 Legal equipment for France

3.3 Identification plates and vehicle identification number

3.3.1 Spare parts and technical questions

3.3.2 Position of identification plate

3.3.3 Explanation of machine identification plate

3.3.4 Position of identification no.

3.3.5 Program version

4 Operating and control elements

4.1 Fitting frame

4.1.1 Pressure gauge

4.1.2 Rear stand

4.1.3 Front stand

4.2 Mower unit

4.2.1 Adjusting aid

4.3 Conditioner

4.3.1 Lever

4.3.2 Star handle

4.4 CLAAS COMMUNICATOR

4.4.1 CLAAS COMMUNICATOR*

Terminal overview

4.4.2 Menu bar

4.5 CLAAS COMMUNICATOR menu

4.5.1 Selecting the program / application

4.5.2 Information

4.5.3 Monitor settings

4.5.4 Time / date

4.5.5 Memory management

4.5.6 Diagnosis

4.5.7 Country settings

4.5.8 Auxiliary (AUX-O)

4.5.9 Key assignment

4.5.10 Key assignment inquiry

4.6 ISOBUS monitor

4.6.1 Overview of monitor

4.6.2 Menu bar

4.6.3 ISOBUS status bar

4.7 ISOBUS Transport menu

4.7.1 Mower units in transport position

4.7.2 Mower unit in working position

4.8 ISOBUS Fieldwork menu

4.8.1 Manual operation – standard display

4.8.2 Manual operation – cross conveyors

4.8.3 Manual operation – mower unit above turning area height

4.8.4 Automatic mode – standard display

4.8.5 Automatic mode – drive monitoring

4.9 ISOBUS menu settings

4.9.1 Overview of settings

4.9.2 Basic adjustment (initialising)

4.10 ISOBUS Information menu

4.10.1 Information overview

4.11 ISOBUS Diagnosis menu

4.11.1 Overview of diagnosis displays

5 Technical specifications

5.1 DISCO 9100 C AUTOSWATHER

5.1.1 Dimensions

5.1.2 Weights

5.1.3 Requirements for the tractor

5.1.4 Version

5.1.5 Sound pressure level

5.1.6 Lubricants

6 Machine preparation

6.1 Tractor preparation

6.1.1 Axle loads, minimum ballast, total weight

6.1.2 Calculating the minimum front ballast

6.1.3 Calculating the minimum rear ballast

6.1.4 Calculating the actual front axle load

6.1.5 Calculating the actual total weight

6.1.6 Calculating the actual rear axle load

6.1.7 Calculation table

6.1.8 Converting the Walterscheid upper link

6.1.9 Adjusting the power supply

6.1.10 Installing the CLAAS COMMUNICATOR*

6.1.11 Connecting the CLAAS COMMUNICATOR* on tractors with ISOBUS socket

6.1.12 Connecting the CLAAS COMMUNICATOR* on tractors without ISOBUS socket

6.2 Shutting down and securing the machine

6.2.1 Switching off and securing the machine

6.2.2 Securing the raised machine

6.3 Adapting the machine

6.3.1 Universal drive shaft – Checking the length

6.3.2 Universal drive shaft – Adapting the length

6.3.3 Cut off the universal drive shaft guard

6.3.4 Fitting the universal drive shaft to the machine

6.3.5 Adapting the lower link / upper link category

6.3.6 Adapting the hydraulics

6.3.7 On-board hydraulics*: Adapting the hydraulic system

6.3.8 Installing the high-cut skids*

6.3.9 Installing wear skids*

6.3.10 Adapting the overlap

Relocating mower units

Fitting the shock absorbers

Installing the adjusting aid

Installing the load relief spring

Adjusting the load relief spring

Adjusting the load relief of the mower units

6.3.11 Removing the cross conveyors

6.3.12 Installing the cross conveyors

6.4 Hitching the machine

6.4.1 Hitching up the attachable frame

6.4.2 Installing the universal drive shaft

6.4.3 Connecting the hydraulic hoses

6.4.4 Connecting the power supply

6.4.5 Connecting the front mower unit speed sensor*

6.4.6 Compensating for internal leakage

6.4.7 Raising the stands

Front stands:

Rear stands:

6.5 Unhitching the machine

6.5.1 General instructions

6.5.2 Lowering the stands

Front stands:

Rear stands:

6.5.3 Disconnecting the power supply

6.5.4 Storing the control terminal

6.5.5 Disconnecting the hydraulic hoses

6.5.6 Removing the universal drive shaft

6.5.7 Unhitching the attachable frame

6.6 Loading the machine

6.6.1 Loading / unloading the machine

7 Operation

7.1 General safety precautions

7.1.1 Prior to operation

7.2 Driving on the road

7.2.1 Road travel

7.3 Fieldwork settings

7.3.1 Adjusting the attachable frame

7.3.2 Adjusting the load relief of the mower units

7.3.3 Adjusting the cutting height

7.3.4 Adjusting the tine conditioner

7.3.5 Adjusting the conditioner speed

7.3.6 Relocating the cross conveyors

7.3.7 Adjusting the swathing plates

7.3.8 Adjusting the guide / safety guard

7.3.9 Tensioning the collision protection

7.4 ISOBUS control unit

7.4.1 Description

General instructions

Manual operating mode

Mowing operating mode

Tractor hydraulics operating mode (P2)

Automatic reverser brake lock

7.4.2 Explanations regarding the ISOBUS terms

7.5 Switching the ISOBUS terminal on/off

7.5.1 Before switching on the terminals

7.5.2 Switching on the terminal

7.5.3 Starting the control program

7.5.4 Pressing the function keys

7.5.5 Switching off the terminal

7.5.6 Switching off the control program automatically

7.6 Calling up ISOBUS menus

7.6.1 Changing the menu

7.6.2 Calling up the Fieldwork manual operation menu

7.6.3 Calling up the Fieldwork automatic operation menu

7.7 ISOBUS transport position

7.7.1 Lifting the mower units into the transport position

7.8 ISOBUS working position

7.8.1 Lowering the mower units to working position

7.9 ISOBUS turning area position

7.9.1 Lifting the mower units to in turning area position in automatic mode

7.9.2 Lowering the mower units in automatic mode

7.9.3 Lift / lower the mower units, using the tractor hydraulics mode

7.10 ISOBUS individual lifting

7.10.1 Individual mower unit lifting in automatic mode

7.11 ISOBUS manual operation

7.11.1 Manual lifting / lowering of mower units

7.11.2 Manual activating of float position

7.12 ISOBUS collision protection / safety frame

7.12.1 Resetting the collision protection

7.12.2 Folding up the safety guards

7.12.3 Lowering the safety guards

7.13 ISOBUS cross conveyors

7.13.1 Lifting / lowering the cross conveyors in automatic mode

7.13.2 Lifting or lowering the cross conveyors manually

7.13.3 Disengaging / engaging the conveyor belts

7.13.4 Changing the speed of conveyor belts

7.13.5 Alternating the speed of conveyor belts

7.13.6 Reducing the speed of conveyor belts automatically

7.14 ISOBUS settings

7.14.1 Adjusting the turning height

7.14.2 Adjusting the load relief of the mower units

7.14.3 Entering the overlap

7.14.4 Activating the tractor hydraulics mode (P2)

Preconditions

Activating the tractor hydraulics (P2)

7.14.5 Deactivating the tractor hydraulics mode (P2)

7.14.6 Activating the automatic reverser brake lock

7.14.7 Deactivating the automatic reverser brake lock

7.14.8 Restoring factory settings

7.14.9 Factory settings – basic values

7.15 ISOBUS drive monitoring

7.15.1 Description

Drive overloaded

7.15.2 Setting the maximum speed difference

7.16 ISOBUS maintenance counter

7.16.1 Maintenance interval reached

7.16.2 Resetting the maintenance counter

7.17 ISOBUS work record management

7.17.1 Displaying job data

7.17.2 Activating / Deactivating a job

7.17.3 Activating / deactivating the area counter for the front mower unit

7.17.4 Creating a job

7.18 ISOBUS fault messages

7.18.1 Hydraulic oil temperature too high

7.18.2 Alarm screen

7.18.3 Sensor fault

7.19 ISOBUS basic setting (initialisation)

7.19.1 Learning the end stop

7.20 ISOBUS Auxiliary function (AUX-O)

7.20.1 Available functions

7.20.2 Application example – Joystick configuration

CLAAS AXION 800 series

FENDT Vario

7.21 ISOBUS operation option – Fendt

7.21.1 Using the tractor terminal

7.21.2 Tractor terminal and joystick

7.21.3 Joystick and CLAAS COMMUNICATOR

7.22 CLAAS COMMUNICATOR

7.22.1 Notes relating to this chapter

7.22.2 Recommendations for optimum use

7.23 Switching the CLAAS COMMUNICATOR on/off

7.23.1 Switching on the CLAAS COMMUNICATOR*

7.23.2 Switching the CLAAS COMMUNICATOR* off

7.24 Operating the CLAAS COMMUNICATOR

7.24.1 Select menu“ / cancel key (ESC)

7.24.2 Function keys

7.24.3 Select wheel – data selection and data input

7.24.4 Text input menu

7.24.5 Navigation in the data field

7.24.6 Programmable keys

7.24.7 Software maintenance

7.25 CLAAS COMMUNICATOR service pgm

7.25.1 Scope of functions

7.25.2 Calling up the service program

7.26 CLAAS COMMUNICATOR menu descriptions

7.26.1 Changing the menu

7.26.2 Information menu

7.26.3 Brightness / contrast menu

7.26.4 Time and date menu

7.26.5 Memory management menu

7.26.6 Diagnosis sub-menu

7.26.7 Country settings menu

7.26.8 Auxiliary function (AUX-O) menu

7.26.9 Key assignment sub-menu

7.27 CLAAS Communicator programmable keys

7.27.1 Introduction

7.27.2 Assigning a function to a key

7.27.3 Deleting a key assignment

7.27.4 Changing key assignment

7.28 Fieldwork

7.28.1 Fieldwork

7.28.2 Swinging to transport position

7.28.3 Folding to working position

7.28.4 Machine use

Optimum PTO speed

7.28.5 Mowing methods

7.28.6 Mowing with / without cross conveyors

Mowing with both cross conveyors

Mowing with one cross conveyor

Mowing without cross conveyors

7.28.7 Turning area position

7.28.8 Lifting / lowering the cross conveyors

7.28.9 Engaging / disengaging the conveyor belts

7.28.10 Instructions for mowing

7.28.11 Difficult conditions of use

7.28.12 Recommendation for environmental protection

8 Faults and remedies

8.1 Overview of faults

8.1.1 Machine problems

8.1.2 Fault code table

8.2 Emergency operation

8.2.1 Notes on emergency operation

8.2.2 Overview of solenoid valves

Solenoid valve block

Solenoid valves of attachable frame

Solenoid valves of mower units

8.2.3 Procedures prior to emergency operation

8.2.4 Actuating hydraulic valves manually

8.2.5 Lifting mower units to transport position using emergency operation

Lifting the left mower unit

Lifting the right mower unit

8.2.6 Lowering the mower unit to working position using emergency operation

Lowering the left mower unit

Lowering the right mower unit

8.2.7 Cancelling the load relief with the emergency operation

Left mower unit

Right mower unit

8.2.8 Lowering the cross conveyors to working position using emergency operation

Lowering the left cross conveyor

Lowering the right cross conveyor

Securing the cross conveyors

9 Maintenance

9.1 Maintenance Information

9.1.1 General warnings

9.1.2 Electrical system

9.1.3 Protective guards

9.1.4 Spare parts

9.1.5 Unbalance

9.1.6 Compressed air and water

9.1.7 Burn prevention

9.1.8 Oils

9.1.9 Fire prevention and explosion prevention

9.1.10 Lines, tubes and hoses

9.2 Overview maintenance intervals

9.2.1 Dealing with maintenance intervals

9.2.2 Before the harvest

9.2.3 After the first 50 operating hours

9.2.4 Every 8 operating hours

9.2.5 Every 20 operating hours

9.2.6 Every 100 operating hours

9.2.7 Every 250 operating hours

9.2.8 Every 500 operating hours or annually

9.2.9 Every 500 operating hours

9.2.10 Every 5 years

9.2.11 As needed

9.2.12 After the harvest

9.3 Common

9.3.1 Clean machine

9.3.2 Preserve the machine

9.3.3 Checking the fittings

9.4 Gearbox

9.4.1 Check gearbox tightness

9.4.2 Main gearbox: Checking the oil level

9.4.3 Main gearbox: Changing the oil

9.4.4 On-board hydraulics* gearbox: Checking the oil level

9.4.5 On-board hydraulics gearbox*: Changing the oil

9.4.6 Angle drive: Checking the oil level

9.4.7 Angle drive: Changing the oil

9.5 Clutch

9.5.1 Adjusting the friction clutch

9.5.2 Removing and installing the friction clutch

9.5.3 Venting the friction clutch

9.6 Universal drive shaft

9.6.1 Maintaining drive shafts

9.7 Hydraulic system

9.7.1 Hydraulic system maintenance

9.7.2 Check the hydraulic hoses

9.7.3 Changing the hydraulic oil filter

9.7.4 Hydraulic oil tank*: Checking the oil level

9.7.5 Hydraulic oil tank*: Changing the oil

9.7.6 Hydraulic oil tank*: Changing the hydraulic oil filter

9.7.7 Hydraulic oil tank*: Cleaning the bleeder

9.7.8 Hydraulic oil tank*: Cleaning the radiator

9.7.9 Pressure accumulator maintenance

9.7.10 Removing hydraulic cylinders

Load relief hydraulic cylinders for left / right mower units

Lift hydraulic cylinders for left / right mower units

9.7.11 Fitting the load relief cylinders

9.7.12 Adjusting the collision protection

Adjusting the length

Adjusting the pressure relief valve

9.8 Electric system

9.8.1 Overview of sensors

9.8.2 Checking and adjusting the angular sensors

9.8.3 Checking and adjusting the reed contact

9.9 Mower unit

9.9.1 Mower head: Checking the oil level

9.9.2 Mower head: Changing the oil

9.9.3 Mower head: Checking the oil level

9.9.4 Mower head: Changing the oil

9.9.5 Mower knife box

9.9.6 Cutting discs: Observe the direction of rotation

9.9.7 Removing the fixing lever

9.9.8 Checking the mower knives

9.9.9 Replacing the knives

9.9.10 Checking the mower knife holder

9.9.11 Checking the cutting discs

9.9.12 Replacing the cutting discs

9.9.13lacthe cutting discs

9.9.14 Installing the pinion units

9.9.15 Installing the pinion units

9.9.16 Replacing adapters

9.9.17 Adjusting the anti-wrap guard

9.9.18 Outer feed cylinder: Adjusting the plates

9.9.19 Adjusting the safety device

Front safety guard holder

Outer safety guard holder

9.10 Crop processing unit

9.10.1 Checking the drive belts

9.10.2 Tensioning the drive belt

9.10.3 Changing the drive belts

9.10.4 Attaching/removing the tines

9.11 Cross conveyor belt

9.11.1 Overview of maintenance operations

Retensioning the conveyor belts

Maintenance operations annually after the harvest

Maintenance operations each time the conveyor belts are replaced

Maintenance operations as required

9.11.2 Checking conveyor belt tension

9.11.3 Slackening the conveyor belts

9.11.4 Tensioning the conveyor belts

9.11.5 Adjusting conveyor belt running

Carrying out a test run

Removing the universal drive shafts

Checking the running on the drive roller

Adjustment instructions

Adjusting the running on the drive roller

Checking the running on the guide roller

Fitting the universal drive shafts

9.11.6 Dismount and clean the conveyor belts

Cleaning the conveyor belts

9.11.7 Adjusting the scraper

9.11.8 Basic adjustment of guide rollers

9.11.9 Laying the conveyor belts

9.11.10 Assembling the cross conveyors

9.11.11 Adjusting the conveyor belt inclination

9.11.12 Adjusting the hydraulic cylinders

9.11.13 Hydraulic motor: Checking the coupler packing

9.11.14 Hydraulic motor: Replacing the coupler packing

9.12 Fitting frame

9.12.1 Adjusting the locking device

9.13 Lubrication chart

9.13.1 Greasing points to be greased every 8 operating hours

9.13.2 Greasing points to be greased every 20 operating hours

9.13.3 Lubricating grease points every 100 operating hours

9.13.4 Lubricating grease points every 250 operating hours

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 EC declaration of conformity

11.1 DISCO 9100 C AUTOSWATHER

11.1.1 EC Declaration of Conformity

12 Technical terms and abbreviations

12.1 Terms and explanations

12.1.1 Technical terms

12.1.2 Abbreviations

00 0296 253 1.pdf:

DISCO 9100 C AUTOSWATHER

Table of contents

1 To this Operator’s Manual

1.1 Notes on the manual

1.1.1 General instructions

1.1.2 Validity of manual

1.1.3 Technical specifications

1.1.4 Symbols and notes

1.1.5 Using the manual

Directions

2 Safety

2.1 Safety rules

2.1.1 Particularly important

2.1.2 Qualification of drivers and maintenance personnel

2.1.3 Intended use

2.1.4 Reasonably foreseeable misuse

2.1.5 Safety and accident prevention regulations

2.1.6 First aid measures

2.1.7 Danger of injury from hydraulic liquid

2.2 Safety decals on the machine

2.2.1 Safety decals

2.2.2 Safety decals of machine

3 Machine description

3.1 Overview and method of operation

3.1.1 Overview of DISCO 9100 C AUTOSWATHER

3.1.2 Overview: cross conveyors

3.1.3 Function of DISCO 9100 C AUTOSWATHER

3.2 Optional equipment

3.2.1 Optional equipment

3.2.2 COMMUNICATOR II*

3.2.3 ISOBUS extension cable for COMMUNICATOR II*

3.2.4 ISOBUS connecting cable*

3.2.5 Speed signal cable for CLAAS OPERATOR*

3.2.6 Job printer for ISOBUS*

3.2.7 High-cut skids*

3.2.8 Double high-cut skids*

3.2.9 Wear skids*

3.2.10 Slip-on yoke for 8-piece universal drive shaft*

3.2.11 Hydraulically folding safety guards*

3.2.12 On-board hydraulics*

3.2.13 Hydraulic connection for AXION 900*

3.2.14 Front mower unit speed sensor*

3.2.15 Cutting height indicator*

3.2.16 Battery cable*

3.2.17 Legal equipment for France*

3.3 Identification plates and vehicle identification number

3.3.1 Spare parts and technical questions

3.3.2 Position of identification plate

3.3.3 Position of identification no.

3.3.4 Explanation of machine identification plate

3.3.5 Program version

4 Operating and control elements

4.1 Fitting frame

4.1.1 Pressure gauge

4.1.2 Rear stand

4.1.3 Front stand

4.2 Mower unit

4.2.1 Adjusting aid

4.3 Conditioner

4.3.1 Lever

4.3.2 Star handle

4.4 ISOBUS monitor

4.4.1 Overview of monitor

4.4.2 Menu bar

4.4.3 ISOBUS status bar

4.5 ISOBUS Transport menu

4.5.1 Mower units in transport position

4.5.2 Mower unit in working position

4.6 ISOBUS Fieldwork menu

4.6.1 Automatic mode – standard display

4.6.2 Automatic operation – Tractor hydraulics

4.6.3 Automatic mode – drive monitoring

4.7 ISOBUS fieldwork menu – Manual operation

4.7.1 Manual operation – standard display

4.7.2 Manual operation – cross conveyors

4.7.3 Manual operation – mower unit above turning area height

4.8 ISOBUS menu settings

4.8.1 Overview of settings

4.8.2 Basic adjustment (initialising)

4.9 ISOBUS Information menu

4.9.1 Information overview

4.10 ISOBUS Diagnosis menu

4.10.1 Overview of diagnosis displays

5 Technical specifications

5.1 DISCO 9100 C AUTOSWATHER

5.1.1 Dimensions

5.1.2 Weights

5.1.3 Requirements for the tractor

5.1.4 Version

5.1.5 Sound pressure level

5.1.6 Lubricants

6 Machine preparation

6.1 Tractor preparation

6.1.1 Axle loads, minimum ballast, total weight

6.1.2 Calculating the minimum front ballast

6.1.3 Calculating the minimum rear ballast

6.1.4 Calculating the actual front axle load

6.1.5 Calculating the actual total weight

6.1.6 Calculating the actual rear axle load

6.1.7 Calculation table

6.1.8 Converting the Walterscheid upper link

6.1.9 Adjusting the power supply

6.1.10 Installing the COMMUNICATOR II*

6.2 Shutting down and securing the machine

6.2.1 Switching off and securing the machine

6.2.2 Securing the raised machine

6.3 Adapting the machine

6.3.1 Universal drive shaft – Checking the length

6.3.2 Universal drive shaft – Adapting the length

6.3.3 Cut off the universal drive shaft guard

6.3.4 Fitting the universal drive shaft to the machine

6.3.5 Adapt the lower link / upper link category

6.3.6 Adapting the hydraulics

6.3.7 On-board hydraulics*: Adapting the hydraulic system

6.3.8 Installing the high-cut skids*

6.3.9 Installing wear skids*

6.3.10 Adapting the overlap

Relocating mower units

Fitting the shock absorbers

Installing the adjusting aid

Installing the load relief spring

Adjusting the load relief spring

Adjusting the load relief of the mower units

6.3.11 Removing the cross conveyors

6.3.12 Installing the cross conveyors

6.4 Hitching the machine

6.4.1 Hitching up the attachable frame

6.4.2 Installing the universal drive shaft

6.4.3 Connecting the hydraulic hoses

6.4.4 Connecting the power supply

6.4.5 Connecting the COMMUNICATOR II*

On tractors without ISOBUS socket

For tractors with ISOBUS socket

6.4.6 Connecting the front mower unit speed sensor*

6.4.7 Compensating for internal leakage

6.4.8 Raising the stands

Front stands:

Rear stands:

6.5 Unhitching the machine

6.5.1 General instructions

6.5.2 Lowering the stands

Front stands:

Rear stands:

6.5.3 Disconnecting the power supply

6.5.4 Disconnecting the COMMUNICATOR II*

On tractors without ISOBUS socket

For tractors with ISOBUS socket

Storing the COMMUNICATOR II* on the machine

6.5.5 Disconnecting the hydraulic hoses

6.5.6 Removing the universal drive shaft

6.5.7 Unhitching the attachable frame

6.6 Loading the machine

6.6.1 Loading / unloading the machine

7 Operation

7.1 General safety precautions

7.1.1 Prior to operation

7.2 Driving on the road

7.2.1 Road travel

7.3 Fieldwork settings

7.3.1 Adjusting the attachable frame

7.3.2 Adjusting the load relief of the mower units

7.3.3 Adjusting the cutting height

7.3.4 Adjusting the tine conditioner

7.3.5 Adjusting the conditioner speed

7.3.6 Relocating the cross conveyors

7.3.7 Adjusting the swathing plates

7.3.8 Adjusting the guide / safety guard

7.3.9 Tensioning the collision protection

7.4 ISOBUS control unit

7.4.1 Description

General instructions

Manual operating mode

Automatic operation mode

Tractor hydraulics operating mode (P2)

Automatic reverser brake lock

7.4.2 Explanations of ISOBUS terminology

7.5 Switching the ISOBUS terminal on/off

7.5.1 Before switching on the terminals

7.5.2 Switching on the terminal

7.5.3 Starting the control program

7.5.4 Pressing the function keys

7.5.5 Switching off the terminal

7.5.6 Switching off the control program automatically

7.6 Calling up ISOBUS menus

7.6.1 Changing the menu

7.6.2 Calling up the Fieldwork manual operation menu

7.6.3 Calling up the Fieldwork automatic operation menu

7.7 ISOBUS transport position

7.7.1 Lifting the mower units into the transport position

7.7.2 Lowering the mower units from the transport position

7.8 ISOBUS working position

7.8.1 Lifting the mower units to in turning area position in automatic mode

7.8.2 Lowering the mower units in automatic mode

7.8.3 Lifting / lowering mower units by using the tractor hydraulics

7.9 ISOBUS individual lifting

7.9.1 Individual mower unit lifting in automatic mode

7.10 ISOBUS manual operation

7.10.1 Manual lifting / lowering of mower units

7.10.2 Manual activating of float position

7.11 ISOBUS collision protection / safety frame

7.11.1 Resetting the collision protection

7.11.2 Folding the safety guards up

7.11.3 Folding the safety guards down

7.12 ISOBUS cross conveyors

7.12.1 Lifting / lowering the cross conveyors in automatic mode

7.12.2 Lifting or lowering the cross conveyors manually

7.12.3 Disengaging / engaging the conveyor belts

7.12.4 Changing the speed of conveyor belts

7.12.5 Change speeds of left and right conveyor belt

7.13 ISOBUS settings

7.13.1 Adjusting the turning height

7.13.2 Adjusting the load relief of the mower units

7.13.3 Adjusting the overlap when driving along a crop edge

7.13.4 Reduction of belt speed with individual lifting

7.13.5 Increase of belt speed during lifting

7.13.6 Activating the tractor hydraulics mode (P2)

Preconditions

Activating the tractor hydraulics (P2)

7.13.7 Deactivating the tractor hydraulics mode (P2)

7.13.8 Activating the automatic reverser brake lock

7.13.9 Deactivating the automatic reverser brake lock

7.13.10 Restoring factory settings

Factory settings

7.14 ISOBUS drive monitoring

7.14.1 Description

Drive overloaded

7.14.2 Listen to the signal tone

7.14.3 Setting the maximum speed difference

7.15 ISOBUS maintenance counter

7.15.1 Deleting the maintenance alarm

7.16 ISOBUS work record management

7.16.1 Displaying job data

Job-dependent counters

Job-independent counters

Selecting a job

Printing a job

7.16.2 Creating a job

7.16.3 Activating / deactivating data acquisition

7.16.4 Activating / deactivating the area counter for the front mower unit

7.17 ISOBUS fault messages

7.17.1 Hydraulic oil temperature too high

7.17.2 Alarm screen

7.17.3 Sensor fault

7.18 ISOBUS basic setting (initialisation)

7.18.1 Learning the end stop

7.19 ISOBUS Auxiliary function (AUX-O)

7.19.1 Available functions

7.19.2 Application example – Joystick configuration

CLAAS AXION 800 series

FENDT Vario

7.20 ISOBUS operation option – Fendt

7.20.1 Using the tractor terminal

7.20.2 Tractor terminal and joystick

7.20.3 Using the COMMUNICATOR II* and joystick

7.21 Fieldwork

7.21.1 Fieldwork

7.21.2 Swinging to transport position

7.21.3 Folding to working position

7.21.4 Machine use

Optimum PTO speed

7.21.5 Mowing methods

7.21.6 Mowing with and without cross conveyors

Mowing with both cross conveyors

Mowing with one cross conveyor

Mowing without cross conveyors

7.21.7 Recommendations for heavy forage quantities

7.21.8 Lifting / lowering the cross conveyors

7.21.9 Switching the conveyor belts on and off

7.21.10 Instructions for mowing

7.21.11 Difficult conditions of use

7.21.12 Recommendation for environmental protection

8 Faults and remedies

8.1 Overview of faults

8.1.1 Machine problems

8.1.2 Fault code table

8.2 Emergency operation

8.2.1 Notes on emergency operation

8.2.2 Overview of solenoid valves

Solenoid valve block

Solenoid valves of attachable frame

Solenoid valves of mower units

8.2.3 Procedures prior to emergency operation

8.2.4 Actuating hydraulic valves manually

8.2.5 Lifting mower units to transport position using emergency operation

Lifting the left mower unit

Lifting the right mower unit

8.2.6 Lowering the mower unit to working position using emergency operation

Lowering the left mower unit

Lowering the right mower unit

8.2.7 Cancelling the load relief with the emergency operation

Left mower unit

Right mower unit

8.2.8 Lowering the cross conveyors to working position using emergency operation

Lowering the left cross conveyor

Lowering the right cross conveyor

Securing the cross conveyors

9 Maintenance

9.1 Maintenance Information

9.1.1 General warnings

9.1.2 Electrical system

9.1.3 Protective guards

9.1.4 Spare parts

9.1.5 Unbalance

9.1.6 Compressed air and water

9.1.7 Burn prevention

9.1.8 Oils

9.1.9 Fire prevention and explosion prevention

9.1.10 Lines, tubes and hoses

9.2 Overview maintenance intervals

9.2.1 Dealing with maintenance intervals

9.2.2 Before the harvest

9.2.3 After the first 50 operating hours

9.2.4 Every 8 operating hours

9.2.5 Every 20 operating hours

9.2.6 Every 100 operating hours

9.2.7 Every 250 operating hours

9.2.8 Every 500 operating hours or annually

9.2.9 Every 500 operating hours

9.2.10 Every 5 years

9.2.11 As needed

9.2.12 After the harvest

9.3 Common

9.3.1 Clean machine

9.3.2 Preserve the machine

9.3.3 Checking the fittings

9.4 Gearbox

9.4.1 Check gearbox tightness

9.4.2 Main gearbox: Checking the oil level

9.4.3 Main gearbox: Changing the oil

9.4.4 On-board hydraulics* gearbox: Checking the oil level

9.4.5 On-board hydraulics gearbox*: Changing the oil

9.4.6 Angle drive: Checking the oil level

9.4.7 Angle drive: Changing the oil

9.4.8 Turning area position

9.5 Clutch

9.5.1 Adjusting the friction clutch

9.5.2 Removing and installing the friction clutch

9.5.3 Venting the friction clutch

9.6 Universal drive shaft

9.6.1 Maintaining drive shafts

9.7 Hydraulic system

9.7.1 Hydraulic system maintenance

9.7.2 Check the hydraulic hoses

9.7.3 Changing the hydraulic oil filter

9.7.4 Hydraulic oil tank*: Checking the oil level

9.7.5 Hydraulic oil tank*: Changing the oil

9.7.6 Hydraulic oil tank*: Changing the hydraulic oil filter

9.7.7 Hydraulic oil tank*: Cleaning the bleeder

9.7.8 Hydraulic oil tank*: Cleaning the radiator

9.7.9 Pressure accumulator maintenance

9.7.10 Removing hydraulic cylinders

Load relief hydraulic cylinders for left / right mower units

Lift hydraulic cylinders for left / right mower units

9.7.11 Fitting the load relief cylinders

9.7.12 Adjusting the collision protection

Adjusting the length

Adjusting the pressure relief valve

9.8 Electric system

9.8.1 Overview of sensors

9.8.2 Checking and adjusting the angular sensors

9.8.3 Checking and adjusting the reed contact

9.8.4 Replace lamps

9.9 Mower unit

9.9.1 Mower head: Checking the oil level

9.9.2 Mower head: Changing the oil

9.9.3 Mower headecking the oil level

9.9.4 Mower head: Changing the oil

9.9.5 Mower knife box

9.9.6 ing discs: Observe the direction of rotation

9.9.7 Removing the fixing lever

9.9.8 Checking the mower knives

9.9.9 Replacing the knives

9.9.10 Checking the mower knife holder

9.9.11 Checking the cutting discs

9.9.12 Replacing the cutting discs

9.9.13 Replacing the cutting discs

9.9.14 Installing the pinion units

9.9.15 Installing the pinion units

9.9.16 Replacing adapters

9.9.17 Adjusting the anti-wrap guard

9.9.18 Outer feed cylinder: Adjusting the plates

9.9.19 Adjusting the safety device

Front safety guard holder

Outer safety guard holder

9.10 Crop processing unit

9.10.1 Checking the drive belts

9.10.2 Tensioning the drive belt

9.10.3 Changing the drive belts

9.10.4 Fitting and removing tines

9.11 Cross conveyor belt

9.11.1 Overview of maintenan

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese