Claas Dominator 150 140 (200) Combines Operator Manual ES

$50.00

- Model: Dominator 150 140 (200) Combines

- Type Of Manual: Operator Manual

- Language: ES

- Format: PDF(s)

- Size: 19.1 MB

File List:

00 0293 212 2.pdf

00 0294 843 0.pdf

00 0293 212 2.pdf:

1. Introduction

1.1 General instructions

1.1.1 Using the instructions

1.1.2 Validity of the manual

1.1.3 Technical data

1.1.4 Road traffic

1.1.5 Note regarding electronic engine management

1.2 Assembled parts/machine casing

1.2.1 Spare parts and technical issues

1.2.2 Machine identification plate

1.2.3 CATERPILLAR 3056 E engine identification plate

1.2.4 PERKINS 1006-6T engine identification plate

1.2.5 CATERPILLAR C6.6 engine identification plate

1.2.6 Drive axle identification plate

1.2.7 Steering axle identification plate

1.2.8 Hitch mouth identification plate

1.2.9 Hitch block identification plate

1.2.10 Cab identification plate

1.2.11 Straw chopper identification plate

2 Overall view of the machine

2.1 Assembled parts/machine casing

2.1.1 Machine summary

2.1.2 Access to the workplace and maintenance stations

3 Security measures

3.1 General instructions

3.1.1 General instructions

3.1.2 Especially important

3.1.3 Proper use of the machine

3.1.4 Predictably foolish misuse

3.1.5 Prescriptions for safety and accident prevention

3.1.6 Prescriptions for safety and prevention of accidents with harvesters

3.1.7 Before start-up, general instructions

3.1.8 Additional weights

3.1.9 Carry additional passengers

3.1.10 General driving

3.1.11 Combine driving operation

3.1.12 Driving on inclined terrain

3.1.13 Getting off the machine

3.1.14 Headers and trailers

3.1.15 Deposit the material / deposit the straw

3.1.16 Grain collection

3.1.17 Air conditioning installation

3.1.18 Adjustment and maintenance work

3.1.19 Pressure accumulator

3.1.20 Antifreeze

3.1.21 First aid measures

3.1.22 Decommissioning and waste disposal

3.1.23 Insert the feed channel safety support

3.1.24 Remove the safety support from the feed channel

3.1.25 Secure the machine with a chock so that it cannot roll

3.1.26 Hook the straw guide bib high

3.1.27 Raise the machine on blocks

3.1.28 Fire extinguisher

3.1.29 Battery separator switch

3.1.30 Risk of accident due to hydraulic fluid

3.1.31 Load and tie down the machine

3.1.32 Unscrew the hook rings

3.2 Safety instructions

3.2.1 Warning and danger signs

3.3 Warning symbols

3.3.1 General information on warning symbols

3.3.2 Engine

3.3.3 Undercarriage

3.3.4 Driver’s cab/platform

3.3.5 Power set

3.3.6 Threshing organs

3.3.7 Separation

3.3.8 Deposit the material / deposit the straw

3.3.9 Grain collection

3.3.10 Assembled parts/machine casing

3.4 Security stickers

3.4.1 General information regarding safety stickers

3.4.2 Undercarriage

4 Technical data

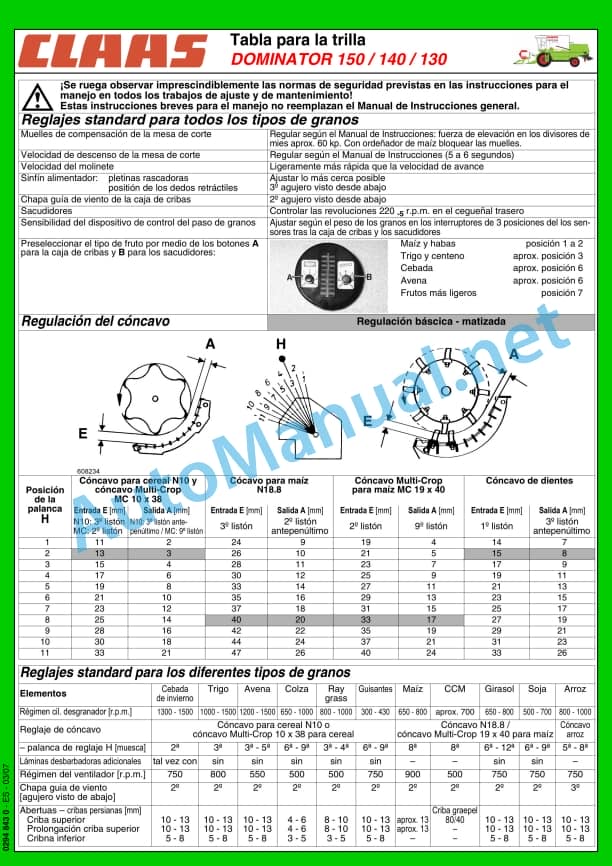

4.1 DOMINATOR 150 / 140 / 130

4.1.1 General instructions

4.1.2 CATERPILLAR C6.6 Engine

4.1.3 CATERPILLAR 3056E Engine

4.1.4 Perkins 1006-T6 Engine

4.1.5 Undercarriage

4.1.6 Chassis tire air pressure

4.1.7 Chassis track width

4.1.8 Brakes

4.1.9 Address

4.1.10 Electrical/electronic installation

4.1.11 Driver’s cabin/platform

4.1.12 Power Assembly

4.1.13 Threshing organs

4.1.14 Separation

4.1.15 Cleaning

4.1.16 Grain collection

4.1.17 Measurements of assembled parts / machine casing

4.1.18 Weights of assembled parts / machine casing

5 Before first start-up

5.1 General instructions

5.1.1 General warning instructions Before initial start-up

5.1.2 Checklist for first start-up

5.2 Undercarriage

5.2.1 Removing/installing the wheels

5.2.2 Steering axle summary

5.2.3 Adjusting the steering axle from the transport position to the working position

5.2.4 Steering axle 00 0649 950 1 – adjust track width

5.3 Hooking device

5.3.1 Installing the trailer coupling (additional equipment)

5.4 Electrical/electronic installation

5.4.1 Install the fan/air conditioning fuse

5.5 Power supply unit

5.5.1 Mount/adjust the support plates

5.5.2 Adjust the retention pins

5.5.3 Check the head cylinders

5.5.4 Check the head discharge springs

5.6 Grain collection

5.6.1 Close the cleaning flap on the grain tank discharge tube

5.6.2 Install the grain tank protection device

6 Before each start-up

6.1 General instructions

6.1.1 General warning instructions Before each start-up

6.1.2 Checklist for daily commissioning

7 Overview of control elements

7.1 General instructions

7.1.1 General warning information Overview of control elements

7.2 Driver’s cabin/platform

7.2.1 Overview of the driver’s position (DOMINATOR 130)

7.2.2 Overview of the driver’s position (DOMINATOR 150/140)

7.2.3 Hydraulic control (DOMINATOR 130 hydraulic lifting system)

7.2.4 Multifunctional control (DOMINATOR 150 / 140)

7.2.5 Control panel (DOMINATOR 130)

7.2.6 Diesel engine speed rotary switch (DOMINATOR 130, CATERPILLAR C-6.6, 3056 E)

7.2.7 Diesel engine speed lever (DOMINATOR 130, Perkins 1006-T6)

7.2.8 Function of warning lights 7 and 8 (DOMINATOR 130)

7.2.9 Control panel (DOMINATOR 150 / 140)

7.2.10 Diesel engine speed rotary switch (DOMINATOR 150 / 140)

7.2.11 Function of warning lights 15 and 18 (DOMINATOR 150 / 140)

7.2.12 Tie Rod Summary

7.2.13 Cab roof control elements

7.2.14 Cabin with fan

7.2.15 Cabin with air conditioning equipment (with York compressor)

7.2.16 Cabin with air conditioning equipment (with Sanden compressor)

7.2.17 Cabin with fan and heating

7.2.18 Control levers

7.2.19 Device for monitoring operation

7.3 Assembled parts / machine housing

7.3.1 Work focuses

7.3.2 Cabin

7.3.3 Awning

7.3.4 Tool box

8 Mount/dismount the front implement

8.1 General instructions

8.1.1 General warning instructions Mounting/dismounting the head

8.2 Assemble the head

8.2.1 Hang front implement

8.2.2 Lock front implement

8.2.3 Assemble cardan shaft

8.2.4 Connect the hydraulic system

8.2.5 Plug in the electrical installation (additional equipment)

8.2.6 Remove the support legs

8.3 Disassemble the head

8.3.1 Assemble the support legs

8.3.2 Uncouple the hydraulic system

8.3.3 Unplug the electrical installation (additional equipment)

8.3.4 Disassemble cardan shaft

8.3.5 Unlock front implement

8.3.6 Unhook front implement

9 Driving and transporting

9.1 General instructions

9.1.1 General warning instructions Driving and transporting

9.1.2 Prepare road traffic

9.1.3 Prepare field circulation

9.2 Engine

9.2.1 Adjusting the diesel engine speed (DOMINATOR 150 / 140)

9.2.2 Starting the diesel engine (DOMINATOR 150 / 140)

9.2.3 Disconnect the diesel engine (DOMINATOR 150 / 140)

9.2.4 Adjusting the speed of the diesel engine (DOMINATOR 130)

9.2.5 Starting the diesel engine (DOMINATOR 130)

9.2.6 Disconnect the diesel engine (DOMINATOR 130)

9.3 Running gear

9.3.1 Gear lever (DOMINATOR 150 / 140)

9.3.2 Shifting into gear (DOMINATOR 150 / 140)

9.3.3 Gear lever (DOMINATOR 130)

9.3.4 Shifting into gear (DOMINATOR 130)

9.3.5 Adjusting the control resistance of the drive lever (DOMINATOR 150 / 140)

9.3.6 Running characteristics

9.3.7 Towing the machine

9.3.8 Towing in front

9.3.9 Towing from behind

9.4 Brakes

9.4.1 Connect the parking brake

9.4.2 Disengage the parking brake

9.4.3 Foot brake

9.4.4 Brake / stop the machine (DOMINATOR 150 / 140)

9.4.5 Brake / stop the machine (DOMINATOR 130)

9.4.6 Parking the machine

9.5 Address

9.5.1 Steer the machine

9.5.2 Adapt the position of the steering bar

9.6 Hooking device

9.6.1 Hitching the trailer

9.6.2 Uncoupling the trailer

9.7 Driver’s cabin/platform

9.7.1 Adjusting the mechanically cushioned driver’s seat (standard equipment)

9.7.2 Adjusting the mechanically cushioned driver’s seat (standard equipment)

9.7.3 Adjusting the driver’s seat with mechanical damping (optional equipment)

9.8 Assembled parts / machine housing

9.8.1 Rotate the front ladder (standard)

9.8.2 Change the position of the rear ladder

10 Setting in operational mode

10.1 General instructions

10.1.1 General warning instructions Field work settings

10.2 Power unit

10.2.1 Adjust the cutting height indicator

10.2.2 Adjust the drainer profiles

10.2.3 Adjust the height of the feed chain

10.2.4 Adjusting the head lowering speed (DOMINATOR 150)

10.3 Threshing organs

10.3.1 Dismantle / assemble the concave segments (multicrop concave)

10.3.2 Adjust the basic concave setting

10.4 Separation

10.4.1 Adjust the separation grain passage control sensors

10.5 Cleaning

10.5.1 Check/adjust the fan speed indicator

10.5.2 Adjust the cleaning grain passage control sensors

10.5.3 Dismantle the sieves

10.5.4 Assemble the screens

10.6 Depositing the material / depositing the straw

10.6.1 Dismantle the straw guide plate (straw chopper with standard distributor)

10.6.2 Assemble the straw guide plate (straw chopper with standard distributor)

10.6.3 Unscrew the chopper blades

10.6.4 Screw the chopper blades

10.6.5 Straw chopper sieve mounting position

10.7 Grain collection

10.7.1 Adjusting the grain tank full indicator DOMINATOR 150

11 Operational service

11.1 General instructions

11.1.1 General warning instructions Use at work

11.2 Structure and operation

11.2.1 Cutting mechanism

11.2.2 Threshing organs

11.2.3 Shakers

11.2.4 Cleaning

11.2.5 Shelling

11.3 Fundamental rules for threshing with a combine harvester

11.3.1 Please keep in mind when harvesting with the combine:

11.4 Head

11.4.1 Horizontal adjustment of the reel (mechanical)

11.4.2 Horizontal adjustment of the reel (hydraulic)

11.4.3 Adjust the reel rotation speed

11.5 Power supply unit

11.5.1 Read support pressure

11.5.2 Read cutting height

11.5.3 Reversing front implement/feed unit

11.5.4 Connect the head

11.5.5 Disconnect the head

11.6 Threshing organs

11.6.1 Connect and disconnect the threshing devices

11.6.2 Disconnect the threshing devices

11.6.3 Adjust the concave

11.6.4 Assemble/dismantle the sheller slats (supplementary equipment)

11.6.5 Unclog the shelling cylinder

11.6.6 Adjust the speed of the shelling cylinder

11.6.7 Reduced speed for the shelling cylinder (chain drive)

11.7 Separation

11.7.1 Adjust the canvas bib

11.7.2 Take into account the straw jam alarm behind the separation

11.7.3 Adjust the separation grain passage control indicator

11.7.4 Assembling/disassembling the cockscombs

11.8 Cleaning

11.8.1 Adjust the fan speed

11.8.2 Adjust the air guide plate

11.8.3 Manually adjust the sieves

11.8.4 Adjust the cleaning grain passage control indicator

11.9 Depositing the material / depositing the straw

11.9.1 Put the straw chopper to work (place the standard spreader in chopping position)

11.9.2 Put the straw chopper in rest position (place the standard spreader in row position)

11.9.3 Placing the standard distributor in the transport position, transport trailer

11.9.4 Adjusting the bed knife (standard straw chopper)

11.10 Grain collection

11.10.1 Control return

11.10.2 Open / close the grain tank lid

11.10.3 Remove / insert the grain tank discharge tube (DOMINATOR 150 / 140)

11.10.4 Remove/insert the grain tank discharge tube (DOMINATOR 130)

11.10.5 Connect/disconnect grain tank discharge

11.10.6 Remove / assemble the grain tank auger cover plates

11.10.7 Clean the machine for a fruit change

11.11 Sieve boards / threshing boards

11.11.1 Screen table

11.11.2 Threshing table

11.12 Shelling

11.12.1 Shelling strips

12 Failures and solutions

12.1 General instructions

12.1.1 General warning information Incident and solution

12.2 Driver’s cabin/platform

12.2.1 Central electrical system

12.2.2 Failures and solutions of the air conditioning installation

12.3 Head

12.3.1 Head

12.4 Power unit

12.4.1 Power unit incident and solution

12.5 Threshing organs

12.5.1 Incident threshing bodies and solution

12.5.2 Sheller cylinder

12.6 Separation

12.6.1 Separation Incident and solution

12.7 Cleaning

12.7.1 Cleaning Incident and solution

12.8 Depositing the material / depositing the straw

12.8.1 Harvest discharge / straw discharge Incident and solution

12.9 Grain collection

12.9.1 Grain collection Incident and solution

12.9.2 Assemble the safety screw for grain tank discharge

13 Maintenance

13.1 General instructions

13.1.1 General warning instructions Maintenance

13.2 General instructions

13.2.1 Front implement

13.2.2 Clean engine compartment and danger areas

13.2.3 Straps

13.2.4 Drives

13.2.5 Screws

13.2.6 Lubrication

13.2.7 Cleaning of lubricants

13.2.8 Brakes

13.2.9 Wheels / tires

13.2.10 Hydraulic system

13.2.11 Electrical installation

13.2.12 Air conditioning installation

13.2.13 Protective devices

13.2.14 Spare parts

13.2.15 Imbalance

13.2.16 Welding work on the combine

13.2.17 Putting the machine out of service

13.2.18 Cleaning surfaces with adhesives

13.2.19 Recommendations for the conservation of the combine during winter

13.2.20 Coolant liquid

13.3 Maintenance table

13.3.1 Maintenance intervals

13.4 Lubricant table

13.4.1 Lubricants

13.5 Engine

13.5.1 Summary of CATERPILLAR C-6.6 engines

13.5.2 Summary of CATERPILLAR 3056 E engines

13.5.3 Summary of PERKINS 1006-6T engines

13.5.4 Overview of the cooling unit

13.5.5 Clean the diesel engine environment

13.5.6 Evacuate fuel from the fuel tank

13.5.7 Refuel the machine

13.5.8 Clean the fuel tank filler filter

13.5.9 Open/close the fuel system stopcock

13.5.10 Bleed the fuel system

13.5.11 Clean the fuel pre-filter filter

13.5.12 Drain condensation water from the fuel prefilter (standard equipment)

13.5.13 Change the fuel prefilter (standard equipment)

13.5.14 Drain the condensation water from the fuel pre-filter (additional equipment)

13.5.15 Change the fuel prefilter (additional equipment)

13.5.16 Change the fuel filter CATERPILLAR C-6.6 / 3056 E

13.5.17 Change the PERKINS 1006-6T fuel filter

13.5.18 Check the diesel engine oil level

13.5.19 Change oil / oil filter in diesel engine

13.5.20 Adjust diesel engine valves

13.5.21 Check the coolant level of the water radiator

13.5.22 Check the coolant mixing ratio

13.5.23 Change the coolant of the water radiator

13.5.24 Drain the coolant from the water radiator

13.5.25 Fill the coolant in the water radiator

13.5.26 Clean the radiator screen

13.5.27 Clean the refrigerant unit

13.5.28 Change the coolant pipes

13.5.29 Clean/replace air filter with plastic casing of diesel engine

13.5.30 Change the safety cartridge of the air filter with plastic casing of the diesel engine

13.5.31 Clean the air intake filter

13.5.32 Change the air suction pipes

13.5.33 Retighten the air intake pipe clamps

13.6 Running gear

13.6.1 Wheels / tires

13.6.2 Check the tightening torque of the wheel nuts / wheel studs

13.6.3 Clean the gearbox, around the drive axle

13.6.4 Check the oil level of the DOMINATOR 150 / 140 reducers

13.6.5 Drain the oil from the DOMINATOR 150 / 140 reducers

13.6.6 Fill the oil in the DOMINATOR 150 / 140 reducers

13.6.7 Check the oil level of the DOMINATOR 130 reducers

13.6.8 Drain the oil from the DOMINATOR 130 reducers

13.6.9 Fill oil in the DOMINATOR 130 reducers

13.6.10 Check the oil level of the gearbox drive shaft

13.6.11 Drain the oil from the gearbox drive shaft

13.6.12 Fill gearbox drive shaft oil

13.6.13 Adjusting the clutch of the DOMINATOR 130 feed device

13.6.14 Adjust the short circuit valve DOMINATOR 130

13.7 Brakes

13.7.1 Check / top up the brake fluid level

13.7.2 Adjust the parking brake

13.7.3 Adjust the foot brake

13.8 Drive belts / drive chains

13.8.1 General warnings

13.8.2 Left drive diagram DOMINATOR 150 / 140 / 130

13.8.3 Right drive diagram DOMINATOR 150 / 140 / 130

13.8.4 Adjust the belt (R1)

13.8.5 Adjust the belt (R2)

13.8.6 Adjust the belt (R3)

13.8.7 Adjust the belt (R4)

13.8.8 Adjust the belt (R5)

13.8.9 Adjust the belt (R8)

13.8.10 Adjust the belt (R9)

13.8.11 Adjust the belt (R10)

13.8.12 Remove the belt (R7)

13.8.13 Install the belt (R7)

13.8.14 Adjust the belt (R12)

13.8.15 Adjust the belt (R13)

13.8.16 Remove the belt (R14)

13.8.17 Install the belt (R14)

13.8.18 Adjust the belt (R14)

13.8.19 Remove the belt (R42)

13.8.20 Install the belt (R42)

13.9 Hydraulic system

13.9.1 Check the oil level of the hydraulic system

13.9.2 Hydraulic system, change oil / oil filter / ventilation filter DOMINATOR 150 / 140

13.9.3 Hydraulic system, change oil / oil filter / ventilation filter DOMINATOR 130

13.10 Electrical/electronic installation

13.10.1 Check the battery acid level

13.11 Driver’s cabin/platform

13.11.1 Clean/change the cabin air filter

13.11.2 Clean the cabin circulation air filter

13.11.3 Clean the cabin roof assemblies

13.11.4 Putting the air conditioning into service

13.11.5 Measures to protect the air conditioning equipment when there are long inactive times DOMINATOR 130 with York compressor

13.11.6 Control the humidity saturation of the cooling agents of the air conditioning equipment

13.11.7 Change the refrigerant agent of the air conditioning unit

13.12 Power supply unit

13.12.1 Clean feed channel receptions

13.12.2 Adjust the feed chains

13.12.3 Adjust the feed chain friction clutch

13.12.4 Check the friction plates in the feed channel

13.13 Threshing organs

13.13.1 Clean the stone collection device

13.13.2 Clean the threshing components

13.14 Separation

13.14.1 Clean the shakers

13.14.2 Check the canvas bib

13.14.3 Clean the separation grain passage control sensor

13.15 Cleaning

13.15.1 Clean the cleaning grain passage control sensor

13.15.2 Clean the fan

13.15.3 Adjust the fan speed indicator

13.15.4 Clean stepped bottoms

13.15.5 Clean the sieves

13.16 Grain collection

13.16.1 Adjust the return elevator chain

13.16.2 Adjust grain elevator chain

13.16.3 Clean the auger trays

13.16.4 Clean the grain tank

13.16.5 Adjust the transportation position of the grain tank discharge tube support

13.17 Assembled parts / machine casing

13.17.1 Check the fire extinguisher

14 Greasing scheme

14.1 Grease points

14.1.1 General warning instructions Greasing scheme

14.1.2 Lubricants

14.1.3 Greasing intervals

14.1.4 Grease points – 10 h left

14.1.5 Greasing points – 10 h right.

14.1.6 Grease points – 50 h left

14.1.7 Grease points – 50 h right.

14.1.8 Grease points – 100 h left

14.1.9 Grease points – 100 h right.

14.1.10 Grease points – 500 h left

14.1.11 Grease points – 500 h right.

Alphabetical index

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese