Claas Dominator 150 140 (200) Combines Operator Manual FR

$50.00

- Model: Dominator 150 140 (200) Combines

- Type Of Manual: Operator Manual

- Language: FR

- Format: PDF(s)

- Size: 18.9 MB

File List:

00 0293 211 2.pdf

00 0294 841 0.pdf

00 0293 211 2.pdf:

Contents

1 Introduction

1.1 General advice

1.1.1 Use of the instructions

1.1.2 Validity of the notice

1.1.3 Technical information

1.1.4 Driving on the road

1.1.5 Advice regarding electronic engine management

1.2 Attached parts / machine casing

1.2.1 Spare parts and technical questions

1.2.2 Machine nameplate

1.2.3 CATERPILLAR 3056 E engine nameplate

1.2.4 PERKINS 1006-6T motor nameplate

1.2.5 CATERPILLAR C6.6 engine nameplate

1.2.6 Drive axle nameplate

1.2.7 Steering axle nameplate

1.2.8 Hitch clevis nameplate

1.2.9 Hitch frame nameplate

1.2.10 Cabin nameplate

1.2.11 Straw chopper nameplate

2 Overview

2.1 Assembled parts / Machine casing

2.1.1 Machine overview

2.1.2 Access to the driving position and maintenance points

3 Security

3.1 General advice

3.1.1 General advice

3.1.2 Important

3.1.3 Use in accordance with instructions

3.1.4 Clearly non-compliant use

3.1.5 Safety and accident prevention instructions

3.1.6 Safety and accident prevention instructions for the combine harvester

3.1.7 Before commissioning – General

3.1.8 Additional weights

3.1.9 Transport of people

3.1.10 General rule of conduct

3.1.11 Moving the combine harvester on the road

3.1.12 Driving on a slope

3.1.13 Exit the machine

3.1.14 Front implements and trailers

3.1.15 Deposit of harvested product / deposition of straw

3.1.16 Grain recovery

3.1.17 Air conditioning

3.1.18 Adjustment and maintenance work

3.1.19 Pressure accumulator

3.1.20 Antifreeze

3.1.21 First aid measures

3.1.22 Decommissioning and disposal

3.1.23 Place the safety support in the supply channel

3.1.24 Remove the safety support from the supply channel

3.1.25 Block the machine with blocks to avoid any risk of movement

3.1.26 Raise and attach the straw guide cloth

3.1.27 Lifting the machine using jacks

3.1.28 Fire extinguisher

3.1.29 Battery cut-off switch

3.1.30 Hydraulic fluid poses a risk of injury

3.1.31 Load the machine and secure it

3.1.32 Unscrew the crane eyes.

3.2 Safety information

3.2.1 Marking of warnings and dangers

3.3 Warning pictograms

3.3.1 General instructions regarding warning pictograms

3.3.2 Motor

3.3.3 Chassis

3.3.4 Cabin / driving position

3.3.5 Power group

3.3.6 Threshing bodies

3.3.7 Separation

3.3.8 Deposit of harvested product / deposit of straw

3.3.9 Grain recovery

3.3.10 Attached parts / machine casing

3.4 Safety sticker

3.4.1 General instructions regarding safety stickers

3.4.2 Chassis

4 Technical characteristics

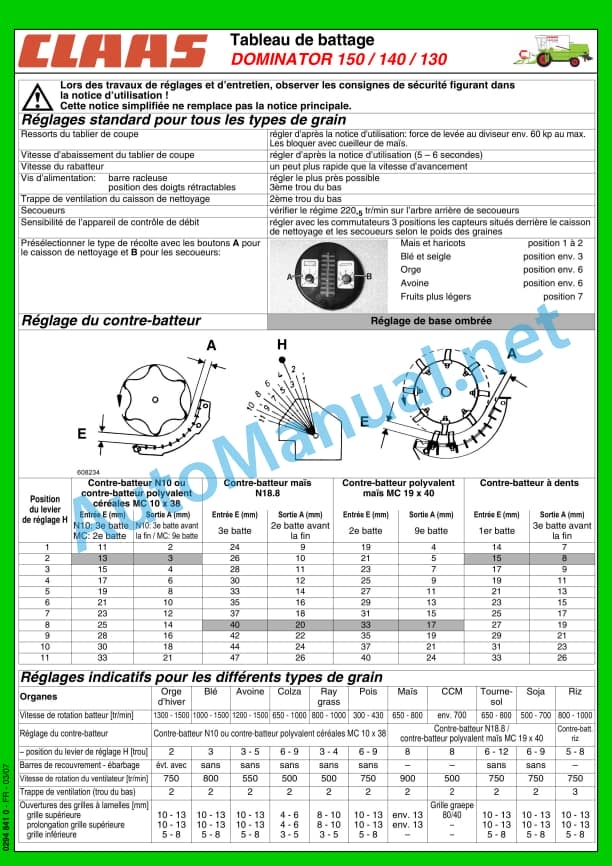

4.1 DOMINATOR 150 / 140 / 130

4.1.1 General advice

4.1.2 CATERPILLAR C6.6 engine

4.1.3 CATERPILLAR 3056E engine

4.1.4 Perkins 1006-T6 engine

4.1.5 Chassis

4.1.6 Chassis tire pressure

4.1.7 Chassis, track

4.1.8 Brake

4.1.9 Management

4.1.10 Electrical/electronic system

4.1.11 Cabin / driving position

4.1.12 Power supply organs

4.1.13 Threshing bodies

4.1.14 Separation

4.1.15 Cleaning

4.1.16 Grain recovery

4.1.17 Dimensions of assembly parts / machine casing

4.1.18 Weight of assembly parts / machine casing

5 Before first commissioning

5.1 General advice

5.1.1 General warnings Before initial commissioning

5.1.2 Checklist for initial commissioning

5.2 Axle frame

5.2.1 Remove/install the wheels

5.2.2 Overview of the steering axle

5.2.3 Adjust the steering axle from road position to working position

5.2.4 Steering axle 00 0649 950 1 – adjust track

5.3 Coupling device

5.3.1 Install the hitch yoke (optional equipment)

5.4 Electrical system / electronic system

5.4.1 Install the fan/air conditioning fuse

5.5 Power unit

5.5.1 Install / adjust the support plates

5.5.2 Align the receiving posts

5.5.3 Check the front tool cylinders

5.5.4 Check the front attachment suspension springs

5.6 Grain recovery

5.6.1 Close the hopper drain tube cleaning hatch.

5.6.2 Install the hopper protection device

6 Before each commissioning

6.1 General advice

6.1.1 General warnings Before each commissioning

6.1.2 Checklist for daily start-up

7 Overview of control elements

7.1 General advice

7.1.1 General warnings overview of control elements

7.2 Cabin / driving position

7.2.1 Overview of the driving position (DOMINATOR 130)

7.2.2 Overview of the driving position (DOMINATOR 150/140)

7.2.3 Hydraulic distributor (DOMINATOR 130 hydraulic lifting system)

7.2.4 Multifunction lever (DOMINATOR 150 / 140)

7.2.5 Control console (DOMINATOR 130)

7.2.6 Diesel engine speed selector (DOMINATOR 130, CATERPILLAR C-6.6, 3056 E)

7.2.7 Diesel engine speed lever (DOMINATOR 130, Perkins 1006-T6)

7.2.8 Function of indicator lights 7 and 8 (DOMINATOR 130)

7.2.9 Control console (DOMINATOR 150 / 140)

7.2.10 Diesel engine speed selector (DOMINATOR 150 / 140)

7.2.11 Functions of indicator lights 15 and 18 (DOMINATOR 150 / 140)

7.2.12 Overview of the steering column

7.2.13 Cab roof control elements

7.2.14 Cabin with fan

7.2.15 Cabin with air conditioning (with York compressor)

7.2.16 Cabin with air conditioning (with Sanden compressor)

7.2.17 Cabin with fan and heater

7.2.18 Control levers

7.2.19 Function monitoring device

7.3 Assembled parts / Machine casing

7.3.1 Work lights

7.3.2 Cabin

7.3.3 Sun roof

7.3.4 Toolbox

8 Mount/dismount the front tool

8.1 General advice

8.1.1 General warnings place/remove the front tool

8.2 Install the front tool

8.2.1 Hanging the front tool

8.2.2 Locking the front tool

8.2.3 Install the cardan shaft

8.2.4 Connect the hydraulic system

8.2.5 Connect the electrical circuit (additional equipment)

8.2.6 Remove the stands

8.3 Remove the front tool

8.3.1 Install the crutches

8.3.2 Disconnect the hydraulic system

8.3.3 Disconnect the electrical circuit (additional equipment)

8.3.4 Dismantle the cardan shaft

8.3.5 Unlock the front tool

8.3.6 Unhook the front tool

9 Road driving and transport

9.1 General advice

9.1.1 General safety instructions Travel and transport

9.1.2 Preparing for driving on the road

9.1.3 Preparing for driving in the field

9.2 Engine

9.2.1 Adjusting the diesel engine speed (DOMINATOR 150 / 140)

9.2.2 Starting the diesel engine (DOMINATOR 150 / 140)

9.2.3 Stopping the diesel engine (DOMINATOR 150 / 140)

9.2.4 Adjusting the speed of the diesel engine (DOMINATOR 130)

9.2.5 Starting the diesel engine (DOMINATOR 130)

9.2.6 Stopping the diesel engine (DOMINATOR 130)

9.3 Axle frame

9.3.1 Advance lever (DOMINATOR 150 / 140)

9.3.2 Shifting gears (DOMINATOR 150 / 140)

9.3.3 Advance lever (DOMINATOR 130)

9.3.4 Shifting gears (DOMINATOR 130)

9.3.5 Adjust the control resistance of the forward lever (DOMINATOR 150 / 140)

9.3.6 Driving characteristics

9.3.7 Towing the machine

9.3.8 Forward towing

9.3.9 Towing in reverse

9.4 Brake

9.4.1 Activate the parking brake

9.4.2 Release the parking brake

9.4.3 Foot brake

9.4.4 Braking / stopping the machine (DOMINATOR 150 / 140)

9.4.5 Brake / stop the machine (DOMINATOR 130)

9.4.6 Park the machine

9.5 Management

9.5.1 Management

9.5.2 Adjusting the steering column

9.6 Coupling device

9.6.1 Hitching the trailer

9.6.2 Unhitching the trailer

9.7 Cabin / driving position

9.7.1 Adjust the driver’s seat with mechanical suspension (standard model)

9.7.2 Adjust the driver’s seat with mechanical suspension (standard model)

9.7.3 Adjusting the mechanically cushioned driver’s seat (optional equipment)

9.8 Attached parts / machine casing

9.8.1 Pivoting the front ladder (standard)

9.8.2 Adjust the rear scale

10 Setting for work

10.1 General advice

10.1.1 General safety instructions, working settings

10.2 Power unit

10.2.1 Setting the cutting height display

10.2.2 Adjust the scraper profiles

10.2.3 Height adjustment of the feed chain

10.2.4 Adjust the lowering speed of the front implement (DOMINATOR 150)

10.3 Threshing bodies

10.3.1 Remove/install the concave segments (Multicrop concave)

10.3.2 Adjusting the concave basic setting

10.4 Separation

10.4.1 Adjust the separation flow control sensors

10.5 Cleaning

10.5.1 Check/adjust fan speed display

10.5.2 Adjust the cleaning flow control sensors

10.5.3 Remove the grids

10.5.4 Mount the grids

10.6 Deposit of harvested product / straw deposit

10.6.1 Remove the straw guide plate (straw chopper with standard distributor)

10.6.2 Install the straw guide plate (straw chopper with standard distributor)

10.6.3 Unscrew the articulated knives

10.6.4 Screw in the articulated knives

10.6.5 Straw chopper, grid mounting position

10.7 Grain recovery

10.7.1 Setting the DOMINATOR 150 hopper full indicator

11.1 General advice

11.1.1 General work warning advice

11.2 Structure and operation

11.2.1 Cutting deck

11.2.2 Threshing bodies

11.2.3 Shakers

11.2.4 Cleaning

11.2.5 Trimming

11.3 Basic rules for harvesting and combining

11.3.1 To be respected during harvesting and combining!

11.4 Front tool

11.4.1 Horizontal adjustment of the reel (mechanical)

11.4.2 Horizontal adjustment of the reel (hydraulic)

11.4.3 Adjust the reel peripheral speed

11.5 Power unit

11.5.1 Measure the ground support pressure

11.5.2 Raise the cutting height

11.5.3 Reverse front attachment / power unit

11.5.4 Switching on the front tool

11.5.5 Disconnect the front tool.

11.6 Threshing bodies

11.6.1 Clutching the threshers

11.6.2 Disconnect the threshing elements

11.6.3 Adjusting the concave

11.6.4 Installing/removing the deburring bats (additional equipment)

11.6.5 Eliminate windings on the beater

11.6.6 Adjust the mixer speed

11.6.7 Reduction of mixer speed (chain drive)

11.7 Separation

11.7.1 Adjusting the anti-splash fabric

11.7.2 Pay attention to straw jam alarms behind the separation

11.7.3 Set separation flow control display

11.7.4 Install/remove the sawtooth separators

11.8 Cleaning

11.8.1 Adjust fan speed

11.8.2 Adjust the ventilation hatch

11.8.3 Manually adjust the grids

11.8.4 Adjust the cleaning flow control display

11.9 Deposit of harvested product / straw deposit

11.9.1 Commissioning the straw chopper (swivel the standard distributor to the crushing position)

11.9.2 Stopping the straw chopper (pivot the standard distributor to the windrowing position)

11.9.3 Swivel the standard spreader into transport position, transport trailer

11.9.4 Adjust the counter-knives (standard straw chopper)

11.10 Grain recovery

11.10.1 Controlling the return of harvest

11.10.2 Open/close the hopper cover

11.10.3 Swivel the hopper discharge tube outwards / inwards (DOMINATOR 150 / 140)

11.10.4 Swivel the hopper discharge tube outwards/inwards (DOMINATOR 130)

11.10.5 Connect/disconnect hopper drain

11.10.6 Remove/install the hopper auger cover plates

11.10.7 Clean the machine to change crops

11.11 Grid tables / Threshing tables

11.11.1 Grid table

11.11.2 Threshing table

11.12 Trimming

11.12.1 Trimming bars

12 Incidents and remedy

12.1 General advice

12.1.1 General warning advice Fault and solution

12.2 Cabin / driving position

12.2.1 Power plant

12.2.2 Air conditioning incidents and remedies

12.3 Front tool

12.3.1 Front tool

12.4 Power supply unit

12.4.1 Failure and solution at the power supply unit

12.5 Threshing bodies

12.5.1 Failure and solution at the level of the threshing body

12.5.2 Drummer

12.6 Separation

12.6.1 Separation, failure and solution

12.7 Cleaning

12.7.1 Cleaning, failure and solution

12.8 Deposit of harvested product / deposition of straw

12.8.1 Harvest deposit / Straw deposit, failure and solution

12.9 Grain recovery

12.9.1 Grain recovery, failure and solution

12.9.2 Installing the hopper drain shear bolt

13 Maintenance

13.1 General advice

13.1.1 General warning advice Maintenance

13.2 General advice

13.2.1 Front tool

13.2.2 Clean the engine compartment and hazardous areas

13.2.3 Belts

13.2.4 Drives

13.2.5 Bolting

13.2.6 Lubrication

13.2.7 Cleanliness of lubricants

13.2.8 Brakes

13.2.9 Wheels / tires

13.2.10 Hydraulic system

13.2.11 Electrical system

13.2.12 Air conditioning

13.2.13 Protective devices

13.2.14 Spare parts

13.2.15 Unbalance

13.2.16 Welding work on the combine harvester

13.2.17 Turn off the machine

13.2.18 Cleaning bonded surfaces

13.2.19 Winterizing tips for combine harvesters

13.2.20 Coolant

13.3 Maintenance table

13.3.1 Maintenance frequencies

13.4 Lubricant table

13.4.1 Lubricants

13.5 Engine

13.5.1 Overview of the CATERPILLAR C-6.6 engine

13.5.2 Overview of the CATERPILLAR 3056 E engine

13.5.3 Overview of the PERKINS 1006-6T engine

13.5.4 Overview of the cooling elements

13.5.5 Clean the area surrounding the diesel engine

13.5.6 Drain fuel from fuel tank

13.5.7 Refueling the machine

13.5.8 Clean the fuel filler strainer

13.5.9 Close / open the fuel circuit shut-off valve

13.5.10 Bleeding air from the fuel system

13.5.11 Clean the fuel filter element

13.5.12 Drain the condensation water from the fuel pre-filter (standard equipment)

13.5.13 Replace the fuel pre-filter (standard equipment)

13.5.14 Drain the condensation water from the fuel pre-filter (additional equipment)

13.5.15 Replace the fuel pre-filter (additional equipment)

13.5.16 Replace fuel filter CATERPILLAR C-6.6 / 3056 E

13.5.17 Replace the PERKINS 1006-6T fuel filter

13.5.18 Check diesel engine oil level

13.5.19 Replace diesel engine oil/oil filter

13.5.20 Adjusting the diesel engine valves

13.5.21 Check the coolant level of the water cooler

13.5.22 Check the dosage of the coolant mixture

13.5.23 Drain the coolant from the radiator

13.5.24 Drain the liquid from the water cooler

13.5.25 Filling the cooler with coolant

13.5.26 Clean the radiator screen

13.5.27 Cleaning the cooling element

13.5.28 Replace coolant hoses

13.5.29 Clean/replace air filter of diesel engine with plastic housing

13.5.30 Replace the safety cartridge of the air filter with plastic housing of the diesel engine

13.5.31 Cleaning the suction grille

13.5.32 Replace the air suction hoses

13.5.33 Tighten the air suction hose clamps

13.6 Axle frame

13.6.1 Wheels / tires

13.6.2 Check the tightening torque of the wheel nuts/wheel bolts.

13.6.3 Drive axle gearbox, clean surrounding area

13.6.4 Check the oil level of the DOMINATOR 150 / 140 axle gearbox

13.6.5 Drain the oil from the DOMINATOR 150 / 140 axle gearbox

13.6.6 Fill the axle box with DOMINATOR 150 / 140 oil

13.6.7 Check the oil level of the DOMINATOR 130 axle gearbox

13.6.8 Drain the oil from the DOMINATOR 130 axle gearbox

13.6.9 Fill the DOMINATOR 130 axle gearbox with oil

13.6.10 Check the oil level of the drive axle gearbox

13.6.11 Change the oil from the drive axle gearbox

13.6.12 Filling the drive axle gearbox

13.6.13 Adjust the DOMINATOR 130 chassis coupling

13.6.14 Adjust the DOMINATOR 130 bypass valve

13.7 Brake

13.7.1 Check/top up the brake fluid level

13.7.2 Adjusting the parking brake

13.7.3 Adjusting the foot brake

13.8 Drive belts / drive chains

13.8.1 General safety advice

13.8.2 Left side drive diagram DOMINATOR 150 / 140 / 130

13.8.3 Right side drive diagram DOMINATOR 150 / 140 / 130

13.8.4 Adjust the belt (R1)

13.8.5 Adjust the belt (R2)

13.8.6 Adjust the belt (R3)

13.8.7 Adjust the belt (R4)

13.8.8 Adjust the belt (R5)

13.8.9 Adjust the belt (R8)

13.8.10 Belt adjustment (R9)

13.8.11 Adjust the belt (R10).

13.8.12 Remove the belt (R7)

13.8.13 Fitting the belt (R7)

13.8.14 Adjust the belt (R12).

13.8.15 Adjust the belt (R13)

13.8.16 Remove the belt (R14)

13.8.17 Fitting the belt (R14)

13.8.18 Adjust the belt (R14)

13.8.19 Remove the belt (R42)

13.8.20 Install the belt (R42)

13.9 Hydraulics

13.9.1 Check the hydraulic system oil level

13.9.2 Hydraulic system, change oil / replace oil filter / air filter DOMINATOR 150 / 140

13.9.3 Hydraulic system, change oil / replace oil filter / air filter DOMINATOR 130

13.10 Electrical/electronic system

13.10.1 Checking the battery acidity level

13.11 Cabin / driving position

13.11.1 Clean/replace the cabin air filter

13.11.2 Clean the cabin forced air filter

13.11.3 Clean the groups in the cabin roof

13.11.4 Commissioning the air conditioning

13.11.5 Measures to protect the air conditioning during prolonged rest periods DOMINATOR 130 with York compressor

13.11.6 Checking the humidity saturation of the air conditioning refrigerant

13.11.7 Replace the refrigerant in the air conditioning

13.12 Power supply unit

13.12.1 Clean feed channel receipts

13.12.2 Adjusting the feed chains

13.12.3 Adjusting the power chain torque limiter

13.12.4 Check the friction plates on the feed channel

13.13 Threshing bodies

13.13.1 Clean the destoner tray

13.13.2 Clean the threshing bodies

13.14 Separation

13.14.1 Cleaning the shakers

13.14.2 Checking the anti-splash fabric

13.14.3 Clean the separation flow control sensor

13.15 Cleaning

13.15.1 Clean flow control sensor cleaning

13.15.2 Clean the fan

13.15.3 Setting the fan speed display

13.15.4 Cleaning stepped waterfalls

13.15.5 Clean the grills

13.16 Grain recovery

13.16.1 Adjusting the grain elevator chain

13.16.2 Adjusting the grain elevator chain

13.16.3 Clean the auger buckets

13.16.4 Clean the hopper

13.16.5 Adjust the transport position of the hopper discharge tube support

13.17 Attached parts / machine casing

13.17.1 Checking the fire extinguisher

14 Lubrication plan

14.1 Lubrication points

14.1.1 General warning tips lubrication scheme

14.1.2 Fats

14.1.3 Lubrication intervals

14.1.4 Lubrication points – 10 o’clock left side

14.1.5 Lubrication points – 10 o’clock right side

14.1.6 Lubrication points – 50 h left side

14.1.7 Lubrication points – 50 h right side

14.1.8 Lubrication points – 100 h left side

14.1.9 Lubrication points – 100 h right side

14.1.10 Lubrication points – 500 h left side

14.1.11 Lubrication points – 500 h right side

Alphabetical index

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08