Claas Elios 240 – 210 Stage3B (A48) Tractors Repair Manual EN

$300.00

- Model: Elios 240 – 210 Stage3B (A48) Tractors

- Type Of Manual: Repair Manual

- Language: EN

- Format: PDF(s)

- Size: 392 MB

File List:

00 1153 367 X.pdf

00 1166 357 1.pdf

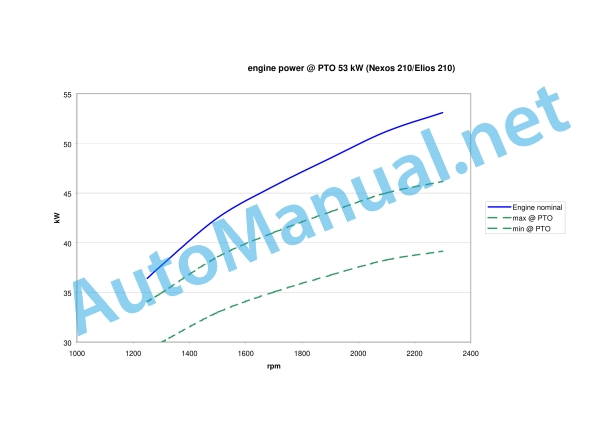

Nexos, Elios 230 – 211 Chapter 01 – Engine curves.pdf

00 1153 367 X.pdf:

ELIOS 240-210

Table of contents

CCN (CLAAS Component Number)

Introduction

General information

Using this repair manual

Scope of the repair manual

General repair instructions

Technical specifications

Cause of damage

Spare parts

Diesel engine

Alternator

Welding work

Drive belt/drive chains

Tapered ring assemblies

Self-locking bolts with microencapsulated glue

Threadlock

Lock collar bearing

Collet bearing

Screwed connectors with cutting rings on the hydraulic pipes

Progressive ring bolt connectors on hydraulic pipes

Double flare unions screwed onto the hydraulic pipes

Flexible hydraulic hoses

Pipe routing

Advice for economical repairs

Torque settings

Tightening torques for NF E25-030-1 2007-12-01 standard metric threads

Tightening torques for CLAAS CN 020 225 standard hydraulic connections

Tightening torques for hydraulic screw connections and air conditioning screw connections with sealing cone and DIN 3865 O-ring

Tightening torques for DIN 3901 threading hydraulic flanges

Tightening torques for ISO 6149-2/ISO 11926-2 (3) adjustable hydraulic screw connections

Tightening torques for hydraulic swivel screw connections

Tightening torques for DIN 7643 hollow bolts

Technical specifications

Lubricants

01 Engine

0102 Complete component

Introduction

General notes

Complete engine

Special tool

Coupling the engine to the chassis

Preparation for work

General specifications

Tightening torques

Disassembling the engine

Reassembling the engine

0110 Engine housing

Tightening torques

Oil sump

Timing gear train housing

Refitting

Flywheel housing

Repairing the cylinder block

Checks and measurements

Checking the supporting surface of the cylinder head on the cylinder block

0115 Engine unit

Specifications

Tightening torques

General engine service

Crankshaft

Measuring the journals and crank pins

Crankshaft journals and crank pins – Measured values

Tolerances

Fitting the crankshaft

Fitting the bearing half-shells

Checking the crankshaft lateral play

Fitting the crankshaft oil deflector

Fitting the crankshaft bearing seal

Conrod/piston assembly

Disassembling

Checking the piston – Characteristics

Pairing the shaft and the piston

Piston rings

Checking the piston rings

Specifications

Fitting the conrod/piston assembly – Coupling the conrod/piston

Fitting the piston rings

Fitting the conrod and piston into the cylinder

Fitting the conrod caps

Piston protrusion measurement

Balancer

0120 Cylinder head / Valves / Idler gear

Specifications

Valves – Cylinder head

Camshaft – Rocker arms

Tightening torques

Cylinder head

Checking the cylinder head contact surface

Fitting the cylinder head

Final operations

Removing the valves

Main dimensions of the intake and exhaust valves

Decarbonising, checking and rectifying the valves

Valve guide

Replacing the valve guide

Valve seats

Main dimensions of the valve seats – in mm

Fitting in the cylinder head

Special tools

Rocker cover

Rocker arm ramp

Final operations

Camshaft

Specifications

Main dimensions of the camshaft bearings

Checking the cam lift and the alignment of the shaft bearings

Main dimensions of the camshaft rings and their seats

Special tools

Replacing the rings

Pushrods

Fitting the pushrods

0125 Injection – / Fuel system

Tightening torques

Fuel tank

Removing the fuel tank

Low-pressure fuel pipes

Fuel filter

Fuel pipes running from the high-pressure pump to the common rail

BOSCH CP4.I injection pump

Common rail

Injectors

Fuel cooler

Removing the fuel cooler

0130 Lubricating oil system

Tightening torques

Engine oil filter

Oil pump

Engine oil heat exchanger

Blow-by (Recirculation of oil vapours)

0135 Cooling system

Tightening torques

Radiator

Removing the radiator

Drive belt

Preliminary operations

Removing the belt

Ventilation

Preliminary operations

Refitting

Water pump

Thermostat

0140 Exhaust system

Tightening torques

Vertical exhaust pipe

Disassembling the vertical exhaust pipe

Turbocharger

Exhaust manifold

0145 Air intake

Tightening torques

Air filter

Removing the air filter

Intake manifold

0150 Engine attachment parts

Tightening torques

Alternator

Refitting

Electric starting motor

0155 Engine control

Tightening torques

Engine management module (ECU)

Engine harness

Pre-heater plugs

0165 Exhaust gas aftertreatment

Tightening torques

Exhaust filter

EGR valve

Refitting

Particulate filter assembly

02 Gearbox / Clutch / Universal drive shaft

0202 Complete component

Transmission special tools

12/12 and 24/24 mechanical reverser

24/24 mechanical doubler and reverser

24/24 hydraulic doubler and mechanical reverser

24/24 and 24/12 hydraulic doubler

24/12 hydraulic reverser

Reduction gear housing

Standard version final drive

Reinforced version final drive

Hydraulic front axle clutch

Front axle hydraulic clutch

Tightening torques, lubricants and sealing products

Clutch housing – 12/12 transmission

Clutch housing – 24/24 transmission with mechanically-controlled doubler

Clutch housing – 24/24 transmission with hydraulically-controlled doubler

Clutch housing – 24/12 transmission

Reduction gear housing

Reduction gear internal controls

Reduction gear external controls

Upper and lower covers

Final drives

Front axle clutch housing

Assembly specifications

All transmission models

12/12 transmission

24/24 transmission with mechanical doubler

24/24 transmission with hydraulic doubler

24/12 transmission

Separating the engine and clutch housing

Draining the transmission oil

Removing the transmission shaft

Removing the pipes

Removing the first pipe

Removing the second pipe

Removing the third pipe

Separating the engine and clutch housing

Installing the trolley underneath the tractor

Immobilising the front axle

Removing the mounting bolts

Separating the elements

Upper covers and linkage

Exploded view

Disassembly

Assembly

0215 Mechanical clutch

Adjusting the clutch

Adjustment

Transmissions with hydraulic doubler – Clutch shaft

Replacing the Teflon seals – Exploded view

Replacement

Special tools

24/12 transmission

24/24 transmission with hydraulic doubler

24/12 and 24/24 transmissions with hydraulic doubler

24/12 transmission

24/24 transmission with hydraulic doubler

24/12 and 24/24 transmissions with hydraulic doubler

Air compressor – 24/12 transmission

Exploded view

Disassembly

Assembly

0218 Clutch control

Reverser and clutch controls – 12/12 transmission

Mechanical reverser without doubler – Exploded view

Disassembly

Assembly

Reverser and clutch controls – 24/24 transmission (Mechanical reverser and doubler)

Mechanical doubler and reverser – Exploded view

Disassembly

Assembly

Adjusting the axial play

Reverser and clutch controls – 24/24 transmission (Mechanical reverser and hydraulic doubler)

Hydraulic doubler and mechanical reverser – Exploded view

Disassembly

Assembly

Adjusting the axial play of the upper shaft

Adjusting the axial play of the reverser shaft

Reverser and clutch controls – 24/12 transmission

Exploded view

Disassembly

Assembly

Adjusting the axial play of the upper shaft

Adjusting the axial play of the reverser shaft

0220 Mechanical reverser

Controls – Mechanical reverser

Exploded view

Disassembly

24/12 transmission

Assembly

24/12 transmission

Synchronised idle gear

Exploded view

Disassembly

Assembly

0222 Hydraulical reverser

Hydraulic reverser

Exploded view

Disassembly

Assembly

Adjusting the play

Wear to the packets of discs

Idle gear

Exploded view

Disassembly

Assembly

0228 Reverser control

Reverser controls

Adjusting the mechanical reverser

Adjustment

0230 Mechanical gearbox

Input shaft – Transmission with mechanical reverser

Exploded view

Disassembly

Assembly

Input shaft – Transmission with hydraulic reverser

Exploded view

Disassembly

Assembly

Primary shaft – Gears – Transmissions with mechanical reverser

Exploded view

Disassembly

Assembly Primary shaft: Gears, assembly (Transmissions with mechanical reverser)

Primary shaft – Gears – 24/12 transmission

Exploded view

Disassembly

Assembly

Determining the axial play

Primary shaft – Ranges

Exploded view

Disassembly

Assembly

Secondary shaft – Gear

Exploded view

Disassembly

Assembly

Secondary shaft – Ranges

Exploded view

Disassembly

Assembly

Primary shaft covers

12/12 transmission – Cross-section

24/24 transmission with mechanical reverser and doubler – Cross-section

24/24 transmission with mechanical reverser and hydraulic doubler – Cross-section

24/12 transmission – Cross-section

Secondary shaft – Measuring the axial play

Cross-section

Mechanical doubler

Exploded view

Disassembly

Assembly

0234 Powershift gearbox

Hydraulic doubler

Exploded view

Disassembly

Assembly

Wear to the packet of discs

0238 Gearbox control

External controls

Exploded view

Disassembly

Assembly

Internal controls

12/12 and 24/24 transmission – Exploded view

Internal controls – 24/12 transmission

Disassembly

Forward/reverse gear:

Assembly

0240 Rear axle housing

Standard version final drives and axle tube

Exploded view

Disassembly

Assembly

Adjusting the axial play

Reinforced version final drives and axle tube 506 UP 6/1

Exploded view

Disassembly

Assembly

Tapered roller bearings preload.

0242 Differential

Differential

Exploded view

Disassembly

Assembly

Differential lock control

Exploded view

Disassembly

Assembly

0248 Rear axle control

Transmission sensors – Exploded view

Location

Sensor/transmission applicability

Disassembly

Description

Assembly

0250 Mechanical front axle drive

Hydraulic front axle clutch

Exploded view

Disassembly

Assembly

0252 Electro-hydraulical front axle drive

Front axle hydraulic clutch

Exploded view

Disassembly

Assembly

0255 Gearbox cooling system

Oil cooler

0260 Universal drive shaft

Front axle transmission shaft

03 Chassis

0310 Axle

Recommendations – Servicing and repair

Shaft seals

Adjustment shims

Roller bearings

Caps and rivets

Plastic protections and caps

Cotter pins

Adhesives and sealing products

Oil drain

Cleaning

Ends of flanges and special tools

Using lubricants

0320 Steering axle

Recommendations – Servicing and repair (2RM)

Tightening torques, lubricants and sealing products (2RM)

Steering actuator

Exploded view

Disassembly/Removal

Reassembling/Refitting

Wheel hub

Exploded view

Disassembly/Removal of the wheel hub

Refitting/Reassembling the wheel hub

Hub support

Exploded view

Disassembly/Removal of the hub support

Refitting/Reassembling the hub support

Axle body

Exploded view

Removal/Disassembly of the axle body

Refitting/Reassembling the axle body

Toe-in / Steering angle

Exploded view

Adjusting the toe-in

Adjusting the steering angle

0325 Driven steering axle, front

Identification of the “AN” and “AR” front axle

Recommendations – Servicing and repair (4RM)

Tightening torques, lubricants and sealing products (4RM)

AN steering actuator

Exploded view

Disassembling the AN steering actuator

Assembling the AN steering

AR steering actuator

ded view

Disassembling the AR steering actuator

Assembling the AR steering actuator

AN epicyclic reduction unit

Exploded view

Disassembling the AN epicyclic reduction unit

Assembling the AN epicyclic reduction unit

AR epicyclic reduction unit

Exploded view

Disassembling the AR epicyclic reduction unit

Assembling the AR epicyclic reduction unit

AN wheel hub

Special tools

Exploded view

Disassembling the AN wheel hub

Assembling the AN wheel hub

AR wheel hub

Special tools

Exploded view

Disassembling the rear wheel hub

Assembling the rear wheel hub

Seals – Bearing/support assembly

Exploded view

Disassembling the bearing/support assembly

Assembling the bearing/support assembly

Differential housing

Special tools

Exploded view

Disassembly

Assembly

If the roller bearings have not been replaced:

If the roller bearings are new:

Alternative procedure after adjusting the play between the pinion/crown gear teeth:

LS-AN differential

Specifications

Exploded view

Disassembling the LS-AN differential

Assembling the LS-AN differential

LS-AR differential

Exploded view

Disassembling the LS-AR differential

Assembling the LS-AR differential

Drive pinion

Special tools

Exploded view

Disassembling the drive pinion shaft

Assembling the drive pinion shaft

If the roller bearings have not been replaced:

If the roller bearings have been replaced:

Alternative procedure:

Front axle body

Special tools

Exploded view

Disassembling the front axle body

Assembling the front axle body

Toe-in / Steering angle

Exploded view

Adjusting the toe-in

Adjusting the steering angle

Dual universal driveshaft seal/hub assembly

Cross-section

Disassembling the dual universal driveshaft seal/hub assembly

Assembling the dual universal driveshaft seal/hub assembly

Dual universal driveshaft seal in the front axle body

Special tools

Replacing the sealing ring

Replacing the ring

Checking after assembly

Pressure check

Test methods

04 Brake

0405 Service brake

Assembly specifications

Mechanical brake

Hydraulic brake control – Tightening torques

Brake master cylinders

Slave cylinder

Exploded view

Disassembly

Assembly

Bleeding the braking circuit

Technical specifications

Preparation for work

Bleeding the braking circuit

0415 Parking brake

Parking brake

Exploded view

Disassembly

Assembly

On each side of the transmission housing

Adjusting the control lever

Method to adjust the control

05 Steering

0505 Steering

Steering gearbox

06 Lift device

0605 Rear power lift

Specifications

Identifying the product

Description

Main components of the linkage

Technical specifications

Main dimensions

Performance

Settings

Sensitivity adjustment valve

Position control lever

Draft control lever

Adjusting the force return bar

Adjusting the end of travel position sensor

Assembling the reaction spring

Internal push bar

Linkage actuator and arm

Exploded view

Assembly

Rear linkage control rod linkage

Exploded view

Assembly

Rear linkage main control

Disassembly

Assembly

Position and draft control rod linkage

Exploded view

Disassembly

Assembly

08 Drives

0802 Rear PTO

Special tools

Rear power take-off

Tightening torques, lubricants and sealing products

Mechanical power take-off – 12/12 and 24/24 transmissions

Switches

Independent power take-off (540/540E – 540/1000)

Independent power take-off (540/540E – 540/1000) and power take-off proportional to ground speed

Hydraulic power take-off – 24/12 transmission

Switches

Independent power take-off (540/540E – 540/1000)

Independent power take-off (540/540E – 540/1000) and power take-off proportional to ground speed

Cover and clutch

Exploded view

Disassembly

Assembly

Rear power take-off clutch

Wear to the packet of discs

Rear power take-off control

Exploded view

Disassembly

Only for 24/12 transmissions.

Assembly

Only for 24/12 transmission

All transmission types

Only for 24/12 transmission

All transmission types

Input shaft

Exploded view

Disassembly

Only without power take-off

All power take-off types

Assembly

Only without power take-off proportional to ground speed

All power take-off types

Output shaft

Exploded view

Disassembly

Assembly

Power take-off brake – 24/12 transmission

Exploded view

Disassembly

Assembly

Power take-off proportional to ground speed

24/12 transmission – Exploded view

Except 24/12 transmission – Exploded view

Disassembly

Assembly

Operation of the power take-off proportional to ground speed:

Rear power take-off sensors

Location

10 Electrical / Electronic equipment

1005 Power supply

1035 Operation / Multifunction control lever

Lifting control panel

12 Cab / Operator’s platform

1210 Cab

Lever trim

Rear screen wiper

Cab mount

Preparation for work

Front cab mount mounting

Rear cab mount mounting

Complete cab

Special tool

1240 Air condition

Air conditioning compressor

80 Various components / Machine body

8025 Panellings / Hoods

Engine bonnet

Removing the engine bonnet

Bonnet side panels

00 1166 357 1.pdf:

ELIOS 240-210

Table of contents

CCN (CLAAS Component Number)

Introduction

General information

Using this repair manual

Scope of the repair manual

General repair instructions

Technical specifications

Cause of damage

Spare parts

Diesel engine

Alternator

Welding work

Drive belt/drive chains

Tapered ring assemblies

Self-locking bolts with microencapsulated glue

Threadlock

Lock collar bearing

Collet bearing

Threaded unions with cutting rings on the hydraulic hoses

Threaded unions with progressive rings on the hydraulic hoses

Threaded double flare unions on the hydraulic hoses

Flexible hydraulic pipes

Pipe routing

Advice for economical repairs

Tightening torques

Tightening torques for NF E25-030-1 2007-12-01 standard metric threads

Tightening torques for CLAAS CN 020 225 standard hydraulic connections

Tightening torques for hydraulic threaded unions and air conditioning threaded unions with sealing cone and DIN 3865 O-ring

Tightening torques for DIN 3901 hydraulic threaded unions

Tightening torques for ISO 6149-2/ISO 11926-2 (3) adjustable hydraulic threaded unions

Tightening torques for hydraulic swivel threaded unions

Tightening torques for DIN 7643 hollow bolts

Technical specifications

Lubricants

01 Engine

0102 Complete component

Introduction

General notes

Complete engine

Special tool

Coupling the engine to the chassis

Preparation for work

General specifications

Tightening torques

Disassembling the engine

Reassembling the engine

0110 Engine housing

Tightening torques

Oil sump

Timing gear train housing

Refitting

Flywheel housing

Repairing the cylinder block

Dimensional specifications

Checks and measurements

Checking the supporting surface of the cylinder head on the cylinder block

0115 Engine unit

Specifications

Tightening torques

General engine service

Crankshaft

Measuring the journals and crank pins

Crankshaft journals and crank pins – Measured values

Tolerances

Fitting the crankshaft

Fitting the bearing half-shells

Checking the crankshaft lateral play

Fitting the crankshaft oil deflector

Fitting the crankshaft bearing seal

Connecting rod/piston assembly

Dismantling

Checking the piston – Characteristics

Pairing the shaft and the piston

Piston rings

Checking the piston rings

Specifications

Fitting the connecting rod/piston assembly – Coupling the connecting rod/piston

Fitting the piston rings

Fitting the connecting rod and piston into the cylinder

Fitting the connecting rod caps

Piston protrusion measurement

Balancer

Technical specifications

Special tool

0120 Cylinder head / Valves / Idler gear

Specifications

Valves – Cylinder head

Camshaft – Rocker arms

Tightening torques

Cylinder head

Checking the cylinder head contact surface

Fitting the cylinder head

Final operations

Removing the valves

Main dimensions of the intake and exhaust valves

Decarbonising, checking and rectifying the valves

Valve guide

Replacing the valve guide

Valve seats

Main dimensions of the valve seats – in mm

Fitting in the cylinder head

Special tools

Rocker cover

Rocker arm ramp

Final operations

Camshaft

Specifications

Main dimensions of the camshaft bearings

Checking the cam lift and the alignment of the shaft bearings

Main dimensions of the camshaft rings and their seats

Special tools

Replacing the rings

Pushrods

Fitting the pushrods

Calibration

0125 Injection – / Fuel system

Tightening torques

Fuel tank

Removing the fuel tank

Low-pressure fuel pipes

Fuel filter

Fuel pipes running from the high-pressure pump to the common rail

BOSCH CP4.I injection pump

Common rail

Injectors

Fuel cooler

Removing the fuel cooler

0130 Lubricating oil system

Tightening torques

Engine oil filter

Oil pump

Engine oil heat exchanger

Blow-by (Recirculation of oil vapours)

0135 Cooling system

Tightening torques

Radiator

Removing the radiator

Drive belt

Preliminary operations

Removing the belt

Ventilation

Preliminary operations

Refitting

Water pump

Thermostat

0140 Exhaust system

Tightening torques

Vertical exhaust pipe

Disassembling the vertical exhaust pipe

Turbocharger

Exhaust manifold

0145 Air intake

Tightening torques

Air filter

Removing the air filter

Intake manifold

0150 Engine attachment parts

Tightening torques

Alternator

Refitting

Electric starting motor

0155 Engine control

Tightening torques

Engine management module (ECU)

Engine harness

Pre-heater plugs

0165 Exhaust gas aftertreatment

Tightening torques

Exhaust filter

EGR valve

Refitting

Particulate filter assembly

02 Gearbox / Clutch / Universal drive shaft

0202 Complete component

Transmission special tools

12/12 and 24/24 mechanical reverser

24/24 mechanical doubler and reverser

24/24 hydraulic doubler and mechanical reverser

24/24 and 24/12 hydraulic doubler

24/12 hydraulic reverser

Reduction gear housing

Standard version final drive

Reinforced version final drive

Hydraulic front axle clutch

Front axle hydraulic clutch

Tightening torques, lubricants and sealing products

Clutch housing – 12/12 transmission

Clutch housing – 24/24 transmission with mechanically-controlled doubler

Clutch housing – 24/24 transmission with hydraulically-controlled doubler

Clutch housing – 24/12 transmission

Reduction gear housing

Reduction gear internal controls

Reduction gear external controls

Upper and lower covers

Final drive ratios

Front axle clutch housing

Assembly specifications

All transmission models

12/12 transmission

24/24 transmission with mechanical doubler

24/24 transmission with hydraulic doubler

24/12 transmission

Separating the engine and clutch housing

Draining the transmission oil

Removing the transmission shaft

Removing the pipes

Removing the first pipe

Removing the second pipe

Removing the third pipe

Separating the engine and clutch housing

Installing the trolley underneath the tractor

Immobilising the front axle

Removing the mounting bolts

Separating the elements

Upper covers and linkage

Exploded view

Disassembly

Assembly

0215 Mechanical clutch

Adjusting the clutch

11 inch clutch

Adjustment

12 inch clutch

Adjustment

Clutch for REVERSHIFT transmission with rear power take-off with mechanical clutch

Adjustment

Transmissions with hydraulic doubler – Clutch shaft

Replacing the Teflon seals – Exploded view

Replacing

Special tools

24/12 transmission

24/24 transmission with hydraulic doubler

24/12 and 24/24 transmissions with hydraulic doubler

24/12 transmission

24/24 transmission with hydraulic doubler

24/12 and 24/24 transmissions with hydraulic doubler

Air compressor – 24/12 transmission

Exploded view

Disassembly

Assembly

0218 Clutch control

Reverser and clutch controls – 12/12 transmission

Mechanical reverser without doubler – Exploded view

Disassembly

Assembly

Reverser and clutch controls – 24/24 transmission (mechanical reverser and doubler)

Mechanical doubler and reverser – Exploded view

Disassembly

Assembly

Adjusting the axial play

Reverser and clutch controls – 24/24 transmission (Mechanical reverser and hydraulic doubler)

Hydraulic doubler and mechanical reverser – Exploded view

Disassembly

Assembly

Adjusting the axial play of the upper shaft

Adjusting the axial play of the reverser shaft

Reverser and clutch controls – 24/12 transmission — Hydraulically controlled power take-off

Technical specifications

Preparation for work

Disassembly

Assembly

Adjusting the axial play of the upper shaft

Adjusting the axial play of the reverser shaft

0220 Mechanical reverser

Controls – Mechanical reverser

Exploded view

Disassembly

24/12 transmission

Assembly

24/12 transmission

Synchronised idle gear

Exploded ew

Disassembly

Assembly

0222 Hydraulical reverser

Hydraulic reverser

Exploded view

Disassembly

Assembly

Adsting the play

Wear to the packets of discs

Idle gear

Exploded view

Disassembly

Assembly

0228 Reverser control

Reverser controls

Adjusting the mechanical reverser

Adjustment

0230 Mechanical gearbox

Input shaft – Transmission with mechanical reverser

Exploded view

Disassembly

Assembly

Input shaft – Transmission with hydraulic reverser

Exploded view

Disassembly

Assembly

Primary shaft – Gears – Transmissions with mechanical reverser

Exploded view

Disassembly

Assembly

Primary shaft – Gears – 24/12 transmission

Exploded view

Disassembly

Assembly

Determining the axial play

Primary shaft – Ranges

Exploded view

Disassembly

Assembly

Secondary shaft – Gear

Exploded view

Disassembly

Assembly

Secondary shaft – Ranges

Exploded view

Disassembly

Assembly

Primary shaft covers

12/12 transmission – Cross-section

24/24 transmission with mechanical reverser and doubler – Cross-section

24/24 transmission with mechanical reverser and hydraulic doubler – Cross-section

24/12 transmission – Cross-section

Secondary shaft – Measuring the axial play

Cross-section

Mechanical doubler

Exploded view

Disassembly

Assembly

0234 Powershift gearbox

Hydraulic doubler

Exploded view

Disassembly

Assembly

Wear to the packet of discs

0238 Gearbox control

External controls

Exploded view

Disassembly

Assembly

Internal controls

12/12 and 24/24 transmission – Exploded view

Internal controls – 24/12 transmission

Disassembly

Forward/reverse gear:

Assembly

0240 Rear axle housing

Standard version final drives and axle tube

Exploded view

Disassembly

Assembly

Adjusting the axial play

Reinforced version final drives and axle tube 506 UP 6/1

Exploded view

Disassembly

Assembly

Tapered roller bearings preload.

0242 Differential

Differential

Exploded view

Disassembly

Assembly

Differential lock control

Exploded view

Disassembly

Assembly

0248 Rear axle control

Transmission sensors – Exploded view

Location

Sensor/transmission applicability

Disassembly

Description

Assembly

0250 Mechanical front axle drive

Hydraulic front axle clutch

Exploded view

Disassembly

Assembly

0252 Electro-hydraulical front axle drive

Front axle hydraulic clutch

Exploded view

Disassembly

Assembly

0255 Gearbox cooling system

Oil cooler

0260 Universal drive shaft

Front axle transmission shaft

03 Chassis

0310 Axle

Recommendations – Servicing and repair

Shaft seals

Adjustment shims

Roller bearings

Caps and rivets

Plastic protections and caps

Cotter pins

Adhesives and sealing products

Oil drain

Cleaning

Ends of flanges and special tools

Using lubricants

0320 Steering axle

Recommendations – Servicing and repair (2RM)

Tightening torques, lubricants and sealing products (2RM)

Steering actuator

Exploded view

Disassembly/Removal

Reassembling/Refitting

Wheel hub

Exploded view

Disassembly/removal of the wheel hub

Assembly/fitting the wheel hub

Hub support

Exploded view

Disassembly/Removal of the hub support

Refitting/Reassembling the hub support

Axle body

Exploded view

Removal/Disassembly of the axle body

Refitting/Reassembling the axle body

Toe-in / Steering angle

Exploded view

Adjusting the toe-in

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish