Claas Frontloader 250-40 (B91) Tractors Operator Manual EN

$50.00

- Model: Frontloader 250-40 (B91) Tractors

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 55.7 MB

File List:

00 0301 051 0.pdf

00 0303 482 0.pdf

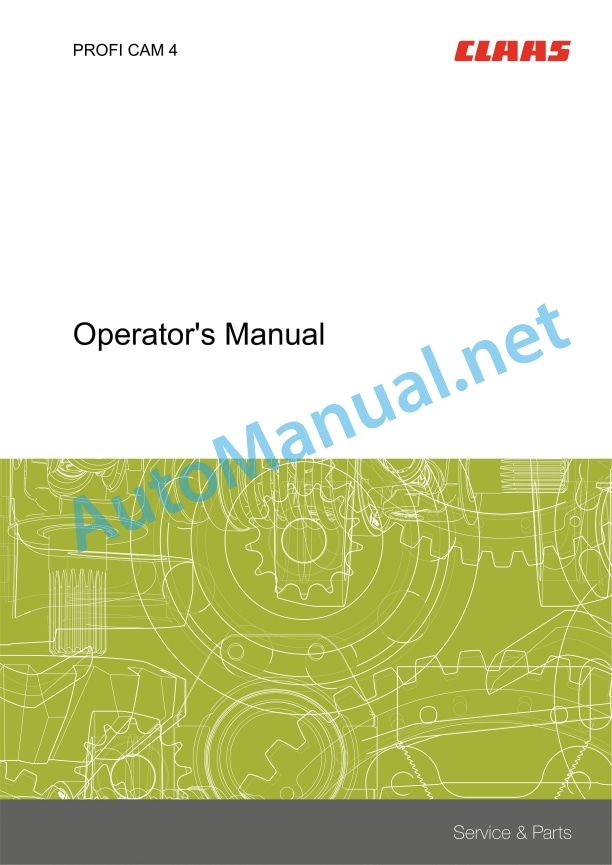

00 1142 032 0.pdf

00 1142 033 0.pdf

00 1165 934 0.pdf

00 1169 984 0.pdf

00 1174 352 1.pdf

00 2151 096 0.pdf

00 2188 308 0.pdf

00 0301 051 0.pdf:

PROFI CAM 3

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Optional equipment and spare parts

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Position of identification plates

3.2.2 Explanation of PROFI CAM identification plate

3.3 Information on the product

3.3.1 CE marking

4 Operating and control elements

4.1 Camera system

4.1.1 Camera system monitor

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

5.1.4 Degree of protection against foreign bodies and water

6 Preparing the product

6.1 Shutting down and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

6.2.4 Connecting the camera electrics

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electrical and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

8.1.2 Replacing the switch box fuse

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Placing out of operation and disposal

10.1 General Information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 0303 482 0.pdf:

PROFI CAM 4

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance information

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Meaning of Operator’s Manual

2.2.2 Structural changes

2.2.3 Optional equipment and spare parts

2.2.4 Operation only following proper putting into operation

2.2.5 Technical status

2.2.6 Respecting technical limit values

Respecting technical limit values

2.2.7 Hazards when driving on roads and fields

3 Product description

3.1 Overview and method of operation

3.1.1 How the PROFI CAM works

3.2 Identification plates and identification number

3.2.1 Identification plates

3.3 Information on the product

3.3.1 CE marking

4 Operating and display elements

4.1 Camera system

4.1.1 Camera system monitor

4.1.2 CEBIS

4.2 Menu structure

4.2.1 Main menu

4.2.2

4.2.3

4.2.4

4.2.5

4.2.6

5 Technical specifications

5.1 PROFI CAM

5.1.1 Monitor

5.1.2 Camera

5.1.3 Switch box

6 Preparing the product

6.1 Switching off and securing the machine

6.1.1 Switching off and securing the machine

6.2 Prior to putting into operation

6.2.1 Carry out prior to operation

6.2.2 Installing the sun protection

6.2.3 Aligning the camera

7 Operation

7.1 Monitor

7.1.1 Switching on the monitor

7.1.2 Calling up the menu

7.1.3 Setting a menu item

7.1.4 Setting the image orientation

7.1.5 Setting automatic screen darkening

7.1.6 Image mirroring

7.1.7 Setting the trigger view

7.1.8 Setting the follow-up time for trigger view

7.1.9 Setting the display mode

7.1.10 Activating/deactivating a display mode

8 Faults and remedies

8.1 Electric and electronic system

8.1.1 Overview of problems on PROFI CAM camera system

9 Maintenance

9.1 Maintenance intervals

9.1.1 Every 10 operating hours or daily

9.2 Camera system

9.2.1 Checking the camera system for dirt

9.2.2 Cleaning the camera

9.2.3 Cleaning the switch box

9.2.4 Cleaning the monitor

10 Putting out of operation and disposal

10.1 General information

10.1.1 Putting out of operation and disposal

11 Technical terms and abbreviations

11.1 Abbreviations

11.1.1 Units

11.1.2 Abbreviations

11.1.3 Technical terms

00 1165 934 0.pdf:

MANUBALC40-C30-U40L6000-L500-L40V7000-V500-V60-V50-V40W500

Table of contents

1 To this Operator’s Manual

1.1 Notes on the manual

1.1.1 Using the user manual

Important information concerning this user manual

Structure by MANUBAL sub-assemblies

Search and find

Direction indications

Specific terminology

Optional and additional equipment

1.1.2 Symbols and instructions

Text and illustrations

Highlighting dangers and warnings

1.1.3 Technical information

2 Safety

2.1 Safety instructions

2.1.1 Recommendations

2.1.2 Appropriate use

2.1.3 Inappropriate use

2.1.4 Safety and accident prevention instructions

2.1.5 MANUBAL

2.1.6 Checking the condition of the MANUBAL

2.1.7 Adjustment, servicing or repair work

2.1.8 Driving and transport

2.1.9 Safety regulations

2.1.10 Safety labels

3 Machine description

3.1 Identification plate and serial number

3.1.1 Identification plate

3.2 Overview

3.2.1 Description

Bale grabber

Wrapped bale grabber

Connections

Bale fork

3.3 Optional equipment

3.3.1 Wrapped bale grabber kit

3.3.2 Lower finger kit

3.3.3 Finger length

3.3.4 Additional fingers

3.3.5 Extension

4 Technical specifications

4.1 MANUBAL

4.1.1 Specifications of the MANUBAL bale grabber

4.1.2 Specifications of the MANUBAL bale fork

5 Machine preparation

5.1 Hitch

5.1.1 Hitching the MANUBAL

For an implement carrying frame with manual unlocking

5.1.2 Unhitching the MANUBAL

For an implement carrying frame with manual unlocking

5.2 Fieldwork settings

5.2.1 Adjusting the grabber opening/closing

Round bale

Rectangular bale

5.2.2 MANUBAL W500 2nd bale sensor

Operating principle

Adjusting the sensor

Forced activation of the sensor

5.2.3 MANUBAL C40 — Adjusting the Power control system

5.2.4 Position of bale fork fingers

Fixed fingers position

Floating fingers position

Inclined position

On-road position of foldable fingers

5.2.5 MANUBAL V7000 lower fingers

Configuratioof lower fingers

Parking position

5.2.6 Finger spacing

5.3 Optional equipment

5.3.1 Wrapped bale grabber kit

Adjusting the opening/closing ofhe wrapped bale grabber

Assembling the wrapped bale grabbers

5.3.2 Lower finger kit

Configuration of lower fingers

Parking position

Adjusting the finger spacing

5.3.3 Extension

6 Operation

6.1 MANUBAL

6.1.1 Picking up bales on cylindrical face

6.1.2 Picking up bales on flat face

6.2 MANUBAL V50

6.2.1 Changing the grabber position

7 Maintenance

7.1 Maintenance Information

7.1.1 Cleaning the MANUBAL

7.2 General maintenance information

7.2.1 Servicing and storage

Maintenance

7.3 Lubrication plan

7.3.1 Greasing

8 EC declaration of conformity

8.1 MANUBAL

8.1.1 MANUBAL C40, C30, L6000, L500, L40, U40, V7000, V500, V60, V50, V40, W500

00 1169 984 0.pdf:

Sensor case for tractors Stage IIIB, IV and VSensor case for tractors Stage IIIB, IV and VSensor case for Stage IIIB, IV and V tractors

Contents

1 Sensorkoffer – Sensor case – Sensor suitcase – Stage IIIB, IV & V

1.1 Auflistung Kofferinhalt

1.1 Listing case content

1.1 Presentation of the contents of the suitcase

00 1174 352 1.pdf:

Front loaderFL 250-150-140-120-100-80-60

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the operator’s manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Notes on warranty

1.1.8 Spare parts and technical questions

1.1.9 Technical information

1.2 Intended use

1.2.1 Use compliant with the instructions

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Importance of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Requirements made on all persons working with the product

2.2.4 Children in danger

2.2.5 High risk areas

2.2.6 Persons riding on the machine

2.2.7 Driving and transport

2.2.8 Hitching the tractor to the machine

2.2.9 Avoiding risks linked to using the front loader

2.2.10 Limits for using the loader on a tractor fitted with a roll hoop with two uprights

2.2.11 Structural changes

2.2.12 Optional equipment and spare parts

2.2.13 Technical condition

2.2.14 Keeping safety devices functional

2.2.15 Personal protective equipment

2.2.16 Wearing suitable clothing

2.2.17 Removing dirt and loose objects

2.2.18 Preparing the machine for road travel

2.2.19 Hazards when driving on the road and on the field

2.2.20 Unsuitable operating utilities

2.2.21 Safe handling of operating and auxiliary utilities

2.2.22 Environmental protection and disposal

2.2.23 Lethal electrocution from overhead lines

2.2.24 Behaviour in case of voltage flash-over from overhead lines and when lightning strikes

2.2.25 Vibrations may cause health problems

2.2.26 Pressurised fluids

2.2.27 Working on machine only after shutting it down

2.2.28 Maintenance work and repairs

2.2.29 Raised tractor parts and loads

2.2.30 Using the front loader

2.2.31 Safety when lifting a load

Extract from section 4.4.4 of the standard EN 12525 and its amendment A2 2010

Extract from Annex E of the standard EN 12525 and its amendment A2 2010

2.2.32 Using the front loader implements

2.2.33 Operation requiring someone underneath the front loader

2.2.34 Welding work prohibited

2.3 Safety marking

2.3.1 Structure of safety decals

2.3.2 Safety labels

2.3.3 Safety labels

3 Machine description

3.1 Overview and method of operation

3.1.1 Overview of the front loader

3.1.2 Overview of the front loader mounting frame

3.2 Identification plates and identification numbers

3.2.1 Front loader identification plate

Identification plate 1

Identification plate 2

Identification plate 3

3.2.2 Front loader identification plate (Australia)

3.2.3 Front loader mounting frame identification plate

Identification plate 1

Identification plate 2

Identification plate 3

3.3 Safety devices

3.3.1 Safety device for lifting and dumping the front loader

3.4 Front loader equipments

3.4.1 FITLOCK hitching system

3.4.2 Level indicator

3.4.3 Implement carrier frame

MX implement carrier frame

Euro implement carrier frame

MX or Euro implement carrier frame

Euro or SMS implement carrier frame

MX or Faucheux-Blanc implement carrier frame

Euro or Sigma4 implement carrier frame

MX, Euro or Tenias implement carrier frame

3.4.4 PCH system

3.4.5 Overview of front implements

Bins, forks, grab and blade

Bale clamp

3.5 Front loader optional equipments

3.5.1 AUTO-UNLOAD system

3.5.2 AUTO-LEVEL system

3.5.3 SHOCK ELIMINATOR system

3.5.4 MACH system

3.5.5 FASTLOCK system implement carrier frame

3.5.6 Locking the implement with the SPEEDLINK System

3.5.7 Dumping retarder

3.5.8 Additional functions

Third function

Fourth function

MACH 2 system

3.6 Information on the machine

3.6.1 Handling points

4 Operating and display elements

4.1 Front loader controls

4.1.1 Safety device for lifting and dumping the front loader

4.1.2 Hydraulic supply to the front loader or the rear hydraulic pressure taps

4.1.3 PROPILOT system handle

4.1.4 FLEXPILOT system handle

4.1.5 Multifunction handle

4.1.6 Multifunction handle

4.1.7 Multifunction handle

4.1.8 ELECTROPILOT handle

5 Technical specifications

5.1 FL 250-60

5.1.1 Technical specifications for FL front loaders

5.1.2 Compatibility of FL front loaders with CLAAS tractors

5.2 Operating utilities

5.2.1 Lubricants

6 Machine preparation

6.1 Front loader

6.1.1 Controlling the front loader or the tractor’s rear pressure taps

6.1.2 Adjusting the position of the control

6.1.3 Hitching the front loader

6.1.4 Unhitching the front loader

6.2 Front loader equipments

6.2.1 Preparing the implement carrier frames

MX or Euro implement carrier frame

Euro or SMS implement carrier frame

MX or Faucheux-Blanc implement carrier frame

Euro or Sigma4 implement carrier frame

MX, Euro or Tenias implement carrier frame

6.2.2 Preparing the level indicator

6.2.3 Preparing the PCH system

6.3 Front loader optional equipments

6.3.1 Preparing the AUTO-LEVEL system function

6.3.2 Preparing the AUTO-UNLOAD system

Main switch

Implement carrier frame with manual locking and FASTLOCK system

Implement carrier frame with SPEEDLINK system automatic locking

6.3.3 Adjusting the dumping retarder

6.4 Front attachment

6.4.1 Hitching an implement to an implement carrier frame with manual unlocking

6.4.2 Hitching an implement with an implement carrier frame with the FASTLOCK system unlocking

6.4.3 Hitching the implement with an implement carrier frame with SPEEDLINK system unlocking

6.4.4 Unhitching an implement with an implement carrier frame with manual unlocking

6.4.5 Unhitching an implement from the implement carrier frame with FASTLOCK system unlocking

6.4.6 Unhitching an implement from the implement carrier frame with SPEEDLINK system unlocking

6.5 Ballast

6.5.1 Tractor balancing

6.6 Transport of the front loader

6.6.1 Transporting and handling the front loader

7 Operation

7.1 Front loader

7.1.1 Safety device for lifting and dumping

7.1.2 Controlling the front loader or the tractor’s rear pressure taps

7.1.3 Using the PROPILOT system control

Locking and unlocking the PROPILOT system control

Using the front loader with PROPILOT system

Using the third and fourth functions for the hitched implement

7.1.4 Using the FLEXPILOT system control

Locking and unlocking the FLEXPILOT system control

Using the front loader with FLEXPILOT system

Using the third and fourth functions for the hitched implement

7.1.5 Using the multifunction handle

Locking and unlocking the multifunction handle

Using the front loader functions

Activating the floating position on one or both of the front loader’s functions

Using the hitched Implement functions

7.1.6 Using the multifunction handle

Locking and unlocking the multifunction handle

Using the front loader functions

Using the hitched Implement functions

7.1.7 Using the multifunction handle

Locking and unlocking the multifunction handle

Using the front loader functions

Activating the floating position on one or both of the front loader’s functions

Using the hitched Implement functions

7.1.8 Using the ELECTROPILOT control (ELIOS / ARION 600-500 / AXION 800)

Locking and unlocking the ELECTROPILOT control

Using the front loader functions

Activating the floating position on one or both of the front loader’s functions

Using the third and fourth functions for the hitched implement

7.2 Front loader optional equipments

7.2.1 Using the AUTO-LEVEL system

AUTO-LEVEL system function with FLEXPILOT system control

AUTO-LEVEL system function with ELECTROPILOT

7.2.2 Using the AUTO-UNLOAD system

7.2.3 Using the SHOCK ELIMINATOR system function

Manual valve

Electrohydraulic valve

8 Faults and remedies

8.1 Difficulty hitching the front loader

9 Maintenance

9.1 Maintenance Information

9.1.1 Personal protective equipment

9.1.2 Cleaning the front loader

9.1.3 Working on the tractor or the front loader

9.1.4 Installing a lifting ram locking system

9.1.5 Removing the system for locking the front loader lifting rams

9.2 Maintenance interval overview

9.2.1 After the first ten hours of operation

9.2.2 After the first 50 hours of operation

9.2.3 Every ten hours of operation

9.2.4 Every month

9.2.5 Every 100 hours of operation

9.3 Lubrication chart

9.3.1 Lubricate the lubrication points every ten hours of operation

9.3.2 Lubricating the lubrication points every three months

9.4 Lifting device maintenance operations

9.4.1 Checking the front loader articulations

9.4.2 Check the hydraulic circuit

9.4.3 Checking the front loader hoses

9.4.4 Checking the front loader controls

9.4.5 Checking the front loader wiring harnesses

9.4.6 Checking the mechanical condition of the front loader

9.5 Maintanance operations chassis

9.5.1 Checking the front loader mounting frame is correctly tightened on the tractor

10 Putting out of operation and disposal

10.1 Disposing of the front loader and getting rid of waste

11 Declaration of Conformity

11.1 Front loader

11.1.1 UKCA and EC declaration of conformity

12 Technical terms and abbreviations

12.1 Units of measurement

12.2 Technical terms

00 2151 096 0.pdf:

CONTENTS

1. USER INSTRUCTIONS

2. SAFETY INSTRUCTIONS

3. SAFETY STICKERS

4. IDENTIFICATION PLATE

5. DOMAIN OF USE

6. OPERATING PRINCIPLES

7. TECHNICAL SPECIFICATIONS

DECLARATION OF CONFORMITY

00 2188 308 0.pdf:

Front loader FL 250-150-120-100-80-60-40

Table of contents

1 To this operator’s manual

1.1 Notes on the manual

1.1.1 Using the operator’s manual

Important information concerning this operator’s manual

Structure based on loader subassemblies

Search and find

Direction indications

Specific terminology

Optional and additional equipment

1.1.2 Symbols and instructions

Text and illustrations

Highlighting dangers and warnings

1.1.3 Validity of the operator’s manual

1.1.4 Technical information

2 Safety

2.1 Safety rules

2.1.1 Recommendations

2.1.2 Appropriate use

2.1.3 Inappropriate use

2.1.4 Safety and accident prevention instructions

2.1.5 Precautions to be taken before starting up

2.1.6 Checking the condition of the front loader

2.1.7 Adjustment, maintenance or repair work

2.1.8 Driving and transport

2.1.9 Lifting safety

2.1.10 Using the front loader

2.1.11 Using the implements of the front loader

2.2 Safety decals on the machine

2.2.1 General advice regarding the safety markings

2.2.2 Safety labels

3 Machine description

3.1 Overview and method of operation

3.1.1 Overview of the front loader

3.1.2 Overview of the adaptation structure

3.2 Safety devices

3.2.1 Safety device for lifting and dumping

3.3 Identification plates and identification number

3.3.1 Loader identification plate

3.4 Front loader equipments

3.4.1 FITLOCK hitching system

3.4.2 Level indicator

3.4.3 Implement carrier frame

Compatibility with the FL 40 front loader

MASTER-ATTACH implement carrier frame

EURO implement carrier frame

MASTER-ATTACH/EURO implement carrier frame

EURO/SMS-ALÖ3 implement carrier frame

MASTER-ATTACH/FAUCHEUX/BLANC implement carrier frame

3.4.4 PCH SYSTEM

3.4.5 Overview of front implements

Bins, forks, grab and blade

Bale clamp

3.5 Front loader optional equipments

3.5.1 SCS SYSTEM

35.2 ACS SYSTEM

3.5.3 SHOCK ELIMINATOR SYSTEM

3.5.4 MACH SYSTEM

3.5.5 Locking the FASTLOCK implement

3.5.6 Locking the SPEED-LINK implement

3.5.7 Additional functions

Third function

Fourth function

MACH 2 system

4 Operating and control elements

4.1 Front loader controls

4.1.1 Safety device for lifting and dumping

4.1.2 Controlling the front loader or the tractor’s rear pressure taps

4.1.3 FLEXPILOT handle

4.1.4 PROPILOT handle

4.1.5 Multifunction handle (ARION 430 – 410)

4.1.6 ELECTROPILOT handle (ARION 600- 500 / AXION 800)

5 Technical specifications

5.1 FL 250-40

5.1.1 Compatibility of CLAAS front loaders and tractors

5.1.2 Front loade specifications

6 Machine preparation

6.1 Front loader

6.1.1 Hitching the FL 40 front loader

6.1.2 Hitching the FL 250-60 front loader

6.1.3 Unhitching the FL 40 front loader

6.1.4 Unhitching the FL250-60 front loader

6.2 Front loader equipments

6.2.1 Preparing the implement carrier frames

MASTER-ATTACH/EURO implement carrier frame

EURO/SMS-ALÖ3 implement carrier frame

MASTER-ATTACH/FAUCHEUX/BLANC implement carrier frame

6.2.2 Preparing the level indicator

6.2.3 Preparing the PCH SYSTEM

6.3 Front loader optional equipments

6.3.1 Preparing the ACS SYSTEM

6.3.2 Preparing the SCS SYSTEM

Main switch

Implement carrier frame with manual and FASTLOCK locking

Implement carrier frame with SPEED-LINK locking

6.4 Front attachment

6.4.1 Hitching the implement using an implement carrier frame with manual unlocking

6.4.2 Hitching the implement using an implement carrier frame with FASTLOCK unlocking

6.4.3 Hitching the implement usig an implement carrier frame with SPEED-LINK unlocking

6.4.4 Unhitching the implement using an implement carrier frame with manual unlocking

6.4.5 Unhitching the implement using an implement carrier frame with FASTLOCK unlocking

6.4.6 Unhitching the implement using an implement carrier frame wth SPEED-LINK unlocking

6.5 Ballast

6.5.1 Tractor balancing

6.6 Transport of the front loader

6.6.1 Transport/handling

7 Operation

7.1 Front loader

7.1.1 Safety device for lifting and dumping

7.1.2 Controlling the front loader or the tractor’s rear pressure taps

7.1.3 Using the FLEXPILOT control

Locking and unlocking

Loader functions

Implement functions

7.1.4 Using the PROPILOT control

Locking and unlocking

Loader functions

Implement function

7.1.5 Using the multifunction handle (ARION 400)

Locking and unlocking

Loader functions

Implement function

7.1.6 Using the ELECTROPILOT control (ARION 600-500 / AXION 800)

Locking and unlocking

Loader functions

Implement function

7.2 Front loader optional equipments

7.2.1 Using the ACS SYSTEM

7.2.2 Using the SCS SYSTEM

7.2.3 Using the SHOCK ELIMINATOR SYSTEM

Manual valve

8 Faults and remedies

8.1 Hitching problems

9 Maintenance

9.1 Maintenance Information

9.1.1 Cleaning the front loader

9.1.2 Maintenance on the tractor with front loader

9.2 Overview maintenance intervalls

9.2.1 After the first 10 hours

9.2.2 After the first 50 hours

9.2.3 Every month

9.2.4 Every 100 hours

9.3 Lubrication chart

9.3.1 Lubricating

Front loader

Implements

9.4 Lifting device maintenance operations

9.4.1 Checking the front loader joints

9.4.2 Checking the hydraulic circuit

9.4.3 Checking the front loader hoses

9.4.4 Checking the front loader controls

9.4.5 Checking the front loader wiring harnesses

9.4.6 Checking the mechanical condition of the front loader

9.5 Maintanance operations chassis

9.5.1 Check the adaptation structure is correctly tightened

10 Service

10.1 FL 250-40

10.1.1 Spare parts and technical questions

11 Placing out of operation and disposal

11.1 Information on the machine

11.1.1 Scrapping and waste disposal

12 EC-declaration of conformity

12.1 Front loader

12.1.1 FL 250-150-120-100-80-60-40

13 Technical terms and abbreviations

13.1 Units

13.2 Technical terms

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98