Claas LEXION 560-540 (584) Combine Assembly Instruction DE

$30.00

- Model: LEXION 560-540 (584) Combine

- Type Of Manual: Assembly Instruction

- Language: DE

- Format: PDF(s)

- Size: 38.2 MB

File List:

– 00 0293 232 3.pdf

– 00 0293 283 1.pdf

– 00 0293 778 0.pdf

– 00 0293 947 1.pdf

– 00 0293 949 0.pdf

– 00 0293 951 0.pdf

– 00 0294 649 1.pdf

– 00 0294 812 0.pdf

– 00 0299 923 1.pdf

00 0293 232 3.pdf

Table of Content:

5 1 Introduction

5.1 1.1 General information

6 2 Security

6.1 2.1 Note

7 3 Scope of delivery

7.1 3.1 Tracked track

8 4 cultivation

8.1 4.1 Installing the crawler track

8.2 4.2 Dismantling the crawler track

8.3 4.3 Converting the crawler track

9 1 Introduction

9.1 1.1 General Information

10 2 Safety precautions

10.1 2.1 Important

11 3 Package list

11.1 3.1 Track roller unit

12 4 Mounting

12.1 4.1 Fitting the track roller unit

12.2 4.2 Removing the track roller unit

12.3 4.3 Fitting the track roller unit

13 1 Introductionaje

16.1 4.1 Montar el tren de rodaje de orugas

16.2 4.2 Dismounting the tren de rodaje de orugas

16.3 4.3 Transformer of the tren de rodaje de orugas

17 1 Introduction

17.1 1.1 General indications

18 2 Sicurezza

18.1 2.1 Because osservare

19 3 Complessivo di fornitura

19.1 3.1 Carrello del cingolo

20 4 Montaggio

20.1 4.1 Monday of the carrello of the cingolo

20.2 4.2 Monday of the carrello of the cingoli

20.3 4.3 Conversion to cingoli

00 0293 283 1.pdf

Table of Content:

4 1 Introduction

4.1 1.1 General information

5 2 Safety instructions

5.1 2.1 Note

6 3 Scope of delivery

6.1 3.1 Retrofit kit 91008021 / 91010189

7 4 cultivation

8 4.1 Attachment quick stop

10 4.1.1 Putting the machine out of operation

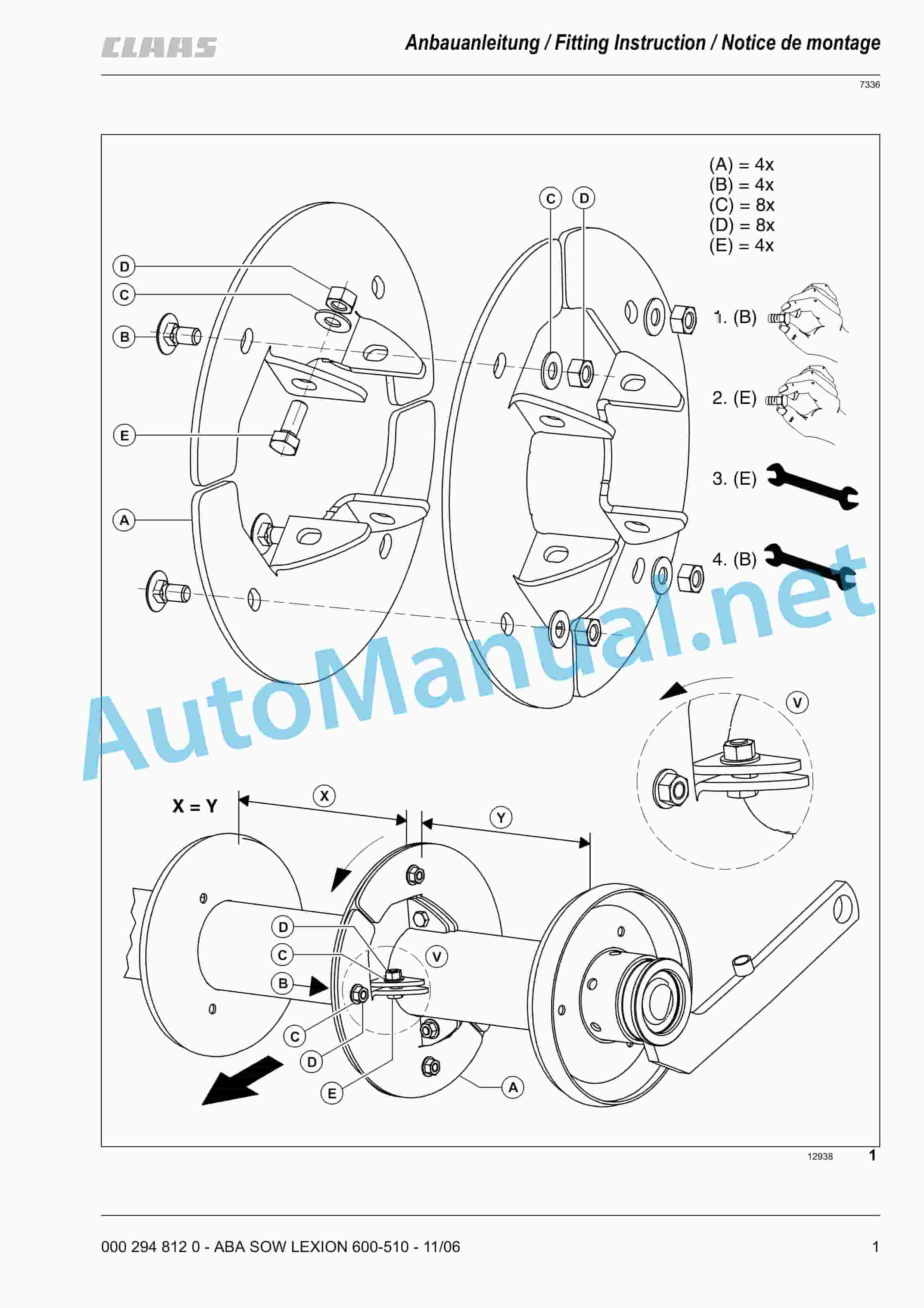

13 (Fig. 1)

15 4.1.2 Install attachment quick stop

19 – Use special tool (V) to create negative pressure in the hydraulic oil tank (P) or drain hydraulic oil.

20 – Special tool: valve combination for generating negative pressure, spare part no. 000 181 619 1.

21 (Fig. 2)

25 – Screw on the hose line (L) from the coupling (K).

26 – Unscrew coupling (K).

27 (Fig. 3)

31 – Screw on the coupling (1) using the existing cylinder screws.

32 (Fig. 4)

36 – Screw on the brake disc (2) with screws (3). Make sure that the smooth flange surface is on the inside.

37 (Fig. 5)

41 – Screw on the support (4) and flat iron (5) with screws (6) and (7).

42 (Fig. 6

46 – Screw the screw-in socket (8) into the brake caliper (9).

47 (Fig. 7)

51 – Screw the brake caliper (9) to the support arm (T) and support (4) with screws (10).

52 – Tightening torque = 123 Nm

53 (Fig. 8)

57 – Remove plug (S).

58 – Unscrew holder (H).

59 (Fig. 9)

63 – Remove the blind plugs (B).

64 – Lightly grease connecting pieces (11).

65 – Insert connecting pieces (11) into the valve disk (12).

66 (Fig. 10)

70 – Screw on the valve disk (12) with screws (13).

71 – Tightening torque = 25 Nm

72 (Fig. 11)

76 – Screw on holder (H) with existing screws.

77 – Screw on the hose line (14).

78 Tightening torque = 35 Nm

79 – Screw on the hose line (15).

80 tightening torque = 35 Nm

81 (Fig. 12)

85 – Screw the hose line (14) to the brake caliper.

86 – Screw on the hose line (L).

87 (Fig. 13)

91 – Remove blind plug on the hydraulic pump.

92 – Screw in the screw-in socket (16).

93 – Screw on the hose line (15).

94 (Fig. 14)

98 – Insert relay (17) into position (K15).

99 (Fig. 15)

106 Bleeding brake caliper hydraulic cylinder

107 – Connect the ventilation hose (L) with the collecting vessel to the ventilation valve (M).

108 – Switch on diesel engine.

109 – Loosen vent valve (M).

110 – Mechanically actuate the electromagnetic valve quick stop attachment (Y101) and circulation valve (Y77) using an auxiliary tool.

111 Auxiliary tool: pin 2 mm

112 Hydraulic oil must come out without bubbles.

113 – After closing the vent valve (M), stop operating the solenoid valves.

114 – Switch off diesel engine.

115 (Fig. 16, 17)

117 4.1.3 Prepare and carry out a test run

118 – If necessary, carry out the following work before the test run:

119 – Tighten screw connections of all newly installed parts.

120 – Install previously removed safety devices.

121 – Check hydraulic oil level. Refill if necessary.

122 – Check transmission oil levels of installed components. Refill if necessary.

123 – Put the used tool back.

124 – Check retrofitted and/or removed electrical connections.

125 – Lubricate all newly added lubrication points.

126 – Check settings on the machine.

127 – Carry out a test run.

128 – Check hydraulic oil lev 128.2 2 Safety precautions

128.3 3 Package list

129 4 Mounting

130 4.1 Front attachment quick stop

132 4.1.1 Putting the machine out of action

135 (Fig. 1)

137 4.1.2 Fitting the front attachment quick stop

141 – Using the special tool (V), create a vacuum in the hydraulic oil tank (P) or drain hydraulic oil.

142 – Special tool:Valve combination for generating a vacuum, spare part no. 000 181 619 1.

143 (Fig. 2)

147 – Unscrew hose line (L) from clutch (K).

148 – Unscrew the clutch (K).

149 (Fig. 3)

153 – Bolt on clutch (1), using the existing cheese-head screws.

154 (Fig. 4)

158 – Bolt on brake disc (2) using bolts (3). Ensure that the smooth flange face is on the inside.

159 (Fig. 5)

163 – Bolt on support (4) and flat bar (5) using bolts (6) and (7).

164 (Fig. 6)

168 – Screw the male connector (8) into brake caliper (9).

169 (Fig. 7)

173 – Bolt the brake caliper (9) down to the supporting arm (T) and support (4), using bolts (10).

174 – Tightening torque = 123 Nm

175 (Fig. 8)

179 – Disconnect plug (S).

180 – Remove bracket (H).

181 (Fig. 9)

185 – Remove the blind plugs (B).

186 – Slightly grease the connecting pieces (11).

187 – Insert the connecting pieces (11) into the hydraulic valve (12).

188 (Fig. 10)

192 – Bolt on hydraulic valve (12) using bolts (13).

193 – Tightening torque = 25 Nm

194 (Fig. 11)

198 – Bolt on bracket (H) using the existing bolts.

199 – Bolt on trousers (14).

200 Tightening torque = 35 Nm

201 – Bolt on hose (15).

202 Tightening torque = 35 Nm

203 (Fig. 12)

207 – Bolt hose (14) to the brake caliper.

208 – Bolt on trousers (L).

209 (Fig. 13)

213 – Remove blind plug from hydraulic pump.

214 – Screw in the male connector (16).

215 – Bolt on trousers (15).

216 (Fig. 14)

220 – Plug relay (17) into location (K15).

221 (Fig. 15)

228 Venting the brake caliper hydraulic cylinder

229 – Connect the vent hose (L) with a collecting container to the vent valve (M).

230 – Start the diesel engine.

231 – Slacken off the vent valve (M).

232 – Actuate the front attachment quick stop solenoid valve (Y101) and the master valve (Y77) mechanically, using an aid.

233 Aid: pin 2 mm

234 The hydraulic oil must come out without bubbles.

235 – After closing the vent valve (M), stop actuating the solenoid valves.

236 – Turn off the diesel engine.

237 (Fig. 16, 17)

239 4.1.3 Prepare and carry out a test run.

240 – Carry out the following work before the test run:

241 – Retighten the threaded joints of all newly fitted parts.

242 – Refit any safety features previously removecessary.

244 – Check the gearbox oil levels of fitted component. Top up if necessary.

245 – Put back the tools used.

246 – Check retrofitted and/or removed electrical connections.

247 – Grease all newly added lubrication points.

248 – Check adjustments on the machine.

249 – Carry out a test run.

250 – Check the hydraulic oil level. Top up if necessary.

250.1 1 Introduction

250.2 2 Security Councils

250.3 3 pieces fournies

251 4 Assembly

252 4.1 Stop rapid de l’outil frontal

254 4.1.1 Setting the machine

257 (Fig. 1)

259 4.1.2 Pose du Stop rapide de l’outil frontal

263 – Using the special tool (V), creates a sous pressure in the hydraulic oil reservoir (P) or from the hydraulic fluid.

264 – Outil special:combinaison de vannes pour crer une depression, pice de change Ne (K).

271 (Fig. 3)

275 – Visser l’accouplement (1) en utilisant les vis tte cylindrique existingantes.

276 (Fig. 4)

280 – Visser the disk of Frein (2) and utilisant les vis (3). Faire attention ce que la moiti lisse du flasque soit vers l’intrieur.

281 (Fig. 5)

285 – Visser le support (4) and le fer plat (5) avec les vis (6) et (7).

286 (Fig. 6)

290 – Visser le manchon filet (8) sur l’trier de frein (9).

291 (Fig. 7)

295 – Visser l’trier de frein (9) sur l 10)

314 – Visser the disk of vanne (12) and utilisant les vis (13).

315 – Couple de serrage = 25 Nm

316 (Fig. 11)

320 – Visser le support (H) and utilisant les vis existingantes.

321 – Visser la conduite flexible (14).

322 Couple de serrage = 35 Nm

323 – Visser la conduite flexible (15).

324 Couple de serrage = 35 Nm

325 (Fig. 12)

329 – Visser la conduite flexible (14) sur l’trier de frein.

330 – Visser la conduite flexible (L).

331 (Fig. 13)

335 – Enlever les tampons borgnes sur la pompe hydraulique.

336 – Visser le manchon filet (16).

337 – Visser la conduite flexible (15).

338 (Fig. 14)

342 – Insert the relay (17) on the placement (K15).

343 (Fig. 15)

350 Purger l’air du vlrge (M).

352 – Start the diesel engine.

353 – Desserrer la vanne de purge d’air (M).

354 – Mechanic action for the quick start of the frontal tool (Y101) and the circulation vane (Y77) for use in a tool appropri.

355 Outil: goupille 2 mm

356 L’huile hydraulique doit sortir sans bulle.

357 – After ferm la vanne de purge d’air (M), finir d’actionner les lectrovannes.

358 – Arrter diesel engine.

359 (Fig. 16, 17)

361 4.1.3 Prepare a functional test and the realiser

362 – Le cas chant, effectuer les travaux suivants avant d’effectuer le test de fonctionnement :

363 – Reserrer les raccords viss ayant t dposs.

369 – Lubrifier tous les new points de graissage ajouts.

370 – Verifier of the settings on the machine.

371 – Procder un test de fonctionnement.

372 – Verifier of the level of hydraulic oil. Faire l’appoint si necessary.

00 0293 778 0.pdf

Table of Content:

1 LEXION 600 – 510

2 Installation instructions

3 Quantimeter

4 Fitting Instructions

5 Quantimeter

6 Notice of assembly

7 Quantimtre

Read and observe 8 safety instructions!

9 Please read and follow the safety instructions!

10 Respect and read the security consignments !

10.2 livery

10.19 1666

10.21 4 cultivation

10.22 4.1 Add Quantimeter

10.23 1706

10.24 4.1.1 Install yield sensor

10.27 1667

10.28 – Unscrew the caps (D) on both sides of the grain elevator. The sealing lids are omitted.

10.29 (Fig. 1)

10.32 1671

10.33 – Screw the pre-assembled light barrier transmitter (1, red) to the rear side of the elevator with screws (2), contact washer (3), washer (4), compression spring (5) and washer (6). Fasten the cable to the elevator with the existing clamp (S).

10.34 (Fig. 2)

10.37 1672

10.38 – Screw the pre-assembled light barrier receiver (7, yellow) to the front side of the elevator with the nut (8) and contact washers (9). Fasten the cable to the elevator with the existing clamp (K).

10.39 (Fig. 3)

10.40 1673

10.44 1674

10.45 – Lock the pre-assembled clamping bolt (S) on the swivel holder (W). Pretension of the clamping bolt (S) with nut and lock nut…

10.46 (Fig. 4, 5)

10.47 1707

10.48 4.1.2 Install hydraulic chain tension

10.51 1675

10.52 Attachment of the hydraulic chain tensioning device only required if not already available

10.53 – Remove pipe (L) of the chain tensioner. Relax the chain by loosening the nut (M). Unscrew the screws (S) and remove the pipe (L).

10.54 (Fig. 6)

10.57 1676

10.58 – Slide angle (11) onto pipe (12).

10.59 – Connect pipe (12 and cylinder (13) with bolt (14).

10.60 – Slide on washer (15) and secure bolt (14) with cotter pin (16).

10.61 (Fig. 7)

10.64 1677

10.67 1678

10.68 – Insert the hydraulic cylinder (13) into the existing guide hole of the old tensioning device. Screw the bracket (11) onto the existing threaded bolts on the elevator shaft with nuts (17). Fasten pipe (12) at the top with existing screws (S).

10.69 (Fig. 8, 9)

10.70 1708

10.71 4.1.3 Install moisture sensor (18)

10.74 1669

10.75 – Use special tool (V) to create negative pressure in the hydraulic oil tank (P) or drain hydraulic oil.

10.76 – Special tool: valve combination for generating vacuum ET no. 181 619.1

10.77 (Fig. 10)

10.80 1679

10.81 – On machines with 3-D, unscrew both angle connectors (W).

10.82 (Fig. 11)

10.85 1680

10.86 – On machines without 3-D, unscrew both blind plugs (T).

10.87 (Fig. 12)

10.90 1681

10.91 – Unscrew the sealing cover (V) on the grain elevator.

10.92 (Fig. 13)

10.95 1682

10.96 – Humidity sensor (18) pre-assembled.

10.97 – Up to mach. no. … use the hydraulic hoses (H).

10.98 – From mach. no. … use the hydraulic lines (21) and (22).

10.99 (Fig. 14)

10.101 1683

10,105 1684

10.106 – Screw the moisture sensor (18) to the grain elevator with nuts (19) and existing nuts.

10.107 – Screw on pipes, angles and T-pieces according to Figures 15 and 16:

10.108 – L-piece (20), pipe (21), pipe (22), pipe (23), pipe (24), T-piece (25), angle (26), hose line (27).

10.109 – Screw on pipes (21) and (22) with clamp (28) and screw (29).

10,110 (Fig. 16)

10,113 1685

10,116 1686

10.117 – Machines with 3-D: Connect the hydraulic line (T) to the distributor at (D). Connect the hydraulic line (P) to the distributor at (B).

10.118 – Pipe (R) only LEXION Montana

10.119 – Hose line (T) chain tension cylinder

10.120 – Remove special tool for generating vacuum or fill up hydraulic oil.

10,121 (Fig. 17, 18)

10,122 1709

10.123 4.1.4 Install tilt sensor

10,126 1687

10.127 – Screw the tilt sensor (30) to the console (32) with screws (31). Fasten cable (K) with clamp (33).

10,128 (Fig. 19)

10,131 1688

10.132 – Unscrew the lower screws (S).

10,133 (Fig. 20)

10,136 1689

10.137 – Screw on the console (32) using the existing screws. Align console (32) parallel to the axis!

10,138 (Fig. 21)

10,141 1690

10.142 – Remove right drive wheel.

10.143 – Remove protection (S).

10,144 (Fig. 22)

10,147 1691

10.148 – Remove protection (K).

10,149 (Fig. 23)

10,152 1692

10.153 – Connect the cable set (34) to the solenoid valve (M) and to the humidity sensor cable (F). Fasten the cable set (34) with cable clamps (33).

10,154 (Fig. 24)

10,156 1693

10.157 – Connect the plug from the cable set (34) to the plug from the light barrier receiver and light barrier transmitter (see arrow).

10,158 (Fig. 25)

10,161 1694

10.162 – Screw on the cable set (34) with pipe clamps (35) and screws (39).

10,163 (Fig. 26)

10,166 1695

10.167 – Screw on the holders (37) using the existing screws. Screw the cable set (34) with pipe clamps (38) to the holder (37).

10,168 (Fig. 27)

10,171 1696

10.172 – Screw on the cable set (34) with pipe clamps (38).

10,173 (Fig. 28)

10,176 1697

10.177 – Screw on cable set (34) with pipe clamp (38).

10,178 (Fig. 29)

10,180 1698

10.181 – Lay the branch of the cable set (34) downwards to the inclination sensor.

10.182 – Screw on the cable set (34) with pipe clamps (35) and existing screws (see arrows).

10,183 (Fig. 30)

10,186 1699

10.187 – Screw on the cable set (34) with the pipe clamp (35) and the existing screw.

10,188 (Fig. 31)

10,191 1700

10.192 – Screw on the cable set (34) with pipe clamps (35) and screw (39).

10.193 – Fasten cable set (34) with cable tie (40).

10,194 (Fig. 32)

10,197 1701

10.198 – Screw on the cable set (34) with pipe clamps (35) and screw (36).

10.199 – Fasten the cable set (34) with cable ties (40).

10,200 (Fig. 33)

10.203 1702

10.204 – Connect the cable set (34) to the cable set of the inclination sensor

10.205 – Fasten cable set (34) with cable tie (40).

10.206 (Fig. 34)

10.209 1703

10.210 – Screw on the cable set (34) with pipe clamps (35) and existing screws (see arrows).

10,211 (Fig. 35)

10,214 1704

10.215 – Unscrew the footplate (T).

10,216 (Fig. 36)

10,219 1705

10.220 – Lay cable set (34) to the central electrical system.

10.221 – Screw the footplate back on.

10,222 (Fig. 37)

10,225 1706

10.226 – Open the screw lock (D) and latch (R).

10.227 – Open the central electrics.

10,228 (Fig. 38)

10,231 1707

10.232 – Unscrew sealing plate (B).

10,233 (Fig. 39)

10,236 1708

10.237 – Remove blind plug (C).

10.238 – Guide cable set (34) through at (C).

10.239 – Insert the cable grommet of the cable set (34) at (C).

10,240 (Fig. 40)

10,243 1709

10.244 – Screw on cable set (34) with pipe clamp (35) and nut (41).

10,245 (Fig. 41)

10,248 1710

10.249 – Fasten the cable set (34) with the clamp (L).

10,250 (Fig. 42)

10,253 1711

10.254 – Insert connector holder (42) so that it locks.

10,255 (Fig. 43)

10,258 1712

10.259 – Insert the plug from the cable set (34) into the plug holder.

10,260 (Fig. 44)

10,262 1713

10.263 – Central electrics up to mach. no. …

10.264 – Plug the second plug from the cable set (34) into the plug location (MP) (see arrow) and secure it with a cable tie (40).

10,265 (Fig. 45)

10,267 1714

10.268 – Central electrics from mach. no. …

10.269 – Plug the second plug from the cable set (34) into the plug location (MP) (see arrow) and secure it with a cable tie (40).

10,270 (Fig. 46)

10,273 1715

10.274 – Insert LEM module (43).

10.275 – Fasten modules with the bracket (H).

10,276 (Fig. 47)

10,277 1712

10.278 4.1.5 Carry out a test run

10,280 1716

10.281 – Close and lock the central electrical circuit board. Reinstall protective panels. Screw the drive wheel back on. For the tightening torque of the wheel nuts, see the combine harvester operating instructions.

10.282 – Close and lock the central electrics. Start the engine and operate the control valve by hand. Cylinder of the humidity sensor m…

10,283 (Fig. 48)

10,284 1 Introduction

10,285 2 Safety information

10,286 1 Introduction

10,287 2 Security Councils

00 0293 947 1.pdf

Table of Content:

2 7 Maintenance

2.1 7.1 Important maintenance instructions

2.2 7.2 Maintenance tables

00 0293 949 0.pdf

Table of Content:

4 1 Introduction

4.1 1.1 General information

5 2 Safety instructions

5.1 2.1 Note

6 3 Scope of delivery

6.1 3.1 Retrofit kit 000 014 922 0

7 4 cultivation

7.1 4.1 Attachment of additional work lighting

8 1 Introduction

8.1 1.1 General Information

9 2 Safety precautions

9.1 2.1 Important

10 3 Package list

10.1 3.1 Retrofit kit 000 014 922 0

11 4 Mounting

11.1 4.1 Installation of additional work lights

12 1 Introduction

12.1 1.1 General Councils

13 2 Security Councils

13.1 2.1 Observer !

14 3 pieces fournies

14.1 3.1 Ultra-equipment kit 000 014 922 0

15 4 Assembly

15.1 4.1 Montage de l’ aire

00 0293 951 0.pdf

Table of Content:

6 1 Introduction

6.1 1.1 General information

7 2 Security

7.1 2.1 Note

8 3 Scope of delivery

8.1 3.1 Telematics

9 4 Cultivation

9.1 4.1 Telematics

10 1 Introduction

10.1 1.1 General Information

11 2 Safety precautions

11.1 2.1 Important

12 3 Package list

12.1 3.1 Telematics

13 4 Mounting

13.1 4.1 Telematics

14 1 Introduction

14.1 1.1 General Councils

15 2 Security Councils

15.1 2.1 Observer !

16 3 pieces fournies

16.1 3.1 Telematics

17 4 Assembly

17.1 4.1 Telematics

18 1 Introduction

18.1 1.1 General indications

19 2 Medidas de seguridad

19.1 2.1 Observar

20 3 Conjunto de suministro

20.1 3.1 Telematics

21 4 Montaje

21.1 4.1 Telematics

22 1 ? tent

2 1 Introduction

2.1 1.1 General information

3 2 Technical data

3.1 2.1 CLAAS LEXION 600 Terra-Trac

3.2 2.2 CLAAS LEXION 580 Terra-Trac

3.3 2.3 CLAAS LEXION 570 Terra-Trac

3.4 2.4 CLAAS LEXION 560 Terra-Trac

4 3 Security

4.1 3.1 Note

4.2 3.2 Warning symbol

5 4 Scope of delivery

5.1 4.1 Rubber half-track

6 5 Cultivation

6.1 5.1 Rubber half-track

7 6 Work input

7.1 6.1 Operation

8 7 Maintenance

8.1 7.1 Important maintenance instructions

8.2 7.2 Maintenance tables

9 8 Lubrication plan

9.1 8.1 Lubrication points

00 0299 923 1.pdf

Table of Content:

7.1 4.1 Dust extraction

8 1 Introduction

8.1 1.1 General Information

9 2 Safety precautions

9.1 2.1 Important

10 3 Package list

10.1 3.1 Dust extraction system (from serial no.)

10.2 3.2 Dust extraction system (up to serial no.)

11 4 Mounting

11.1 4.1 Dust extraction system

12 1 Introduction

12.1 1.1 General Councils

13 2 Security Councils

13.1 2.1 Observer !

14 3 pieces fournies

14.1 3.1 Dispositif d’aspiration de la poussire ( partir de la machine N?

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98