Claas Rollant 455 Uniwrap (750) Balers Repair Manual EN

$300.00

- Model: Rollant 455 Uniwrap (750) Balers

- Type Of Manual: Repair Manual

- Language: EN

- Format: PDF(s)

- Size: 38.4 MB

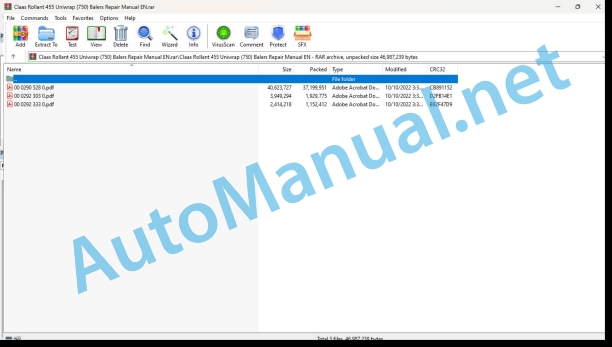

File List:

00 0290 528 0.pdf

00 0292 303 0.pdf

00 0292 333 0.pdf

00 0290 528 0.pdf:

Introduction

General Information

Using the manual

Validity of manual

General repair instructions

Specifications

Reason of damage

Spare parts

Welding Work

Tensioning the steel roller chains

Taper ring fasteners

Gib head key joints

Self-locking bolts with micro-encapsulated adhesive

Liquid locking compound

Lock collar bearing

Adapter sleeve bearing

Ferrule fittings on hydraulic lines

Progressive ring fittings on hydraulic lines

Taper fittings on hydraulic lines

Hydraulic hoses

Some advice for speedy and correct repair work

Torque settings

Tightening torques for metric standard threads

Tightening torques for metric fine threads

Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

Tightening torques for hydraulic screw fittings and air conditioner fittings with a sealing cone and O-ring DIN 3865

Tightening torques for hydraulic male connector DIN 3901

Tightening torques for direction-adjustable hydraulic male connectors ISO 6149-2 / ISO 11926-2 (3)

Tightening torques for hydraulic swivelling screw fittings

Tightening torques for hollow screws DIN 7643

Tightening torques of brake line screw fittings

Tightening torques for screw thread clamps

Wheel tightening torques

Specifications

Lubricants

CCN explanations

CCN (CLAAS Component Number)

Electric system standard

Hydraulic system standard

General information

Important notice

Identification of warning and danger signs

General safety and accident prevention regulations

Leaving the machine

Adjustment and maintenance work

Danger of injury due to escaping hydraulic liquid

Pressure accumulator

First aid measures

Jack up the machine

Putting the machine out of action

03 Chassis

03 10 Axle

Overview of stub axle

Removing a stub axle

Fitting a stub axle

Removing a wheel hub

Fitting a wheel hub

04 10 Service brakes

Overview of brake mechanism

Removing a brake

Fitting a brake

Overview of pneumatic brake chamber

Removing a pneumatic brake chamber

Fitting a pneumatic brake chamber

Overview of pneumatic brake system

Removing the compressed air tank

Fitting the compressed air tank

Overview of hydraulic brake cylinder

Removing a hydraulic brake cylinder

Fitting a hydraulic brake cylinder

04 15 Parking brake

Overview of parking brake

Setting the parking brake

09 Hydraulic system

09 00 Hydraulic system General points

Hydraulic system damage

General rules

09 20 Valves

Overview of ROLLANT 455 and 455 Uniwrap baler hydraulic block

Main block (1) – Overview A

Main block (1) – Overview B

Electric block (2) – Overview

Control block (3) – Overview A

Control block (3) – Overview B

Overview of ROLLANT 454 and 454 Uniwrap baler hydraulic block

Control block (3) – Overview A

Control block (3) – Overview B

Overview of wrapper hydraulic block WITH anti-roll

Wrapper main block (1) – Overview A

Wrapper main block (1) – Overview B

Wrapper main block (1) – Overview C

Flow divider (2) – Overview

Wrapper control block WITH anti-roll (3) – Overview

Cutter flow divider (4) – Overview

Wrapper controlled valves block (5) – Overview

Overview of wrapper hydraulic block WITHOUT anti-roll

Wrapper control block WITHOUT anti-roll (3) – Overview

Removing the baler hydraulic block

Fitting the baler hydraulic block

Removing the wrapper hydraulic block

Fitting the wrapper hydraulic block

Removing / Fitting a solenoid valve

Removing / Fitting a proportional solenoid valve

Removing / Fitting valve (7032)

Removing / Fitting valve (7060)

Calibrating the wrapping arm speed

Calibrate the hydraulic system protection valve (7190)

09 20 Special tool, valves

Checking and then setting the pressure limit valve

Extracting the hydraulic block components

Removing the seals and rings

10 Electric / electronic equipment

10 00 Special tools for electric system, general

Replacing terminals and connectors in the electric system

Diagnosis of electric components

Diagnosis of electric components

10 10 Central electric system

Overview of emergency stop U025

Removing the emergency stop

Fitting the emergency stop

10 12 Sensors / Modules

Overview of module A023

Removing the module

Fitting the module

Overview of tailgate position detector

Removing the sensor assembly

Disassembling the sensor assembly

Assembling the sensor assembly

Fitting the sensor assembly

Setting the sensor assembly

21 Feeder unit

21 25 Rotor

Overview of cutting frame sensor B067

Removing the cutting frame sensor

Fitting the cutting frame sensor

Setting the cutting frame sensor

Overview of cutting frame

Removing the cutting frame assembly

Disassembling the cutting frame assembly

Assembling the cutting frame assembly

Fitting the cutting frame assembly

Removing the pivoting floor

Fitting the pivoting floor

Overview of rotor scraper

Removing the rotor scraper

Fitting the rotor scraper

Overview of the blade frame

Removing a blade activation shaft

Fitting a blade activation shaft

Removing the blade tilting shaft

Disassembling a tilting lever

Assembling a tilting lever

Fitting the blade tilting shaft

Removing the blade locking shaft

Disassembling the blade locking shaft

Assembling the blade locking shaft

Fitting the blade locking shaft

Overview of rotor drive

Removing the rotor drive chain

Fitting the rotor drive chain

Removing the motor gear

Fitting the motor gear

Removing the rotor drive gear

Fitting the rotor drive gear

Removing the idle gear

Fitting the idle gear

Removing the tensioning gear

Disassembling the tensioning gear

Assembling the tensioning gear

Fitting the tensioning gear

Setting the rotor chain tension

Overview of blade activation cylinders

Removing the right-hand blade activation cylinder

Fitting the right-hand blade activation cylinder

Removing the left-hand blade activation cylinder

Fitting the left-hand blade activation cylinder

Overview of cutting frame cylinders

Removing the cutting frame cylinders

Fitting the cutting frame cylinders

Overview of roller 1

Removing roller 1

Fitting roller 1

46 Tying system

46 15 Net tying

Overview of net tying structure

Removing the net tying structure

Disassembling the net tying structure

Assembling the net tying structure

Fitting the net tying structure

Overview of box and net brake

Removing the box and net brake

Disassembling the box and net brake

Assembling the box and net brake

Fitting the box and net brake

Overview of cutter resetting spring cylinder

Removing the resetting cylinder

Disassembling the resetting cylinder

Assembling the resetting cylinder

Fitting the resetting cylinder

Overview of net runner

Removing the net runner

Fitting the net runner

View of tying system rubber roller drive

Removing the tying system drive

Fitting the tying system drive

View of tying clutch drive

Removing the clutch drive

Fitting the clutch drive

47 Bale wrapper

47 05 Tilting box

Overview of tilting box position sensor B211

Removing the tilting box sensor B211

Fitting the tilting box sensor B211

Setting the tilting box sensor B211

Overview of tilting box

Removing the tilting box

Disassembling the tilting box

Assembling the tilting box

Fitting the tilting box

Operating check on box bale presence sensor B102

Overview of tilting box hydraulic hoses

Overview of tilting box hydraulic cylinder

Removing the tilting box hydraulic cylinders

Fitting the tilting box hydraulic cylinders

47 10 Chassis

Overview of wrapper chassis

Removing the wrapper chassis

Fitting the wrapper chassis

47 15 Wrapping table

Overview of wrapping table sensor B210

Removing the wrapping table sensor

Fitting the wrapping table sensor

Setting the wrapping table sensor B210

Overview of wrapping table

Removing the wrapping table

Disassembling the wrapping table

Removing the bale twister supports (according to equipment)

Assembling the wrapping table

Fitting the bale twister supports (according to equipment)

Fitting the wrapping table

Overview of wrapping table rollers

Removing the wrapping table rollers

Fitting the wrapping table rollers

Overview of wrapping table belts

Removing the wrapping table belts

Fitting the wrapping table belts

Overview of wrapping table hydraulic hoses

Overview of wrapping table hydraulic cylinders

Removing the wrapping table hydraulic cylinders

Fitting the wrapping table hydraulic cylinders

Overview of wrapping table drive

Removing the wrapping table drive

Fitting the wrapping table drive

47 20 Bale twister

Overview of bale twister

Disassembling the bale twister

Assembling the bale twister

47 25 Support clamp

Overview of support clamp

Removing the support clamp

Fitting the support clamp

47 30 Wrapping arm

Overview of wrapping arm

Removing the wrapping arm

Fitting the wrapping arm

Overview of safety hoop

Removing the safety hoop

Fitting the safety hoop

Disassembling the safety hoop

Assembling the safety hoop

Setting the safety hoop stop

Setting the safety hoop activation sensor (Z091)

Removing the original position sensor (B106)

Fitting the original position sensor (B106)

Setting the original position sensor (B106)

Operating check on wrapping arm original position sensor (B106)

Overview of wrapping arm hydraulic hoses

Overview of wrapping arm hydraulic drive

Removing the wrapping arm hydraulic drive

Fitting the wrapping arm hydraulic drive

47 35 Drawing device

Overview of drawing device

Removing the drawing device

Disassembling the drawing device

Assembling the drawing device

Fitting the drawing device

Wrapping film unwinding sensors B109 operating check

47 40 Film cutter

Overview of film cutter

Overview of film cutter hydraulic hoses

Removing the film cutter

Disassembling the film cutter

Assembling the film cutter

Fitting the film cutter

Overview of film cutter cylinder

Removing the film cutter cylinder

Fitting the film cutter cylinder

47 45 Film roller holder

Overview of film roller holder

Removing the film roller holder

Fitting the film roller holder

Overview of film roller holder hydraulic hoses

Overview of film roller holder cylinder

Removing the film roller holder cylinder

Fitting the film roller holder cylinder

60 Crop output

60 40 Bale chute

Overview of bale discharge guide

Removing the bale discharge guide assembly

Fitting the bale discharge guide assembly

Overview of bale discharge guide hoses

Overview of bale discharge guide cylinder assembly

Removing the bale discharge guide hydraulic cylinders

Fitting the bale discharge guide hydraulic cylinders

75 Central lubrication system

75 10 Control valves

Overview of control valves

Control valve 1

Control valve 2, ROLLANT 454 and 454 Uniwrap

Control valve 2, ROLLANT 455 and 455 Uniwrap

Control valve 3, ROLLANT 454 and 454 Uniwrap

Control valve 3, ROLLANT 455 and 455 Uniwrap

Main control valve

75 15 Lubrication system / pipes

Overview of automatic lubrication pump

Removing the lubrication pump

Fitting the lubrication pump

Setting the lubrication pump flow

Removing the pump activation stop

Disassembling the pump activation stop

Assembling the pump activation stop

Setting the pump activation stop

Fitting the pump activation stop

Overview of chain lubrication system

Removing the chain lubrication pump

Disassembling the chain lubrication pump

Assembling the chain lubrication pump

Fitting the chain lubrication pump

Setting the chain lubrication pump

CCN (CLAAS Component Number)

00 0292 303 0.pdf:

ROLLANT 454 UNIWRAP

ROLLANT 455 UNIWRAP

Content assignment

Spis tre��ci

Vsebinsko kazalo

Table of Contents

1 Bendrieji nuidomai

1.2 Reikalingo’s conditions

1.3 Ma��ino’s paper preparation

Hidraulinis is filtered

Nuimti valva����-ribotuv��

Functional AR (CCN 7068) valdymas

Hidraulinio slukato tikrinimas

Alyvo’s temperature

1.4 Veikimo is tested

2 Nustatymai

2.1 Stalo / peties vejdjo santykio sureguliavimas (atk��rimas)

2.2 Maksimalaus vyniojimo peties sukimosi vejdjos numisma

6 stages stages

2.3 Tikrinimas ir bandymas

1 General informaaf

1.3 Preparing the machine

Hydraulic filter

Dismantle de begrenzerklep (depends on configuration)

8)

Controle van de hydraulic branch part van de achterklep

Oil temperature

1.4 Test van de werking

2 The appointment

2.1 Adjustment of the table/arm ratio (overlapping)

2.2 Adjustment of the maximum speed of the winding arms

2.3 Control a test

1 General tips

1.1 Security

1.2 Before you begin

1.3 Preparation of the machine

Hydraulic filter

Remove the restriction valve (depending on configuration)

Checking the OR function (CCN 7068)

Checking the tailgate’s hydraulic lock

Oil temperature

1.4 Functional test

2 Settings

2.1 Setting the ratio between the speed of the packing table and the packing arm (coverage)

2.2 Setting the packing arm’s maximum speed

2.3 Control and testing

1 General instructions

1.1 Bezpiecze��stwo

1.2 Introduction

1.3 Preparing the machine

Filter hydraulic

Wymontowa�� zaw��r redukcyjny (dependenie od konfigurazione)

Control function WYBORU (CCN 7068)

Kontrola sy��wnika hydraulicznegemperature

1.4 Test operation

2 Settings

2.1 Regulation of speed control

2.2 Regulation of the maximum speed of the ramie owijaj��cego

2.3 Kontrola i pr��ba ��anje

1 Splosna warn

1.1 Security

1.2 Preliminary requirements

1.3 Prepare the garment

Hydraulic filter

Despitetev reducirnega ventila (glede na konfiguratijo)

Kontrola wo��ka za sz����y funksi (CCN 7068)

Kontrola hydraulicne blokade last pokro

Oil temperature

1.4 Probe’s action

2 Settings

2.1 Setting the speed of the podesta in roke (prekrivije)

2nd st stage

2.2 Nes 7th stage

2.3 Control in test

1 General instructions

1.1 Security

1.2 Preparations

1.3 Prepare the machine

Hydraulic filter

Remove the throttle valve (depending on configuration)

Checking the OR function (CCN 7068)

Checking the tailgate hydraulic lock

Oil temperature

1.4 Functional test

2 Settings

2.1 Setting the speed ratio between table and arm (overlap the wrapping arm

2.3 Control and test

Dalykin�� rodykle

Alphabetical index

00 0292 333 0.pdf:

ROLLANT 454 UNIWRAP

ROLLANT 455 UNIWRAP

Content assignment

Eat content

Vsebinsko kazalo

Index of contents

1 Bendrieji nuidomai

1.2 eikalingo’s conditions

2 Nustatymai

2.1 Ma��ino’s paper preparation

2.2 Stalo / peties vejdjo santykio sureguliavimas (atk��rimas)

5 ssimalaus vyniojimo peties sukimosi vejsto namistamiya

2.4 Tikrinimas ir bandymas

Po bandymo

1 General information

1.1 Security

2 The appointment

2.1 Preparing the machine

2.2 Adjustment of the table/arm speed ratio (overlap)

2.3 Adjustment of the maximum speed of the winding arm

2.4 Control a test

1 General tips

1.1 Security

1.2 Before You Begin

2 Settings

2.1 Preparation of the machine

2.2 Setting the ratio between the speed of the packing table and the packing arm (coverage)

2.3 Setting the packing arm’s maximum speed

2.4 Control and testing

After testing

ns

1.1 Bezpiecze��stwo

1.2 Prerequisites

2 Ustavyane

2.1 Preparing the machine

2.2 Regulacja nadzicka ve��i�� sto��u / ramienia (zak��adka)

2.3 Regulacja maximum speed ramienia owijaj��cego

2.4 Control of trial operations

Po przeprowadzeniu pr��by

1 General warnings

1.1 Security

1.2 Prerequisites

2 Settings

2.1 Prepare the machine

2.2 Setting the speed of the podesta in roke (prekrivije)

2.3 Setting the maximum speed of the vehicle

2.4 Control in test

After testing

1 General instructions

1.1 Security

1.2 Preparations

2 Settings

2.1 Prepare the machine

2.2 Setting the speed ratio between table and arm (overlapping)

2.3 Setting the maximum speed of the filler arm

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF